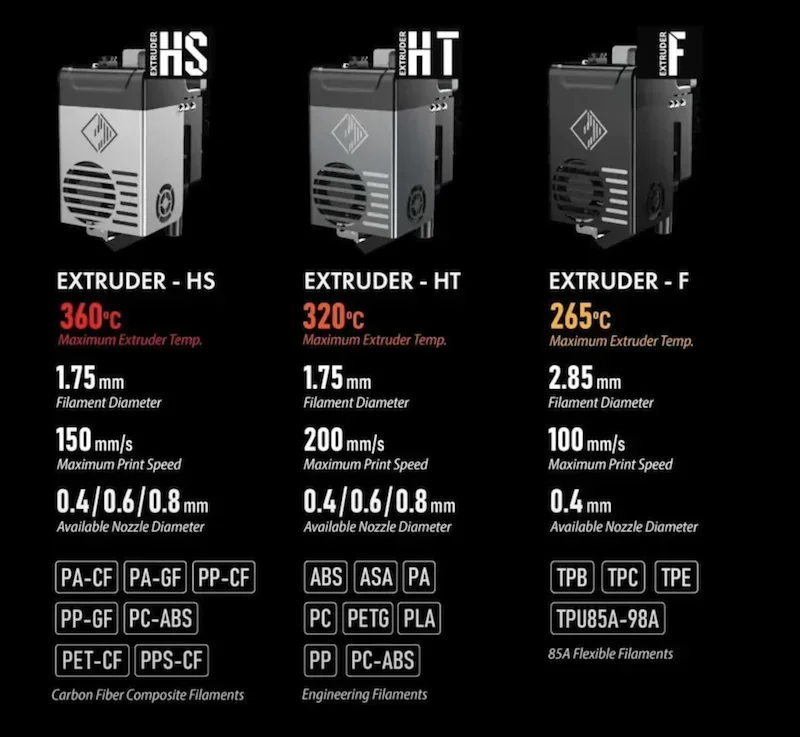

The FlashForge Creator 4 is an industrial high-performance FDM 3D printer with a 400 × 350 × 500 mm build volume, heated chamber (up to 65°C), and precision motion system for high-quality, dimensionally stable prints. Its IDEX system supports three interchangeable extruders—F (flexibles, 265°C), HT (engineering materials, 320°C), and HS (composites, 360°C)—alongside a 130°C heated bed to handle materials like PC, PA, and carbon fiber. Designed for professional use in industries like automotive and aerospace, it offers features such as auto bed leveling, HEPA 13 filtration, remote monitoring, and dual-extrusion modes for efficient mass production.

The FlashForge Creator 4A and 4S share core specs but differ in extruder setups and supported materials.

| Feature | Creator 4A | Creator 4S |

|---|---|---|

| Extruder Configuration | 2x 320°C Extruders-HT | 2x 360°C Extruders-HS + 2x 320°C Extruders-HT |

| Maximum Temperature | 320°C | 360°C |

| Print Speed | Up to 200 mm/s | Up to 150 mm/s (HS extruders) Up to 200 mm/s (HT extruders) |

| Standard Materials | ABS, ASA, PA, PC, PETG, PLA, PP, PC-ABS | ABS, ASA, PA, PC, PETG, PLA, PP, PC-ABS |

| Composite Materials | Not supported | PA-CF, PA-GF, PP-CF, PP-GF, PC-ABS, PET-CF, PPS-CF |

The FlashForge Creator 4 offers layer heights from 0.05–0.4mm for fine detail or faster drafts, with ±0.2mm accuracy for stable dimensions. Its S-type motion control and precision linear guides ensure accurate nozzle positioning, smooth surfaces, and reliable results on complex geometries.

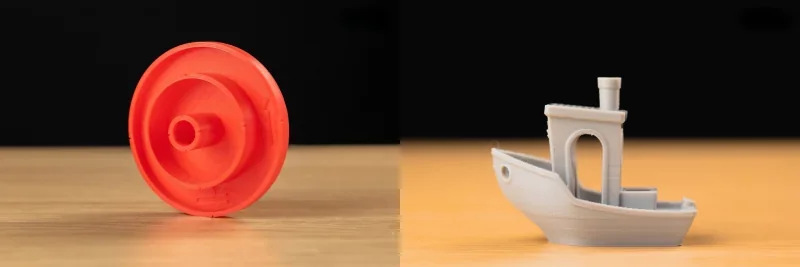

Tests show the Creator 4 excels with multiple materials. In ABS, it scored 86.12/100 on the 3DPI benchmark with no spike defects. Circular trajectory tests showed deviations of 0.0344mm (X) and 0.0973mm (Y), averaging 0.0659mm overall. The Benchy test achieved 0.0454mm deviation—well above the 0.15mm average for comparable FDM printers.

Source: 3D Printing Industry

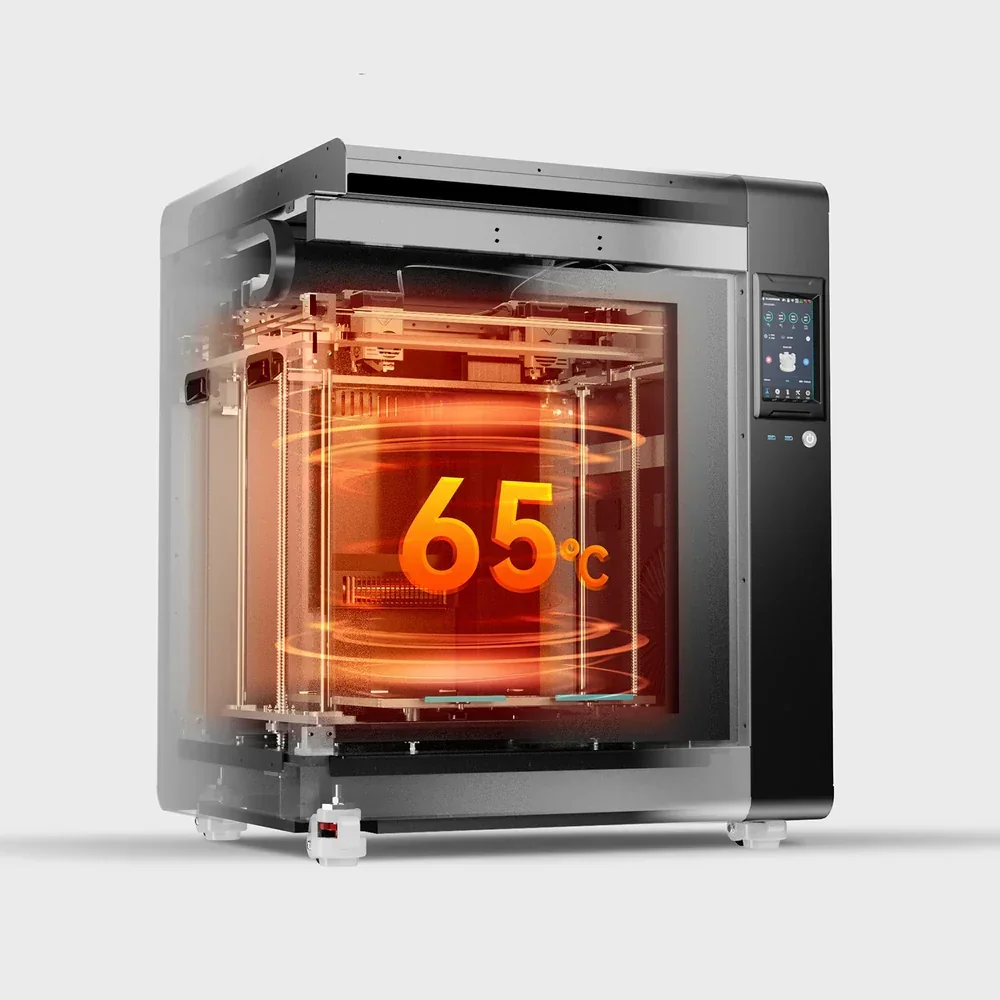

The FlashForge Creator 4’s heated chamber (65°C) and bed (130°C) prevent warping and layer separation, ensuring stable prints with materials like ABS, PC, and PA that are prone to thermal contraction.

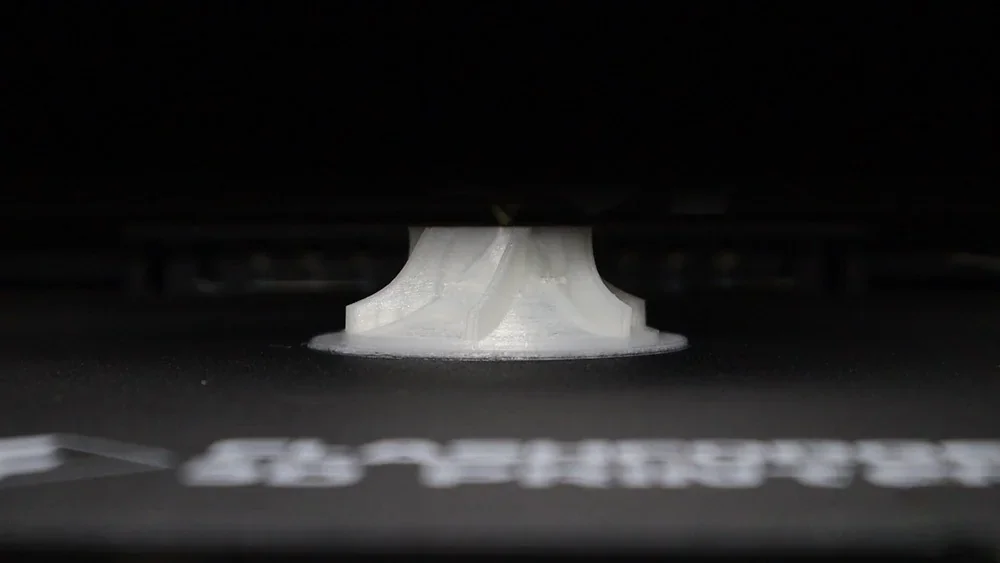

The auto bed leveling system uses a magnetic sensor on the left nozzle to map the build plate, ensuring accurate first layers without manual calibration.

In a real-world case, the Creator 4’s IDEX system cut print time from 103 hours to 54 when producing a split model of the Kul-Sharif Mosque.

In a real-world case, the Creator 4’s IDEX system cut print time from 103 hours to 54 when producing a split model of the Kul-Sharif Mosque.

