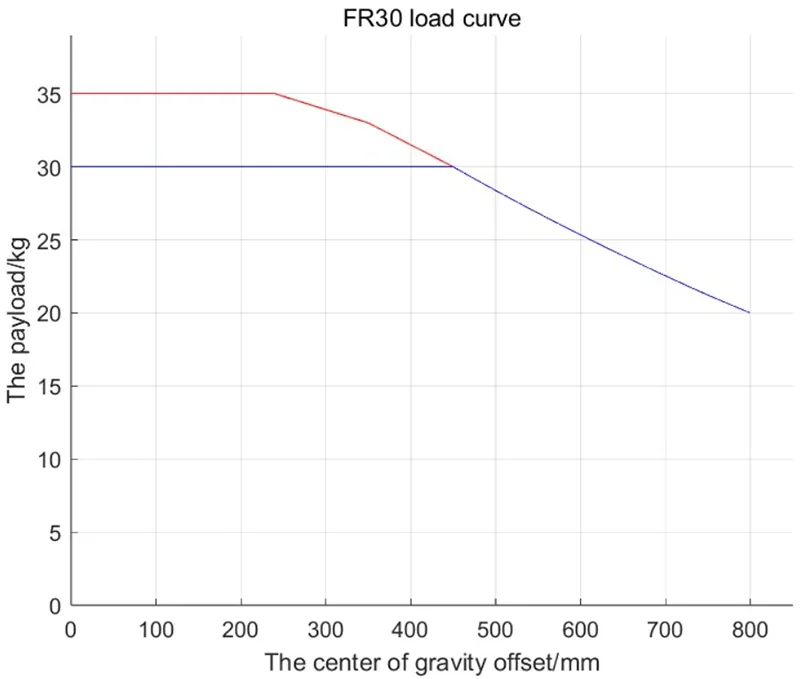

The FAIRINO FR30 is a 6-axis collaborative robot with a 30 kg payload (max 35 kg), 1403 mm reach, and ±0.1 mm repeatability (ISO 9283), designed for high-throughput applications. It supports any mounting orientation, offers IP54 protection (IP65 optional), and features an open development stack (C#/C++/Python/ROS/ROS 2) with optional real-time Ethernet fieldbus boards. The FR series cobots meet ISO 10218/13849/15066 safety standards and hold global certifications (CE, KCs, NRTL, RoHS 2.0, SEMI). Target users include industry manufacturing, logistics, and education, with available application kits and training support.

The FAIRINO FR30 is a powerful 6-axis collaborative robot that supports a 30 kg rated payload, with an extended range up to 35 kg. Loads up to 30 kg fall within the full-performance “blue” envelope; 30–35 kg requires reduced range operation in the “extended” envelope.

