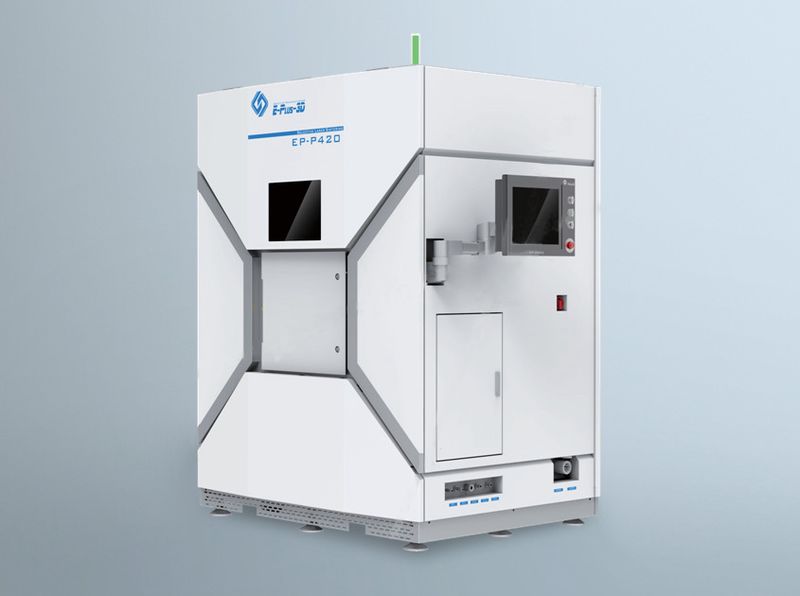

The EP-P420 is an industrial SLS 3D printer with a spacious build volume, capable of high-performance printing of large polymer parts as well as small-batch production. Due to its independent four-zone thermal control system and advanced scanning path strategy, the EP-P420 ensures consistent final part quality with less than 5% deviation in mechanical properties between builds.

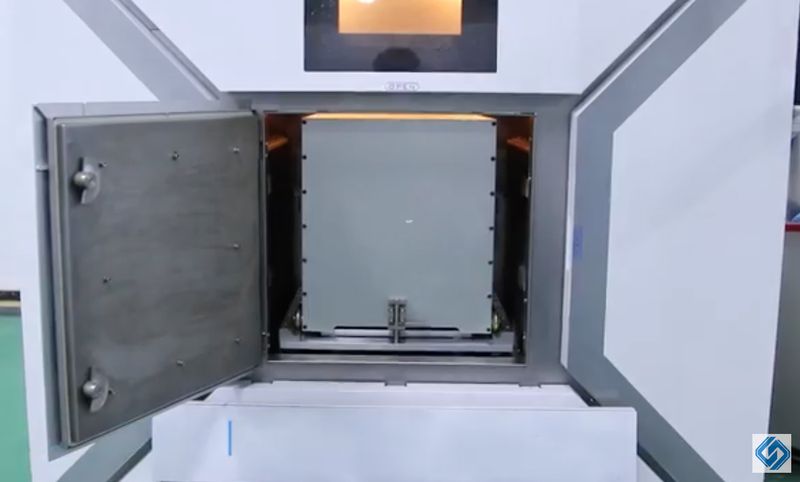

The machine features a scanning speed of up to 13 m/s, and its maximum build speed of 25 mm/h provides high productivity. The detachable forming cylinder allows for reduced downtime between printing sessions since there is no need to wait for the printed part to cool down inside the machine.

Equipped with a number of smart functions and technologies, the EP-P420 ensures user-friendly and reliable operation, offering such features as one-click scanning path generation and one-click printing. The proprietary control software automatically generates printing reports that allow analyzing the printer’s performance.

Having a modular design, the EP-P420 allows adding optional equipment depending on the application requirements, which significantly increases printing efficiency and convenience of use. The printer can be used with an optional powder cleaning station, sand blaster, powder mixer, forklift truck, and a vacuum cleaner.

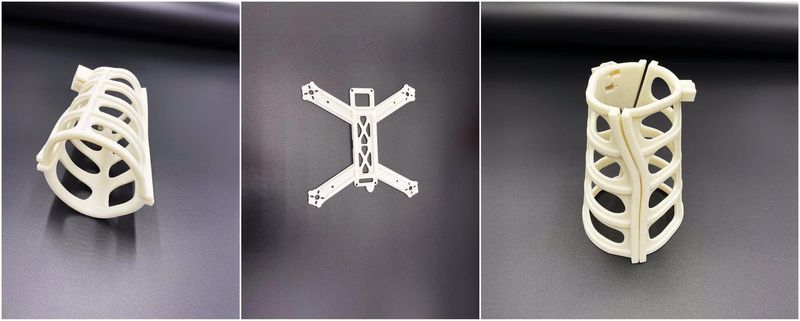

The EP-P420 can print layers with a minimum thickness of 60 microns which can be adjusted based on a certain application. The 120W CO₂ laser and advanced scanning path strategy make for detailed models with high surface quality and dimensional accuracy. Thanks to the SLS capability of support-free printing, the EP-P420 allows creating complex functional prototypes and end-use parts for various industries including automotive, engineering, electronics, medicine, clothing and footwear fabrication, and more.

Nylon, 135 x 40 x 100 mm, printing time 6 h

Customized scoliosis braces

Due to the building temperature of up to 260 °C, the EP-P420 is compatible with a variety of polymer powder materials suitable for a wide application range. The machine can handle PA6, PA11, PA12 powders as well as their composites.

The industrial-size build volume of 420 x 420 x 465 mm allows printing medium to large parts or batches of smaller objects in one go. The high-capacity material feed bin contains enough powder for a whole printing session.

The EP-P420 is operated via a control screen with a user-friendly interface which provides access to multiple control settings and allows adjusting various printing parameters. The proprietary E-Plus 3D control software is a powerful tool for printing process management, from build preparation and part positioning to printing monitoring and report generation function. Open printing parameters allow for precise setting adjustment for specific applications.

The EP Hatch process planning software provides a number of advanced scanning strategies like long straight lines, short straight lines, and checkerboards. It also offers optimal print settings for various materials. The software allows the user to set the scanning path separately for the outline, inside, top, and bottom surface of the part.

The EP-P420 SLS 3D printer is available in white with gray trimmings. Its stylish look and modular design make it ideal for a variety of industrial applications.

The machine dimensions are 66.1 x 55.1 x 97.2 in (1680 x 1400 x 2470 mm). It weighs 4409 lbs (2000 kg).

To learn the current price of the EP-P420 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now