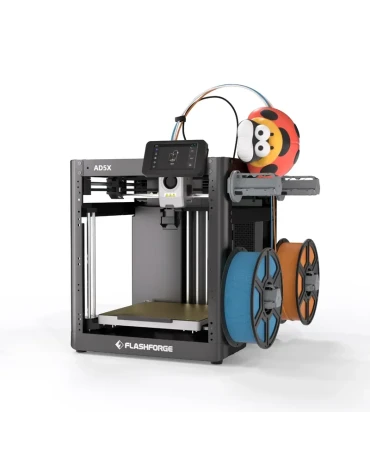

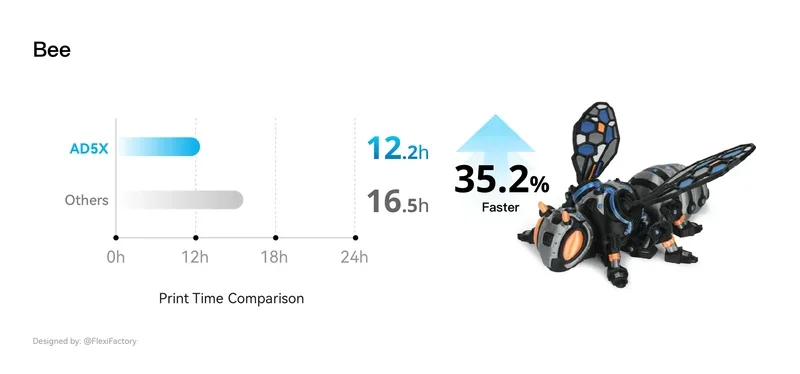

PLA Print Sample: A mechanical bee with black, silver, orange, and translucent blue parts was printed in 12.2 hours.

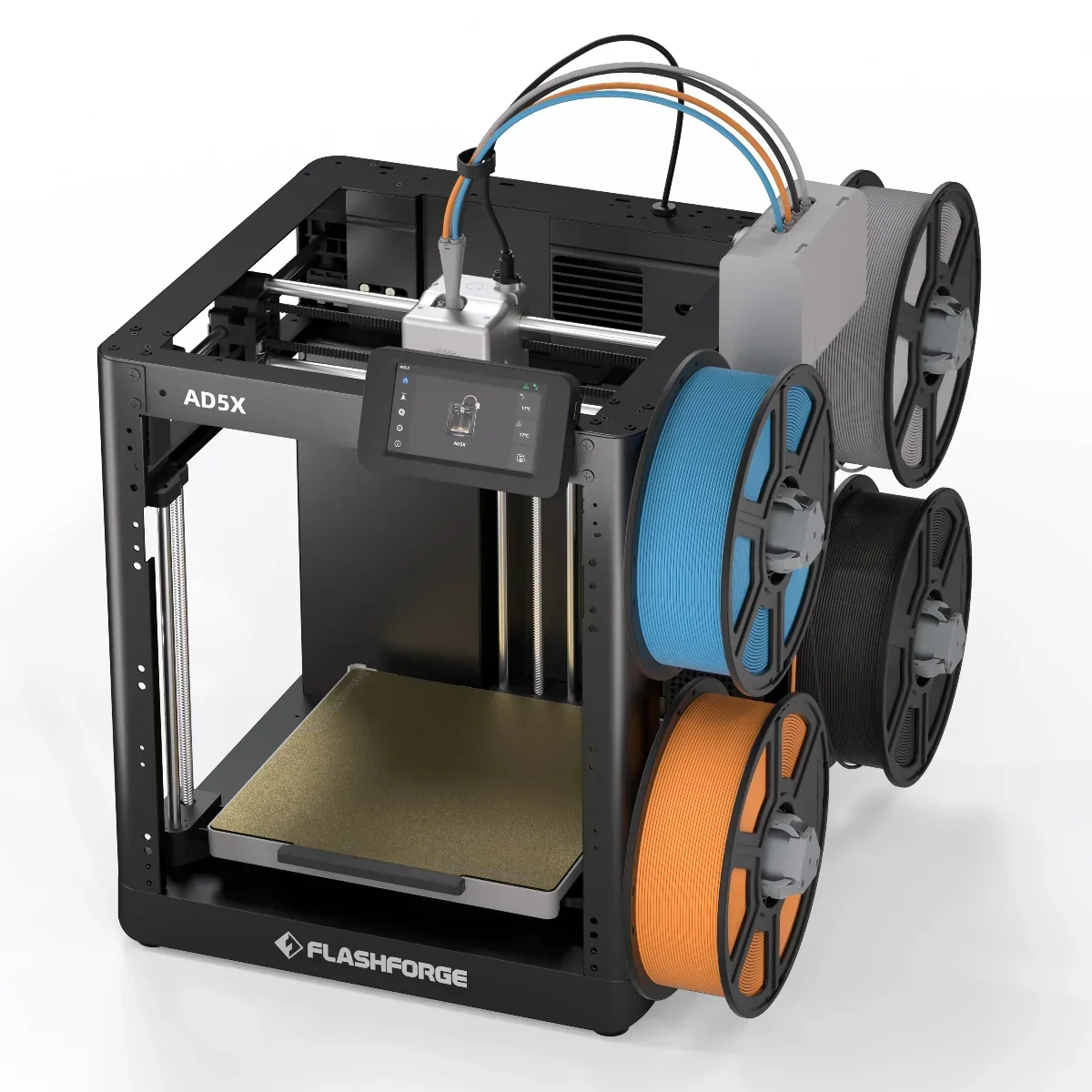

The Flashforge AD5X is a high-speed CoreXY 3D printer offering precise, multi-color prints at up to 600mm/s, with support for flexible TPU 95A—a first for Flashforge. It features automatic filament switching, a cutter-equipped extruder for smooth transitions, and 99% power-loss recovery. Easy to set up in 10 minutes, it includes a 4.3-inch touchscreen, supports multiple materials (PLA, PETG, ASA, TPU), and works with Orca-Flashforge and Flash Maker software, making it ideal for designers, hobbyists, educators, and professionals.

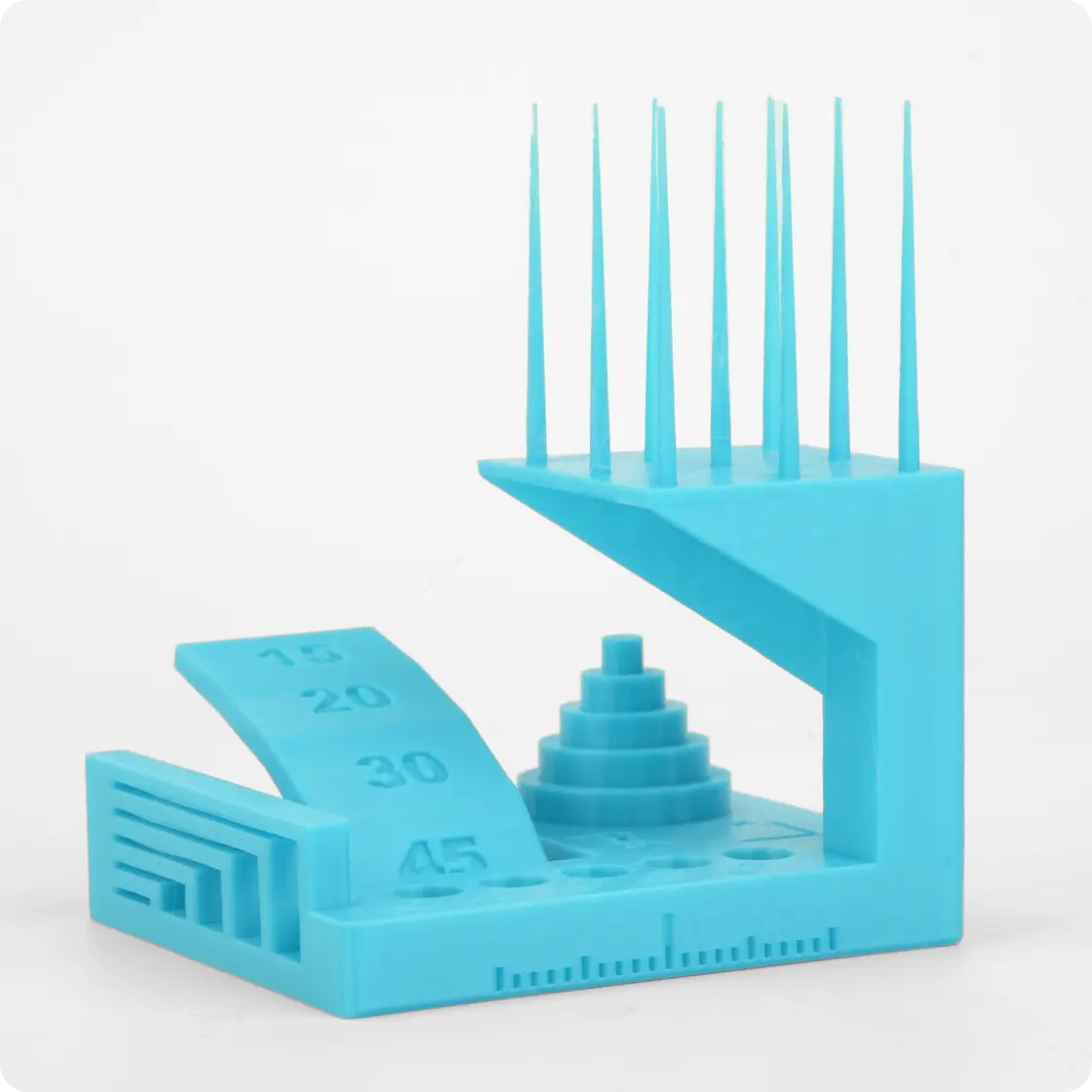

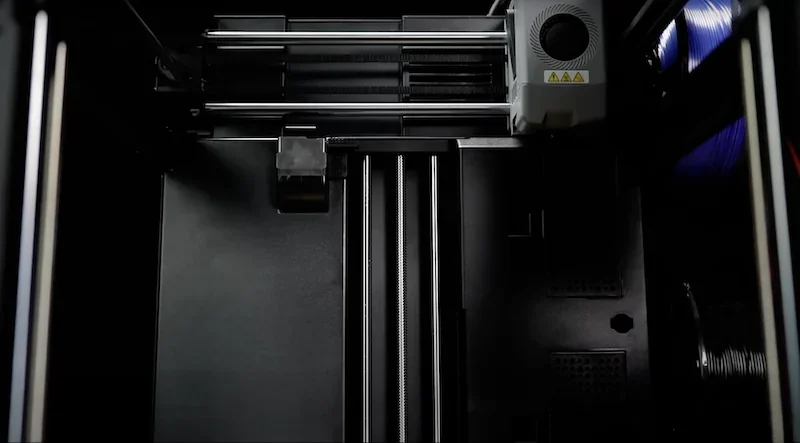

The Flashforge AD5X’s CoreXY motion system reduces print vibration deviations for consistent, high-detail prints. It delivers smooth surfaces, sharp peaks, clean overhangs up to 45°, and precise bridging, showing strong cooling and motion control.

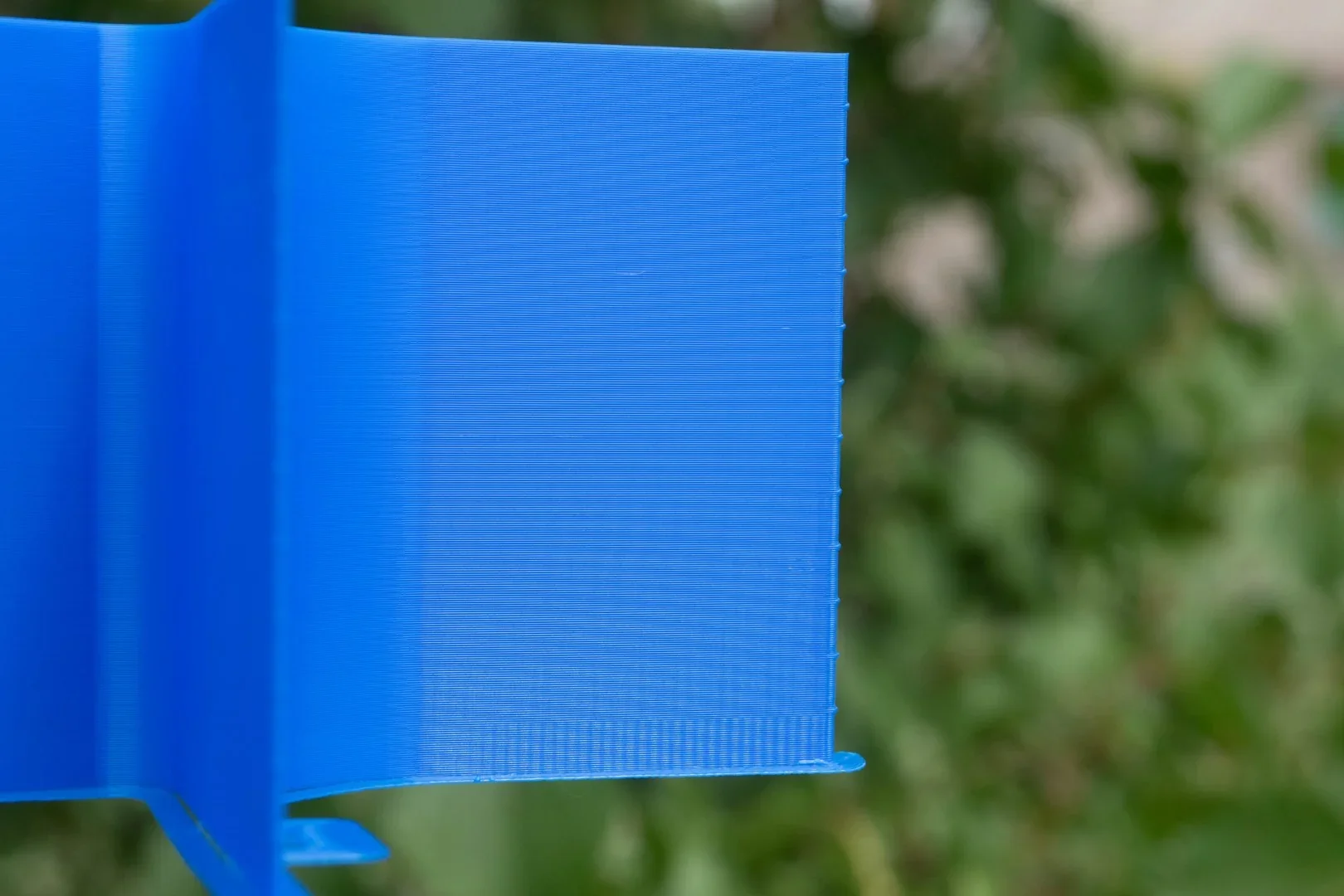

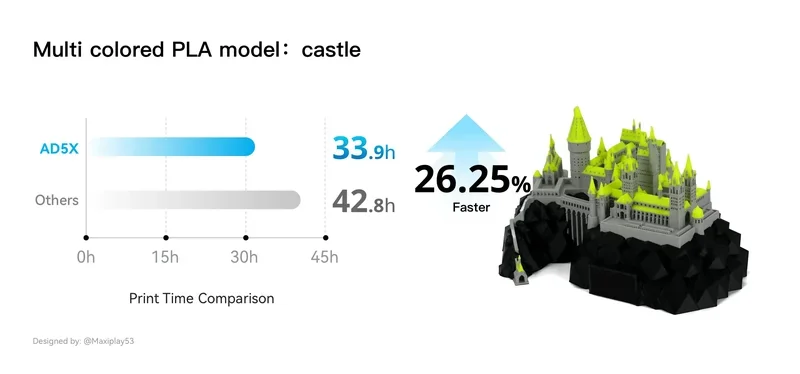

The AD5X reaches speeds of 600mm/s with 20,000mm/s² acceleration for rapid printing while maintaining precision. In a VFA test with PLA at 320mm/s (23–24mm³/s flow rate), minor rippling appeared at 50–60mm/s but smoothed out at higher speeds — typical for CoreXY systems.

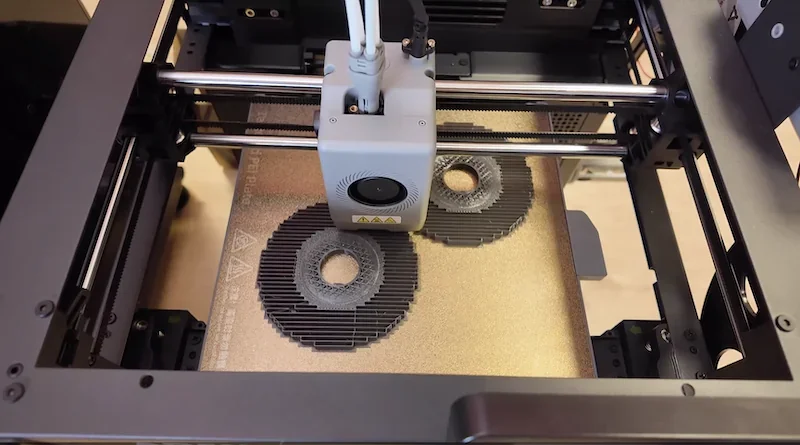

The CoreXY design uses dual stepper motors for balanced X/Y motion, enhancing stability and positioning accuracy while reducing wear. In a batch of 70 parts, including flanged and geared components, all prints showed uniform quality with no visible errors.

