The E-Plus 3D EP-M1250 is an industrial SLM 3D printer with an industry-leading build volume of 2136 L, designed for efficient production of large-scale, high-quality metal parts for aerospace, automotive, engineering, and other industries. Equipped with 9 fiber lasers with the power of 500, 700, or 1000 W, each of them covering its own area, the company’s flagship ensures reliable and highly productive printing with various metal and metal alloy powders.

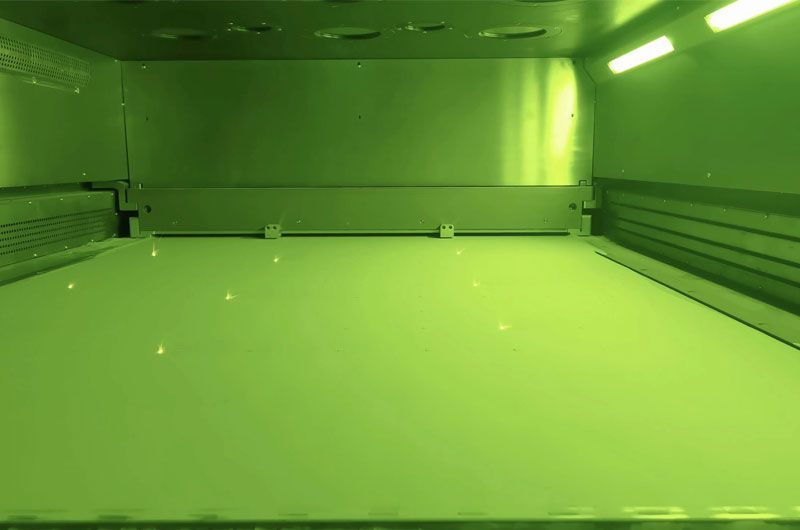

The machine features optimized gas flow for homogeneous part properties throughout the entire build volume and efficient smoke and splash removal. The EP-M1250 build rate reaches 240 cm³/h with final part density of up to 99.9% and <5% deviation in part mechanical properties. To ensure reliable, safe operation, the build chamber is tightly sealed, the oxygen concentration is kept below 100 ppm during printing and can be monitored in real time. Scanning speed of up to 7 m/s and bi-directional powder recoating make for reduced overall print time and increased productivity.