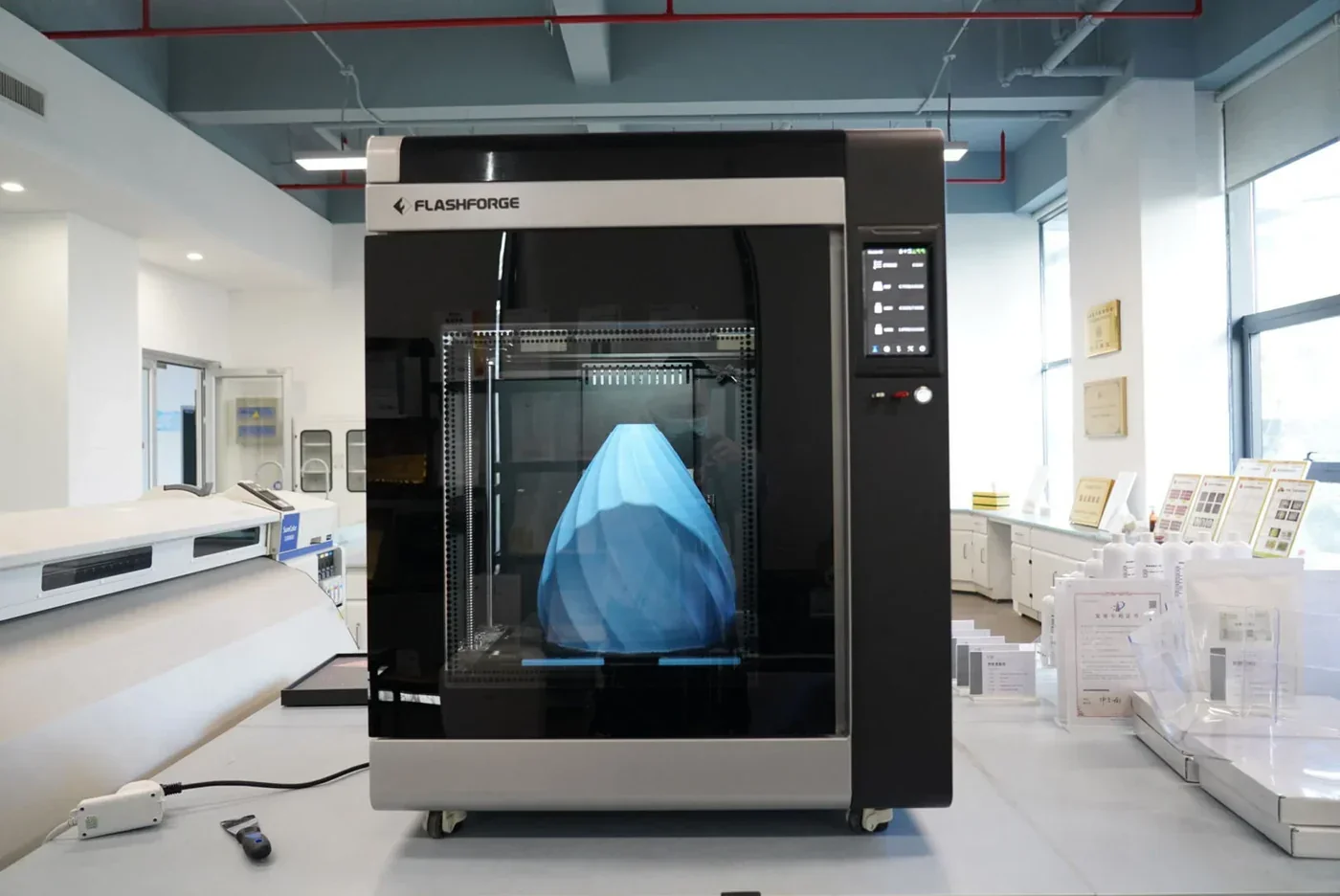

The Biomass Science and Technology Museum used the Creator 4 to create full-sized lampshades, relying on its 400 × 350 × 500 mm build volume and 65°C heated chamber for accuracy and warping prevention. Using UPM Formi bio-composite filament, chosen for its wood-like texture and translucency, they produced market-ready lampshades in over six hours directly from the printer.

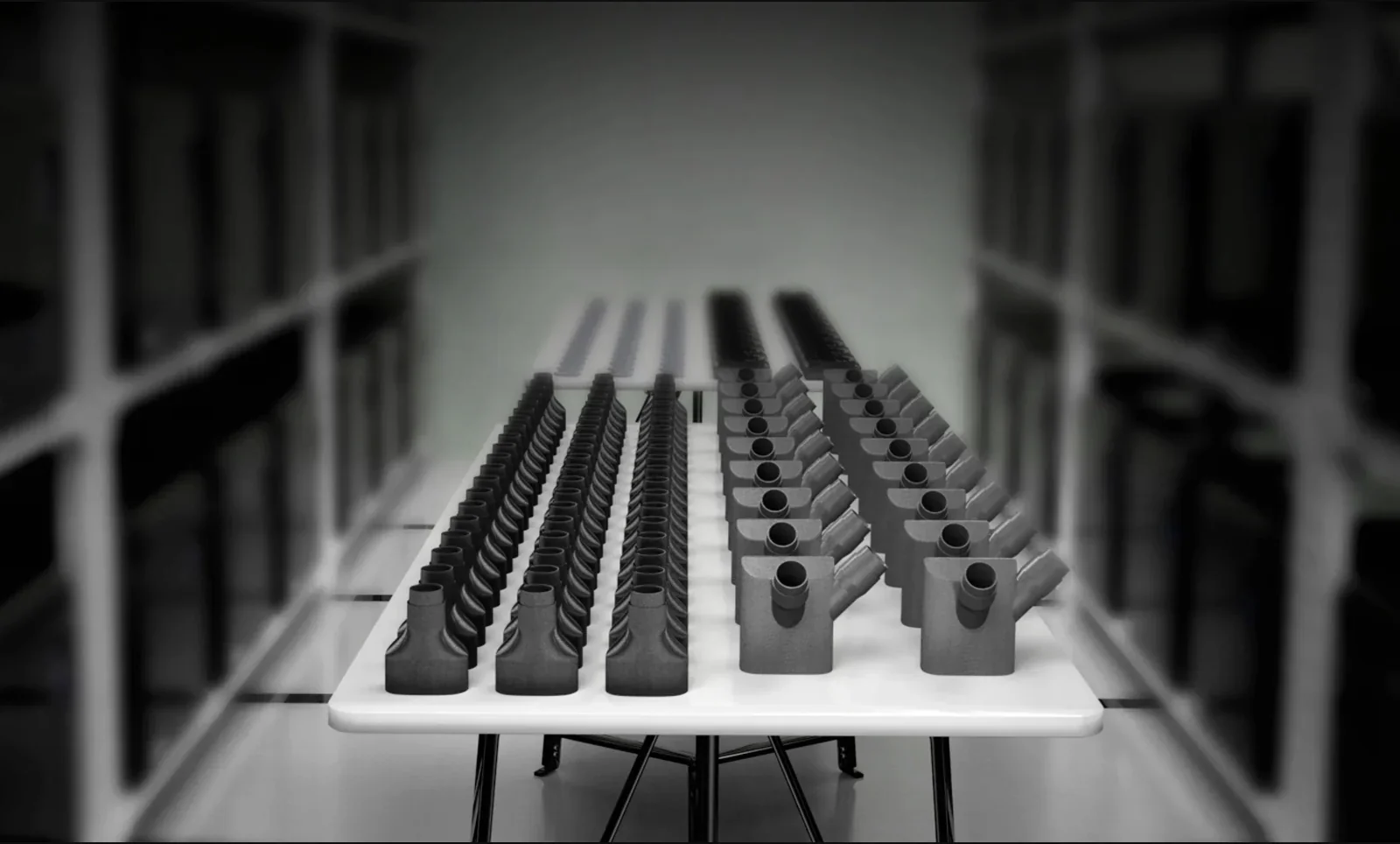

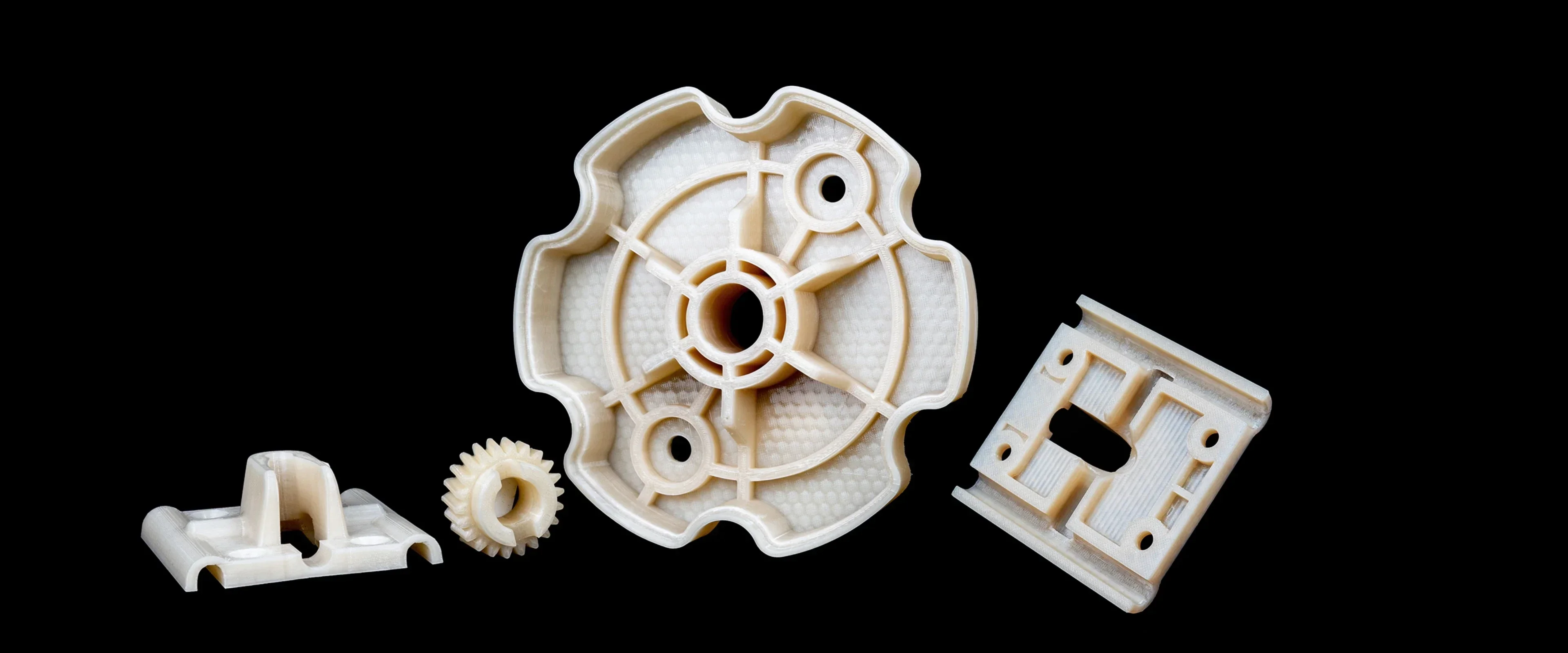

Factories use Creatbot 4 print farms to scale up production of mechanical parts, with over 48 parts printed simultaneously on each setup.

The FlashForge Creator 4 supports 22+ filament types with three interchangeable extruders:

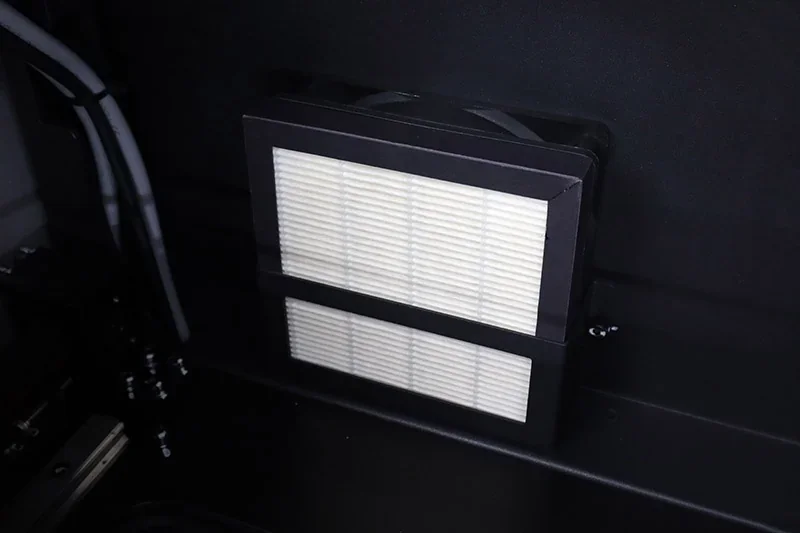

The enclosed design with HEPA 13 filtration maintains stable temperatures and removes harmful particles when printing engineering materials.

The FlashForge Creator 4 works best with FlashForge filaments but supports third-party materials with parameter adjustments. The FlashPrint 5 slicer provides material profiles, though ASA can be difficult to print reliably with default settings.

FlashForge advises sealing filaments when not in use and drying them by type: ABS/PC/ASA/PA at 80°C for 10–12 hours, PLA/PETG at 50–60°C for 4–5 hours, and carbon fiber filaments at 100°C for 10–12 hours.