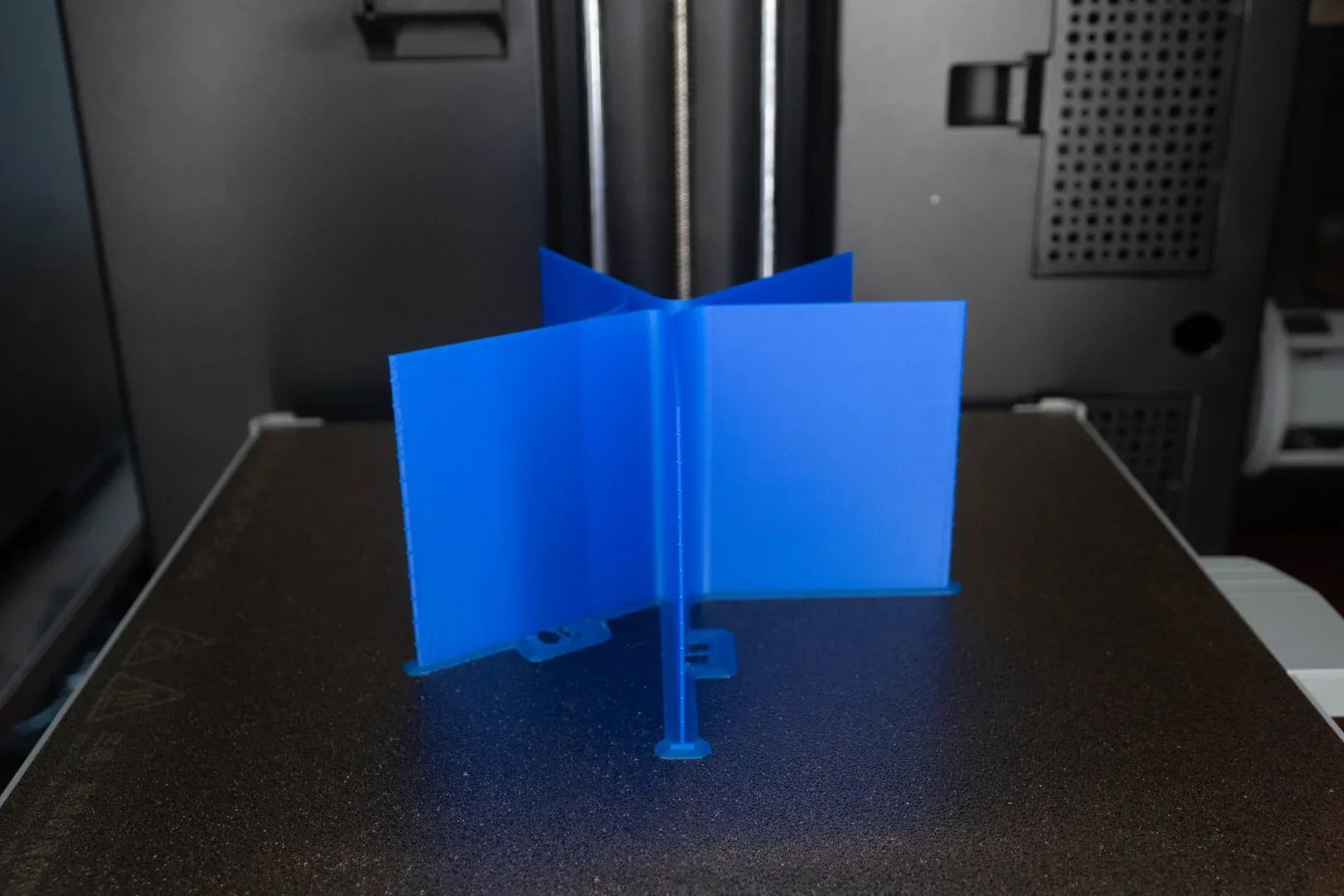

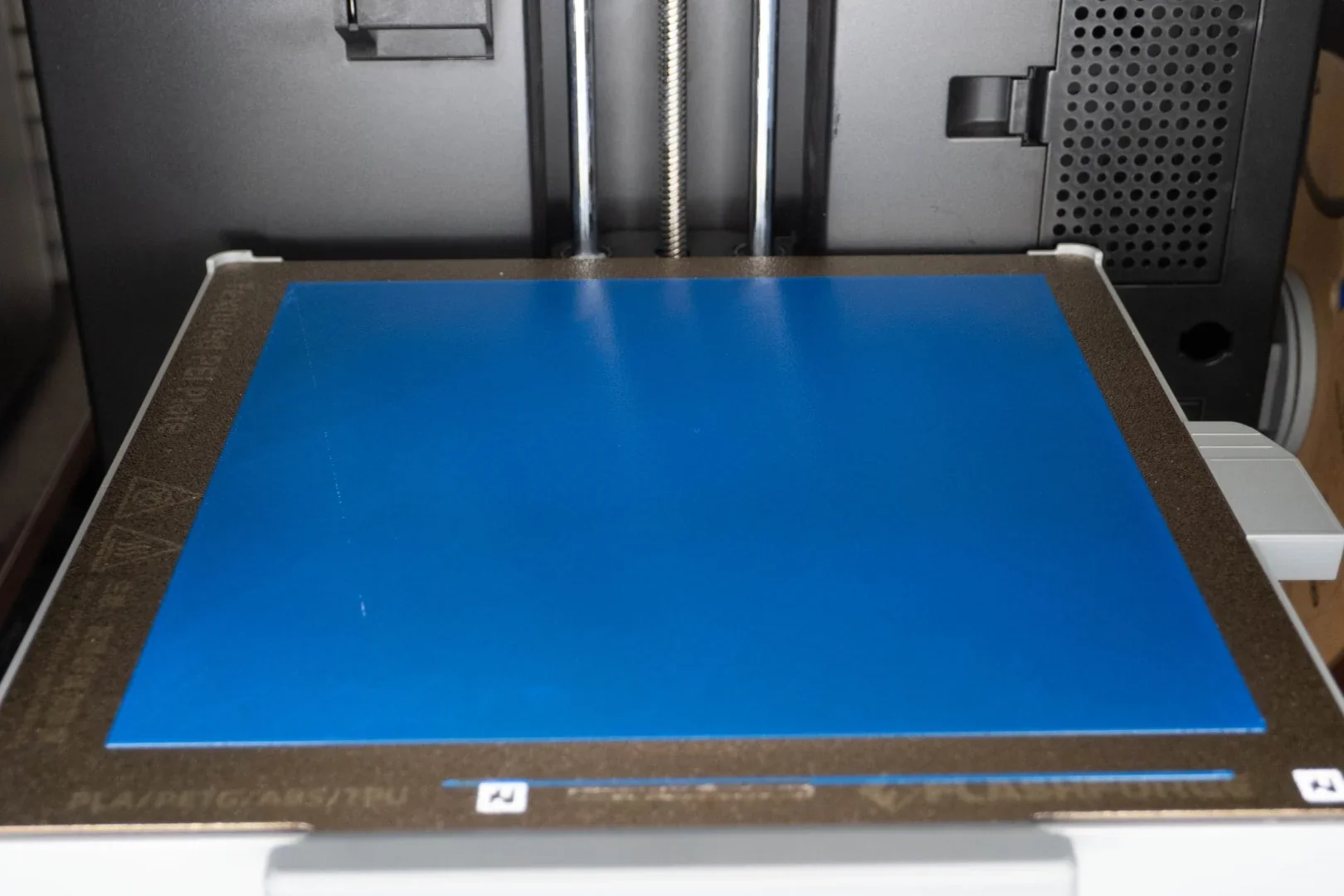

The AD5X features automatic bed leveling with pressure sensing, removing the need for manual Z-axis calibration and ensuring strong first-layer adhesion. Internal tests showed a smooth, uniform first layer across the build plate.

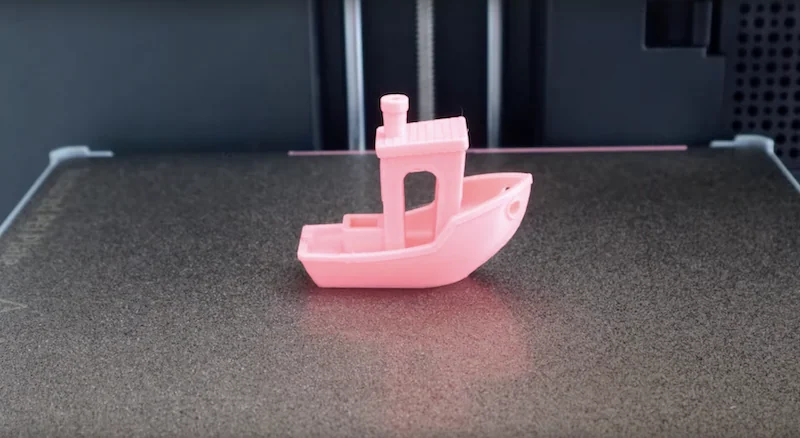

The AD5X’s dual-sided cooling system ensures thorough model cooling. A 3DBenchy printed in 30 minutes with 0.2mm layers using pink PLA came out clean and accurate.

A test with Elegoo 95A TPU produced an elastic part with well-fused layers. Minor stringing in holes was observed, which is typical for flexible filament.

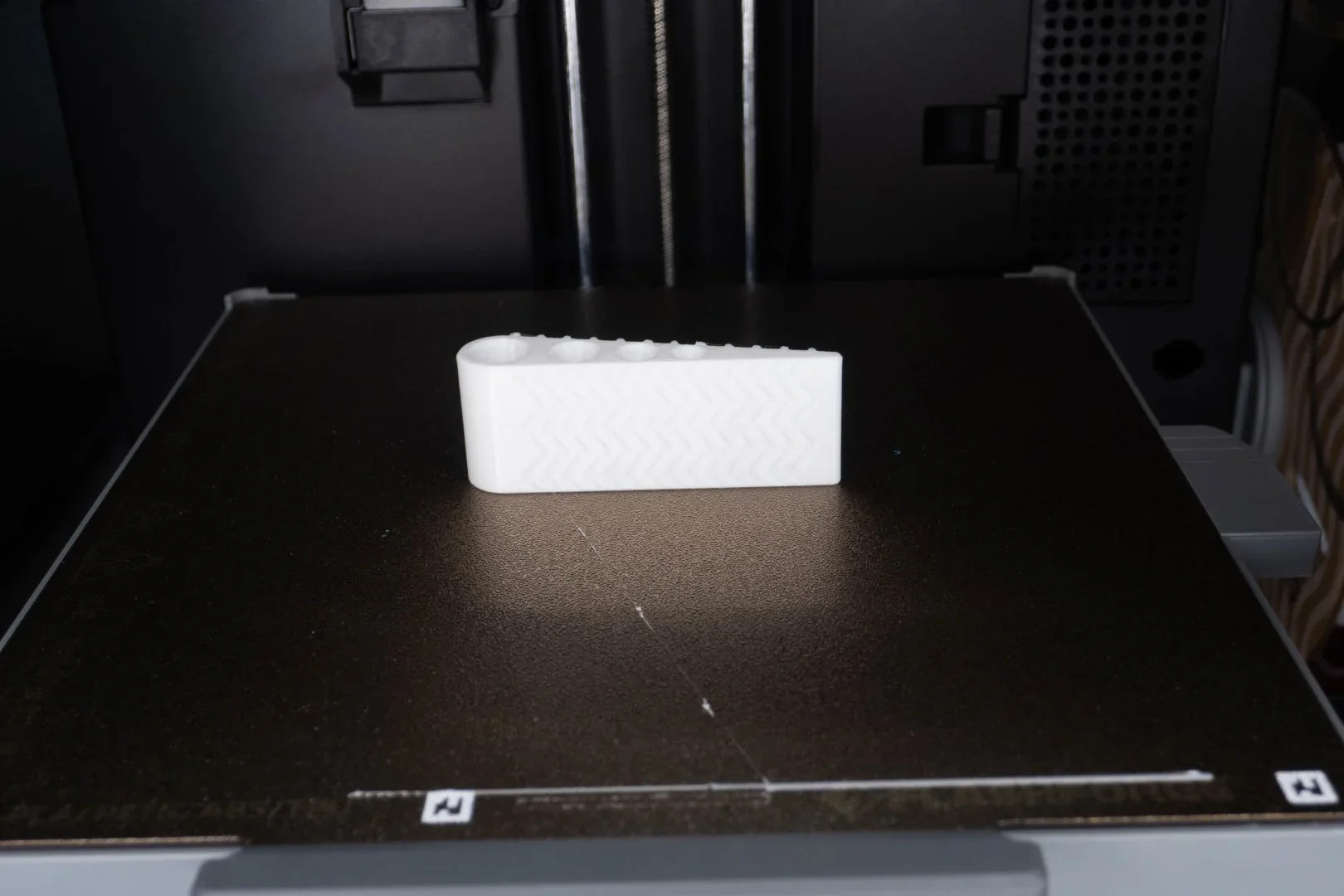

The flexible PEI steel build plate heats to 110°C for strong adhesion with various materials. In testing, two large gear models adhered well to the textured surface, despite covering over half the build area.