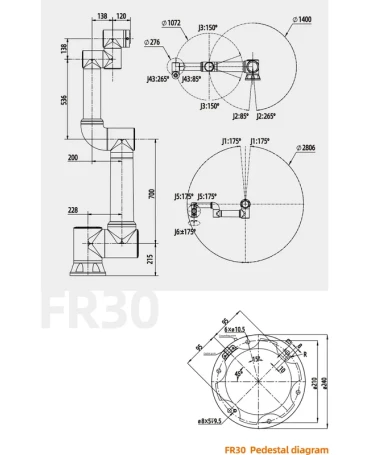

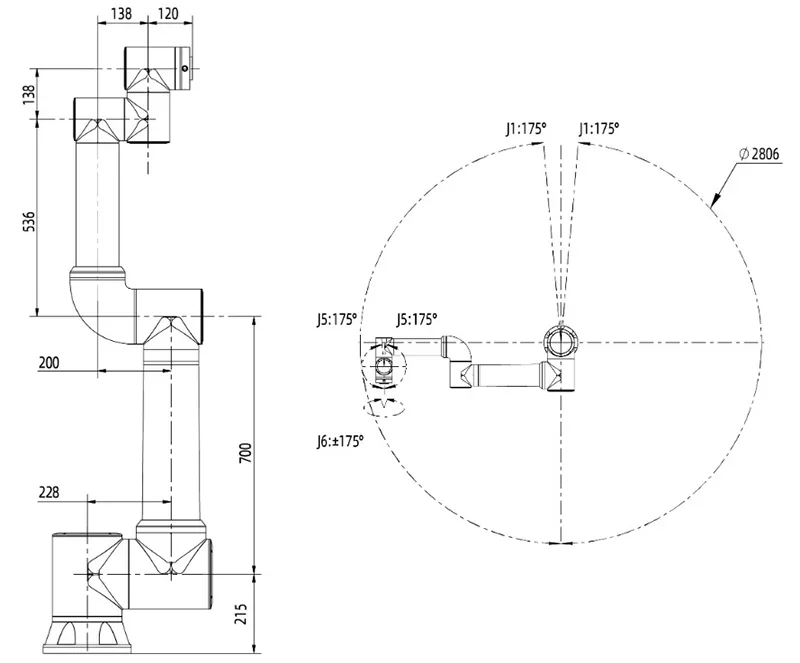

The FR30 has a maximum TCP reach of 1403 mm, with a working envelope defined by its joint limits. The shoulder's range of +85° to −265° and articulated wrist allow above- and below-base poses, while the base rotates nearly a full circle at ±175°. Mechanical limits for each axis are as follows: the base (J1) moves ±175°, the shoulder (J2) moves from +85° to −265°, the elbow (J3) allows ±160°, wrist 1 (J4) moves from +85° to −265°, and both wrist 2 (J5) and wrist 3 (J6) rotate ±175°. These combined motions establish the FR30’s full physical workspace.

The FR30 offers ±0.1 mm pose repeatability per ISO 9283, serving as its core precision benchmark. Designed for fast, heavy-payload tasks, it reaches up to 2 m/s TCP speed, with joint speeds of 120°/s on the arm and 180°/s on the wrist, enabling consistent, short-cycle movements. It supports linear, circular, helical, and spline paths, with real-time look-ahead and built-in checks for mid-points, end-points, and spline data to ensure smooth interpolation and accurate path execution.