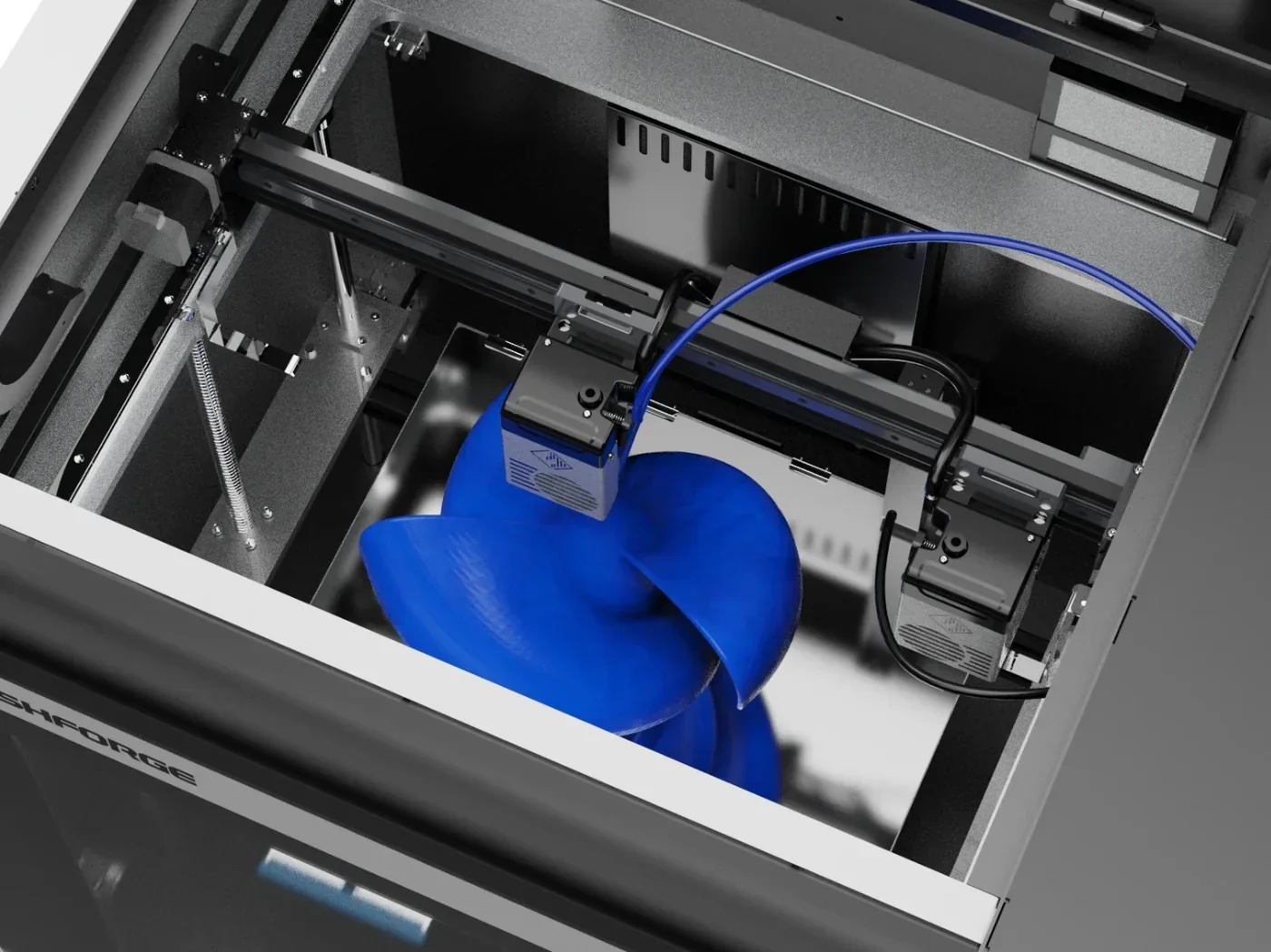

PA (Nylon): The impeller printed in 2h 38m, with thin curved blades produced distortion-free.

PA-CF: A laptop stand printed from carbon fiber–reinforced polyamide (300°C melt point) weighed 116g with 20% infill, remaining lightweight yet very rigid.

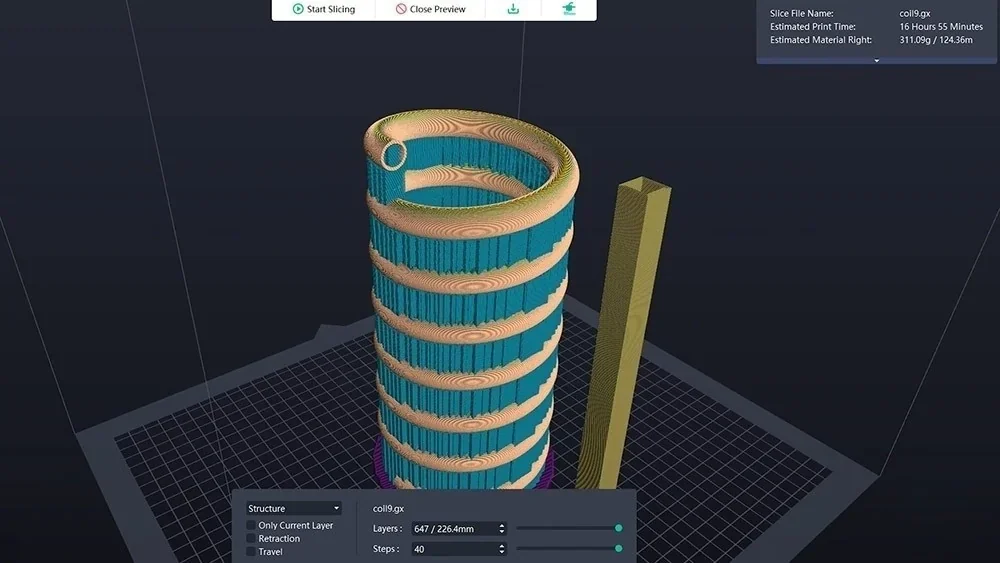

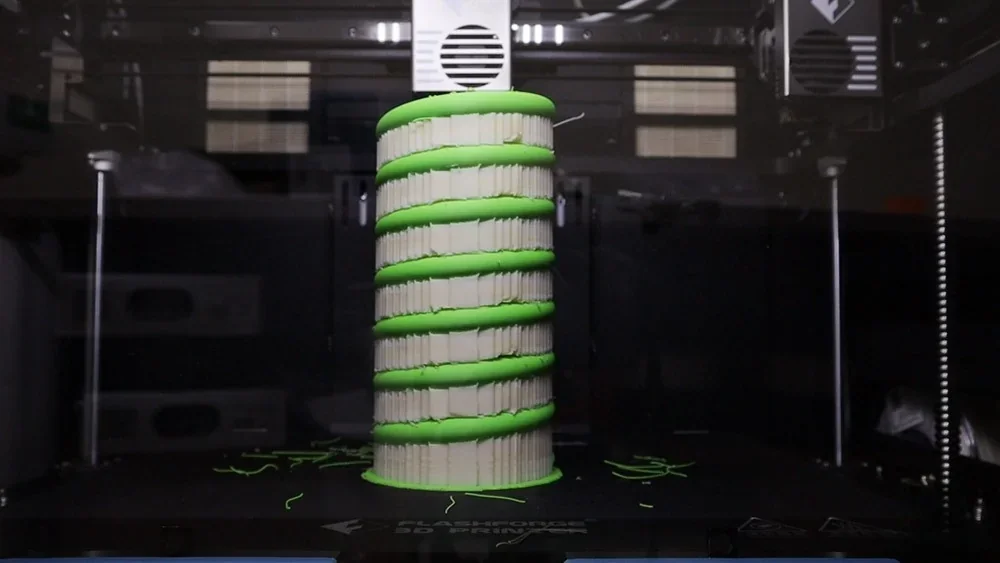

ABS + HIPS: A tubular coil with soluble supports printed in 18h 47m. Stringing on the tower separated cleanly, and external HIPS supports removed easily. Internal supports dissolved fully in D-Limonene.

CF-PA:

PA:

TPU:

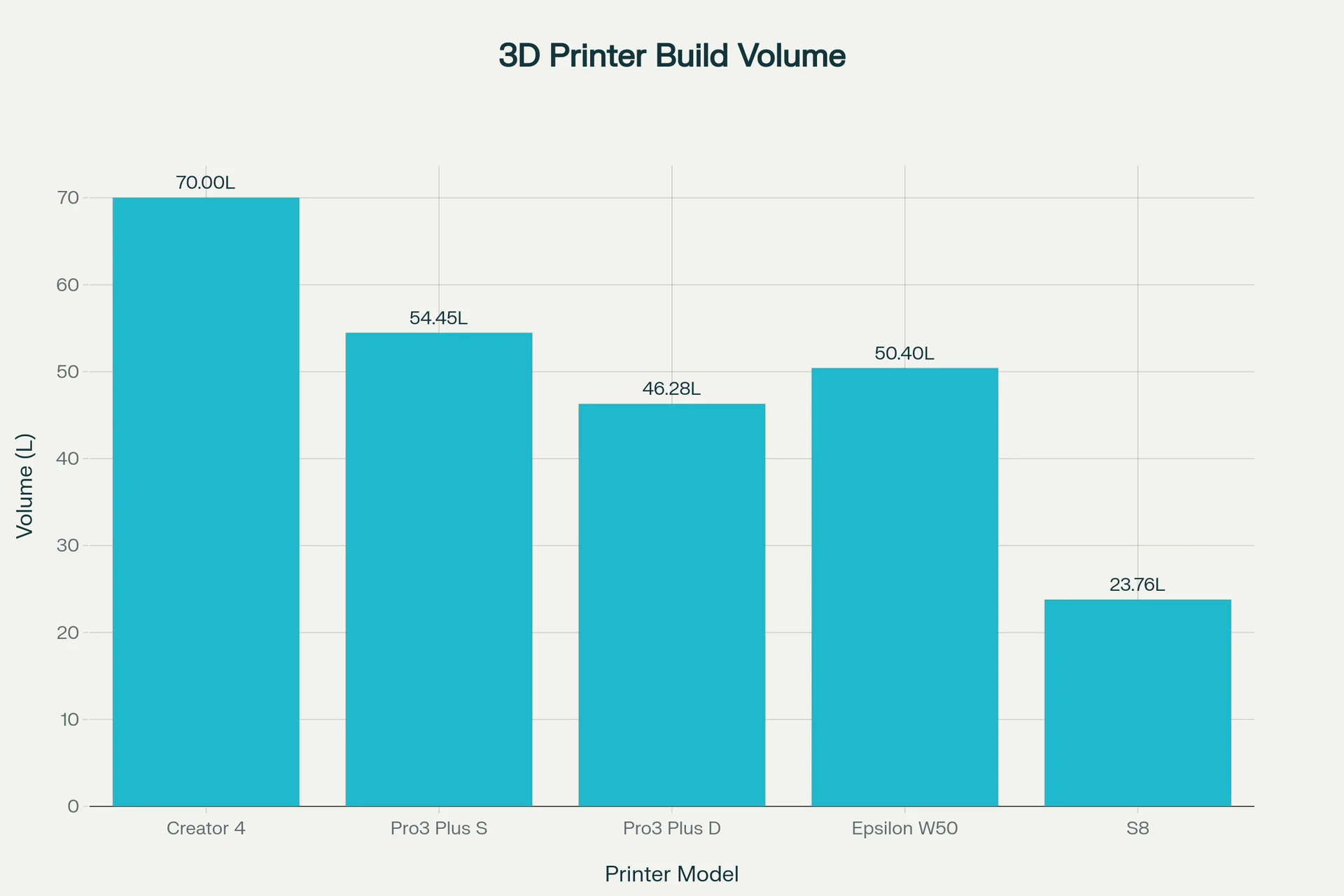

The FlashForge Creator 4 offers a 400 × 350 × 500 mm build volume (70,000 cubic cm), ideal for large prototypes and parts. Its 500mm vertical height accommodates tall models without splitting. Usable print volume is slightly smaller (396 × 348.4 × 495.8mm) due to edge constraints. With IDEX, production capacity doubles in mirror or duplicate mode for parts under 183mm on the X-axis.

Flashforge Creator 4 — Large 400×350×500 mm IDEX with swap-in A/HT/HS extruders, 65 °C chamber and 130 °C bed for controlled printing across general-use and engineering plastics, and their CF/GF composites; the hotend temperature is up to 360 °C (HS), but the printing speeds are moderate (100–200–150 mm/s).

