The EP-C5050 is an industrial SLS 3D printer with a large build volume, capable of printing with polystyrene, powdered wax, or resin sand to create molds for the traditional casting process. High accuracy and repeatability of SLS-printed molds increase casting quality, while reduced lead times for mold production allow for a significant cost reduction of the final part.

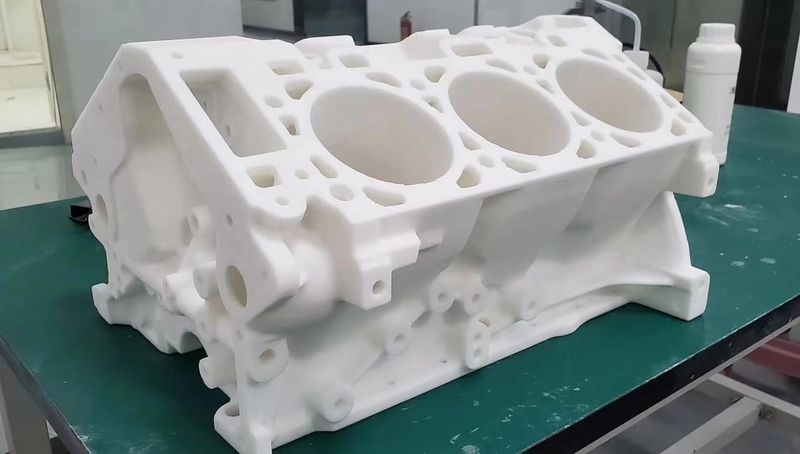

The low-cost multi-purpose casting material can also be used for rapid prototyping of metal parts, including models with complex geometries, such as engine cylinder blocks, cylinder heads, turbines, impellers, and others.

The machine features a scanning speed of up to 6 m/s and uses bi-directional powder feeding to increase productivity. Equipped with a number of smart functions and technologies, the EP-C5050 ensures user-friendly and reliable operation. The proprietary control software automatically generates printing reports that allow analyzing the printer’s performance.

Having a modular design, the EP-C5050 allows adding optional equipment depending on the application requirements, which significantly increases printing efficiency and convenience of use. The printer can be used with an optional powder cleaning station, sand blaster, powder mixer, forklift truck, and a vacuum cleaner.

The EP-C5050 can print layers with a minimum thickness of 80 microns which can be adjusted based on a certain application. The machine is seamlessly integrated to a traditional investment casting process and brings the quality of the cast parts to a higher level.

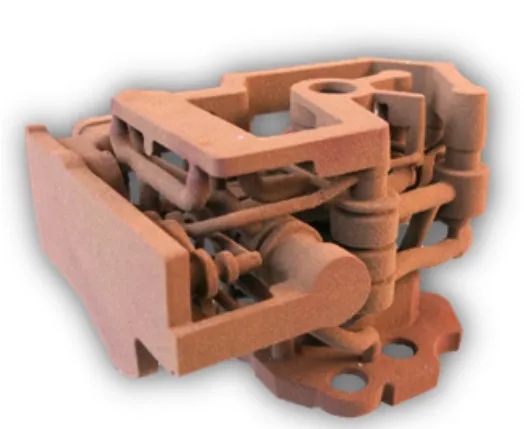

TPT, 320 x 280 x 350 mm, printing time 17 h

Wax mold

The EP-C5050 is compatible with PS, PP, PE, TPU, and other polymer powders. Used for mold manufacturing and rapid prototyping, the machine is a cost-effective solution that helps save time in R&D and product testing stages of the production cycle, thereby increasing productivity.

The large build volume of 520 x 520 x 500 mm allows printing fairly large parts or batches of smaller objects in one go.

The EP-C5050 is operated via a control screen with a user-friendly interface which provides access to multiple control settings and allows adjusting various printing parameters. The proprietary E-Plus 3D control software is a powerful tool for printing process management, from build preparation and part positioning to printing monitoring and report generation function. Open printing parameters allow for precise setting adjustment for specific applications.

The EP Hatch process planning software provides a number of advanced scanning strategies like long straight lines, short straight lines, and checkerboards. It also offers optimal print settings for various materials. The software allows the user to set the scanning path separately for the outline, inside, top, and bottom surface of the part.

The EP-C5050 SLS 3D printer is available in white with black trimmings. Its stylish look and modular design make it ideal for a variety of industrial applications.

The machine dimensions are 78.7 x 51.2 x 90.6 in (2000 x 1300 x 2300 mm). It weighs 3527 lbs (1600 kg).

To learn the current price of the EP-C5050 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now