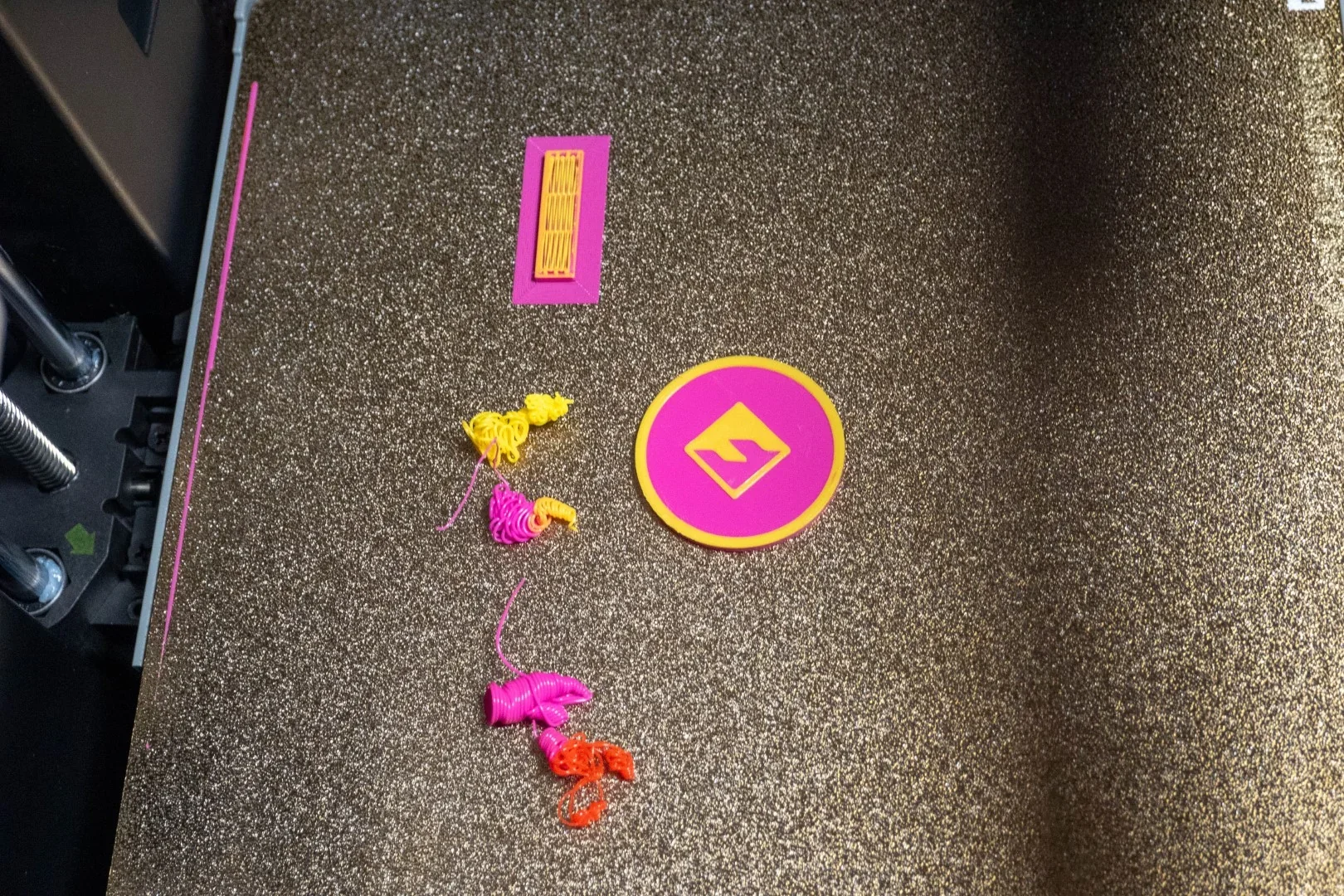

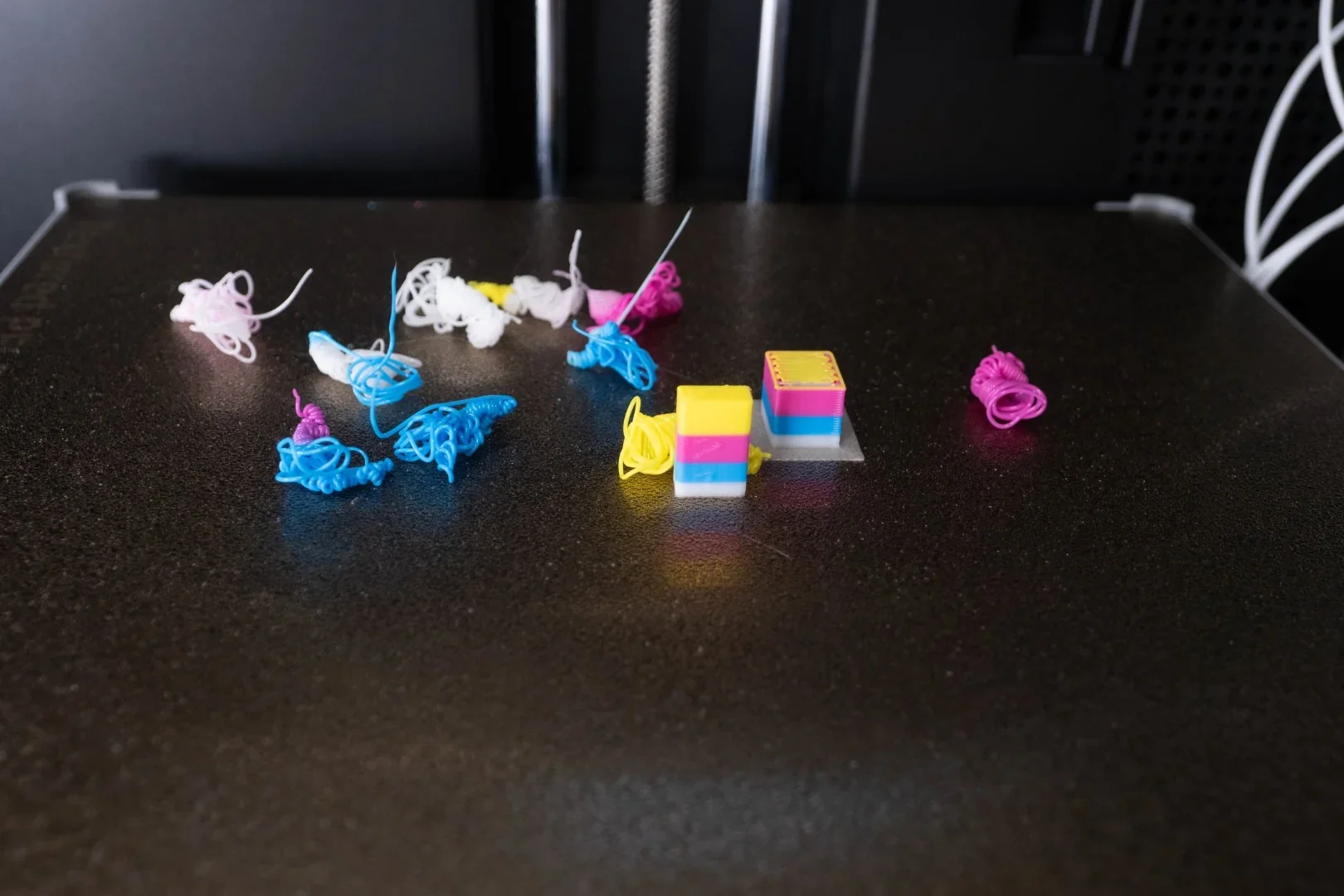

The AD5X's nozzle cleaning system prevents color bleeding during material changes, ensuring sharp color transitions and edges without color mixing. In a 15-minute two-color test print, yellow and pink filaments showed clean separation, with purged material collected separately.

A two-color XYZ calibration cube showed sharp transitions between blue and yellow filaments, with clean perimeters and smooth surfaces.

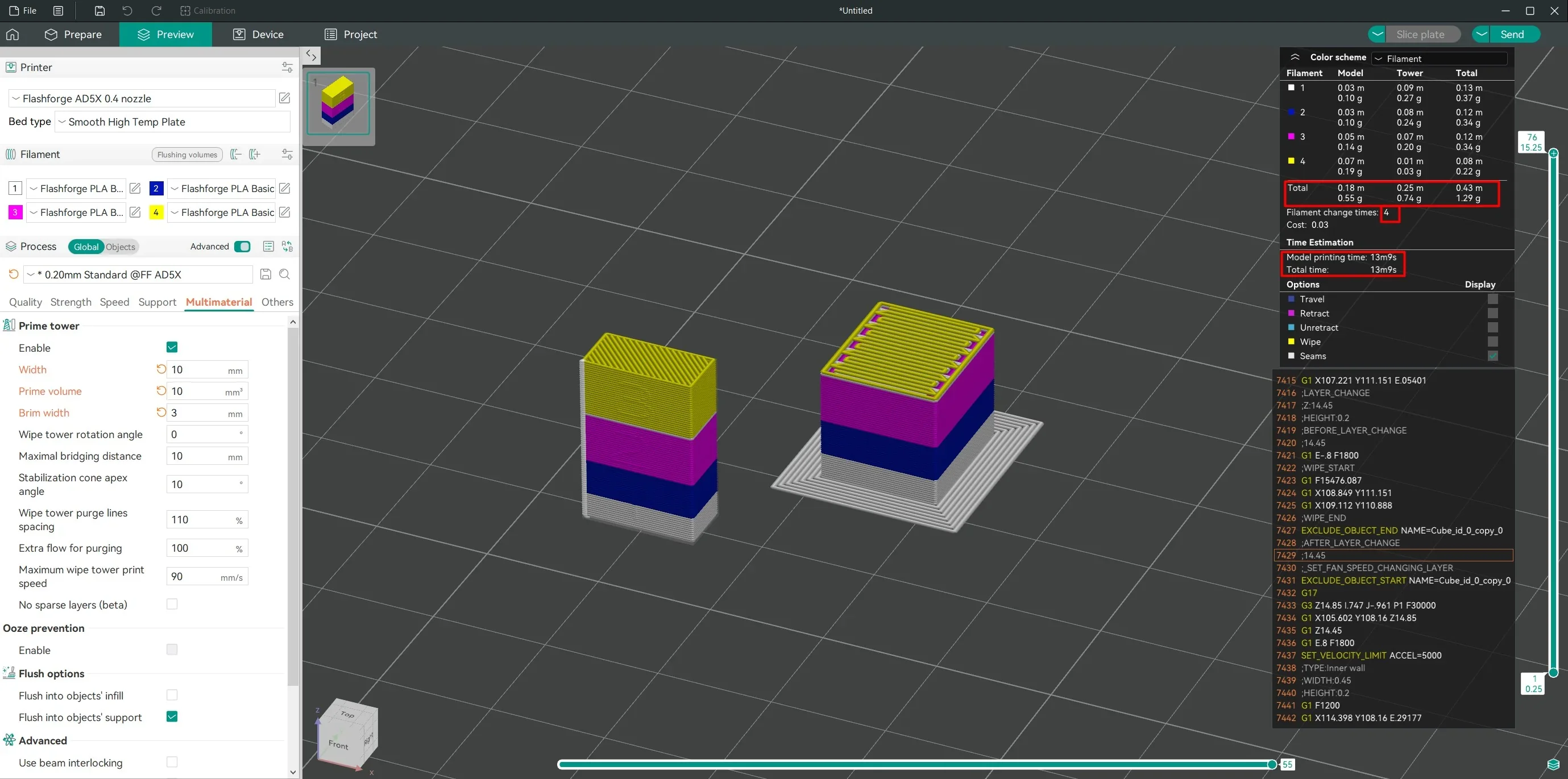

A full-color test model sliced into four color segments was printed in 14 minutes, with four automatic filament changes.

A complex model was printed with matte filament, using color transitions only on part of the height to save time and material. The print quality was excellent.

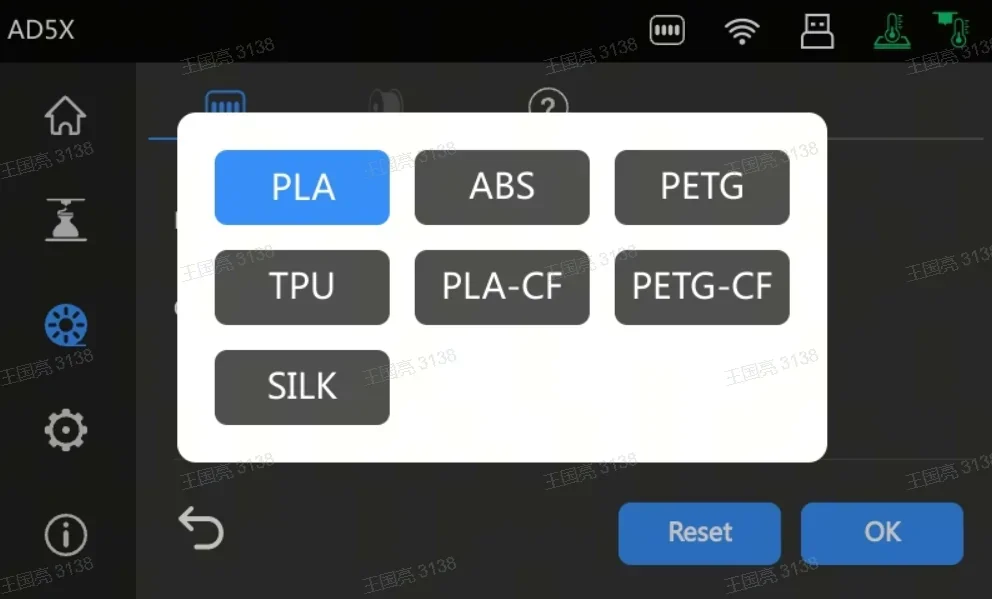

The Flashforge Adventurer 5M Pro supports over nine filament types, handling standard PLA variants with precision and also printing advanced materials like PETG, PETG Pro, HS PETG, and ASA for added durability and heat resistance.

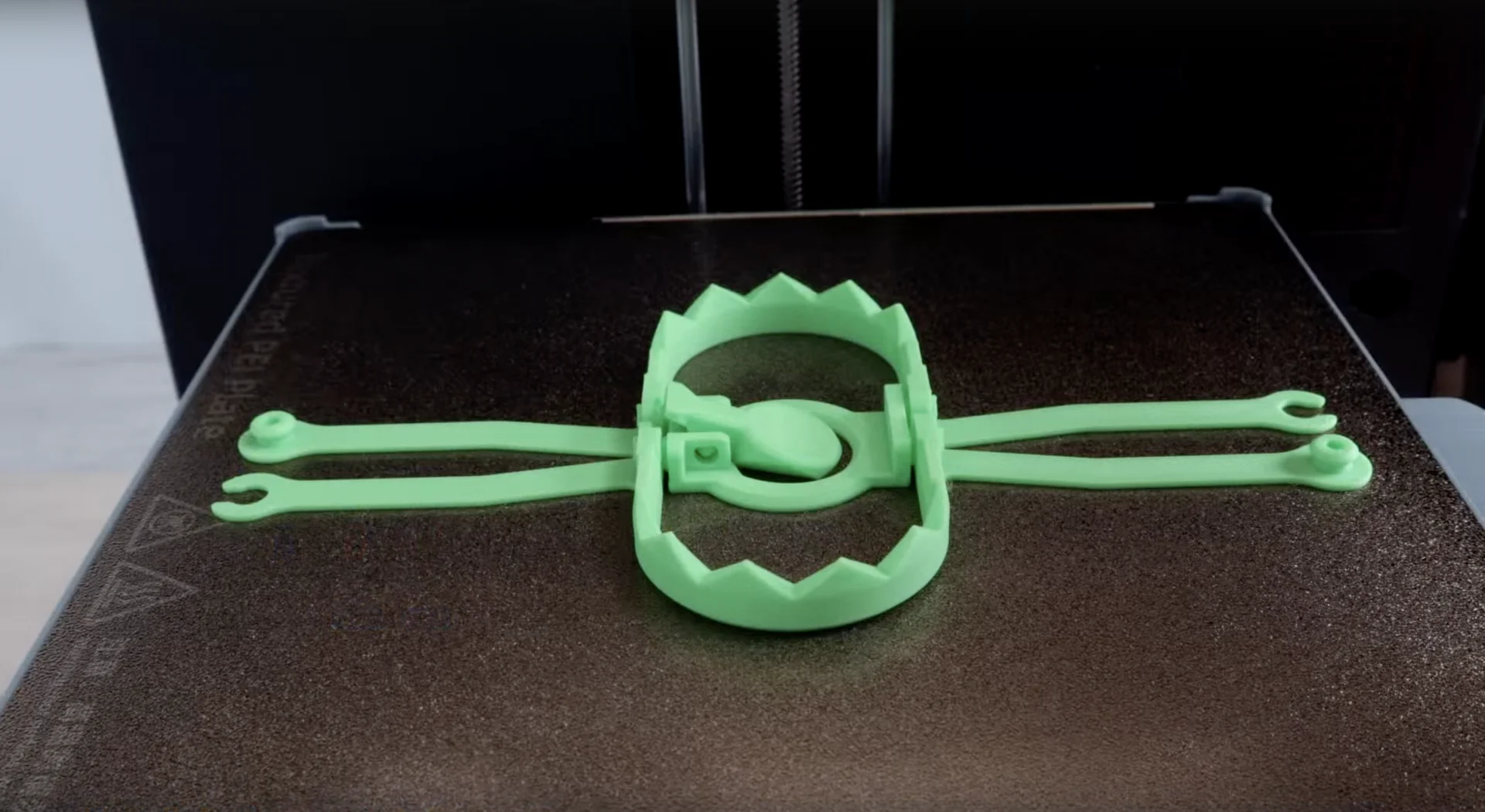

PLA Print Sample: This bear trap model printed in 45 minutes and functions once the ends are connected.

PLA Print Sample: A multi-part Oni mask was printed with white eSUN fast PLA over 20 hours as an endurance test.

PLA Print Sample: A white eSUN fast PLA Oni mask was printed in multiple parts over 20 hours as an endurance test.

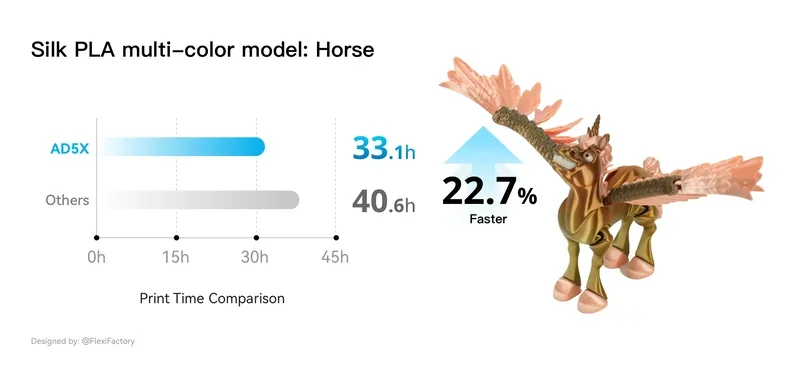

Silk PLA Print Sample: A multi-color winged horse model was printed in 33.1 hours.

PLA Print Sample: A mechanical bee with black, silver, orange, and translucent blue parts was printed in 12.2 hours.

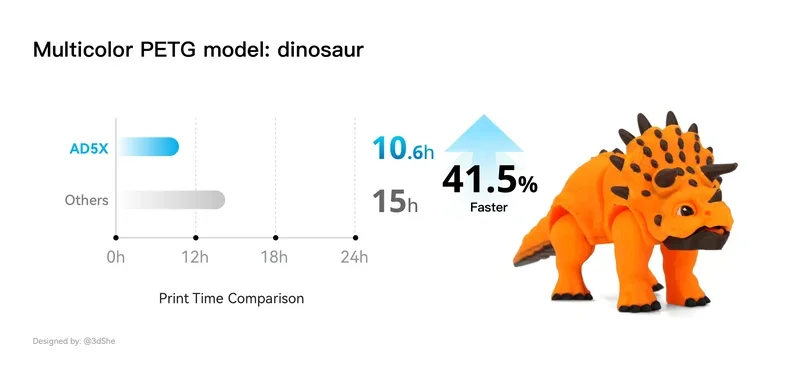

Multicolor PETG Print Sample: An orange and black triceratops model was printed in 10.6 hours.