In contrast:

| Specification | Flashforge Creator 4 | Raise3D Pro3 Plus HS | BCN3D Epsilon W50 (Gen2) | UltiMaker S8 |

|---|---|---|---|---|

| Price (USD, from) | $10,900+ | $7,599+ | $9,300+ | $7,900+ |

| Build volume (mm) | 400 × 350 × 500 | 300 × 300 × 605 (Single) / 255 × 300 × 605 (Dual) | 420 × 300 × 400 | 330 × 240 × 300 |

| Extrusion system | IDEX (A/HT/HS extruders) | Dual-head with electronic nozzle lifting (non-IDEX) | IDEX | Dual extrusion with auto nozzle-lifting |

| Filament Ø | 1.75 mm | 1.75 mm | 2.85 mm | 2.85 mm |

| Max nozzle temp (°C) | 360 (HS) / 320 (HT) / 265 (A) | 320 | 300 | 340 |

| Bed max (°C) | 130 | 120 | 120 | 120 |

| Chamber | Heated, 65 °C | Enclosed; HEPA + activated carbon (no temp spec) | Passive heated, up to 60 °C (depends on ambient) | Enclosed build volume < 50 °C (open-loop) |

Bottom-Line:

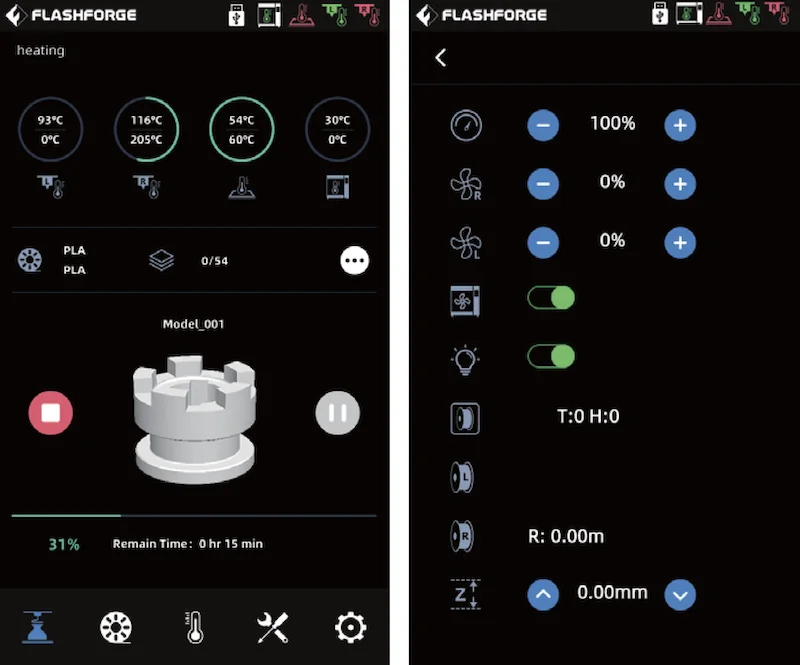

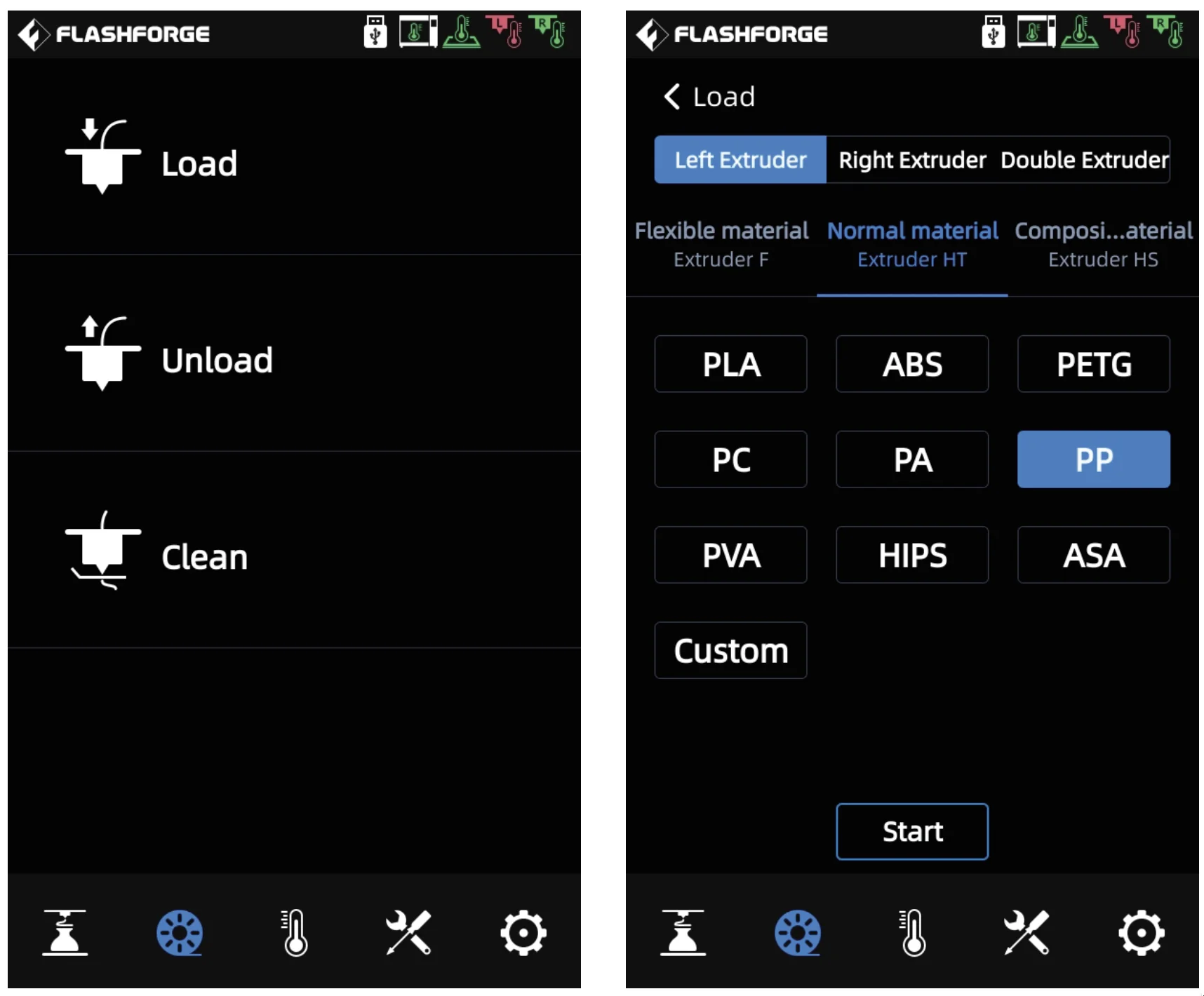

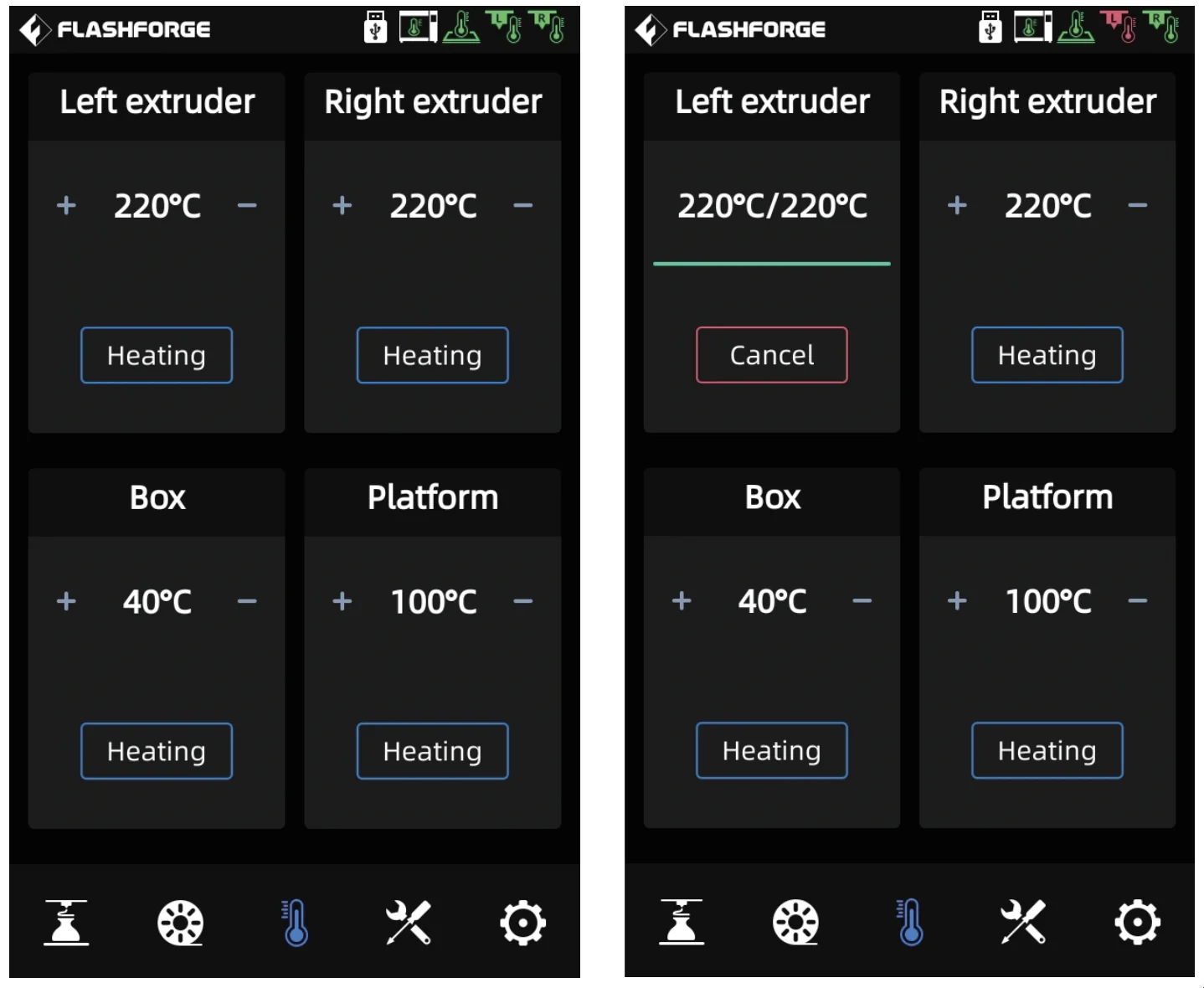

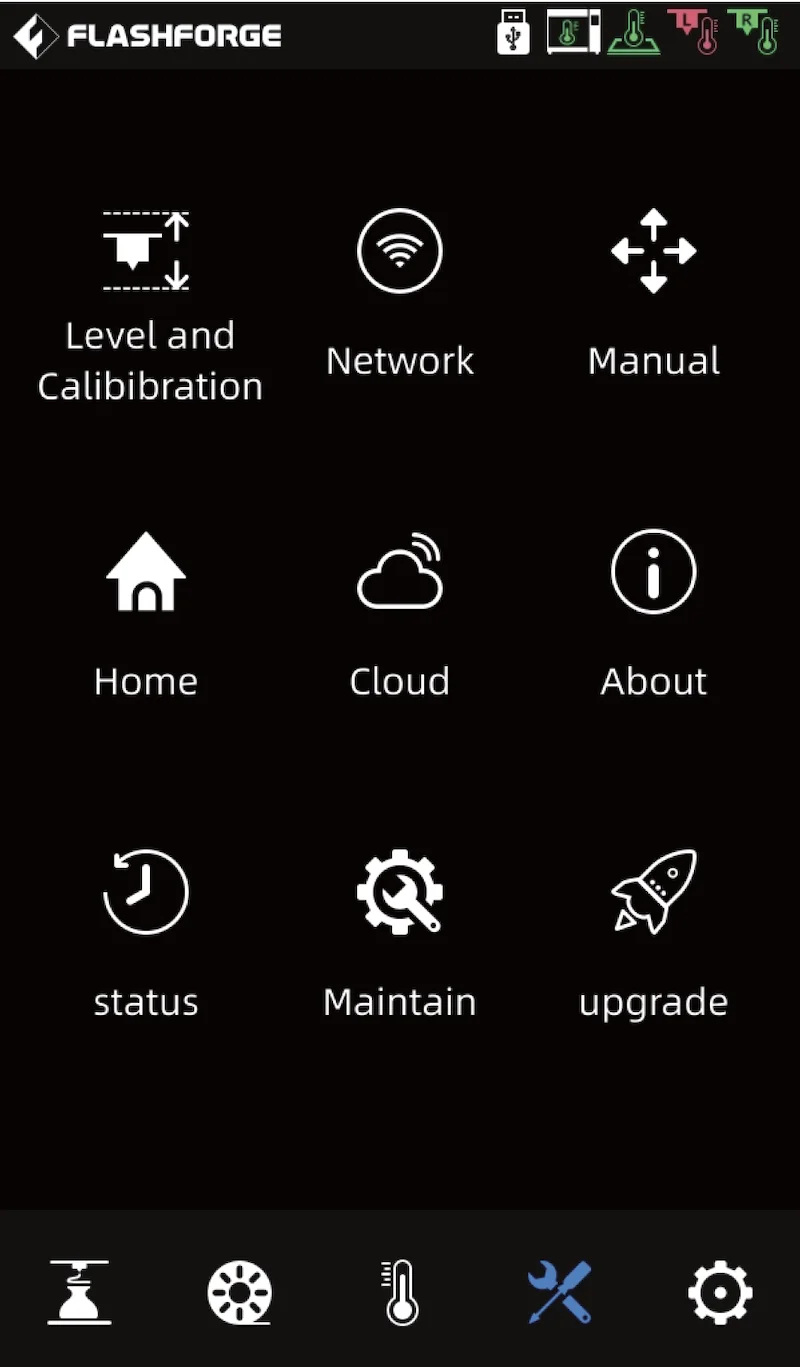

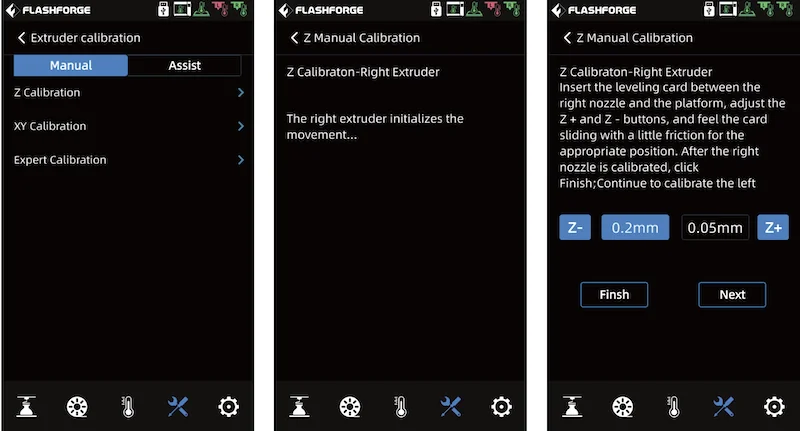

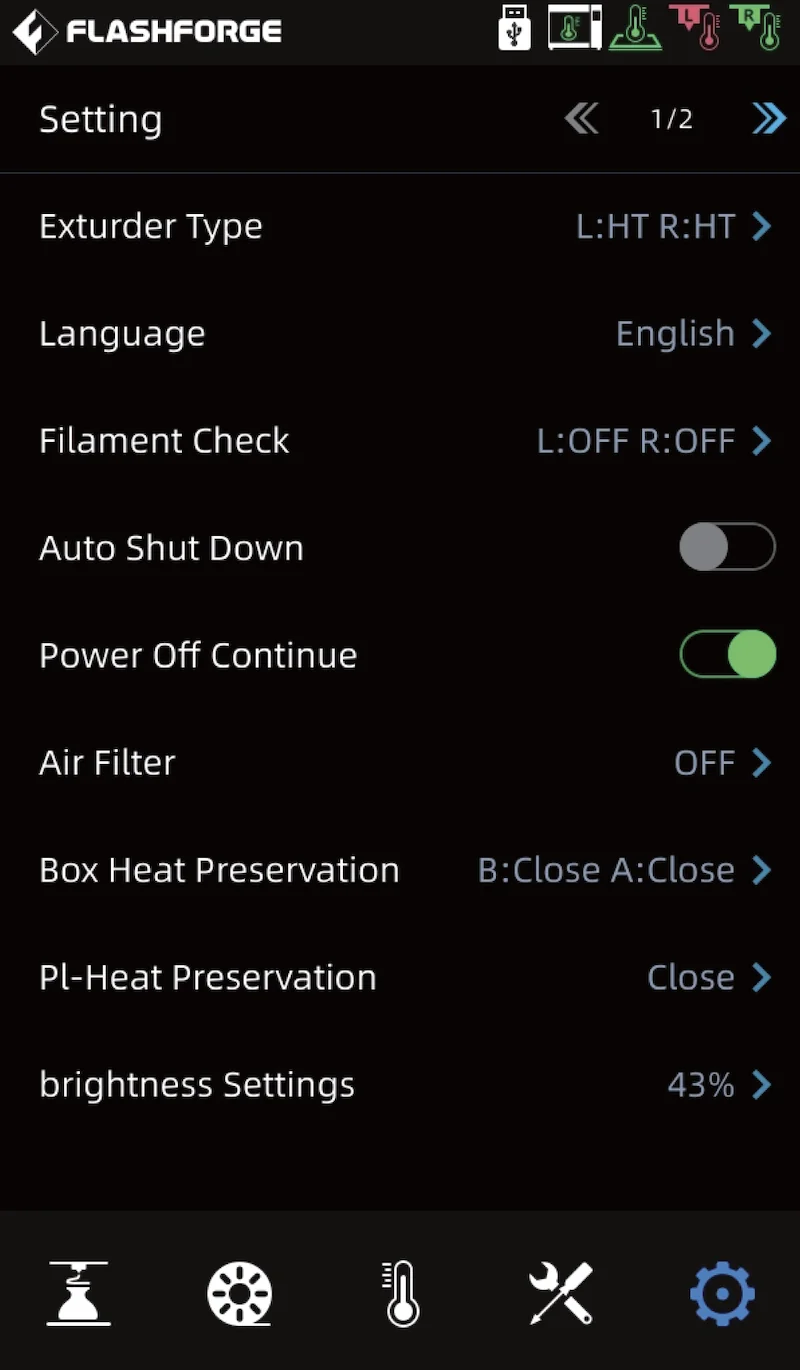

