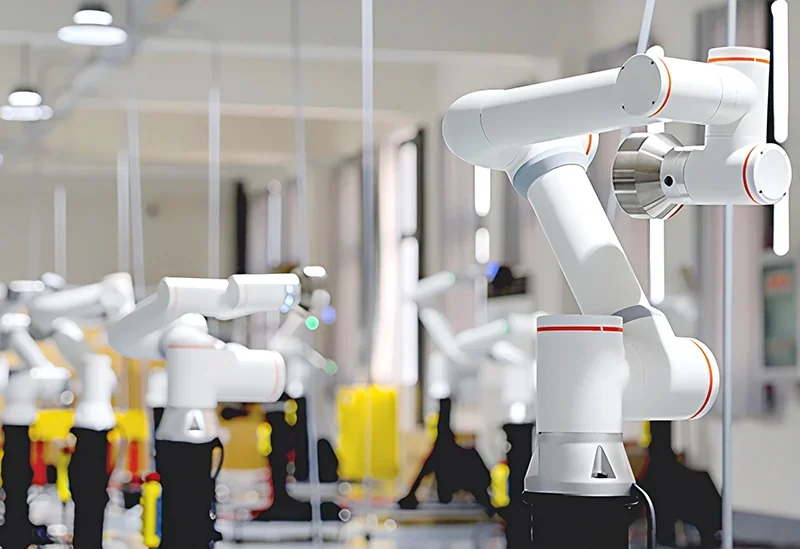

The FAIRINO FR3 is a 6-axis collaborative robot designed for industry automation in electronics, machining, and general manufacturing. It offers a 3 kg payload, 622 mm reach, and ±0.02 mm repeatability for precise work in compact spaces. Programming is accessible via a browser-based WebAPP and optional Teach Pendant, with SDKs for C# / C++ / Python and ROS / ROS 2 for integration. Weighing around 15 kg, it has an IP54 rating (IP65 optional) and mounts in any orientation. Preconfigured factory kits — vision, palletizing, welding, bin-picking, and CNC tending — speed setup and ease integration.

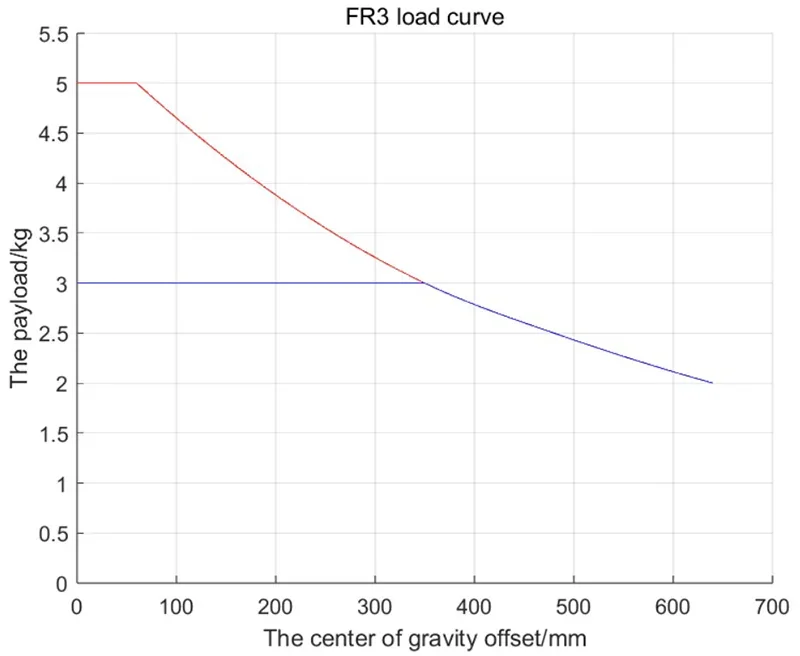

The FAIRINO FR3 has a 3 kg rated payload but can handle up to 5 kg with a close center of gravity and limited motion range.