The extruder heats up to 300°C and the bed to 110°C, allowing use of engineering-grade filaments.

The AD5X features an open filament system. Tests confirmed successful prints with filaments from Flashforge, Sunlu, Anycubic, Overture, and Inslogic. While minor adjustments may be needed for temperature differences, the flexible PEI build plate ensures strong adhesion for materials like PLA, PETG, and TPU.

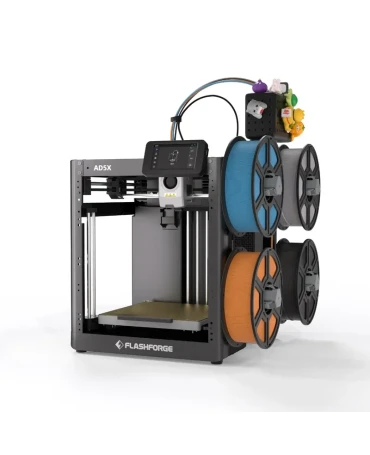

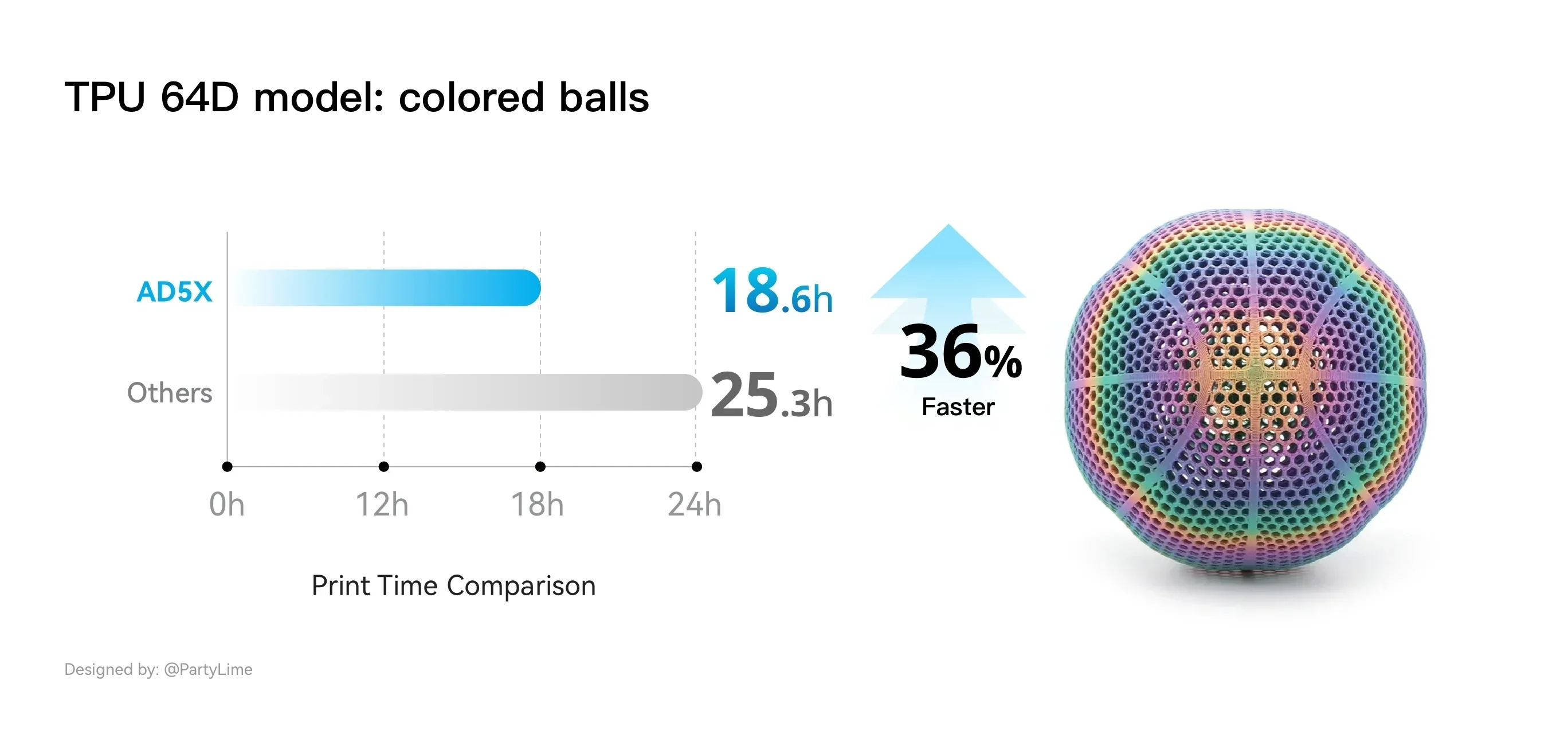

The AD5X uniquely supports full-color printing with flexible TPU 95A — unavailable in previous Flashforge models. For example, a multi-colored lattice sphere was printed in 18.6 hours.

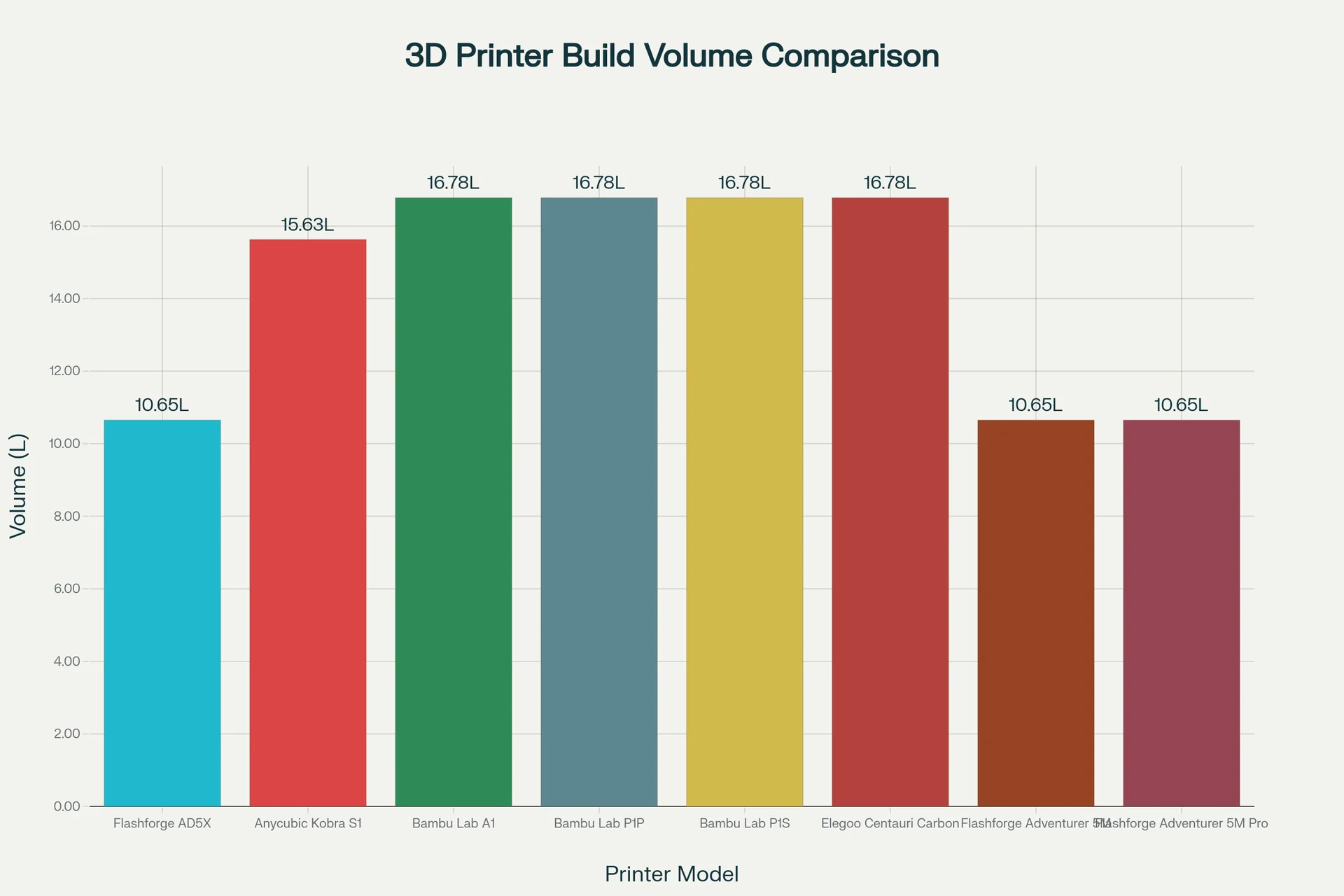

The Flashforge AD5X has a 220 × 220 × 220 mm build volume, offering a balanced cubic space suitable for various projects. This matches the build size of other Adventurer models like the AD5 and AD5M Pro, ensuring continuity for existing users.

| 3D Printer Model | Build Volume (mm) | Build Volume (liters) | Price (USD) |

|---|---|---|---|

| Flashforge AD5X | 220 × 220 × 220 | 10.65 | $400+ |

| Anycubic Kobra S1 Combo (w/ AMS) | 250 × 250 × 250 | 15.63 | $600+ |

| Bambu Lab A1 Combo (w/ AMS) | 256 × 256 × 256 | 16.78 | $499+ |

| Bambu Lab P1S Combo (w/ AMS) | 256 × 256 × 256 | 16.78 | $749+ |

| Elegoo Centauri Carbon (no AMS) | 256 × 256 × 256 | 16.78 | $300+ |

| Flashforge Adventurer 5M (no AMS) | 220 × 220 × 220 | 10.65 | $290+ |

| Flashforge Adventurer 5M Pro (no AMS) | 220 × 220 × 220 | 10.65 | $450+ |

The Flashforge AD5X is a strong budget option for multi-color 3D printing at around $400, offering reliable four-color prints, fast speeds, and low filament waste. Its trade-offs include a smaller 220mm³ build volume and open-air design, limiting compatibility with temperature-sensitive materials.

Multi-Color Competitors:

Single-Color Competitors:

The AD5X is ideal for users wanting affordable multi-color printing without needing a large build area or enclosure. While single-color printers offer more space for less, the AD5X balances speed, quality, and multi-color features at a competitive price.

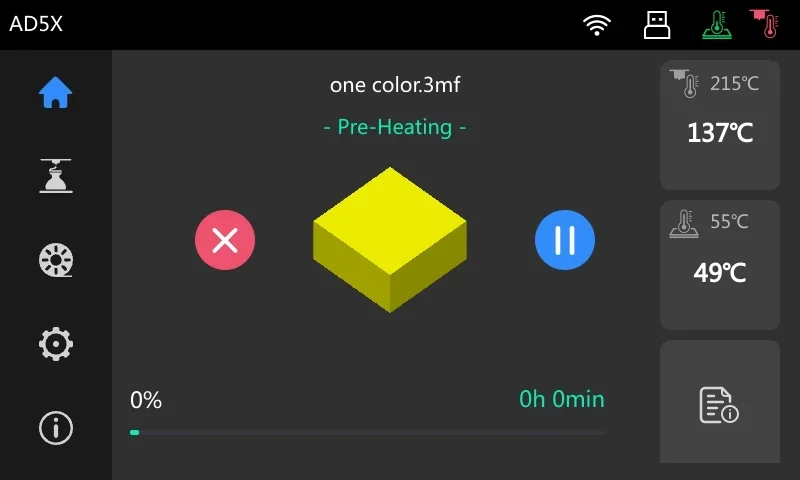

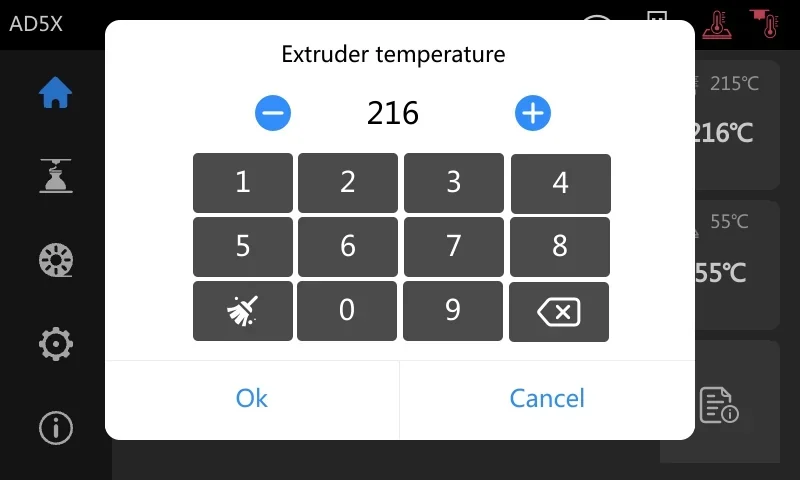

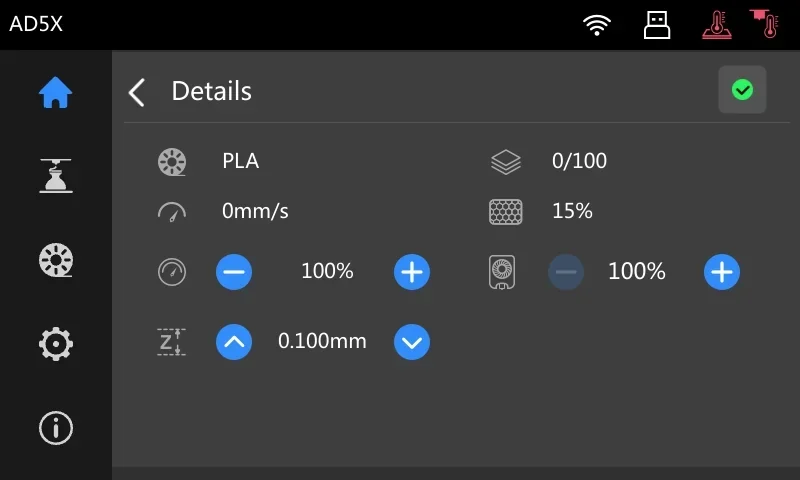

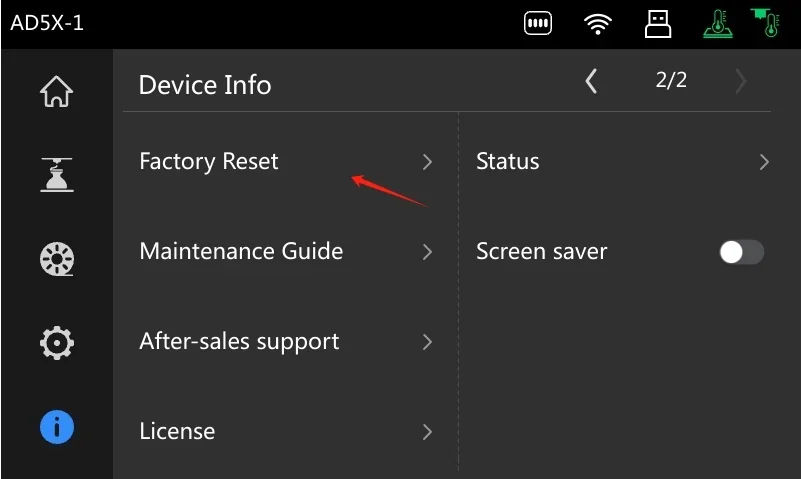

The Flashforge AD5X uses a 4.3-inch color touchscreen with 14 primary controls organized across key menus:

Home Menu:

Details Menu:

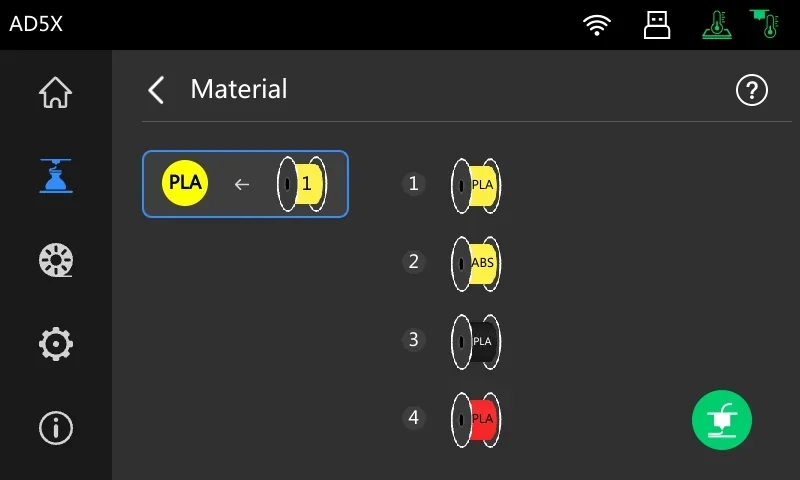

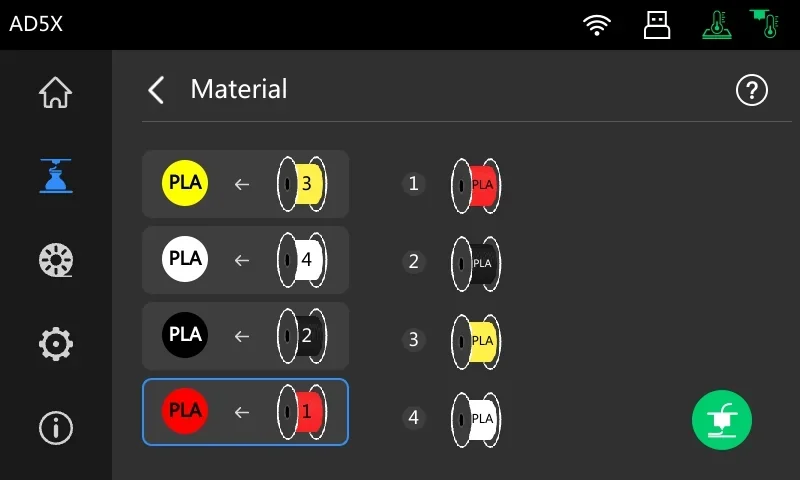

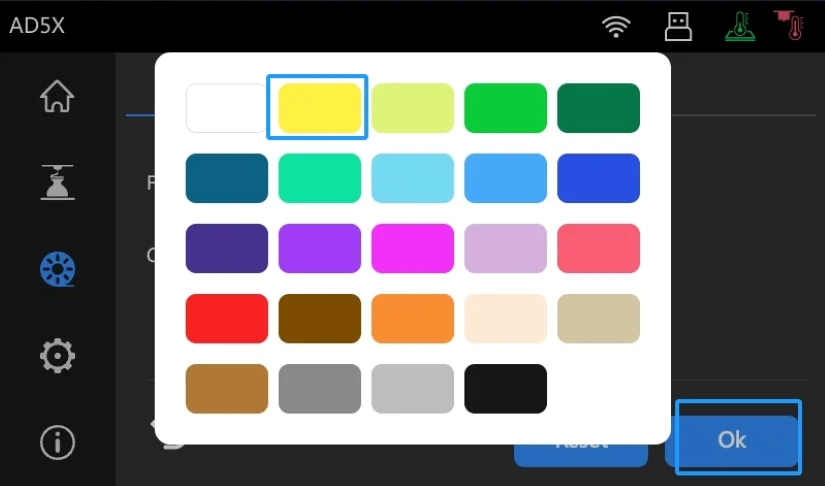

Print Management ("Material" Menu):

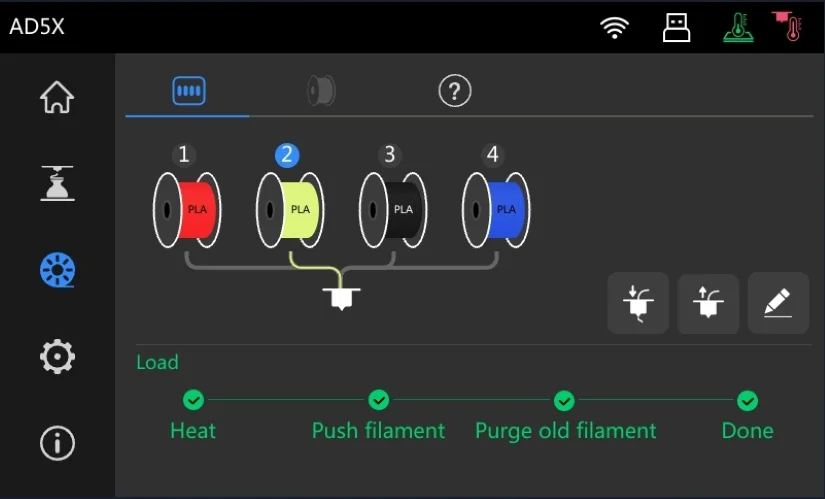

Filament Management:

Settings Menu:

Calibration:

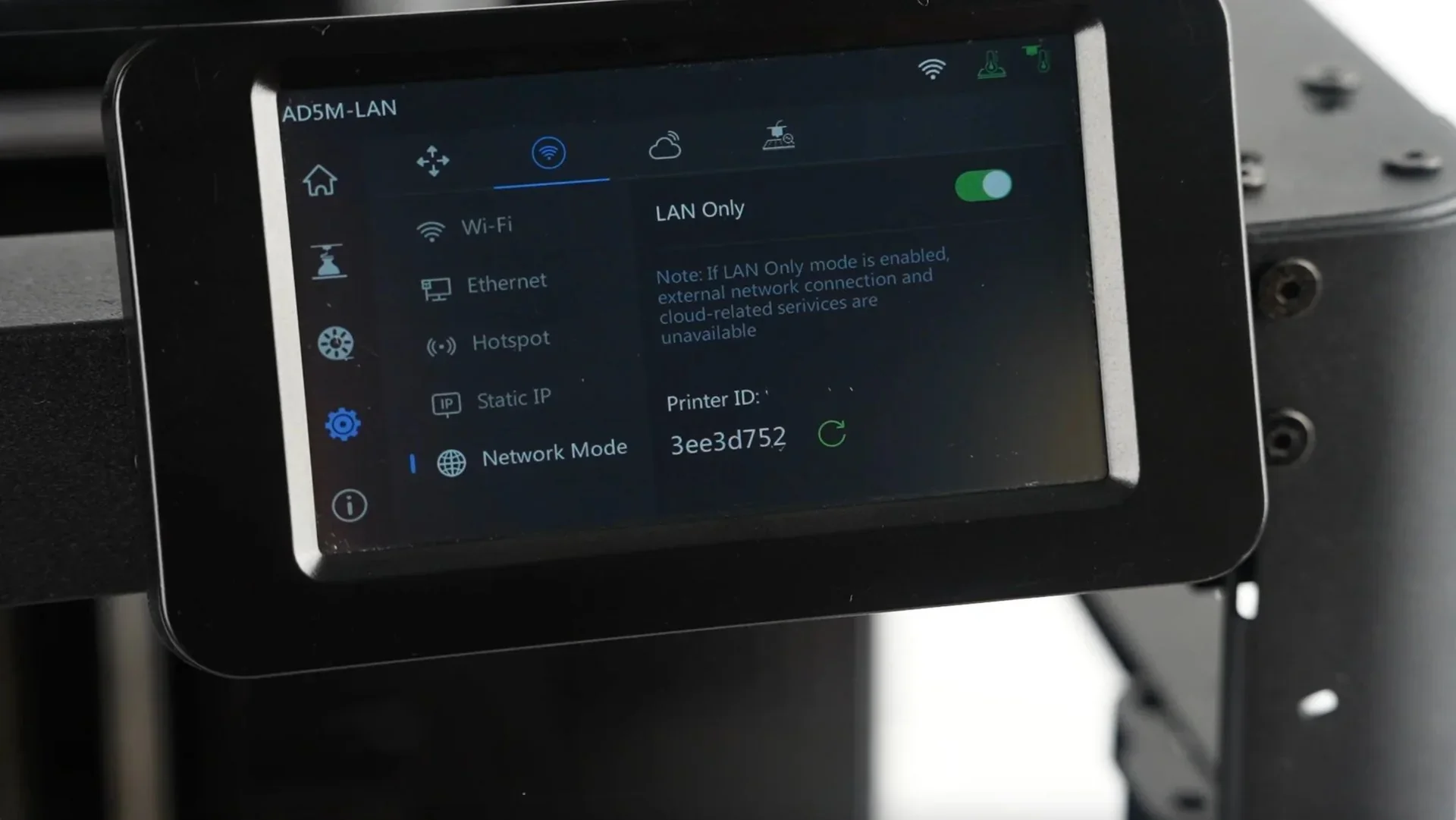

Network Settings:

Timelapse Menu:

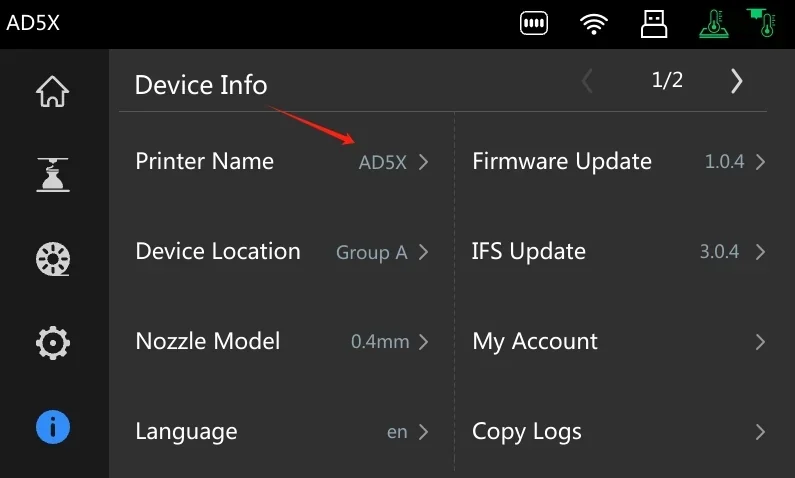

Device Info:

The Flashforge AD5X offers 3 connectivity options:

The AD5X integrates with Orca-Flashforge and Flash Maker software. During setup, users connect to Wi-Fi and link their Flash Maker account by scanning a QR code on the screen. This enables remote print control, job monitoring, and multi-printer management from desktop or mobile devices — ideal for home, office, or classroom use.

The Flashforge AD5X uses Orca-Flashforge, a customized version of OrcaSlicer optimized for Flashforge printers. It features an intuitive interface, smart slicing tools, object exclusion for failed prints, and streamlined multi-color print setup.

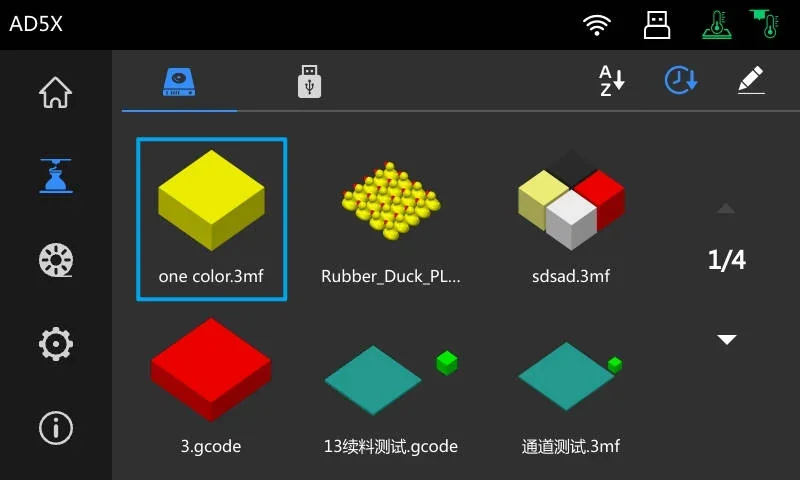

The AD5X supports standard file formats like G-code and 3MF, automatically mapping model colors to the four IFS channels. Users can also print directly from FAT32 USB drives, providing flexibility in offline environments.

Full user manual: https://wiki.flashforge.com/en/Orca-Flashforge-and-Flashmaker/orca-flashforge-quick-start-guide

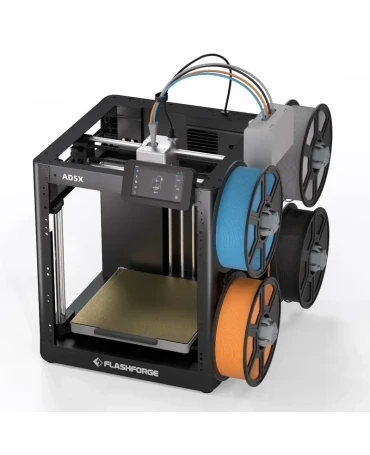

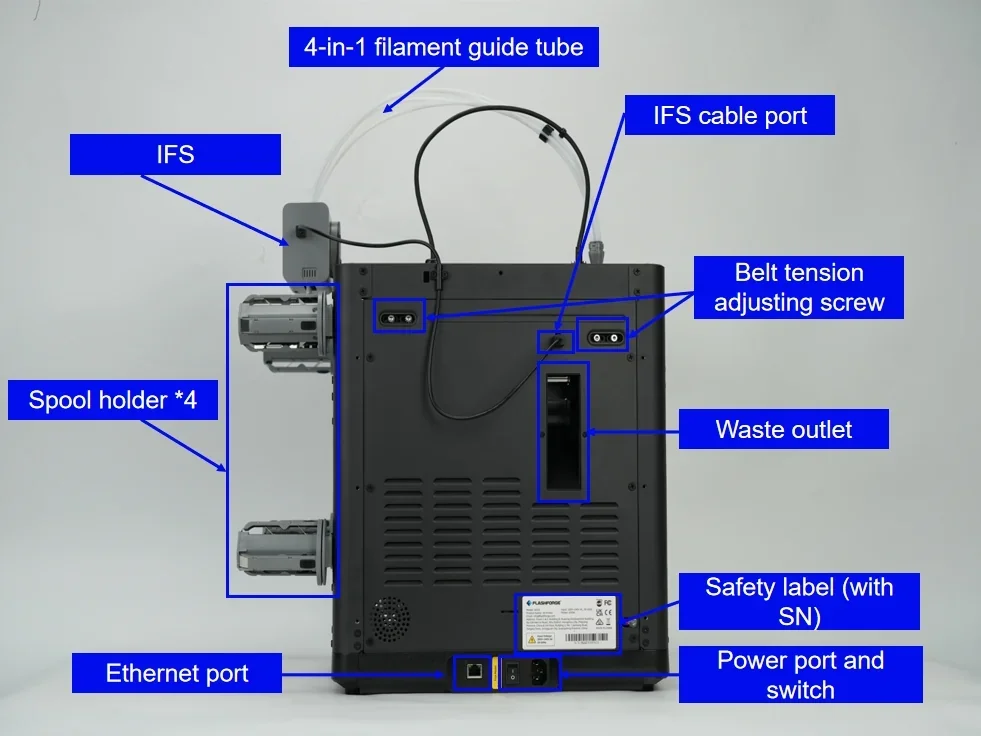

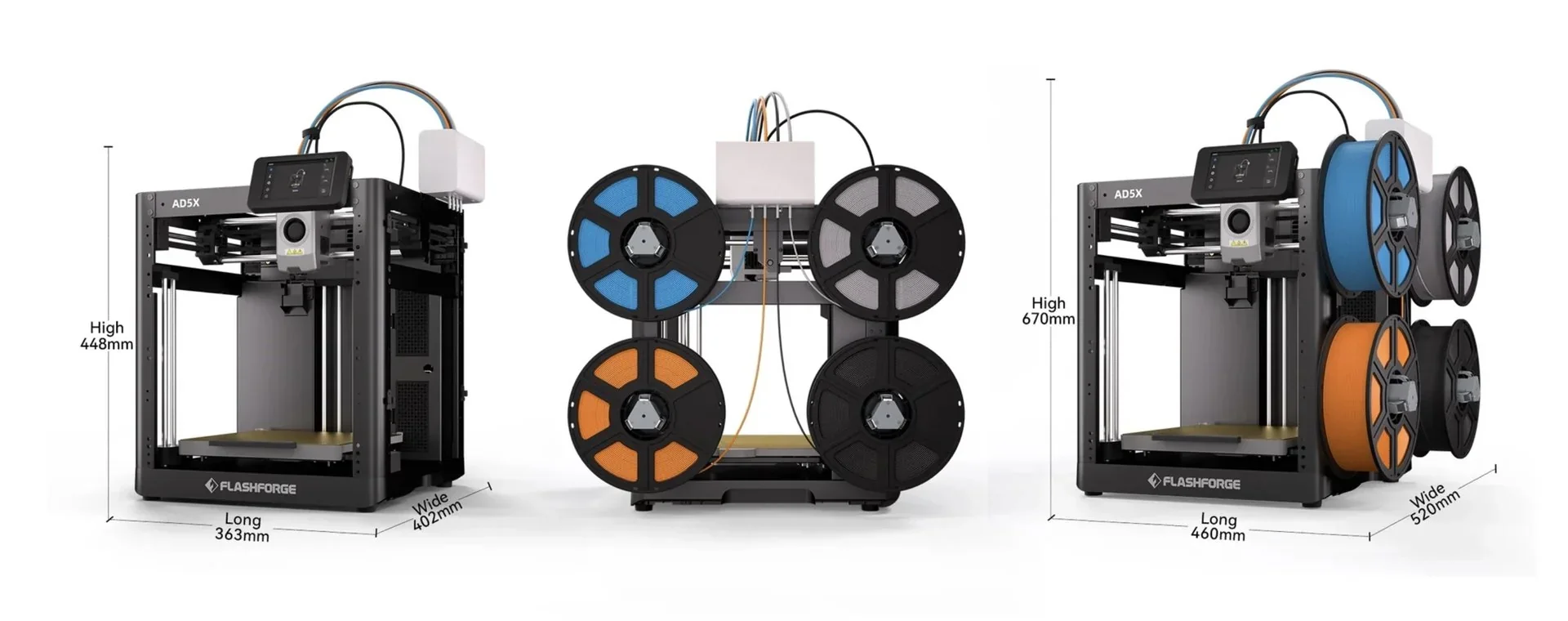

The Flashforge AD5X has a compact, cube-shaped open-frame design for easy access. The base measures 363 × 376 × 413 mm (14.29 × 14.8 × 16.26 inches) and the fully assembled printer measures 363 × 402 × 448 mm (14.29 × 15.83 × 17.64 inches), weighing 11.4 kg (25.13 lbs) net and 14.2 kg (31.31 lbs) gross.