The Flashforge Creator 4 offers comprehensive printer controls including precise print operation adjustments (speed, fan, LED), filament management (load, unload, clean, custom temps), temperature settings (extruder up to 360°C, chamber 65°C, platform 130°C), manual axis movement and calibration (automatic bed leveling, Z/X/Y calibration), network and firmware management, as well as extensive system settings like extruder selection, auto shutdown, power recovery, and HEPA filtration toggles.

Main Interface Navigation:

Print Operation Controls:

Filament Management Controls:

Temperature Control System:

Tools and Utilities Controls:

Calibration and Leveling Controls:

System Settings Controls:

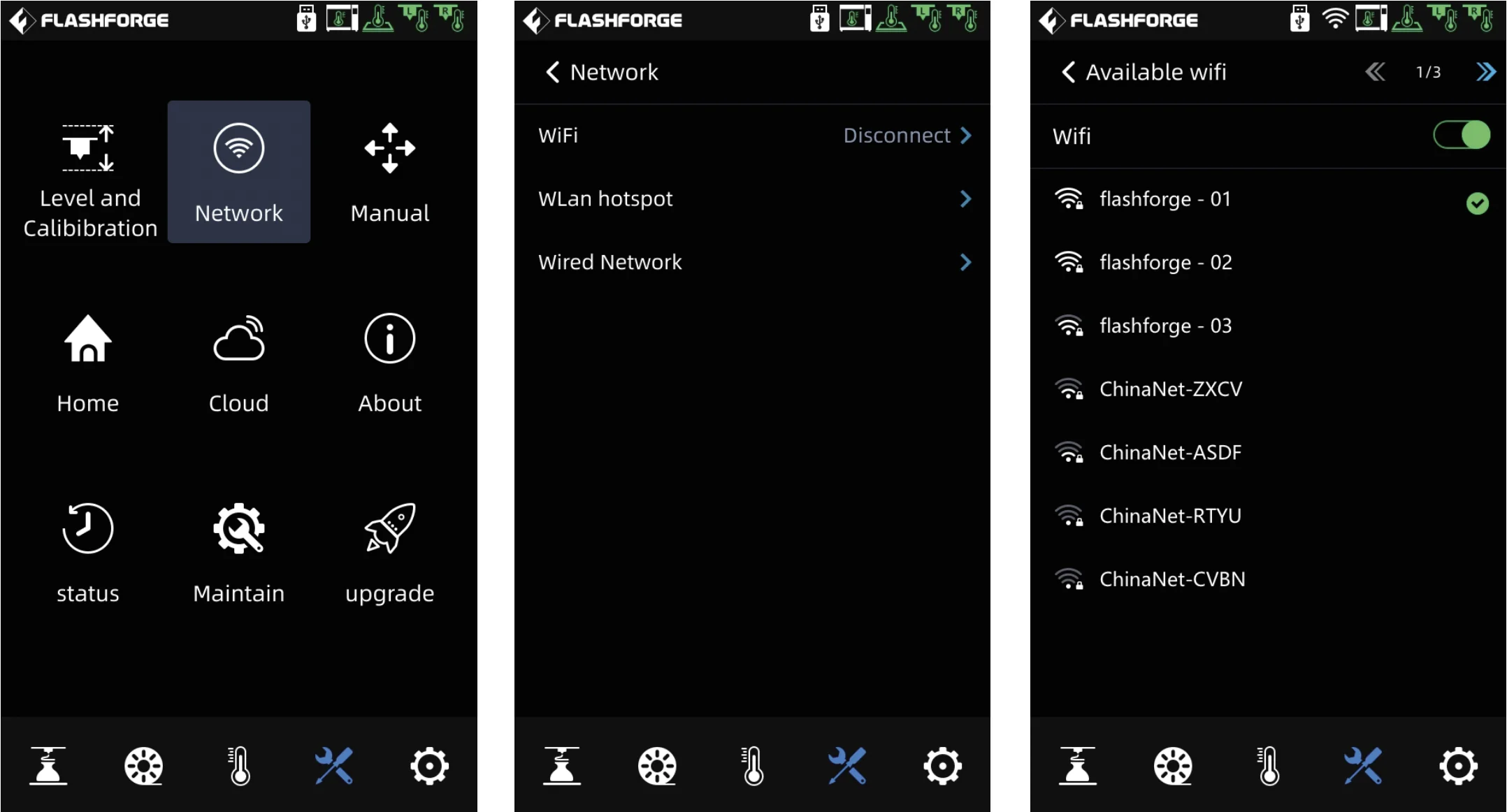

The FlashForge Creator 4 connects via Wi-Fi, Ethernet, or USB. Ethernet ensures stable wired use, while Wi-Fi supports wireless printing. Connectivity status appears on the touchscreen. For offline use, sliced files can be loaded from a USB flash drive.

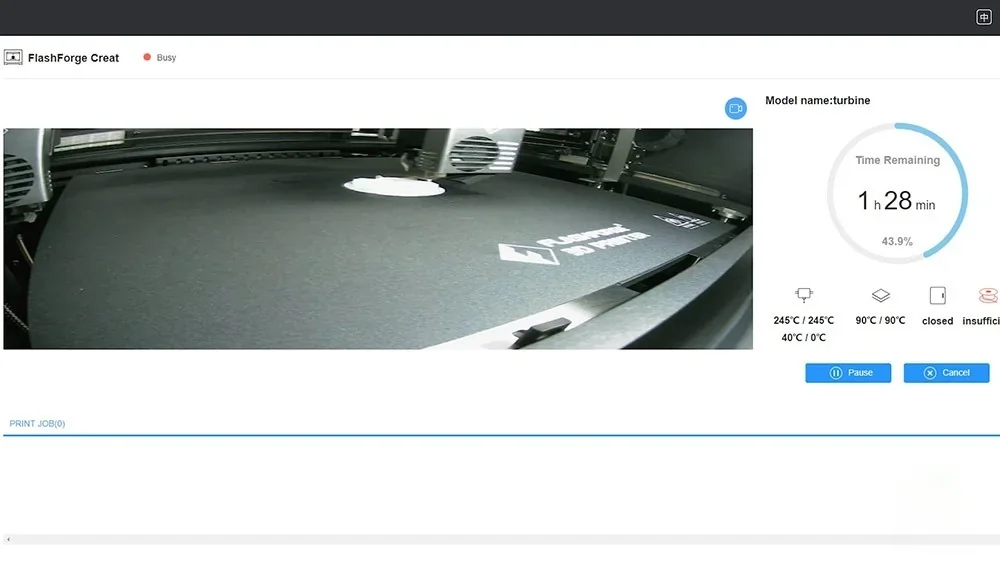

The Creator 4 integrates with FlashPrint 5, transferring files via Wi-Fi or Ethernet. A built-in camera allows remote print monitoring over the network.