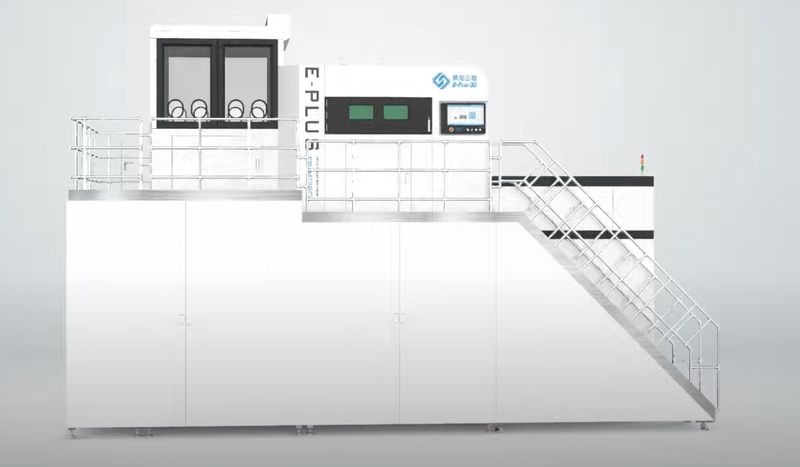

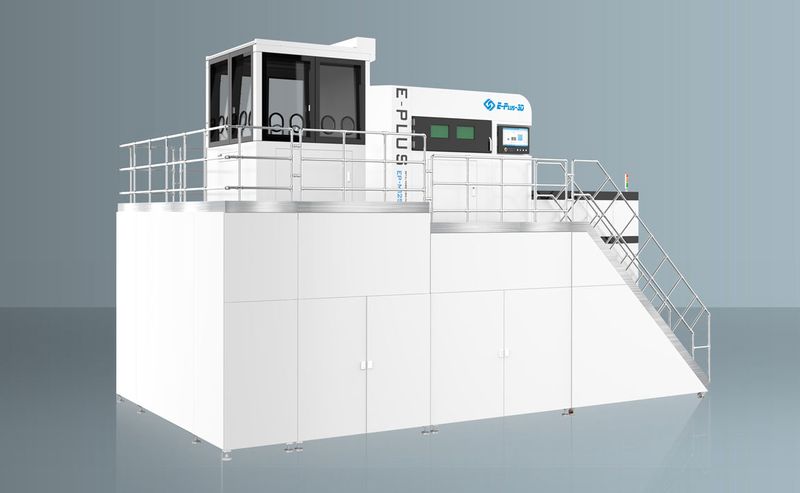

The EP-M1250 is a modular system, including powder cleaning, printing, and filtration units, which greatly facilitates installation and maintenance of the machine.

The EP-M1250 can print layers with a thickness ranging from 20 to 120 microns, allowing for precise print setting adjustment depending on a certain application and required print quality and level of detail. Nine lasers with a spot size of 80–120 microns and nine galvanometers ensure highly accurate and fast printing. The integrated software provides the possibility to divide the model into sections and apply different process parameters to each of them, thus allowing for building complex parts with required properties in various areas.

This rocket engine nozzle expansion section was printed with stainless steel and has dimensions of 1050 x 160 mm. Printing took 160 hours.

The rocket compartment was printed with nickel chromium alloy In718. The model’s dimensions are 630 x 630 x 1100 mm.

The machine prints with metal and metal alloy powders that are suitable for direct manufacturing of high-quality metal components with various properties. It can process titanium, aluminum, and nickel-based alloys, maraging steel, stainless steel, cobalt chrome and copper alloys, and others.

The huge build volume of 1258 x 1258 x 1350 mm opens up wide opportunities for the industries requiring large, high-quality metal parts. It is an effective solution for series manufacturing.

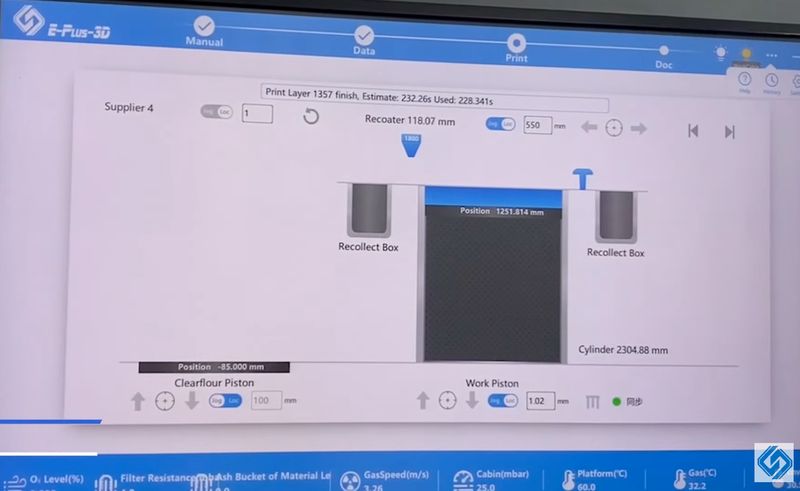

The EP-M1250 is operated via an integrated control unit with a user-friendly interface, real-time monitoring and adjustment of printing parameters, and fully automatic one-click printing function. The software calculates the estimated processing time and generates a printing report when the printing is over.

For some items, package content may change. In case of any questions, please get in touch.

The EP-M1250 SLM 3D printer is available in white. Its solid look makes it ideal for a variety of industrial applications in the aerospace, automobile, and other fields.

The machine dimensions are 354.3 x 189 x 248 in (9000 x 4800 x 6300 mm). It weighs 110231 lbs (50000 kg).

To learn the current price of the EP-M1250 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now