Example: Palletizing Solution

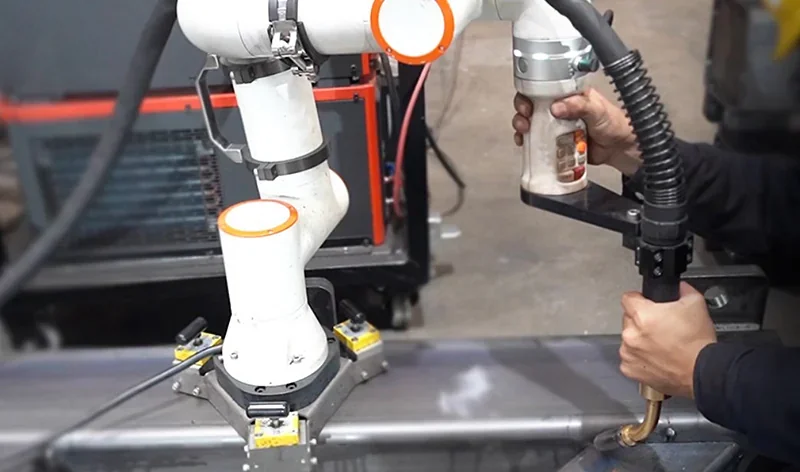

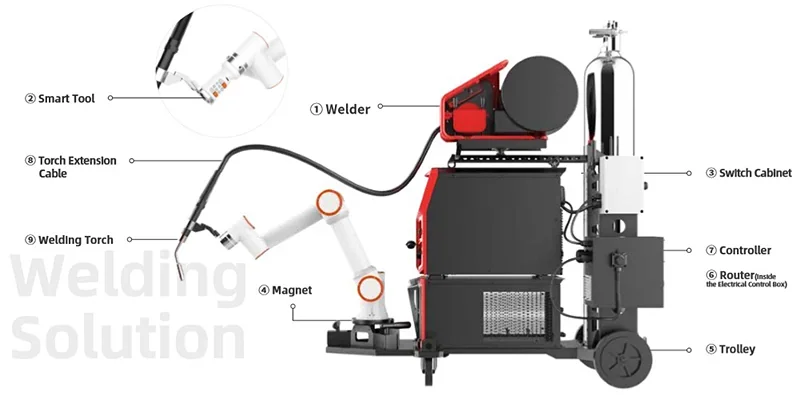

Example: Welding

Example: Plasma Cutting Technology

Example: Healthcare

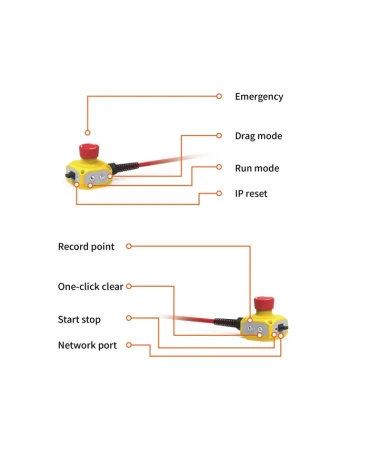

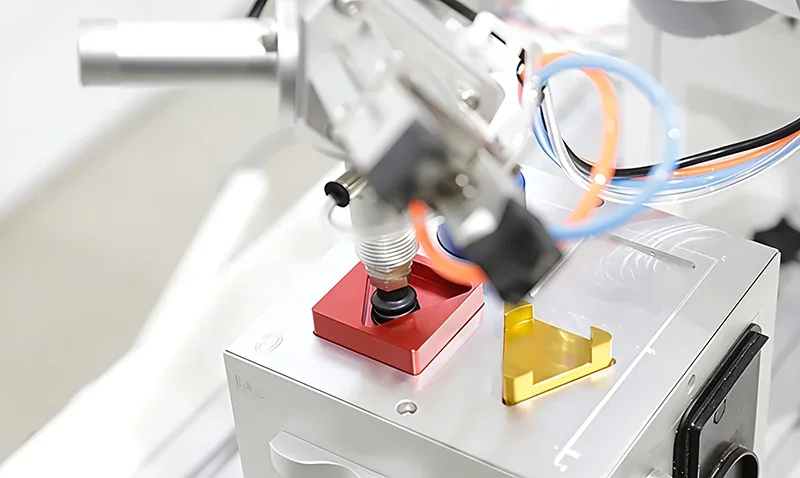

The FR30 includes a hardware emergency stop on the button box and supports two separate emergency-stop inputs and two safety-stop inputs on the controller, enabling direct wiring of category-style stop circuits.

The tool-end status LED gives clear visual feedback, cycling at power-up, showing steady green when enabled, and displaying distinct colors for auto, manual, drag, run, stop, error, and zero-calibration modes, allowing quick status checks by operators.

The FR30 provides built-in collision protection through joint-torque monitoring and configurable responses that stop motion, retract from contact, and return to a safe state. It also supports force/torque-sensor guarding and real-time torque logging for collision detection. Three levels of protective reduced modes are available, with the highest level enforcing a stop for added safety. Hand-guiding is supported natively via drag mode, activated from the button box or tool-end button, allowing safe, compliant teaching alongside human operators.

FAIRINO lists ISO 10218, 13849, and 15066 functional-safety certifications, along with CE, KCs, NRTL, RoHS 2.0, NSF, and SEMI product approvals, aligning the FR30 and the broader FR series with global human-robot collaboration standards.

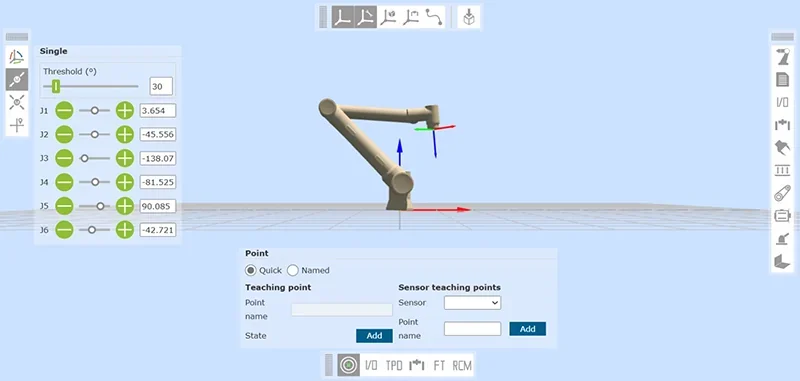

The FR30 is programmed using FAIRINO’s browser-based WebAPP, accessible on a PC, tablet, or phone, and mirrored to the optional Teach Pendant.

The interface supports graphical programming and Lua scripting in a single environment, with a multilingual user interface.

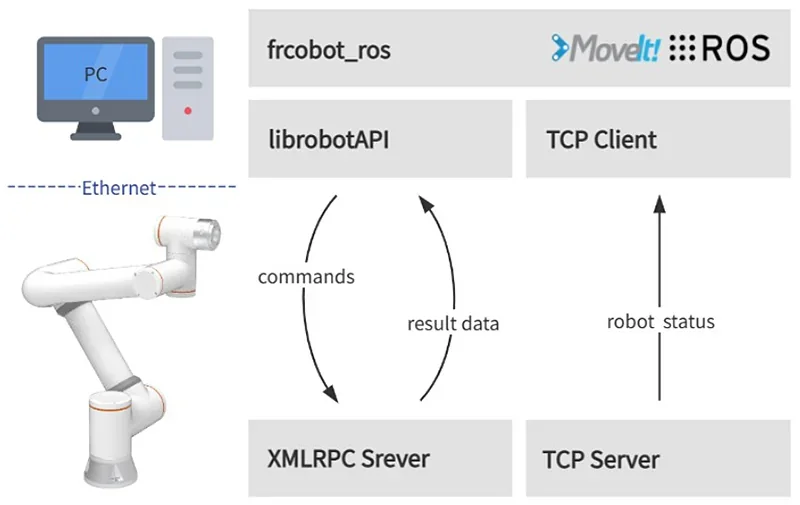

For integration and advanced development, FAIRINO offers SDKs for programming languages like C#, C++, Python, and ROS/ROS 2. The Controller Communication Command Protocol gives external software direct access to motion, I/O, and safety controls. In WebAPP, device commands can be embedded in Lua scripts to coordinate peripherals with robot motion for turnkey applications.

Offline programming and virtual commissioning are supported through simulation flags on linear and circular moves (e.g., SimMoveC), enabling trajectory checks without motion execution. Program-safety features like over-speed protection and singularity avoidance can be toggled via the API to validate paths under real-world constraints.

