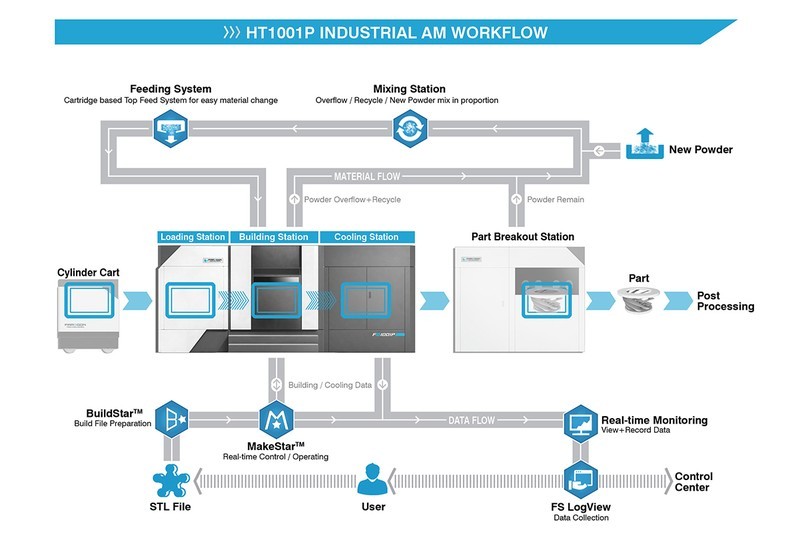

The Farsoon HT1001P is a polymer laser sintering (PLS) solution introducing the new patented technology known as CAMS — Continuous Additive Manufacturing Solution. It has been created to sustain intensive manufacturing cycles with minimum downtime between sessions, thus enhancing the productivity of SLS printing.

The HT1001P system applies powerful multi-laser scanning with the speed of up to 15.2 m/s, smart thermal control with a multi-zone heater, and open printing parameters. With a closed loop powder change mechanism, it offers increased automation and requires little operator interaction. The printer is equipped with an impressive build cylinder of 39.4 x 19.7 x 17.7 inches (1000 x 500 x 450 mm). Moreover, the machine has a heated build chamber (max. 220 °C) making it ideal for processing industrial materials. In combination with the minimum layer thickness of 60 microns, this PLS system becomes a valuable tool for a wide range of applications.

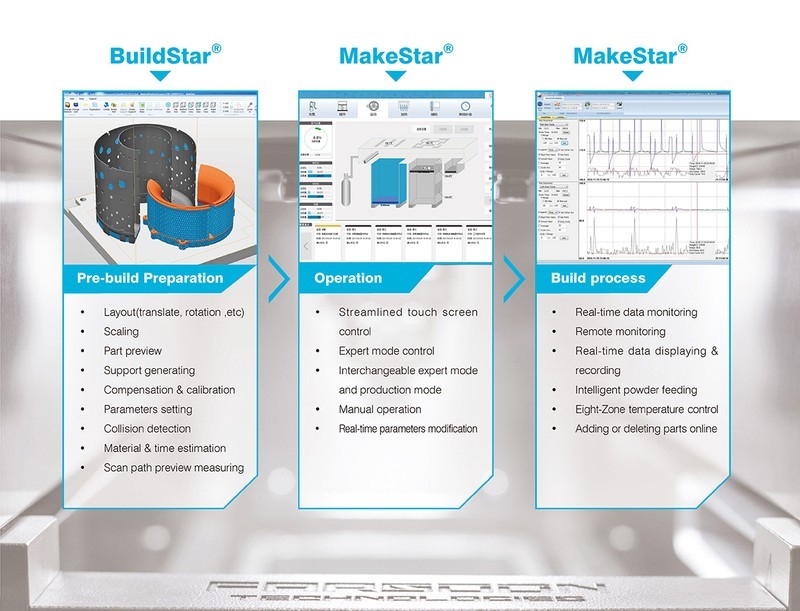

Along with the mentioned benefits, the HT1001P is supplied with user-friendly flexible software featuring open settings, real-time build modification, 3D visualization, and diagnostic procedures. Due to its modular design, the system allows for easy expansion by adding new stations for pre- and post-processing as well as integration into existing production lines.