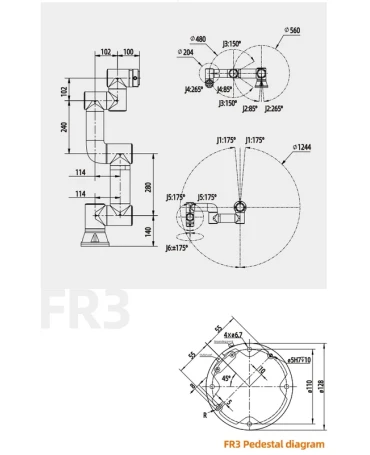

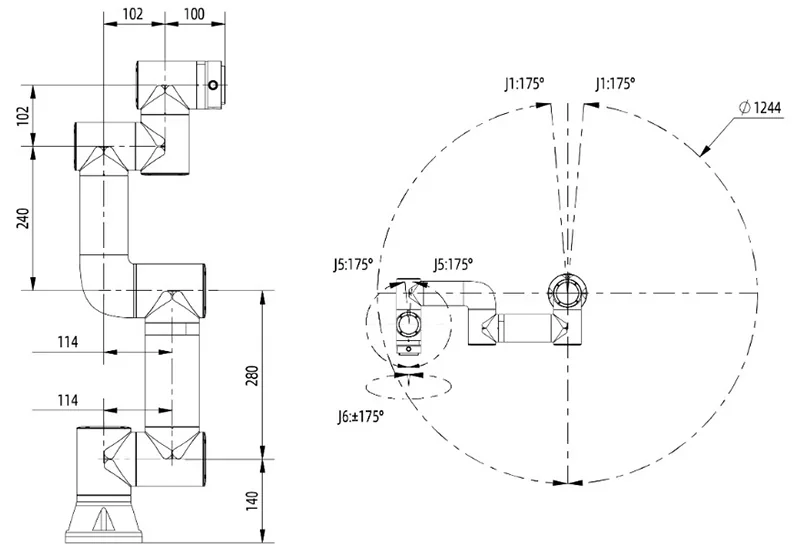

The FR3 has a 622mm TCP reach within a spherical-segment workspace, enabling overhead and below-base positioning. Joint limits define this envelope: base ±175°, shoulder +85°/−265°, elbow ±150°, and wrist axes +85°/−265°, ±175°, and ±175°, leaving only a small unswept area at the base.

The FR3 achieves ±0.02 mm repeatability (ISO 9283), with 1 m/s TCP speed and joint velocities up to ±180°/s, enabling fast, precise motion.

Example: Food & Beverage Service Cells

Example: Photography Robot

Example: Crop Harvesting

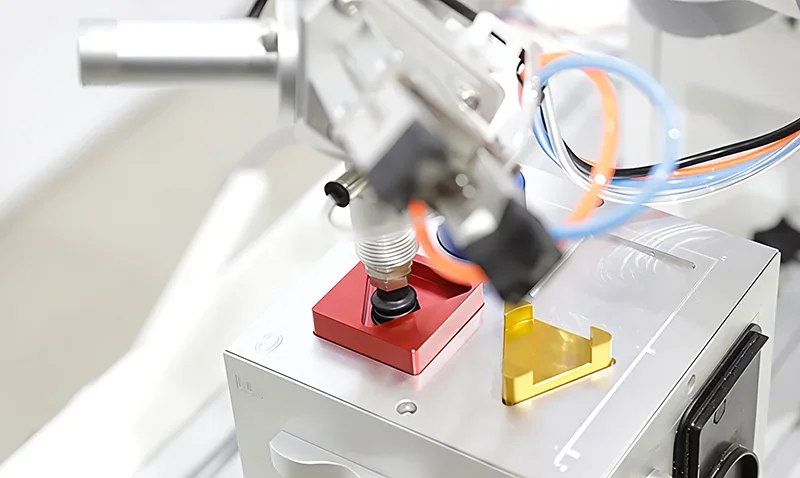

Example: Screw Fastening

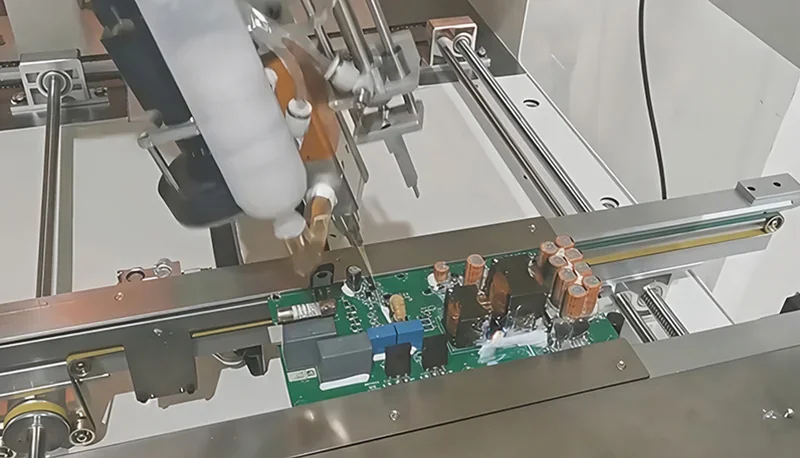

Example: Industrial Gluing Operations

Example: Assembly of Components

Example: Palletizing

Example: Healthcare

Example: Sewing

Example: Pick & Place

The controller supports point-to-point and linear moves with joint-overspeed protection to maintain path accuracy near joint limits. B-spline look-ahead planning smooths motion and reduces jerk, while a singularity strategy ensures continuous travel through difficult poses.