The FR30 supports 50+ connectivity options. Its controller includes 16 digital inputs, 16 digital outputs, 2 analog inputs, 2 analog outputs, and two high-speed pulse inputs. The tool flange adds 2 digital inputs, 2 digital outputs, 1 analog input, and 1 analog output, along with a 24 V/1.5 A power rail for end-effectors. All I/O uses 24 V industrial signaling with selectable NPN/PNP wiring and configurable valid-level behavior for safe integration with plant equipment.

Standard networking includes Ethernet (TCP/IP) with Modbus TCP and Modbus RTU for PLC or SCADA integration. A built-in socket interface supports UDP and TCP (server/client) with ASCII or HEX payloads for custom device communication.

For fieldbus integration, optional MiniPCIe real-time Ethernet boards support CC-Link, PROFINET, EtherNet/IP, and EtherCAT. The controller API allows fieldbus-slave selection for Siemens, CC-Link, EtherCAT, and EtherNet/IP. The Modbus TCP slave map lets external controllers start programs and control digital outputs. The Safety Box connects via RJ45 with PoE, presenting the WebAPP over TCP/IP for line-side access.

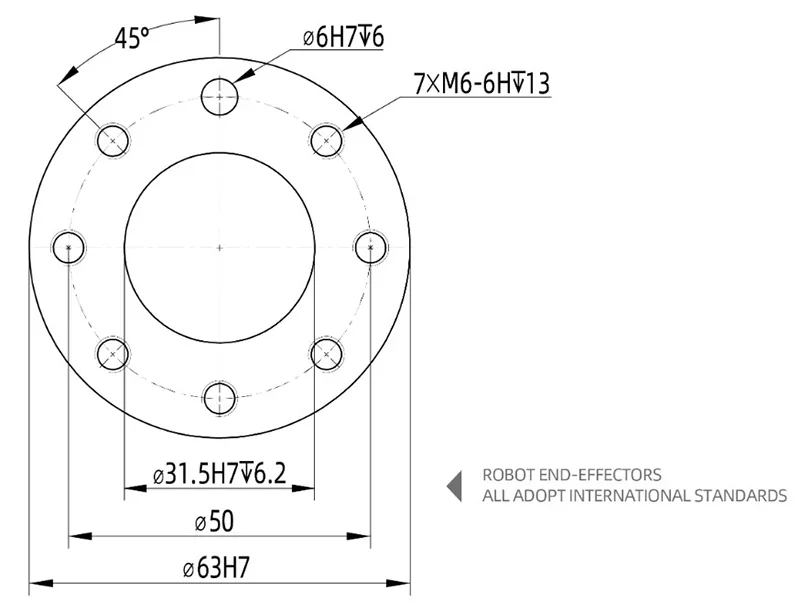

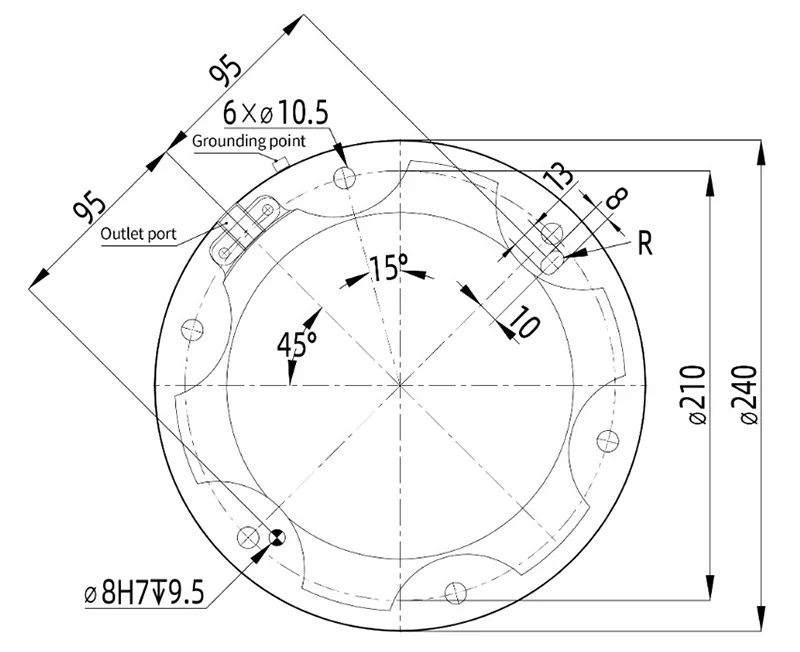

With a 240 mm base footprint and ~85 kg arm mass, the FR30 fits dense cell layouts while providing a rigid platform. Its aluminum-steel structure features six rotary joints and a standard end flange with four M6 threaded holes for tool mounting.

The controller has a galvanized IP54-rated chassis, measuring 245 x 180 x 44.5 mm and weighing 2.1–2.5 kg.