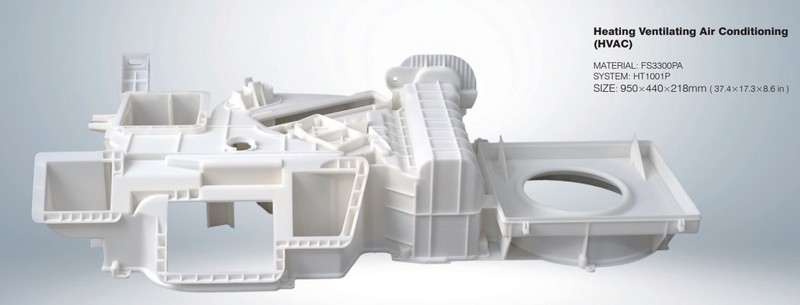

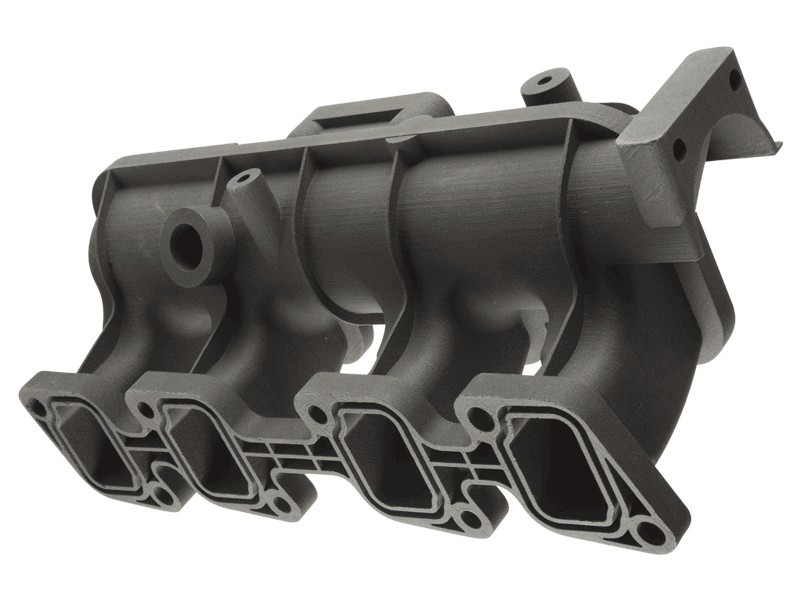

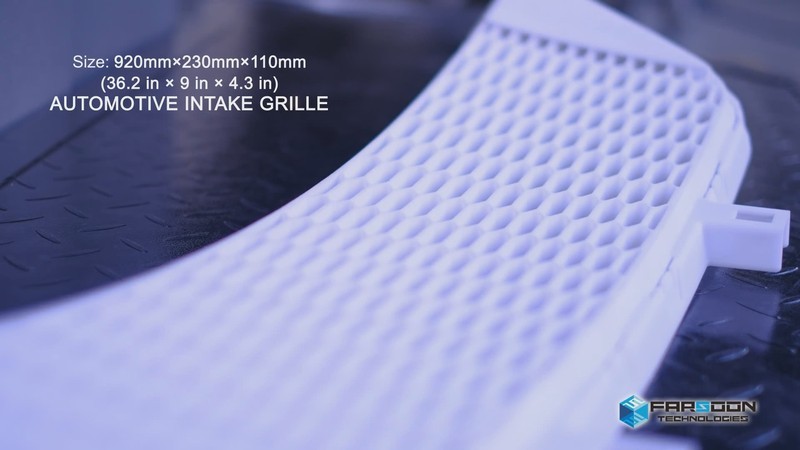

The Farsoon HT1001P solution is perfect for professional use in various industrial spheres, including automotive, aerospace and aviation, medicine, mold production, and more.

The Farsoon HT1001P Build station can sinter layers with a minimum thickness of 60 microns. It is equipped with a dual 100W CO2 laser and a high-precision three-axis digital galvo system to ensure high accuracy and detail of printed parts.

In addition, the printer is engineered with a heated chamber capable of reaching 220 °C. This allows you to work with high performance materials, including PA6 and PA12. Moreover, the integrated multi-zone heater and intelligent temperature control greatly reduce the risk of deformation, making for smooth and quality production.

The Farsoon HT1001P works with polymer powder stored in replaceable cartridges. The machine features an open parameter and material system. It is compatible with FS3300PA, FS3401GB, FS4100PA, FS3150CF, FS3250MF, FS6140GF, Ultrasint® PP nat 01, FS1092A-TPU, FS1088A-TPU, and Ultrasint® PA6. Some of the listed powders are currently in the build process development, while more will be available in the future.

Credit: youtube.com

The Farsoon HT1001P PLS system is engineered with a build cylinder of 39.4 x 19.7 x 17.7 inches (1000 x 500 x 450 mm) to satisfy all production needs. With a volume like this, the machine lets you print large parts as a whole as well as multiple items in one go, which greatly speeds up the manufacturing process.

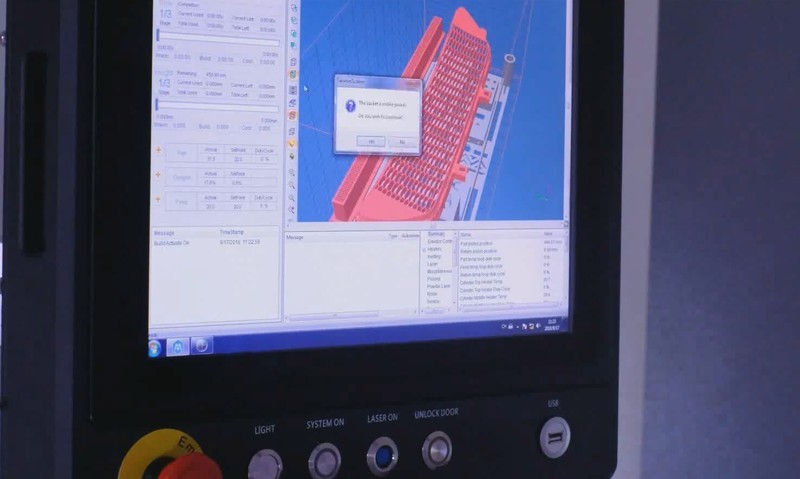

The Farsoon HT1001P PLS system can be operated via a mounted control unit with a clear and user-friendly interface. It is available in two interchangeable modes: Expert and Production.

Credit: youtube.com

The solution is supplied with the Farsoon brand BuildStar and MakeStar software for efficient build package preparation and comprehensive machine control. Both programs are designed with streamlined systems and various handy features making the manufacturing process fast, open, simple, and efficient. The integrated software runs on Windows 10 (64 bit). It supports the STL file format.

Credit: en.farsoon.com

The Farsoon HT1001P PLS system is available in a black-and-gray color scheme. Its stylish look makes it ideal for a range of applications in a variety of industries, including aerospace and aviation, automotive, medical, engineering, and more.

The full module dimensions are 219.9 x 78.7 x 117.3 in (5585 x 2000 x 2980 mm). It weighs approximately 9259.4 lb (4200 kg).

To learn the current price of the Farsoon HT1001P PLS system, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now