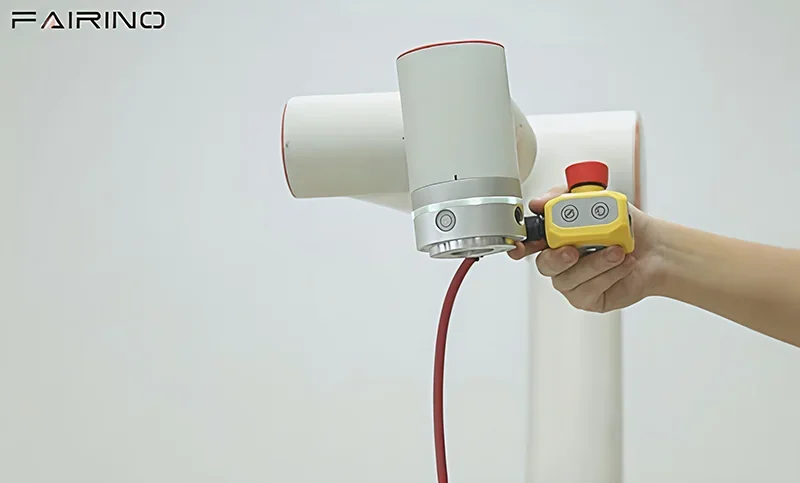

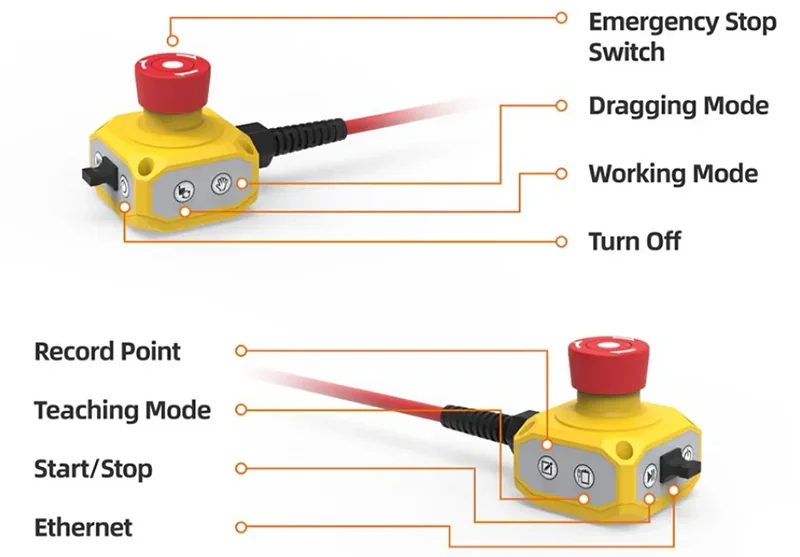

The FR3 includes an emergency stop on the teach pendant or button box that instantly halts motion and cuts joint power.

An end-of-arm LED shows robot states — Automatic, Manual, Drag, Start/Stop, Enable, and errors — to keep operators informed during close interaction.

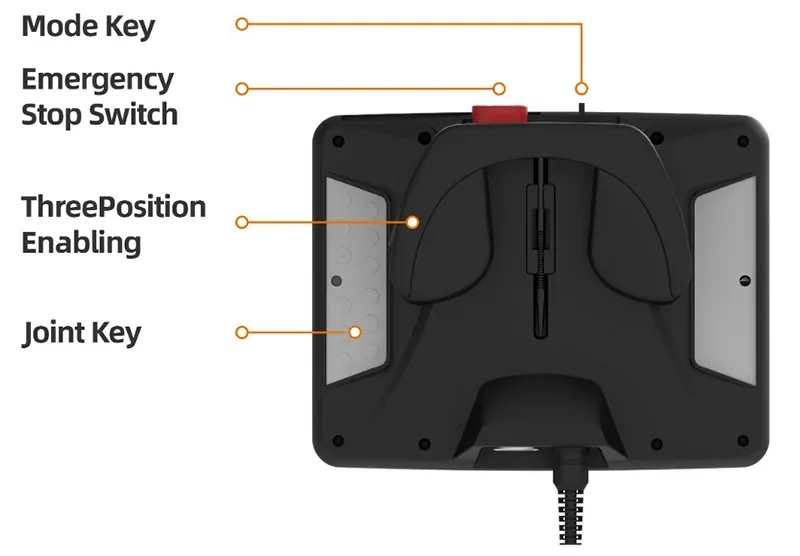

The FR3 supports hand-guiding via Drag mode with user-defined joint soft limits to restrict movement. Collision detection is adjustable by level (1–10 or custom %) with selectable responses — error-stop or continue — allowing behavior to match risk assessments.

The FR series meets ISO 10218, ISO 13849, ISO/TS 15066, CE, and RoHS 2.0 standards, enabling compliant human-robot collaboration technology deployment.