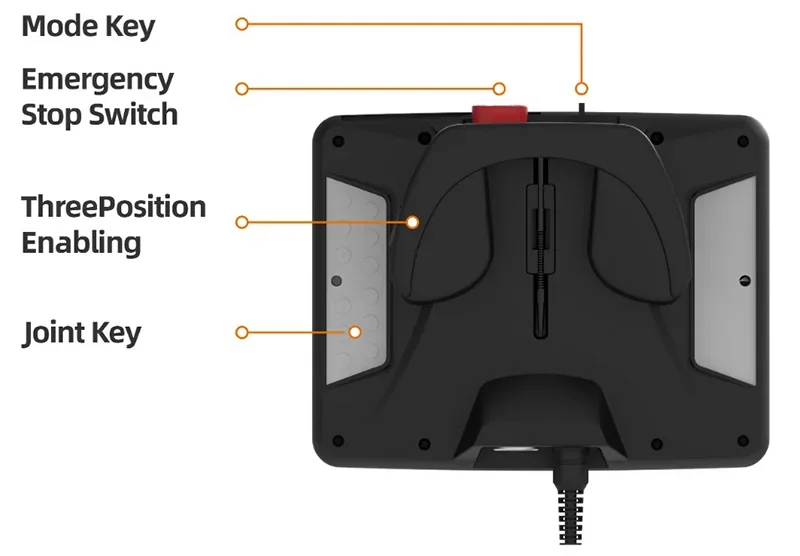

The optional teach pendant is an IP54-rated ABS/PP unit, 268 x 210 x 88 mm, weighing 1.6 kg — durable and compact for industrial use.

The FR30 operates below 70 dB noise and is rated for 0–45 °C and up to 90% non-condensing humidity. It comes with IP54 protection standard, with an optional IP65 version for harsher environments.

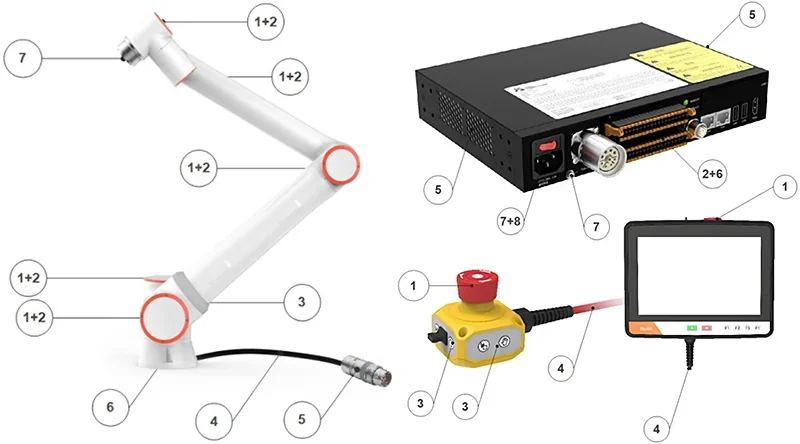

The standard FAIRINO FR30 collaborative robot arm package includes:

The FR30 ships fully assembled with a separate control and button box. After securing the base and connecting the cables and power, it’s ready to run via the WebAPP.

Please Note: Package contents are determined by the manufacturer and may change without notice. To confirm the current items included with this product, please contact a Top3DShop sales representative before placing your order.

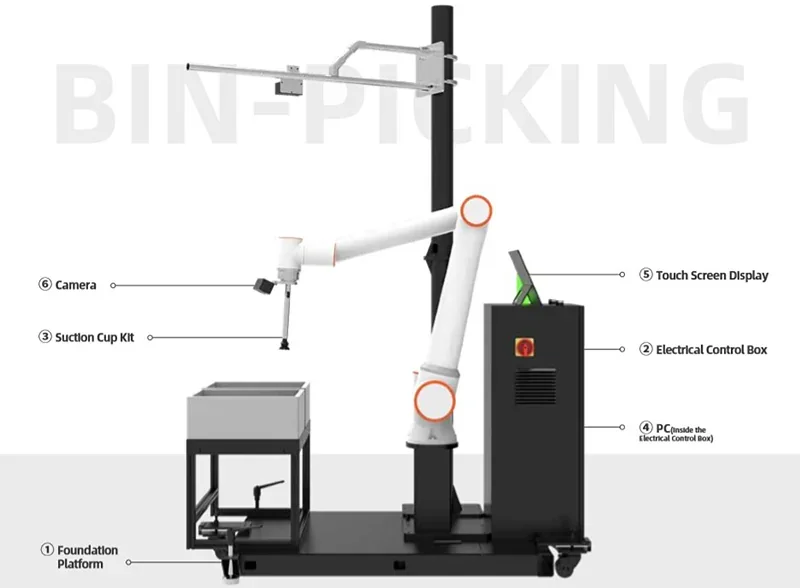

The FR30 supports 8+ accessories and turnkey kits, including operator tools (Teach Pendant, Safety Box, Explosion-Proof Cabinet), end-effectors and sensors (EPG40-050 gripper, force/torque sensor, depth camera), and two prebuilt workstations for bin-picking and welding.