While the open-frame improves usability and reduces cost, it lacks an enclosed chamber, limiting performance with high-shrinkage materials. The four-color IFS module integrates cleanly, saving space.

The Flashforge AD5X uses a CoreXY motion system with two motors controlling the X and Y axes — moving in the same direction for X-axis motion and opposite for Y. Linear rods and bearings on all axes ensure consistent movement.

The Z-axis uses dual rods and a lead screw driven by a motor.

High-quality stepper motors power the classic Core XY structure, with two 28-type motors supporting the Intelligent Filament System (IFS).

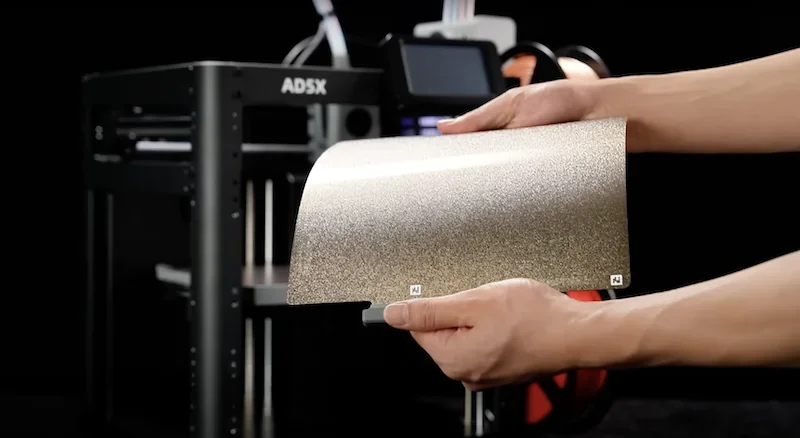

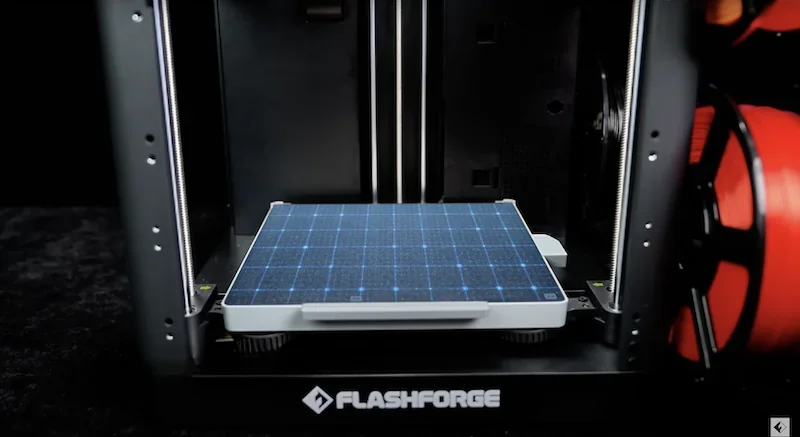

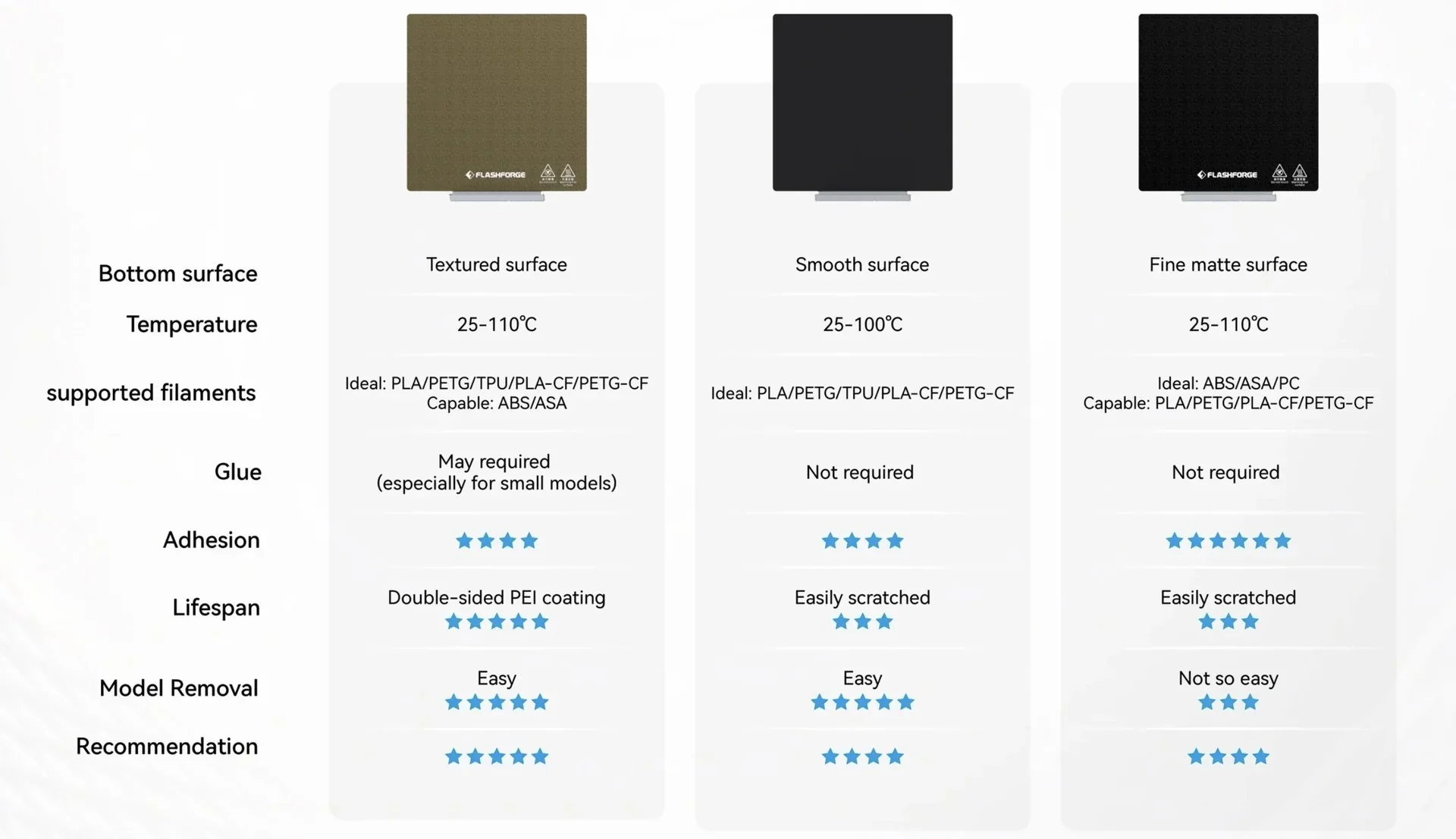

The Flashforge AD5X 3D printer has a 220 × 220 × 220 mm heated build platform (10.65L volume) with a removable PEI-coated flexible steel sheet on a heated aluminum bed. It reaches 110°C, supporting materials like PLA, PETG, and TPU.

The flexible sheet enables easy, tool-free print removal.

A built-in pressure sensor provides automatic Z-axis calibration and bed leveling for consistent first-layer adhesion.