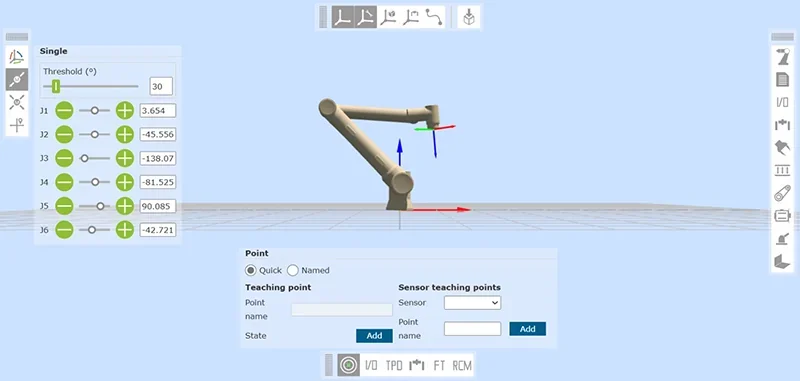

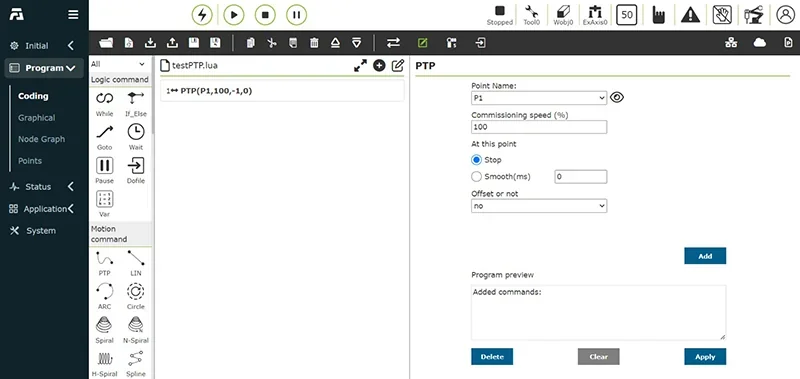

The FR3 uses FAIRINO’s self-developed browser-based WebAPP for programming on PC, tablet, or phone, with a mirrored interface on the optional teach pendant.

The interface supports graphical programming and Lua scripting, allowing users to drag-and-drop functions or write code in one environment.

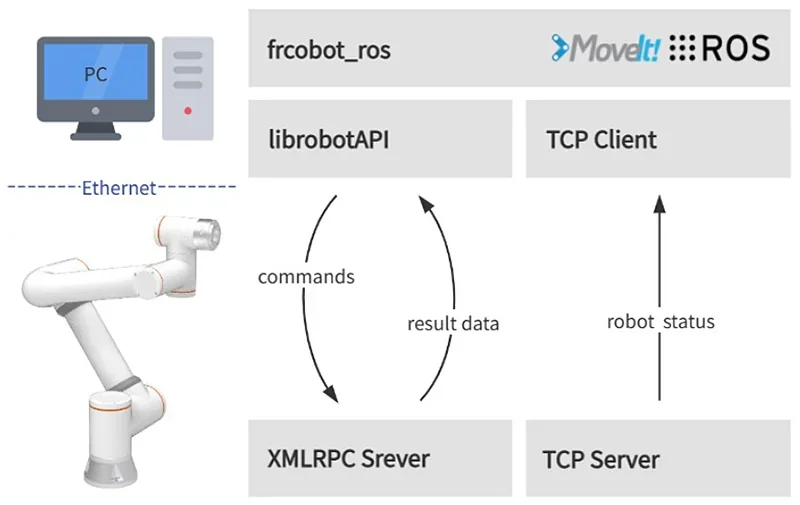

FAIRINO offers SDKs for C#, C++, and Python, plus ROS/ROS2 integration for robotics secondary development.

FAIRINO’s application kits offer no-code workflows — palletizing sets up in three guided steps, and welding includes prebuilt logic. For advanced control, the Controller Communication Protocol provides API access to motion, I/O, safety, and peripherals.

The WebAPP and teach pendant UI support multiple languages, including Chinese, English, French, and Japanese, to suit local operators.

The FR3 offers 50+ connectivity options. Its controller includes 16 DI, 16 DO, 2 AI, 2 AO, and 2 high-speed pulse inputs (24 V) for cell-level I/O. The tool flange adds 2 DI, 2 DO, 1 AI, 1 AO, and a 24 V / 1.5 A power rail for end-effector integration.

The digital I/O uses 24 V industrial signaling with selectable NPN/PNP wiring. Outputs sink up to 1 A (≈0.5 V drop, ≤0.1 mA leakage), and inputs trigger at 11–30 V. An internal 24 V supply (1.5–2 A) supports light loads; external power is recommended for higher draw.

Standard networking includes Ethernet (TCP/IP) with Modbus TCP/RTU for PLC/SCADA integration. Optional MiniPCIe cards add EtherCAT, EtherNet/IP, PROFINET, and CC-Link IE Field Basic for fieldbus support.

FAIRINO’s Safety Box connects via RJ45 and PoE, presenting the WebAPP over TCP/IP for easy operator access, commissioning, and handshaking on the plant network.