The FlashForge Creator 4 uses FlashPrint 5, designed for all Creator 4 variants. It supports IDEX modes (normal, dual-extruder, mirror, duplicate) and includes material profiles for Extruder-F, HT, and HS. Files can be sent via Wi-Fi using automatic network discovery or manual IP entry.

The Creator 4 integrates with FlashCloud for remote file transfer and print management. Firmware updates can be installed via USB, a key fix for early boot issues. Current firmware supports auto bed leveling, power-failure resume, and auto shutdown. While it doesn’t support third-party slicers directly, it accepts common file formats like 3MF, STL, OBJ, FPP, BMP, PNG, and JPEG.

The Flashforge Creator 4 features a robust stainless steel frame and fully enclosed design with transparent doors for stability and temperature control, a large 500mm Z-height, a heated bed up to 120°C with dual 14mm lead screws and four 16mm guide shafts, dual exhaust fans with HEPA filtration, ergonomic filament holders for 2kg and 500g–1kg spools.

The fully enclosed design with transparent doors lets users monitor prints while keeping temperatures stable and reducing noise.

The FlashForge Creator 4’s thermal system includes a heated bed up to 120°C, moved by dual 14mm lead screws and four 16mm guide shafts for smooth precision. Safety features include dual exhaust fans with HEPA filters, providing ventilation and particle filtration, making it suitable for office use.

The Creator 4’s ergonomic design includes two rear filament holders: one for 2kg spools and another for 500g–1kg spools, both behind a transparent door.

The Creator 4’s flexible steel build plate uses a twist-lock to stay secure during printing and releases easily afterward. Its surface allows tool-free part removal, avoiding damage from scrapers.

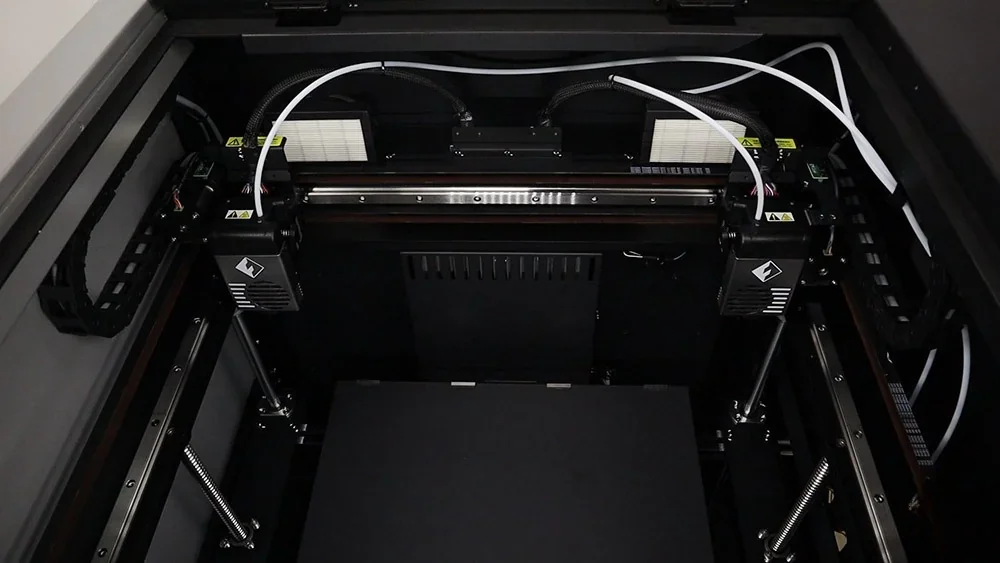

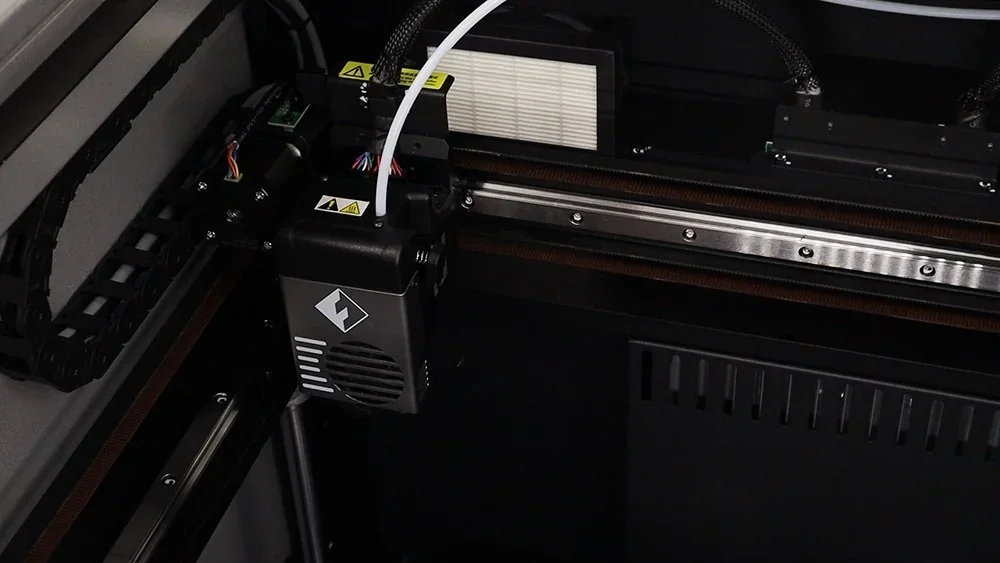

The motion system uses high-precision X/Y linear guides with an S-type control system that smooths start and stop movements.

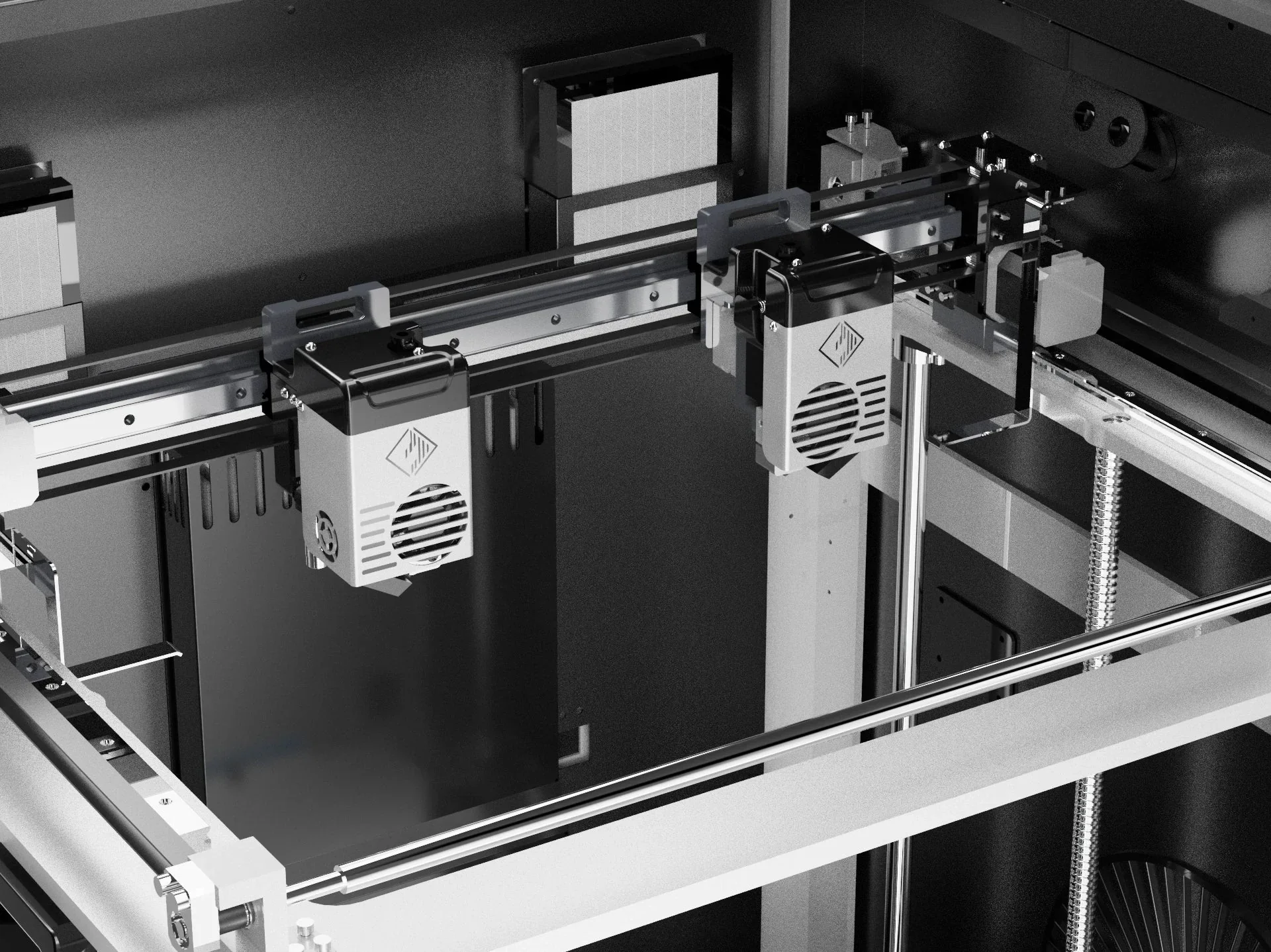

The Creator 4 uses quiet TMC2209 stepper drivers for accuracy with low noise. Dual printheads on the X-axis run independently in IDEX mode, while plug systems prevent overflow from inactive nozzles during single-extruder printing.

The Creator 4 uses quiet TMC2209 stepper drivers for accuracy with low noise. Dual printheads on the X-axis run independently in IDEX mode, while plug systems prevent overflow from inactive nozzles during single-extruder printing.