| Accessory | Function | Target User | Price (USD) |

|---|---|---|---|

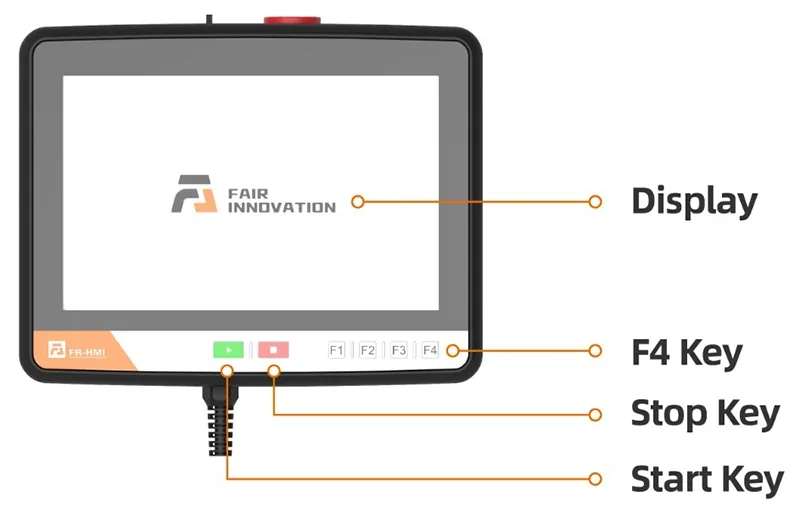

| Teach Pendant | 10.1″ handheld HMI for teaching via WebApp | Operators & technicians | $840+ |

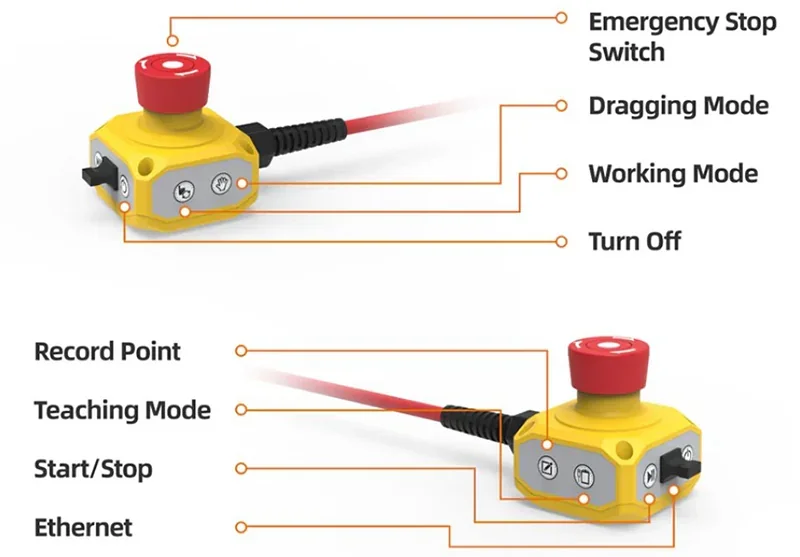

| Safety Box | RJ45 PoE button box with E-stop/jog & quick WebApp access | Line operators; safety supervisors | $430+ |

| Explosion-Proof Cabinet | Positive-pressure IP-rated controller cabinet for hazardous areas | EX/flammable-area installations | $700–$1,500+ |

| Intelligent Welding Workstation | Mobile welding cell with 3D camera & process kit | Fabrication & job shops | $25,000+ |

| Intelligent Bin-Picking Workstation | 3D vision bin-picking cell for mixed SKUs | E-commerce/DCs; kitting lines | $30,000+ |

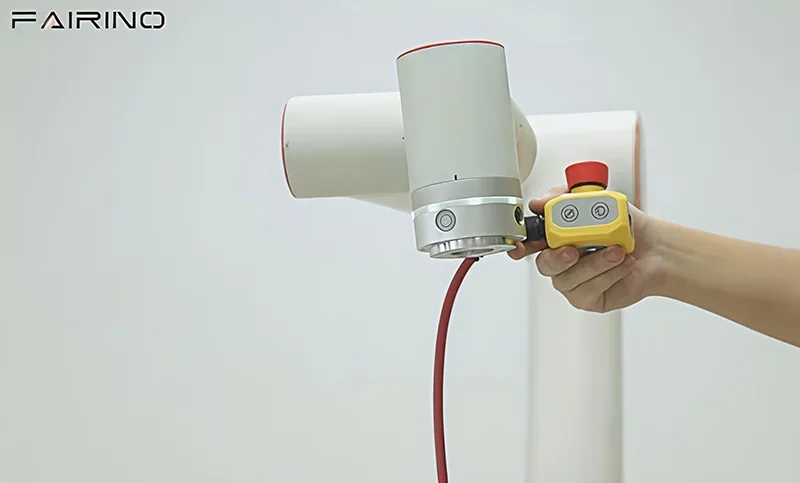

The Teach Pendant is a wired handheld HMI that mirrors the WebAPP, allowing jogging, point teaching, and cell-side control. It features IP-rated hardware and a fixed cable for industrial use with the FR5.