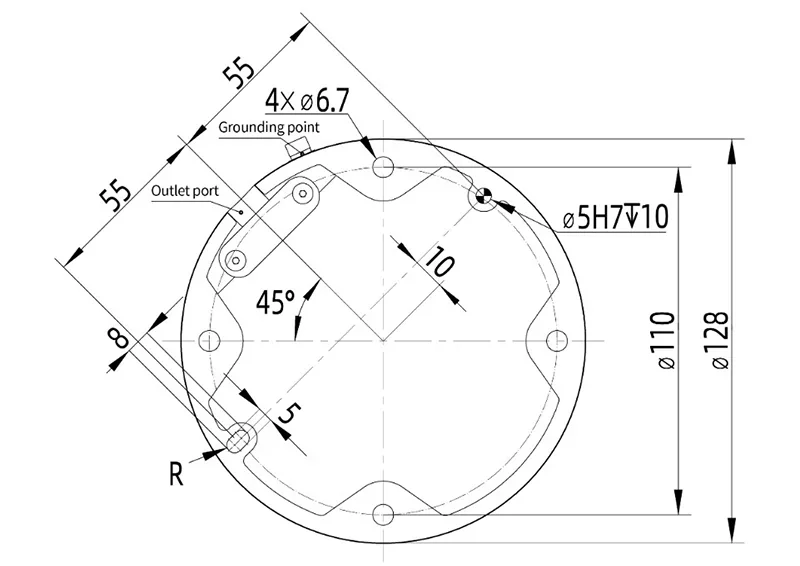

The FAIRINO FR3 is a 6-axis cobot with aluminum and steel links on a 128 mm footprint, weighing ≈15 kg for stability and low inertia. It’s rated IP54 (IP65 optional), operates at 0–45 °C and up to 90% Relative Humidity (non-condensing), runs below 65 dB, and supports any mounting orientation for flexible cell layouts.

The controller has a galvanized IP54-rated chassis, measuring 245 x 180 x 44.5 mm and weighing 2.1–2.5 kg.

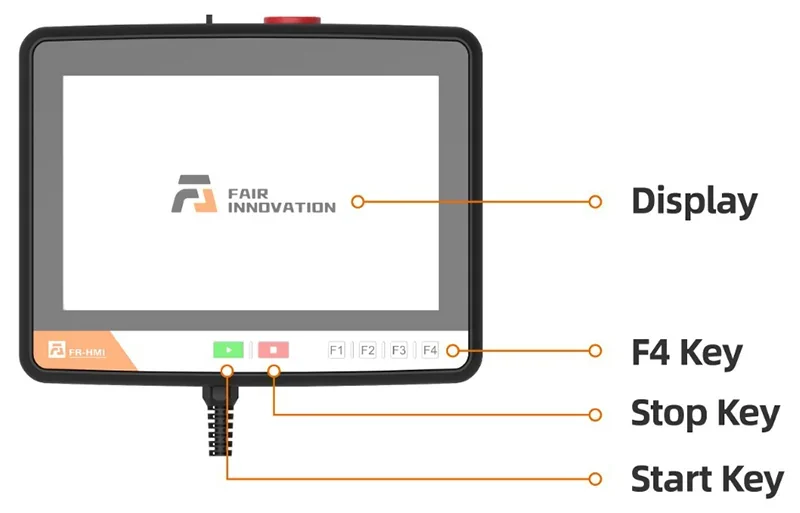

The optional teach pendant is an IP54-rated ABS/PP unit, 268 x 210 x 88 mm, weighing 1.6 kg — durable and compact for industrial use.

Installations should avoid shock, corrosive or explosive environments, and unstable power — standard practice for collaborative arms.

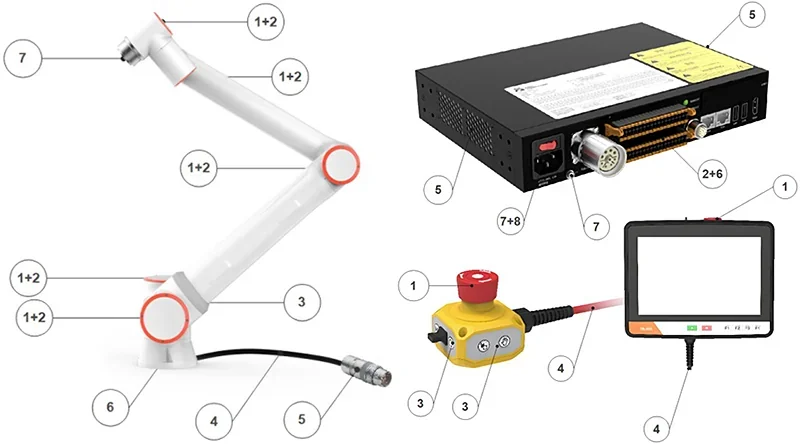

The standard FAIRINO FR3 collaborative robot arm package includes:

The FR3 ships fully assembled with a separate control and button box. After securing the base and connecting the cables and power, it’s ready to run via the WebAPP.

Please Note: Package contents are determined by the manufacturer and may change without notice. To confirm the current items included with this product, please contact a Top3DShop sales representative before placing your order.

