The FELIX Food 3D printer is an innovative solution from the Dutch company FELIXprinters that has been developing and manufacturing FDM machines since 2011. Food 3D printing uses basically the same process of material extrusion as FDM with the difference in the material used for printing. Instead of plastic models, the FELIX Food 3D printer creates culinary objects using edible ingredients in the form of homogeneous pastes. The printer comes in three modifications, namely Single, Twin, and Switch versions with the difference between them being the extruder type.

The Single head model is equipped with a syringe with a capacity of 100 ml. The syringe is filled with a selected paste which is extruded onto a heated build plate.

The Twin head version features two cartridges that print simultaneously, just like a dependent dual extruder in an FDM printer, allowing you to double the production volume. In this case, the print area is divided into two equal parts, so the maximum object size you can print is reduced but the quantity of the objects is doubled.

Finally, the FELIX Food 3D printer with a Switch head allows you to combine two different materials in a single project. Two 100 ml syringes are filled with pastes, and the switch mechanism swaps between them, combining two materials in a single print.

The printer has an open-frame design and comes mostly assembled, all you have to do is mount the foot bracket, connect the extruder and the LCD screen. The machine comes standard with a flexible stainless steel build plate that can heat up to 100 °C. Additionally, you can buy a silicone mat. Both print surfaces can be used in the oven at temperatures up to 250 °C and are dishwasher-safe. The syringe uses a standard Luer lock system, and an optional heated syringe is available to ensure better results with some ingredients. The automated bed leveling function and a built-in webcam for remote print monitoring make for user convenience and allow using the printer for a wide application range not only in restaurants but also at home. It is also a great research tool for food laboratories to test various food mixtures before using them on an industrial scale.

Below you can see the printing process of broccoli Bulbasaur.

The FELIX Food 3D printer features interchangeable nozzles with available diameters from 1.2 to 3.5 mm. The layer height ranges from 0.5 to 2 mm, allowing you to create sophisticated shapes and make attractive dishes out of various ingredients. The recipe can be easily customized in each particular case to suit a certain diet or personal preference. Some ingredients, such as dough or meringues, can be baked after printing, providing even more versatility in the machine’s application area.

The FELIX Food 3D printer is versatile enough to use various food mixtures it can handle for creating culinary masterpieces. Viscosity and texture are key characteristics of the material for successful printing. Ingredients with low viscosity may not hold a proper shape, while high-viscosity pastes can cause nozzle clogging. Viscosity can be adjusted by changing the temperature of the ingredient. As for texture, the best results can be achieved by using smooth, homogeneous pastes that flow easily through the nozzle.

Some 3D printed dishes are ready to serve right after printing, others can be left to harden for further cooking, such as pasta, or be baked, like pastries or cookies.

The list of common materials includes vegetable and fruit purees, butter, chocolate, sugars, like marzipan or icing, soya, seaweeds, dough, including pasta, and other paste-like substances. The user can combine different ingredients and add salt, spices, herbs, or sugar, if needed.

The build volume of the three versions of the FELIX Food 3D printer is shown in the table below.

| Single head | Twin head | Switch head | |

| Build volume | 270 x 195 x 170 mm (10.6 x 7.6 x 6.7 in) | 130 x 195 x 170 mm (5.1 x 7.6 x 6.7 in) x 2 | 260 x 195 x 170 mm (10.2 x 7.6 x 6.7 in) |

| Print volume capacity | 100 cm³ | 200 cm³ (2 x 100 cm³ syringes) | 200 cm³ (2 x 100 cm³ syringes) |

The printer is operated via a 5" capacitive LCD touchscreen with a simple and clear interface. Connectivity options include Wi-Fi, USB, and Ethernet. The built-in camera allows for remote monitoring of the printing process. The device is equipped with 16 GB of internal memory.

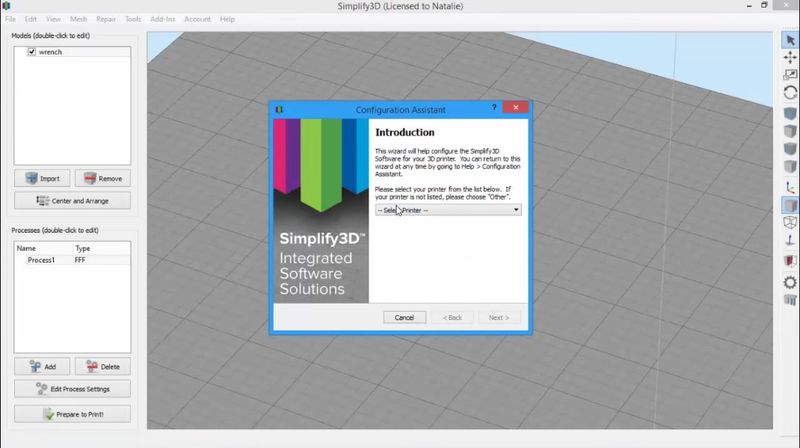

The manufacturer recommends using the well-known Simplify3D software. It is important to employ slice profiles provided by FELIXprinters specifically for their food printers to get the best results. You can find the corresponding profiles on the supplied SD card or on the manufacturer’s website.

For some items, package content may change. In case of any questions, please get in touch.

The FELIX Food 3D printer is available in a combination of black and metal-gray colors. Its desktop size and stylish look make it ideal for use in restaurants, cafes, or food labs as well as for catering services and at home.

The machine dimensions are 20.1 x 16.5 x 27.6 in (510 x 420 x 700 mm). It weighs 30.9 lb (14 kg).

To learn the current price of the FELIX Food 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now