The Safety Box is a PoE RJ45 operator panel with core run/teach functions — Manual/Auto, Drag, Point Record, Start/Stop, and Shutdown — and direct WebAPP access to the FR5 over TCP/IP.

The Explosion-Proof Cabinet is a positive-pressure, IP65 enclosure for housing the FR5 controller in hazardous or dusty environments.

The Intelligent Welding Workstation is a trolley-mounted system with welder hardware, Smart Tool, controller, router, and 3D camera/software for path generation and seam tracking with the FR5.

The Intelligent Bin-Picking Workstation includes a 3D camera, suction-cup kit, IPC, and touchscreen HMI for automated mixed-SKU picking with the FR5.

End-effector ecosystem (selected FR30-compatible tools)

| Tool | Function | Target User | Price (USD) |

|---|---|---|---|

| EPG40-050 | Electric parallel gripper (0–40 mm stroke, programmable force/position) | General assembly, pick-and-place, machine tending | $500+ |

| Orbbec Gemini 2 | Active-stereo depth camera for 3D detection and guidance | Vision-guided bin-picking, localization, inspection | $250+ |

| GZCX-6F-75MM | 6-axis force/torque sensor for force control and contact tasks | Insertion, polishing, compliance testing | $850+ |

| XJC-6F-D80-H28-A | 6-axis force/torque sensor with RS-485/422 options | Advanced force applications, research, compliance control | $3,300+ |

The FR5 supports the EPG40-050 gripper via digital I/O or Modbus RTU (RS-485), enabling precise pick-and-place and tending with closed-loop position and force control.

The FR5 uses the Orbbec Gemini 2 for 3D guidance via UVC stream and official SDK, providing calibrated depth for part localization with defined working and imaging ranges.

The FR5 supports the GZCX-6F-75MM force/torque sensor via RS-485/422 for force-controlled insertion, polishing, and guarded moves, with rated loads, repeatability, and temperature compensation.

The FR5 uses the XJC-6F-D80-H28-A wrist-mounted F/T sensor via RS-485 for guarded motion and force control, with load ratings and stability suited for precision assembly and finishing.

Tool interface standards and mounting: The FR30 end flange includes four M6 threaded holes and Ø6 mm locating pin holes. When attaching tools, use bolts with ≤8 mm thread engagement and strength class ≥8.8. The tool interface also provides 2 digital inputs, 2 digital outputs, 1 analog input, 1 analog output, and a 24 V/1.5 A supply for end-effector integration.

The FR+ ecosystem includes vision (AL-M PND0700GB4, 0.08 mm z-repeatability @ 500 mm, 0.8 s acquisition), no-code welding kits, and turnkey bin-picking/CNC cells. Components connect via Modbus RTU, digital I/O, or USB/UVC, with the controller supporting higher-level links like Modbus TCP.

Secure the FR30 to a rigid base using six M10 bolts (strength ≥ 8.8) torqued to at least 45 Nm, with Ø8 mm dowel pins for alignment. Due to the arm’s mass and inertia, FAIRINO recommends direct floor mounting. The base must support at least 5x the robot’s weight and 10x the J1 torque, have a flat contact surface, and be isolated from other moving equipment to prevent resonance. Allocate an installation space of 3 m x 3 m x 2 m (LxWxH), adding at least 500 mm clearance if using additional end load.

FR30 model collaborative robot installation size

The FR30 uses either the AC Controller 5 kW or DC Controller 5 kW. Use a controller that matches the available supply — 30–60 VDC, 176–264 VAC 50/60 Hz, or 100–240 VAC 50/60 Hz — and connect protective earth, verifying ground resistance is ≤ 1 Ω. Mount the control box 0.6–1.5 m above the floor, away from heat, with at least 150 mm clearance on the heavy-load-line side and 100 mm on other sides for cooling. Follow environmental limits: 0–45 °C, 20–80% RH (non-condensing), altitude below 2000 m, and no exposure to corrosives, liquids, explosive gases, oil mist, dust, metal powder, or strong EMI. Install an upstream air switch and EMC filter.

| Maximum Input (for customers to configure the front-stage power supply) | Maximum Output (maximum output peak) | |

| DC 2kW | 30–60VDC/30A | 2000W/48VDC/41A |

| DC 5kW | 30–60VDC/40A | 5000W/48VDC/104A |

| AC narrow voltage 2kW | 176–264VAC/10A/Single Machine/50Hz | 2000W/48VDC/41A |

| AC wide voltage 2kW | 100–240VAC/10A/Single Machine/50–60Hz | 2000W/48VDC/41A |

| AC wide voltage 5kW | 100–240VAC/16A/Single Machine/50–60Hz | 5000W/48VDC/104A |

Connect the Button Box or PC to the controller and access the WebAPP at 192.168.58.2 to begin commissioning. Set the installation orientation (Base → Mounting), enter the end payload mass and center of gravity, and calibrate the TCP/tool coordinates before running any motion.