The FR3 supports 8+ accessories and turnkey kits, including operator tools (Teach Pendant, Safety Box, Explosion-Proof Cabinet), end-effectors and sensors (EPG40-050 gripper, force/torque sensor, depth camera), and two prebuilt workstations for bin-picking and welding.

| Accessory | Function | Target User | Price (USD) |

|---|---|---|---|

| Teach Pendant | 10.1″ handheld HMI for teaching via WebApp | Operators & technicians | $840+ |

| Safety Box | RJ45 PoE button box with E-stop/jog & quick WebApp access | Line operators; safety supervisors | $430+ |

| Explosion-Proof Cabinet | Positive-pressure IP-rated controller cabinet for hazardous areas | EX/flammable-area installations | $700–$1,500+ |

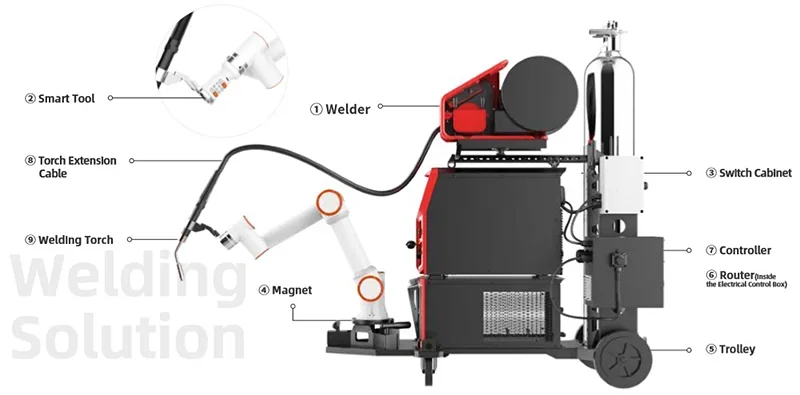

| Intelligent Welding Workstation | Mobile welding cell with 3D camera & process kit | Fabrication & job shops | $25,000+ |

| Intelligent Bin-Picking Workstation | 3D vision bin-picking cell for mixed SKUs | E-commerce/DCs; kitting lines | $30,000+ |

The Teach Pendant is a wired handheld HMI that mirrors the WebAPP, allowing jogging, point teaching, and cell-side control. It features IP-rated hardware and a fixed cable for industrial use with the FR3.

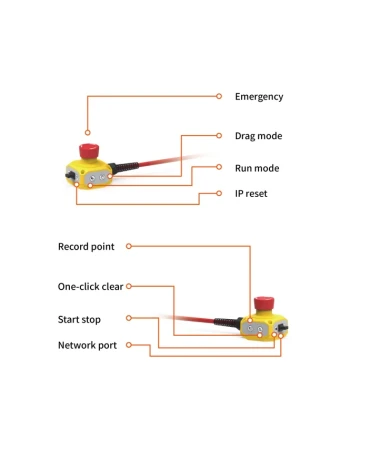

The Safety Box is a PoE RJ45 operator panel with core run/teach functions — Manual/Auto, Drag, Point Record, Start/Stop, and Shutdown — and direct WebAPP access to the FR3 over TCP/IP.

The Explosion-Proof Cabinet is a positive-pressure, IP65 enclosure for housing the FR3 controller in hazardous or dusty environments.

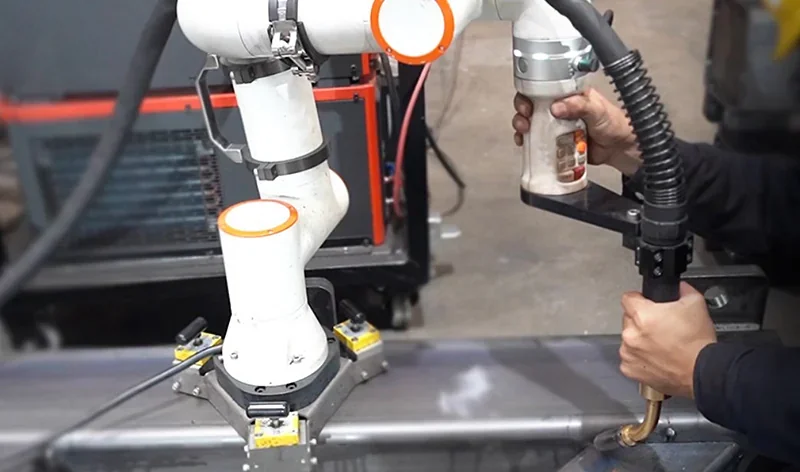

The Intelligent Welding Workstation is a trolley-mounted system with welder hardware, Smart Tool, controller, router, and 3D camera/software for path generation and seam tracking with the FR3.

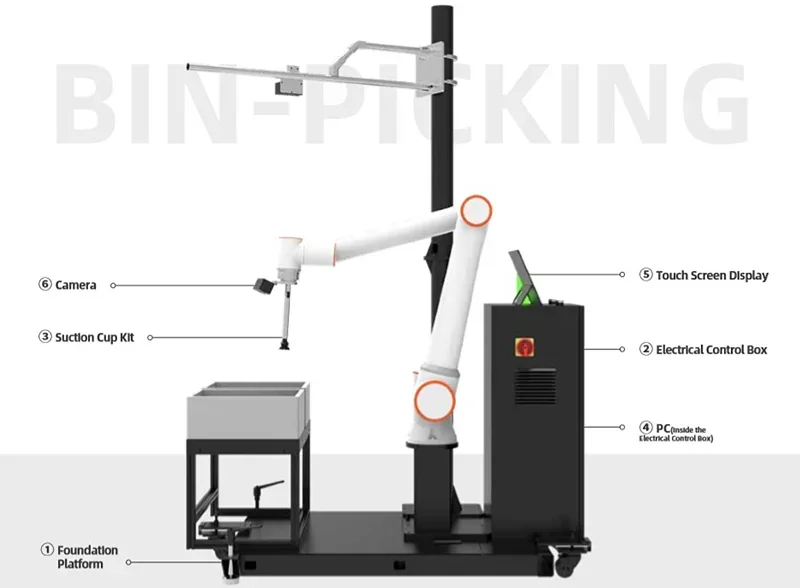

The Intelligent Bin-Picking Workstation includes a 3D camera, suction-cup kit, IPC, and touchscreen HMI for automated mixed-SKU picking with the FR3.