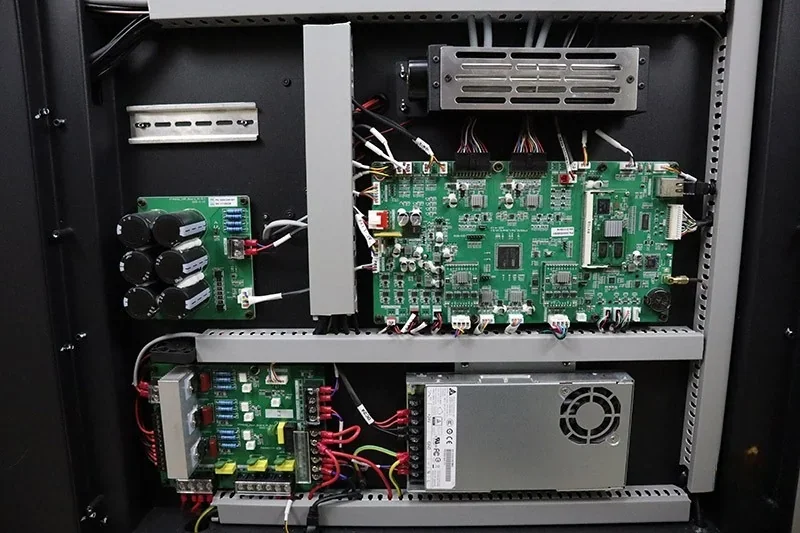

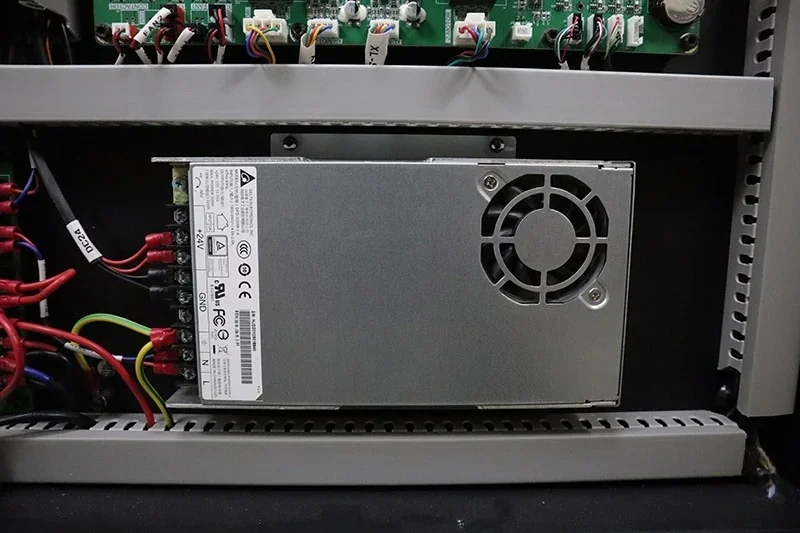

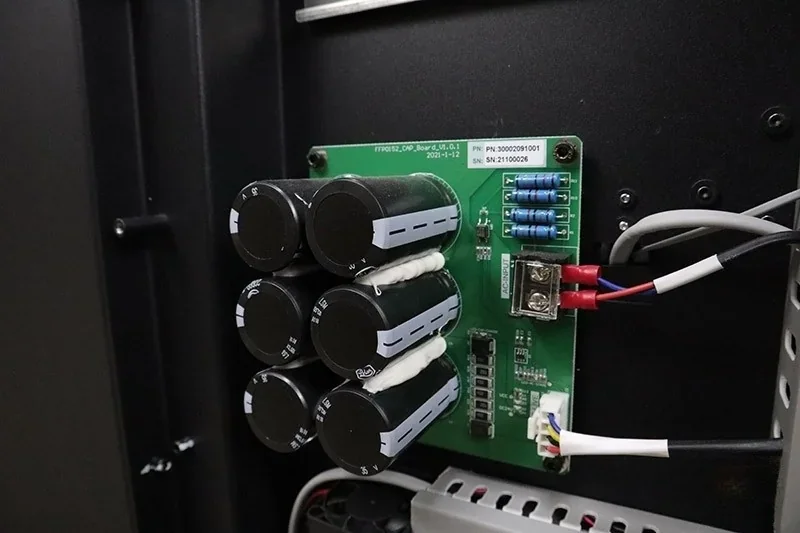

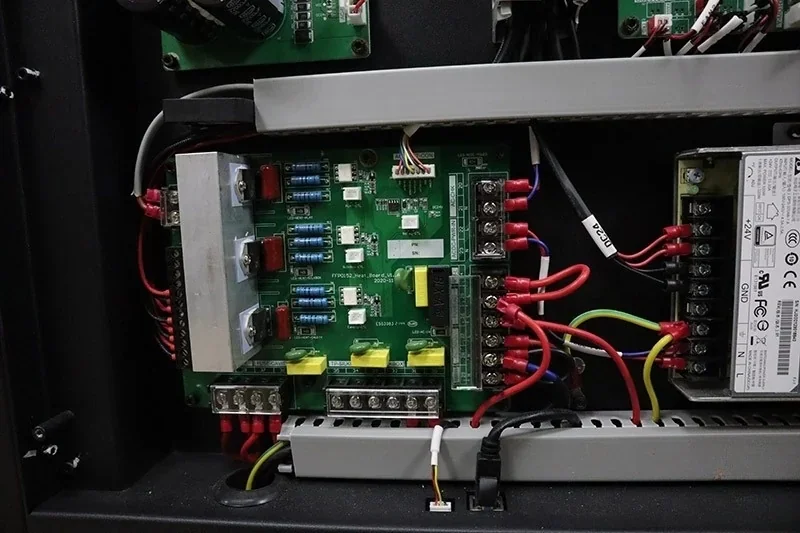

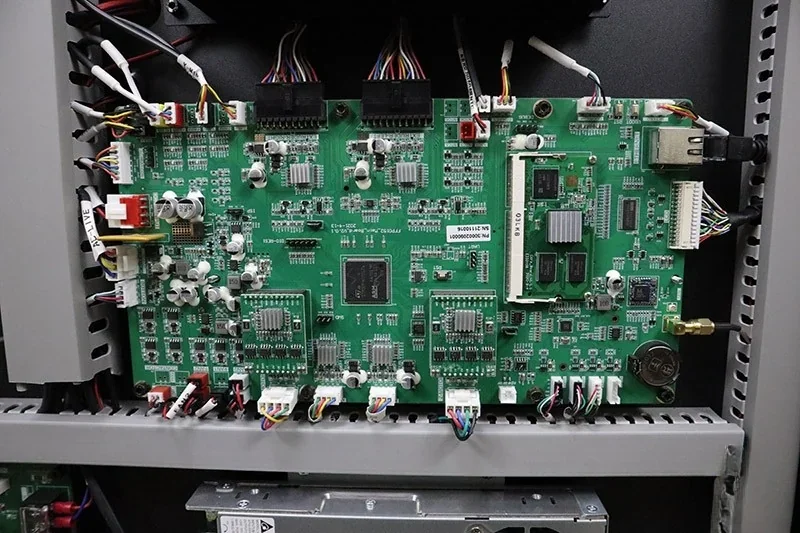

Behind its rear panel, the Creator 4 houses industrial electronics: a 320W Delta power supply, 330μF input filtering capacitors, dedicated heater control boards, and a 32-bit ARM Cortex-M4 control board.

320W Delta Electronics power supply:

Input filtering with 330μF capacitors:

Dedicated heating element control boards:

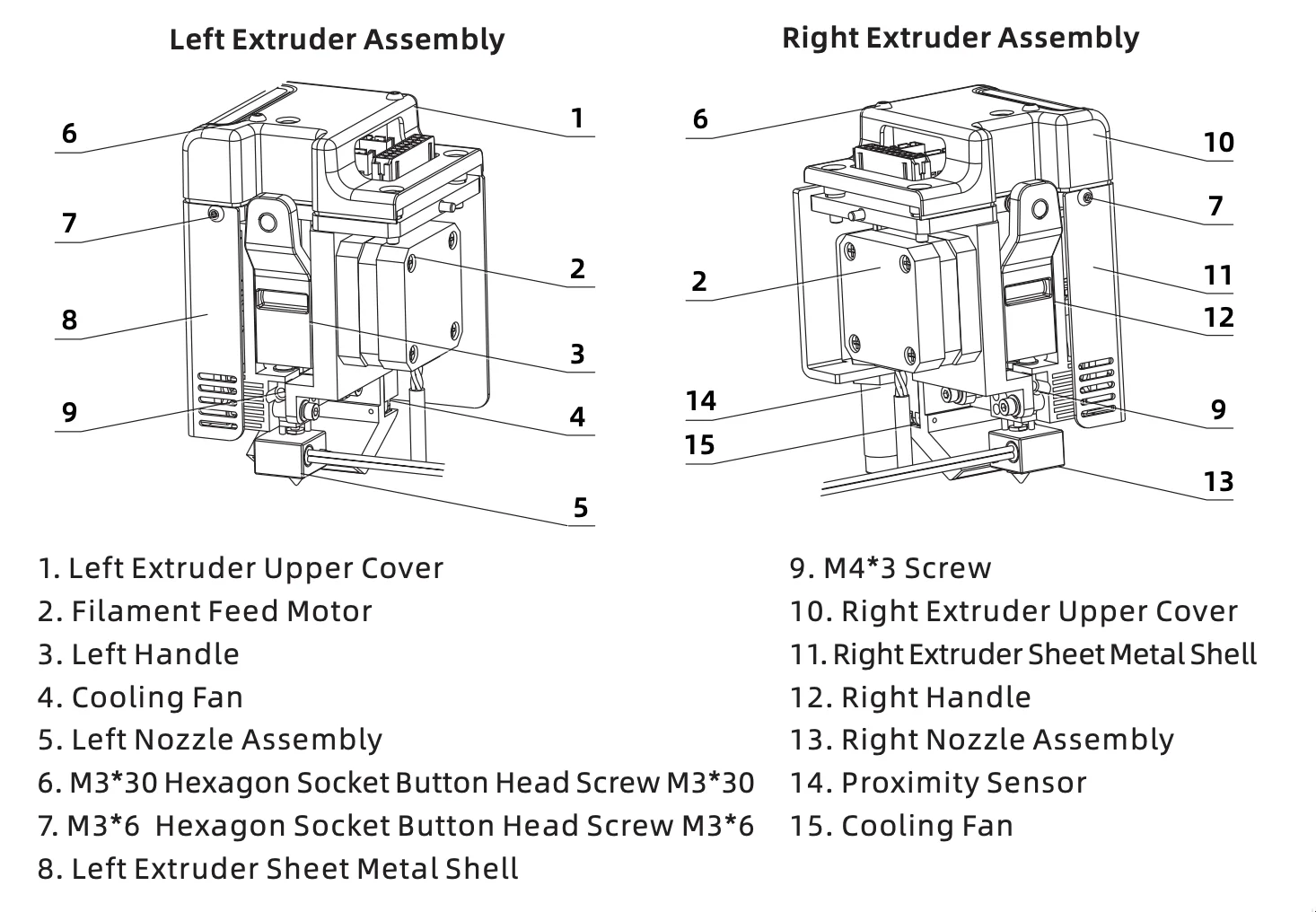

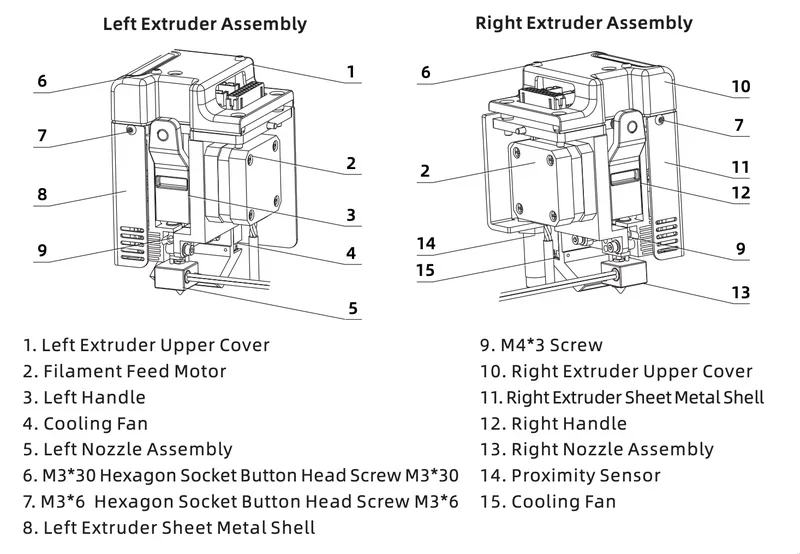

Extruder Assemblies (by model):