Validate safety by wiring and testing the controller’s two emergency-stop and two safety-stop circuits, confirming correct enable/stop behavior and end-LED status, then performing a controlled power-on and enable sequence.

Robot wiring schematic diagram

The FAIRINO FR30 requires 10+ maintenance procedures to preserve collaborative safety functions, mechanical integrity, and placement stability across monthly, semi-annual, and annual intervals; FAIRINO additionally prescribes a monthly check of the emergency-stop and protective-stop functions.

Arm checklist (rear covers, screws, rubber rings, cables / cable links, base mounting bolts, and end-tool mounting bolts)

| Check item | Monthly | Semi-annually | Annually | ||

| 1 | Check joint rear cover * | V | ✓ | ||

| 2 | Check joint rear cover screws | F | ✓ | ||

| 3 | Check joint rubber ring | V | ✓ | ||

| 4 | Check robot cables | V | ✓ | ||

| 5 | Check robot cable links | V | ✓ | ||

| 6 | Check robot base mounting bolts * | F | ✓ | ||

| 7 | Check end tool mounting bolts * | F | ✓ |

Note: F = Functional check, V = Visual inspection, * = Must be checked after severe collision.

Controller / teach pendant / button-box checklist (E-stop, safety I/O, mode switching, pendant cable, control-box air filter, terminal tightness, ground resistance ≤1 Ω, and main power checks)

| Check item | Monthly | Semi-annually | Annually | ||

| 1 | Emergency stop button on test button box (teach pendant) | F | ✓ | ||

| 2 | Safety input and output functions on the test terminal strip | F | ✓ | ||

| 3 | Detection button box start/stop, mode switching function | F | ✓ | ||

| 4 | Test button box (teach pendant) cable | V | ✓ | ||

| 5 | Check and clean the air filter on the control box | V | ✓ | ||

| 6 | Check whether the terminals of the control box are firm | F | ✓ | ||

| 7 | Ground resistance of detection control box ≤1Ω | F | ✓ | ||

| 8 | Check the main power supply of the control box | F | ✓ |

Note: F = Functional check, V = Visual inspection.

Operational maintenance (during planned stops with power off)

When possible, return the arm to zero, disconnect control-box power, and visually inspect the robot–controller cable and overall condition. Clean only with water, isopropyl alcohol, 10% ethanol, or 10% naphtha — never use compressed air or bleach. Small grease traces at joints are normal and acceptable.

Preventive maintenance (monthly & semi-annually)

Inspect the arm’s rear covers, rear-cover screws, rubber rings, cables, and cable links. Perform torque checks on the base and tool-flange fasteners using a torque wrench to spec. Include monthly verification of the emergency stop and protective stop functions.

Comprehensive maintenance (annually)

Repeat the full inspection, recheck fastener torque — six M10 bolts at ≥45 Nm for the FR30 base — and confirm the integrity of joint backs and tool-flange bolts. If stored long term, visually inspect the robot at least every six months.

Maintenance must be performed by qualified personnel following the manufacturer’s instructions, with the system powered down before any inspection or adjustment.

The FAIRINO FR30 includes a 12-month warranty covering material and workmanship defects, excluding damage from misuse, unauthorized modifications, or user program errors. Technical support is provided by FAIR Innovation (Suzhou) via phone (+86-400-811-0929), email (sales@frtech.fr), and the official website. Operator training is available through formal courses, with inquiries directed to jiling@frtech.fr. Self-service resources include manuals and software packages from the official documentation portal.

Full warranty terms: https://fairino.com/SupportCenter

The FAIRINO FR30 is priced at $18,199.00, offering enterprise-grade collaborative automation with scalable integration, a mature accessory ecosystem, and browser-based programming that reduces commissioning time and total cost of ownership. Operator interfaces typically add 3–6% for the Teach Pendant and 2–4% for the Safety Box, or 5–9% combined. Application tooling varies more: electric grippers add 3–5%, vision kits 15–25%, 6-axis force/torque sensors 4–7%, palletizing hardware 20–35%, and explosion-proof cabinets 18–30%. Contact Top 3D Shop for personalized quotes. Enterprise packages are scoped by use case, including welding or bin-picking kits, fieldbus support, end-effectors, mounting, training, warranty, spare parts, logistics, and taxes.

Update your browser to view this website correctly. Update my browser now