End-effector ecosystem (selected FR3-compatible tools)

| Tool | Function | Target User | Price (USD) |

|---|---|---|---|

| EPG40-050 | Electric parallel gripper (0–40 mm stroke, programmable force/position) | General assembly, pick-and-place, machine tending | $500+ |

| Orbbec Gemini 2 | Active-stereo depth camera for 3D detection and guidance | Vision-guided bin-picking, localization, inspection | $250+ |

| GZCX-6F-75MM | 6-axis force/torque sensor for force control and contact tasks | Insertion, polishing, compliance testing | $850+ |

| XJC-6F-D80-H28-A | 6-axis force/torque sensor with RS-485/422 options | Advanced force applications, research, compliance control | $3,300+ |

The FR3 supports the EPG40-050 gripper via digital I/O or Modbus RTU (RS-485), enabling precise pick-and-place and tending with closed-loop position and force control.

The FR3 uses the Orbbec Gemini 2 for 3D guidance via UVC stream and official SDK, providing calibrated depth for part localization with defined working and imaging ranges.

The FR3 supports the GZCX-6F-75MM force/torque sensor via RS-485/422 for force-controlled insertion, polishing, and guarded moves, with rated loads, repeatability, and temperature compensation.

The FR3 uses the XJC-6F-D80-H28-A wrist-mounted F/T sensor via RS-485 for guarded motion and force control, with load ratings and stability suited for precision assembly and finishing.

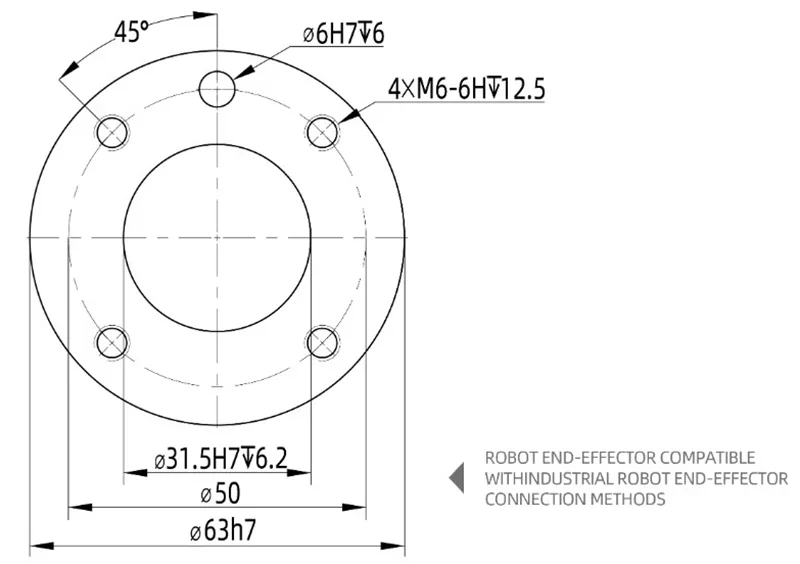

Tool interface standards and mounting: The FR3 end flange has four M6 threads (tightened to 8 Nm) with Ø6 locating holes; bolt length must not exceed 8 mm. Tool-side I/O includes 2 DI, 2 DO, 1 AI, 1 AO, and 24 V / 1.5 A power.

The FR+ ecosystem includes vision (AL-M PND0700GB4, 0.08 mm z-repeatability @ 500 mm, 0.8 s acquisition), no-code welding kits, and turnkey bin-picking/CNC cells. Components connect via Modbus RTU, digital I/O, or USB/UVC, with the controller supporting higher-level links like Modbus TCP.

Mount the FR3 to a rigid, flat surface using four M6 bolts (≥10 Nm) and two Ø5 mm locating pins. The base must support 5x the robot’s weight and 10x the J1 torque, and be isolated from moving equipment to avoid vibration or resonance — keep external-axis acceleration minimal.

FR3 model collaborative robot installation size

Connect cables in order: robot–controller umbilical, button-box cable, then power. Ensure the button-box E-stop is released before powering on. During startup, the end-of-arm LED cycles red–green–blue; solid green indicates the controller is ready.