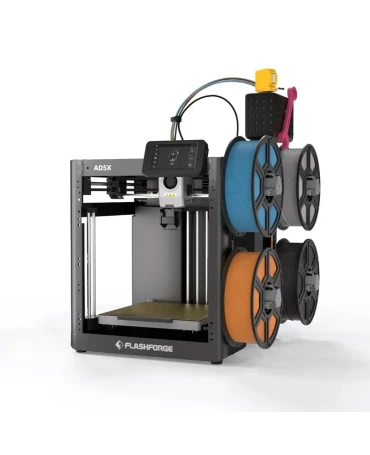

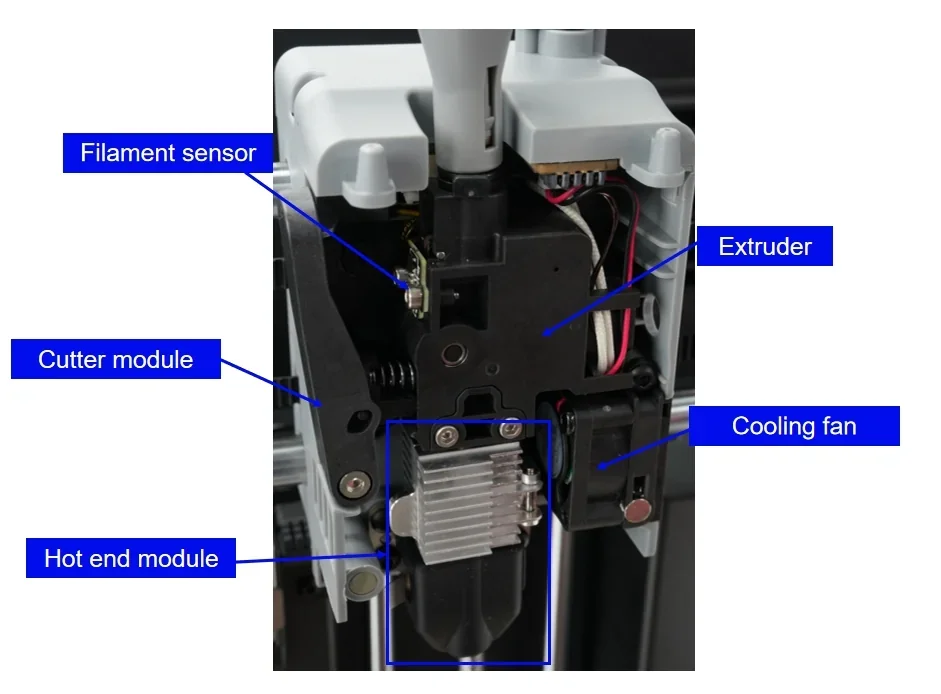

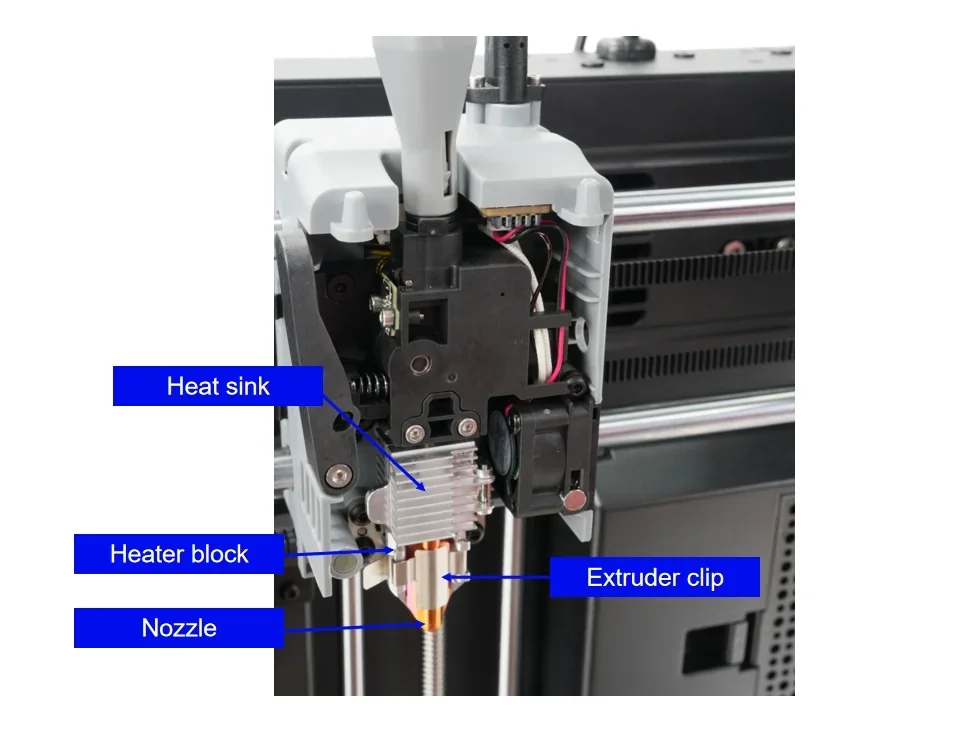

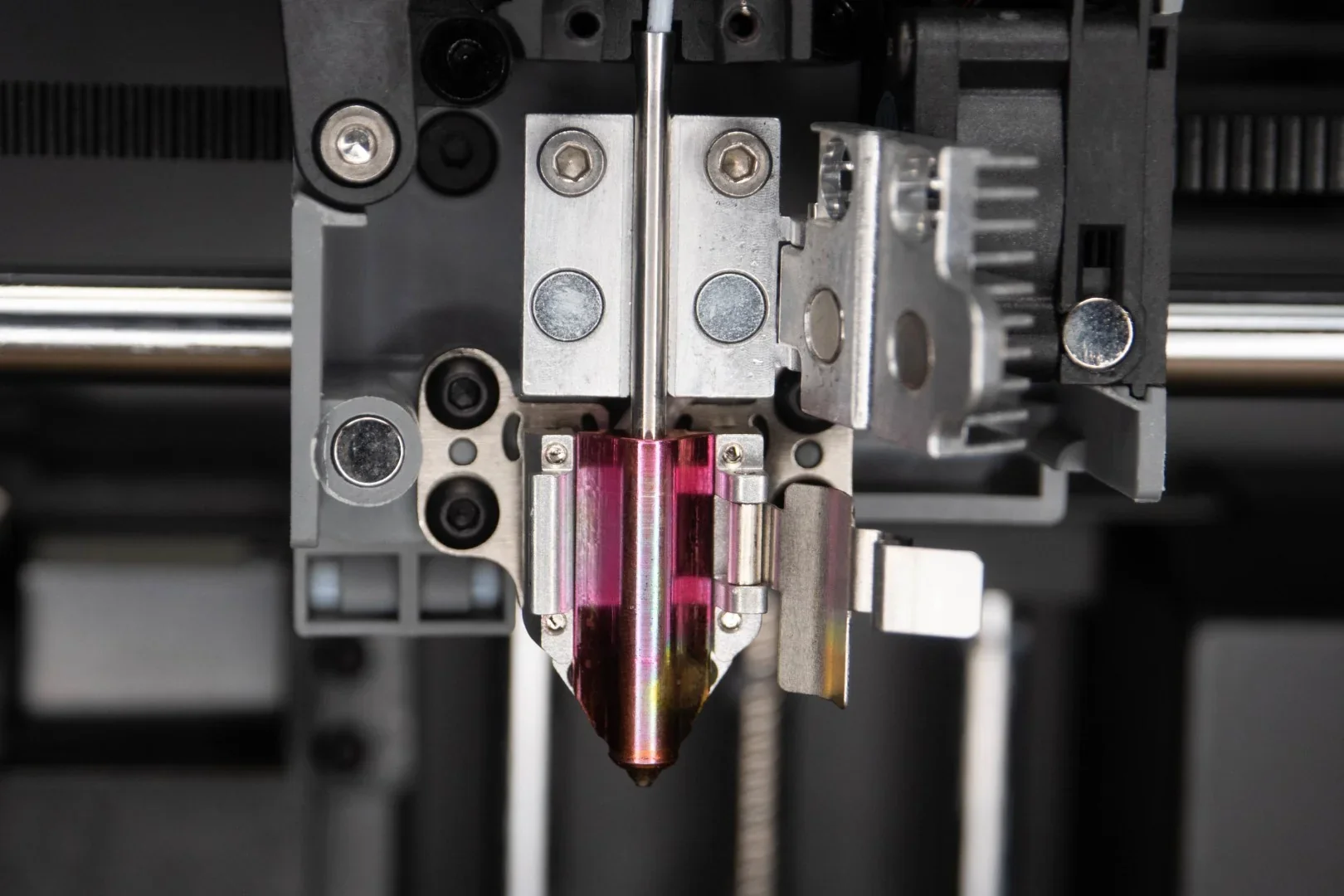

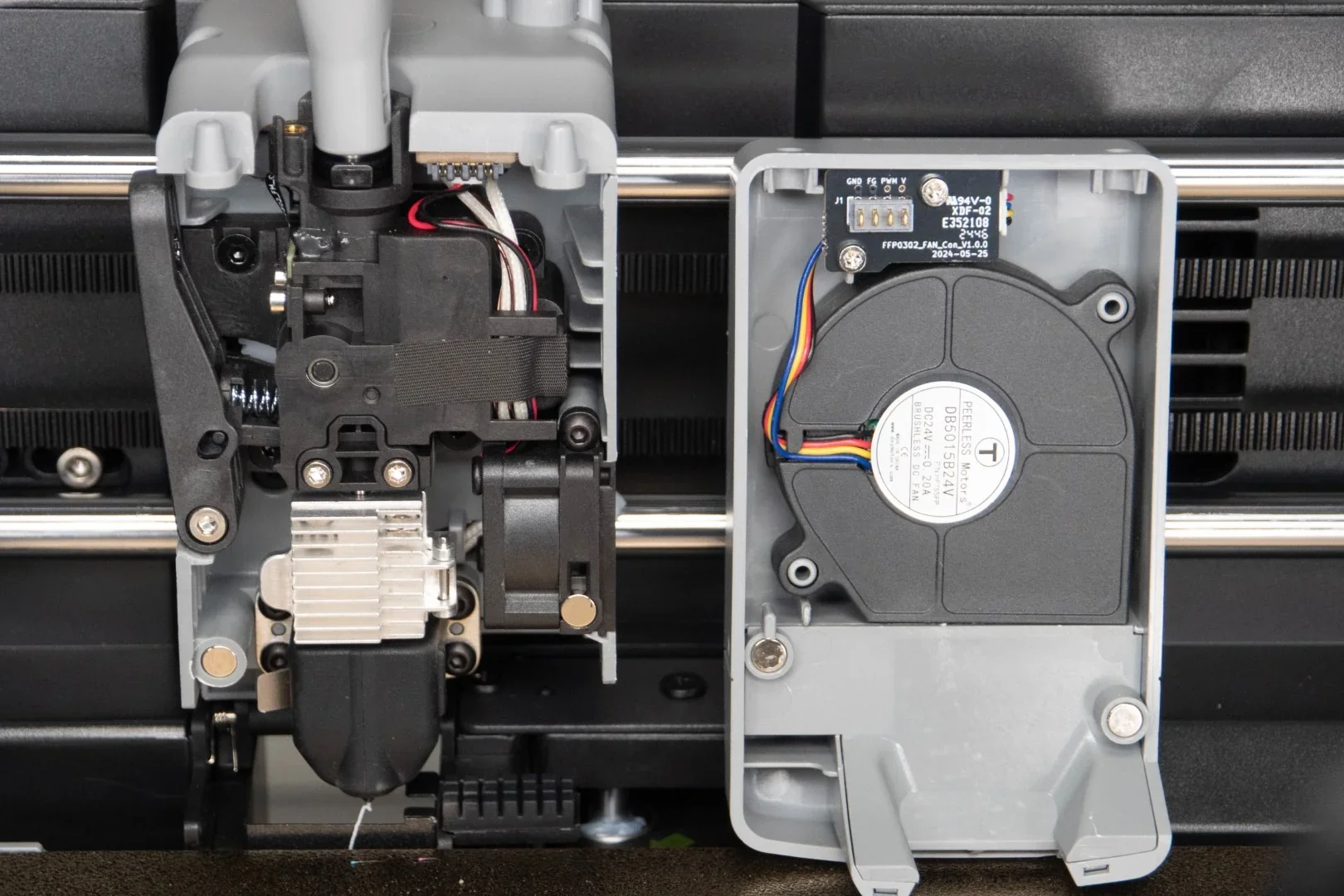

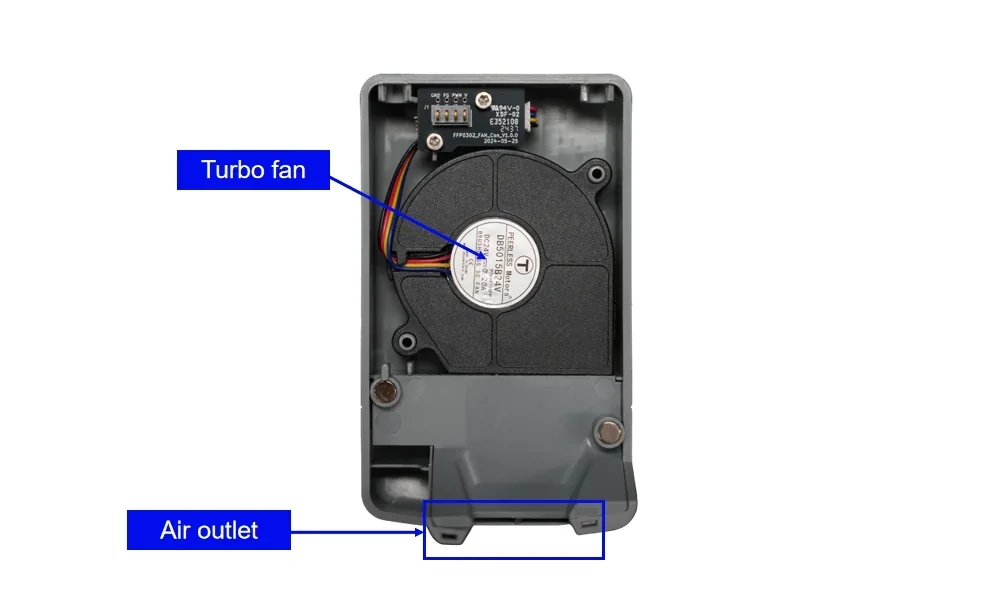

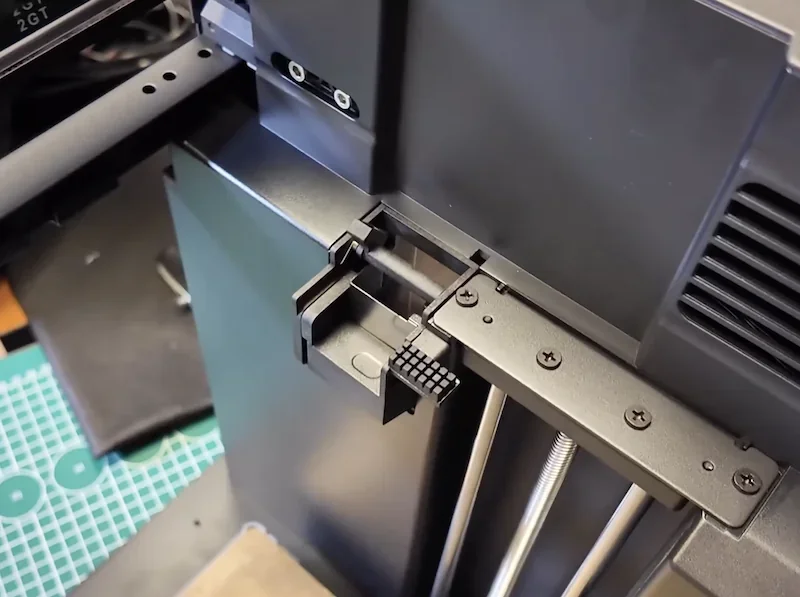

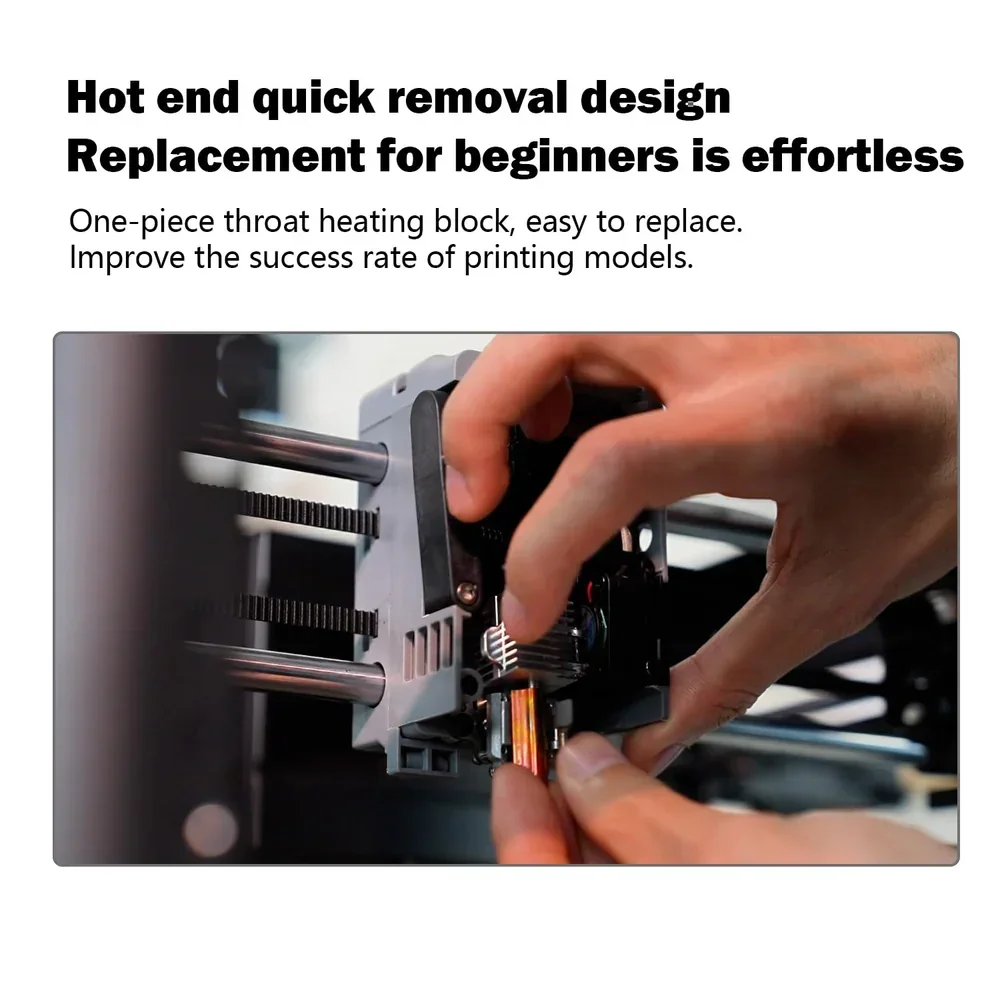

The Flashforge AD5X uses a single direct-drive extruder that integrates the hotend, cooling fan, cutter module, filament sensor, heat sink, and nozzle, with a clip for tool-free nozzle changes.

The hotend reaches 300°C, supporting materials from PLA to engineering-grade filaments.

The default 0.4 mm nozzle can be swapped for 0.25, 0.6, or 0.8 mm variants without tools, cutting maintenance costs by 30%.

Dual-sided cooling ducts improve part cooling, while an automatic nozzle cleaning system purges material during color changes to prevent bleeding.

A retractable cleaning mechanism and waste collector support seamless multi-color printing.

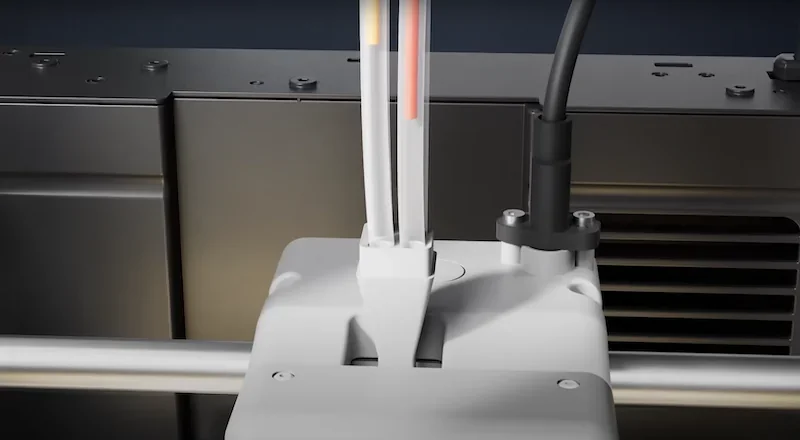

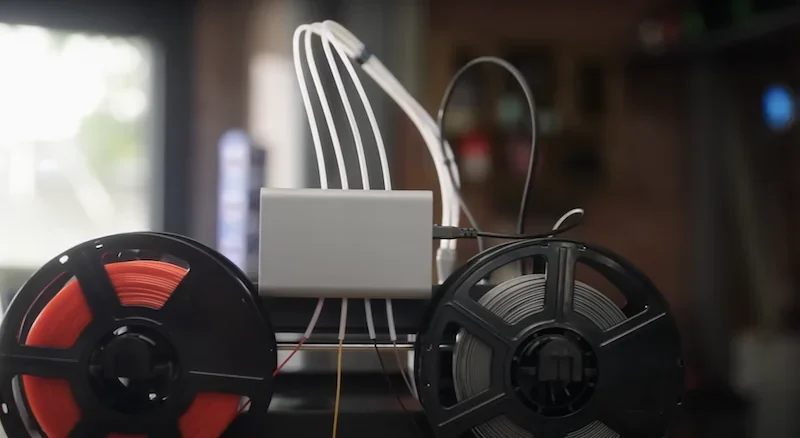

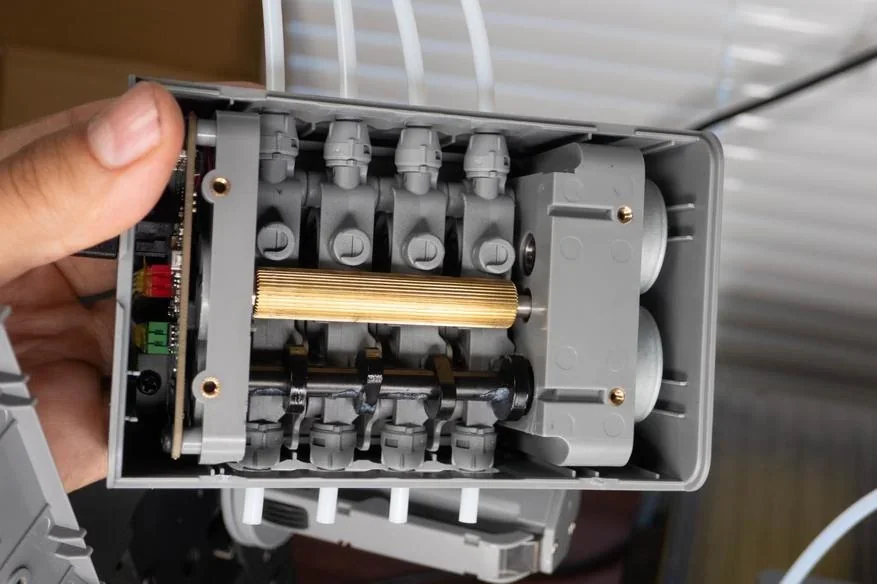

The Flashforge AD5X's Intelligent Filament System (IFS) is a compact multi-color printing module that controls four independent channels for automated multi-color printing. Numbered, side-mounted spool holders arranged side by side save space and offer easy access, with spring-loaded mechanisms to prevent tangling.

The IFS auto-detects filament, enables automatic filament feeding and retraction, handles loading and color transitions while reducing the time the material is switched, and monitors flow to detect clogs or runout. For single-color prints, it can switch between spools of the same material for uninterrupted printing.

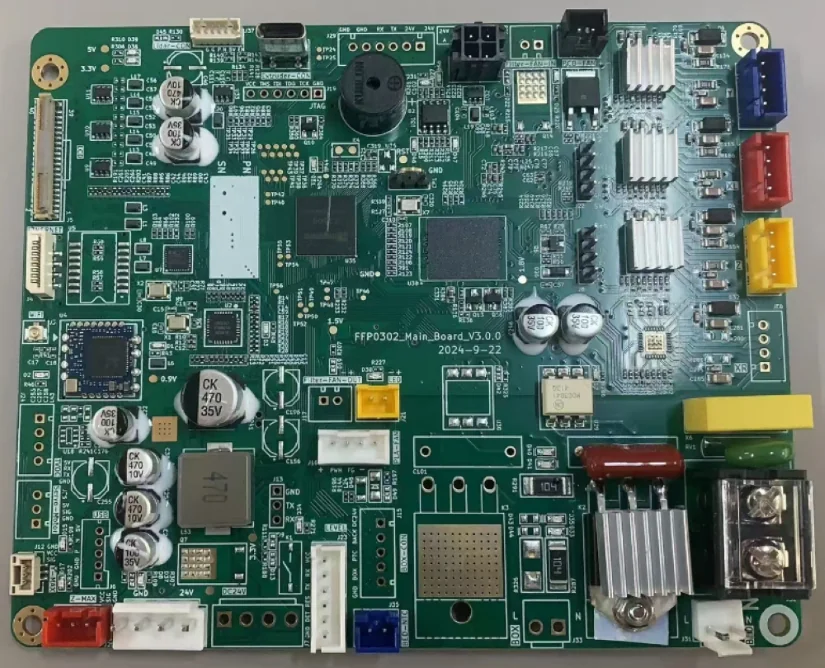

The Flashforge AD5X runs on a dual-core Cortex-A53 mainboard with 8 GB storage and supports 2.4G/5G Wi-Fi for wireless printing and remote monitoring. Silent stepper drivers reduce noise while maintaining precision. The control system manages temperature, motion, filament monitoring, and auto-calibration, with support for over-the-air updates and Flashforge’s cloud platform.