Robot wiring schematic diagram

The FR series offers control boxes with varying input ratings. For the FR3, the matched controllers are the AC MINI Controller 2 kW or the DC MINI Controller 2 kW (input 30–60 VDC); check the nameplate, ground the system, and use quick connectors for wiring.

| Maximum Input (for customers to configure the front-stage power supply) | Maximum Output (maximum output peak) | |

| DC 2kW | 30–60VDC/30A | 2000W/48VDC/41A |

| DC 5kW | 30–60VDC/40A | 5000W/48VDC/104A |

| AC narrow voltage 2kW | 176–264VAC/10A/Single Machine/50Hz | 2000W/48VDC/41A |

| AC wide voltage 2kW | 100–240VAC/10A/Single Machine/50–60Hz | 2000W/48VDC/41A |

| AC wide voltage 5kW | 100–240VAC/16A/Single Machine/50–60Hz | 5000W/48VDC/104A |

For commissioning, connect a PC to the button box via Ethernet, set the PC IP to 192.168.58.xx (not .2), and go to 192.168.58.2 to activate using the controller SN. After the success prompt, power-cycle the controller, wait for solid green, then log in (admin / 123) and check enable–start–stop and E-stop in the WebAPP. If needed, set the install orientation (floor/side/ceiling) using SetRobotInstallPos for correct gravity compensation and safety limits.

The FR3 requires 15+ maintenance tasks at monthly, semi-annual, and annual intervals to ensure safe operation, electrical safety, and placement accuracy.

These include:

1. The manufacturer’s arm checklist (rear covers, screws, rubber rings, cables / cable links, base mounting bolts, and end-tool mounting bolts).

| Check item | Monthly | Semi-annually | Annually | ||

| 1 | Check joint rear cover * | V | ✓ | ||

| 2 | Check joint rear cover screws | F | ✓ | ||

| 3 | Check joint rubber ring | V | ✓ | ||

| 4 | Check robot cables | V | ✓ | ||

| 5 | Check robot cable links | V | ✓ | ||

| 6 | Check robot base mounting bolts * | F | ✓ | ||

| 7 | Check end tool mounting bolts * | F | ✓ |

Note: F = Functional check, V = Visual inspection, * = Must be checked after severe collision.

2. The controller / teach pendant / button-box checklist (E-stop, safety I/O, mode switching, pendant cable, control-box air filter, terminal tightness, ground resistance ≤1 Ω, and main power checks).

| Check item | Monthly | Semi-annually | Annually | ||

| 1 | Emergency stop button on test button box (teach pendant) | F | ✓ | ||

| 2 | Safety input and output functions on the test terminal strip | F | ✓ | ||

| 3 | Detection button box start/stop, mode switching function | F | ✓ | ||

| 4 | Test button box (teach pendant) cable | V | ✓ | ||

| 5 | Check and clean the air filter on the control box | V | ✓ | ||

| 6 | Check whether the terminals of the control box are firm | F | ✓ | ||

| 7 | Ground resistance of detection control box ≤1Ω | F | ✓ | ||

| 8 | Check the main power supply of the control box | F | ✓ |

Note: F = Functional check, V = Visual inspection.

Operational maintenance (during planned stops)

Power down, then visually inspect the robot–controller cable, base and tool bolts, joints, and seals. Clean the arm with water, isopropyl alcohol, or 10% ethanol/naphtha. Never use compressed air on the arm or in the control box. Small grease traces at joints are normal and don’t affect lifespan.

Preventive maintenance (monthly & semi-annually)

Inspect the arm's rear covers, screws, rubber rings, and cables. Check base and tool-flange fasteners with a torque wrench to spec. Test the control system — E-stop, safety I/O, and mode switching. Verify pendant cable condition, clean the control-box air filter, re-seat terminals if needed, and ensure ground resistance is ≤ 1 Ω.

Comprehensive maintenance (annually)

Repeat full arm and controller checks. Test E-stop from the pendant and button box — verify the robot stops, joint power is cut, then recovers. Re-check mounting torque: base 4xM6 ≥ 10 Nm with Ø5 mm pins; tool flange 4xM6 at 8 Nm, bolts ≤ 8 mm long. Avoid storage over 6 months without inspection.

The FAIRINO FR3 includes a 12-month warranty and lifetime maintenance support. FAIRINO commits to 24/7 service response, with remote triage targeting a 12-hour resolution. The warranty excludes damage caused by misuse, alterations, or unauthorized modifications. Support is available around the clock through FAIRINO’s Support Center by phone or email. For training and troubleshooting, users have access to downloadable manuals, an online FAQ, a dedicated documentation portal, and a command-tutorial video channel for hands-on learning.

Full warranty terms: https://fairino.com/SupportCenter

The FAIRINO FR3 is priced at $6,099.00. Add-ons for operator interfaces add modest cost to the base unit, typically around 14% for the Teach Pendant and 7% for the Safety Box. Application tooling has a larger impact: electric grippers usually add 3–5%, vision starter kits 15–25%, 6-axis force/torque sensors 4–7%, palletizing hardware 20–35%, and explosion-proof controller cabinets 40–60%. Enterprise packages are quoted individually based on project scope, including options like welding or bin-picking kits, fieldbus support, end-effectors, mounting hardware, commissioning, training, extended warranty, spare parts, logistics, and applicable taxes. For an exact quote, contact the Top 3D Shop team.

Update your browser to view this website correctly. Update my browser now