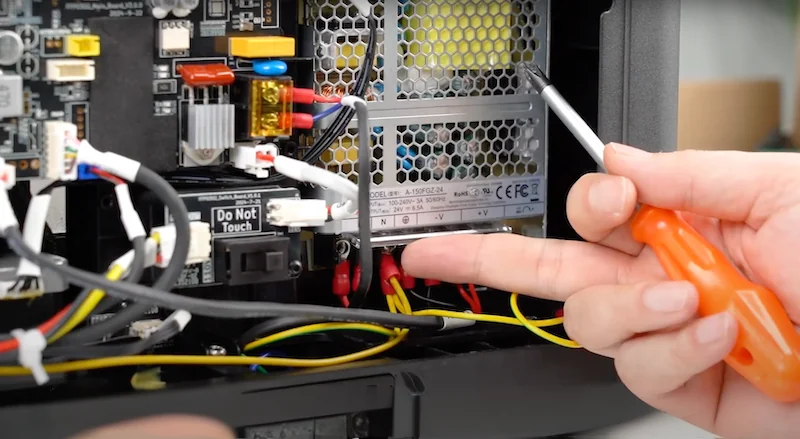

The Flashforge AD5X operates on AC 100–240V at 50/60 Hz with a 650W power supply, compatible with global voltage standards. Its power capacity supports simultaneous heating of the extruder (up to 300°C), heated bed (110°C), and electronics during high-speed printing.

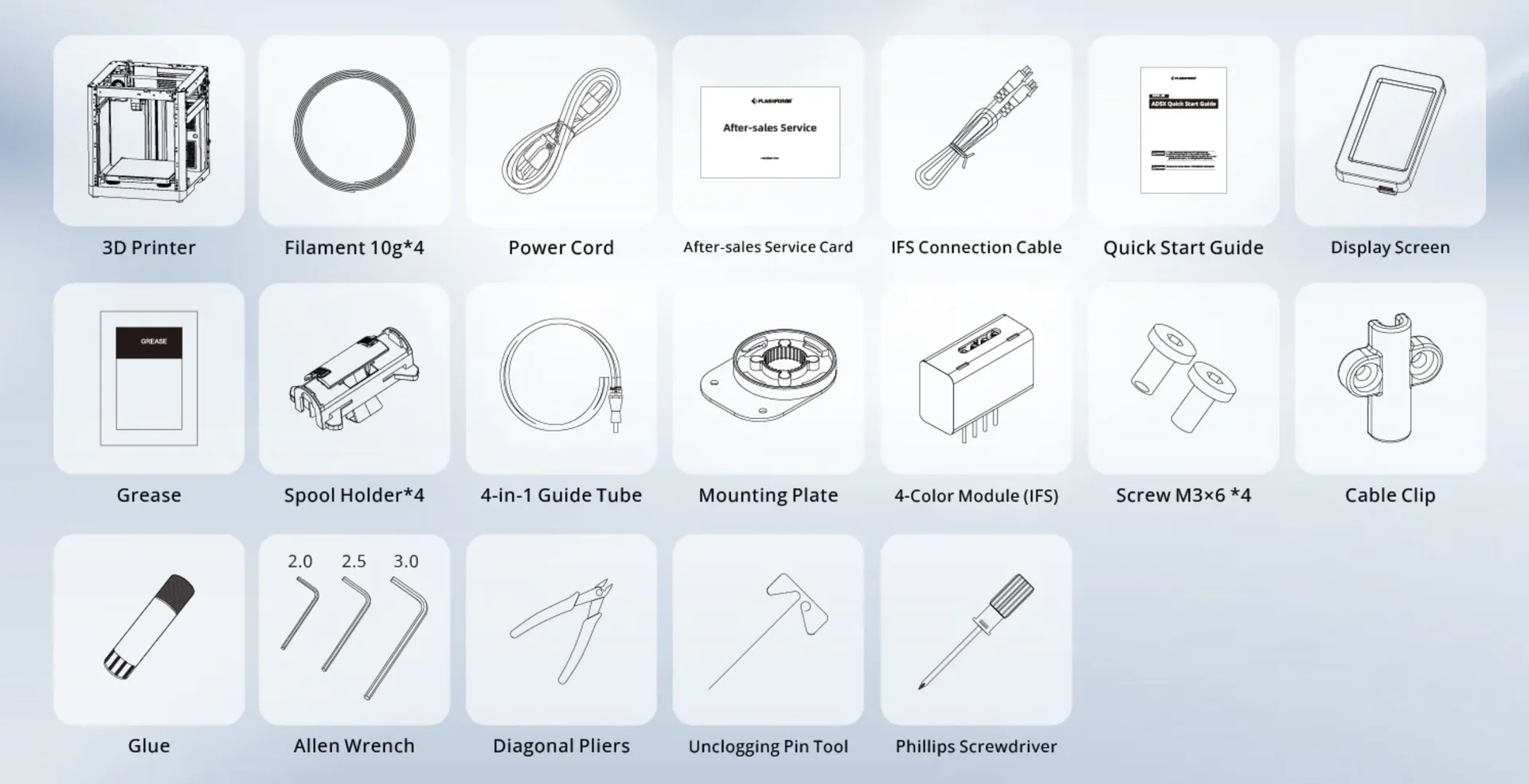

What's Included in the Box:

The Flashforge AD5X comes partially assembled, requiring installation of the touchscreen, filament holder, and 4-color IFS module. Setup takes 15–20 minutes. The PEI-coated steel build plate offers strong adhesion and easy print removal. The pre-configured IFS enables automatic filament detection, loading, and multi-color printing.

Please Note: Package contents are determined by the manufacturer and may change without notice. To confirm the current items included with this product, please contact a Flashforge sales representative before placing your order.

The Flashforge AD5X supports various accessories and upgrades for improved performance, maintenance, and longevity:

| Accessory | Function | Target User | Price (USD) |

|---|---|---|---|

| Enclosure Kit | Controls temperature and improves safety | Users needing a stable print environment | $49+ |

| Nozzle Assembly | Replacement for worn or upgraded nozzles | Users performing nozzle maintenance/upgrades | $25+ |

| PEI Textured Build Plate | Enhances adhesion and surface finish | Users seeking better print quality | $19+ |

| Touch Screen Assembly | Replacement interface | Users replacing or upgrading the screen | $50+ |

| Camera Kit | Enables remote monitoring | Users wanting remote oversight | $40+ |

| IFS System Parts | Replacement parts for filament system | Users maintaining the IFS | $10+ |

The Enclosure Kit converts the open-frame AD5X into a fully enclosed system, improving safety, temperature control, and print quality. It reduces noise from 65dB to 55dB, contains fumes, and shields users and household members from hot or moving parts. The enclosure maintains stable internal temperatures, aiding prints with temperature-sensitive materials.

The Flashforge AD5X Nozzle Assembly features a one-piece copper nozzle design with an interference fit to prevent leaks and material shedding. It offers fast heating, stable 280°C temperature control, and easy tool-free replacement for beginners. The assembly measures 54mm with a 28mm heating block. A nozzle pack includes 0.25mm, 0.4mm, 0.6mm, and 0.8mm sizes.

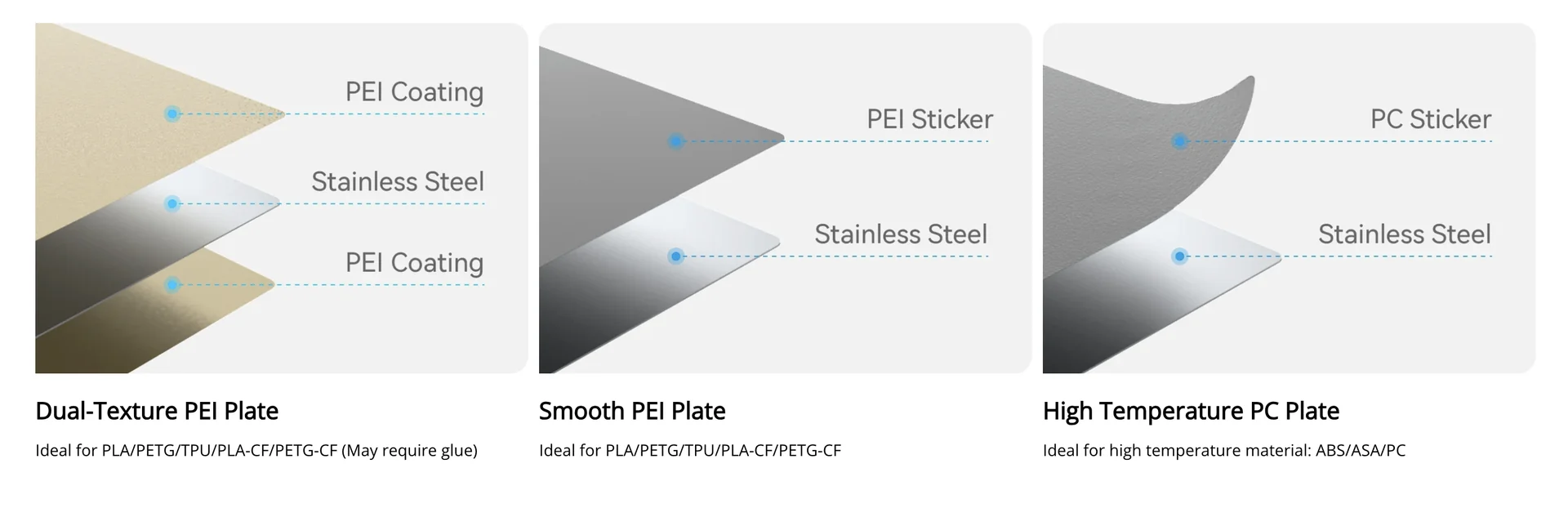

The PEI Textured Build Plate for the Flashforge AD5X features dual-sided PEI coating on stainless steel, supporting 25°C to 110°C operation for filaments like PLA, PETG, TPU, PLA-CF, and PETG-CF. Its textured surface improves adhesion and allows easy model removal once cooled, eliminating the need for glue in most cases. Small prints may need adhesive. Regular cleaning maintains performance, and the durable coating resists wear better than standard surfaces.

The 4.3-inch resistive Touch Screen Assembly for the Flashforge AD5X restores full control over printing, workflow, and system operations. It features pre-connected wiring for easy, tool-free installation, aligning with the AD5X’s user-friendly design.

The Camera Kit for the Flashforge AD5X connects via USB and enables real-time, high-resolution print monitoring. Users can remotely check print status, inspect layer quality, and capture time-lapse videos. It helps detect issues early, reducing failures and material waste for improved print management.

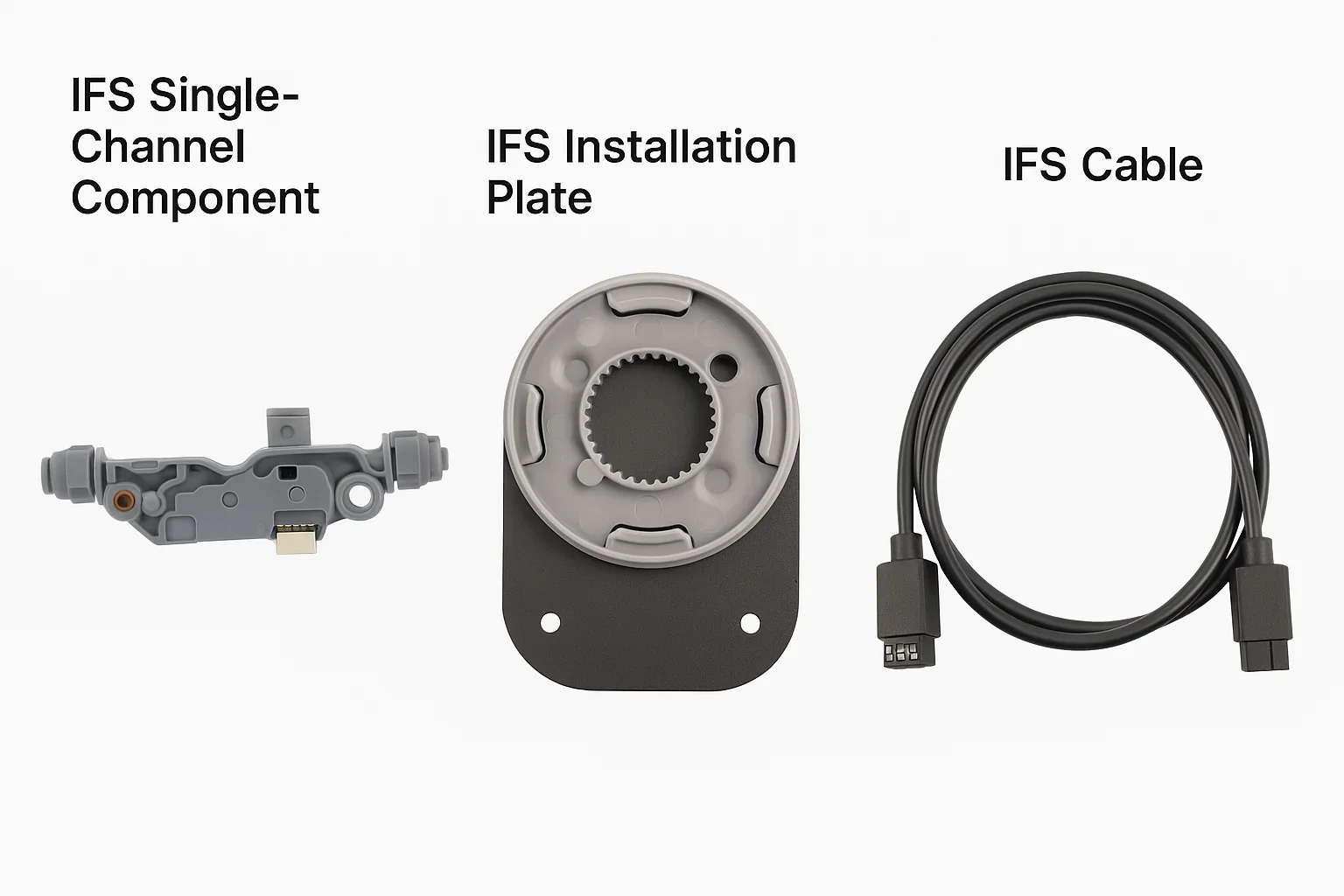

The IFS System Parts for the Flashforge AD5X include four key components that enable multi-color printing. The instation plate mounts the IFS module to the frame with two M3×6 screws for stability. The IFS cable connects the module to the control system for automatic filament switching. The IFS host manages loading, unloading, and switching across four channels. Individual single-channel parts allow modular maintenance without full disassembly. Mounted on top of the printer, the IFS uses short PTFE tubes to reduce filament feed resistance.

The Flashforge AD5X requires over 35 maintenance procedures, grouped into basic, intermediate, advanced, and IFS-specific tasks. Full video guides are available at: https://wiki.flashforge.com/en/ad5x/maintenance

Basic Maintenance – Daily upkeep to maintain print quality:

Intermediate Maintenance – Component-level replacements:

Advanced Maintenance – Structural and power system replacements:

IFS Maintenance – Multi-filament system tasks:

The Flashforge AD5X includes a 12-month limited warranty for the printer and 3 months for extruder components, starting from the purchase date. It covers defects and malfunctions under normal use, with free parts, replacements, or refunds if repair isn't possible.

Warranty Exclusions:

Full warranty terms: https://www.flashforge.com/pages/warranty-and-return-policy, https://www.flashforge.com/pages/after-sales-policy.

Support & Warranty Claims:

Firmware Updates:

The Flashforge AD5X is available at $339.00, offering strong value as a 4-color multi-material 3D printer. It features CoreXY architecture, 600mm/s speed, 20,000mm/s² acceleration, and the Intelligent Filament System (IFS) for true multi-color printing, including with flexible TPU. Buyers can choose between the base unit or a bundle with four random filament colors for 8–10% more. Both options include a 12-month warranty, free tech support, and access to Orca-Flashforge and Flash Maker software.

Update your browser to view this website correctly. Update my browser now