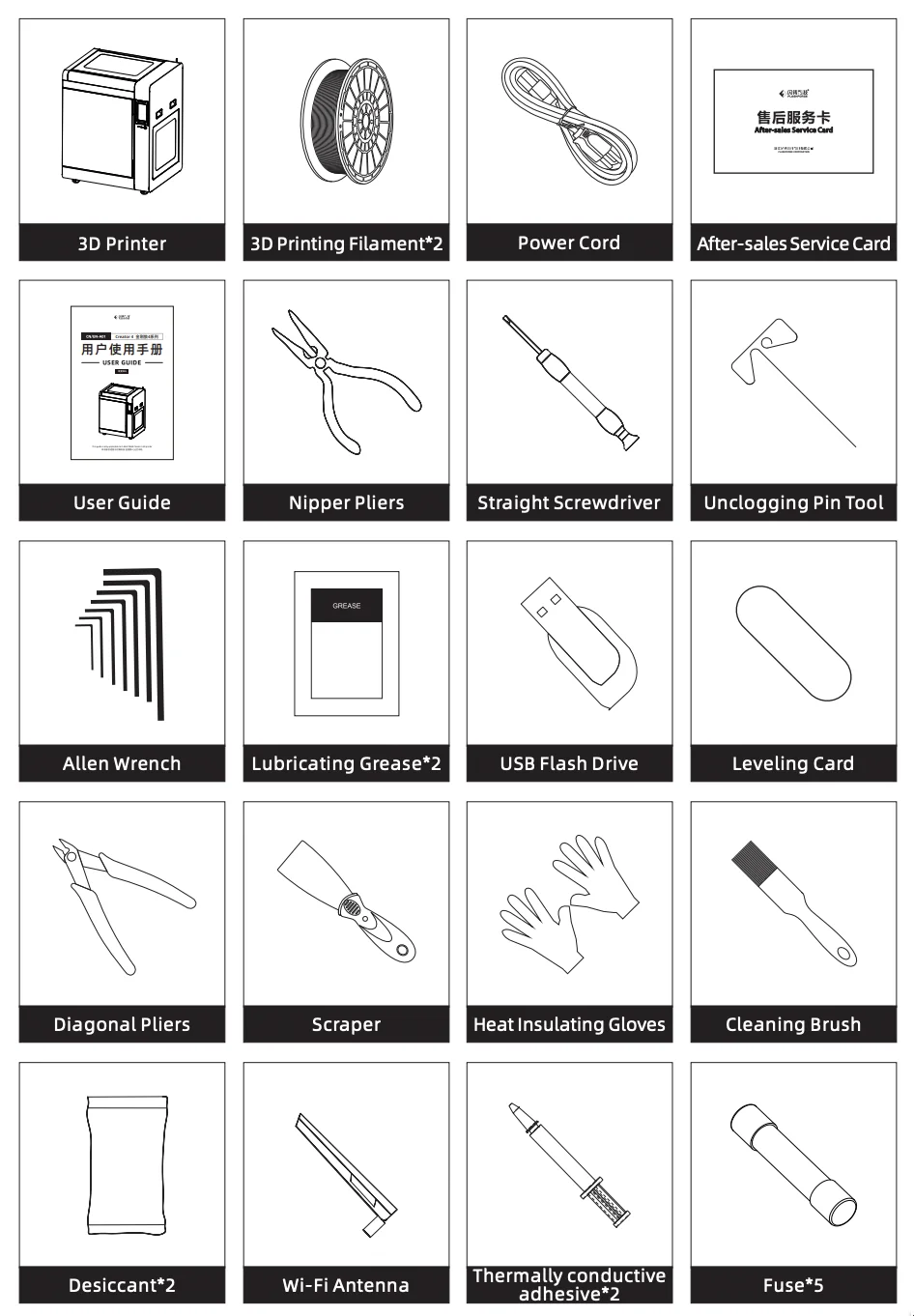

The FlashForge Creator 4 ships partially assembled with tools and accessories for quick setup. It includes two filament spools, thermal paste, fuses, and an unclogging pin for maintenance. Heat-resistant gloves protect during hot handling, and lubricating grease supports upkeep of bearings and guide rails.

Note: Package contents may vary by manufacturer. Confirm included items with a Top3DShop sales representative before ordering.

The Flashforge Creator 4 offers upgrades and accessories including a Filament Drying Station for moisture-sensitive materials, interchangeable extruders—Extruder-F (265°C) for flexible filaments, Extruder-HT (320°C) for engineering materials, and Extruder-HS (360°C) for composites—plus maintenance parts like HEPA 13 filters, nozzles in 0.4/0.6/0.8mm sizes, and PTFE tubes to ensure optimal performance and longevity.

| Accessory | Function | Price (USD) | |

|---|---|---|---|

| Filament Drying Station | Dries/stores filament, can be used as printer stand | $1,969 |  |

| Extruder-F Assembly (Left) | For printing of flexible filaments | $699 |  |

| Extruder-F Assembly (Right) | For printing of flexible filaments | $699 |  |

| Extruder-HT Assembly (Left) | For printing of standard/engineering filaments | $699 |  |

| Extruder-HT Assembly (Right) | For printing of standard/engineering filaments | $699 |  |

| Extruder-HS Assembly (Left) | For printing of composite filaments | $699 |  |

| Extruder-HS Assembly (Right) | For printing of composite filaments | $699 |  |

| HEPA 13 Filter Elements | Particle filtration | $19 |  |

| Hardened Steel Nozzle | Available in 0.4 / 0.6 / 0.8 mm | $24.95 |  |

| Stainless Steel Nozzle | Available in 0.4 / 0.6 / 0.8 mm | $15.95 |  |

The FlashForge Creator 4 includes a 12-month warranty for the printer and 3 months for FFF extruder parts. FlashForge provides free replacements for defects, with coverage starting from the manufacture date.

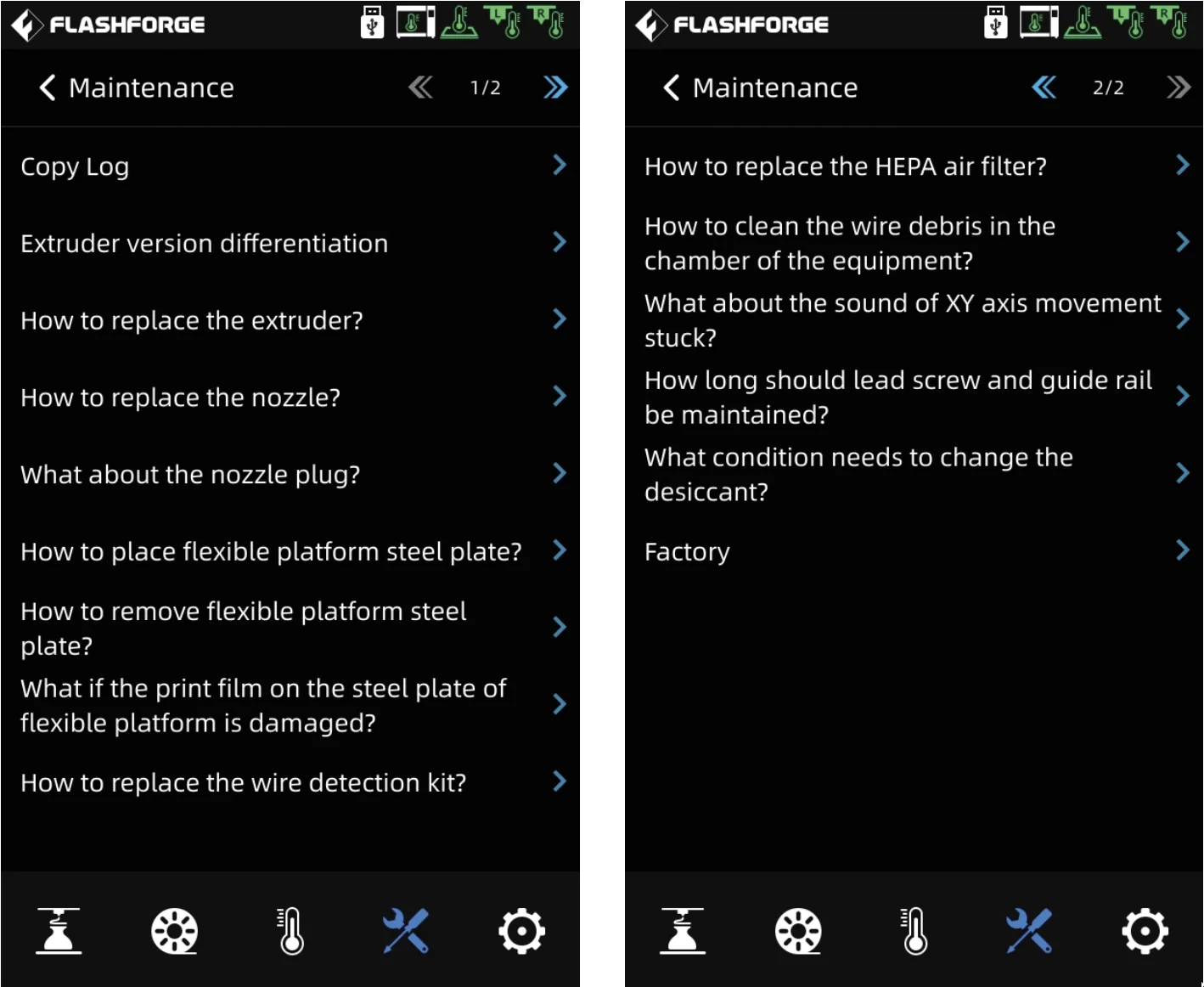

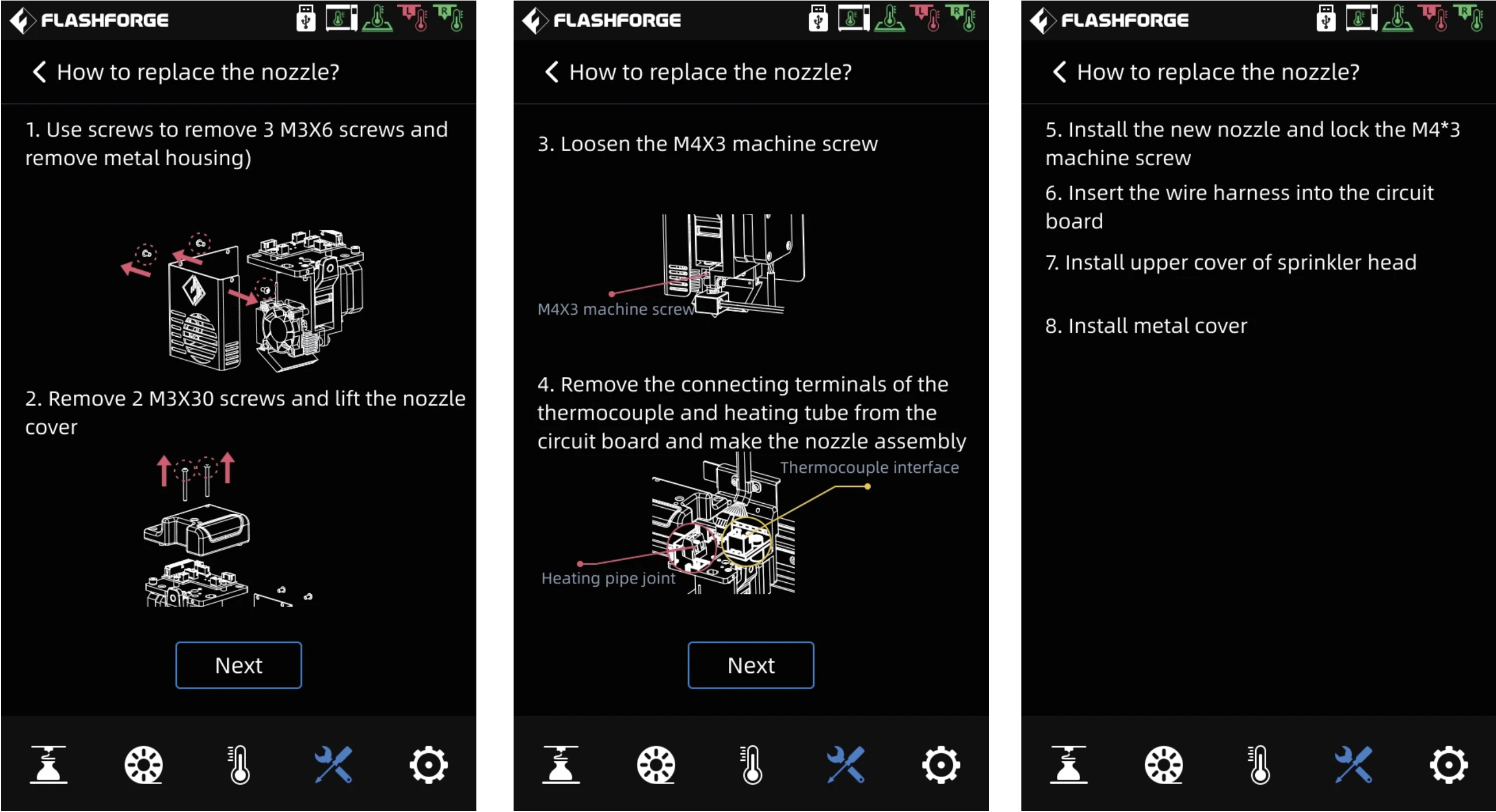

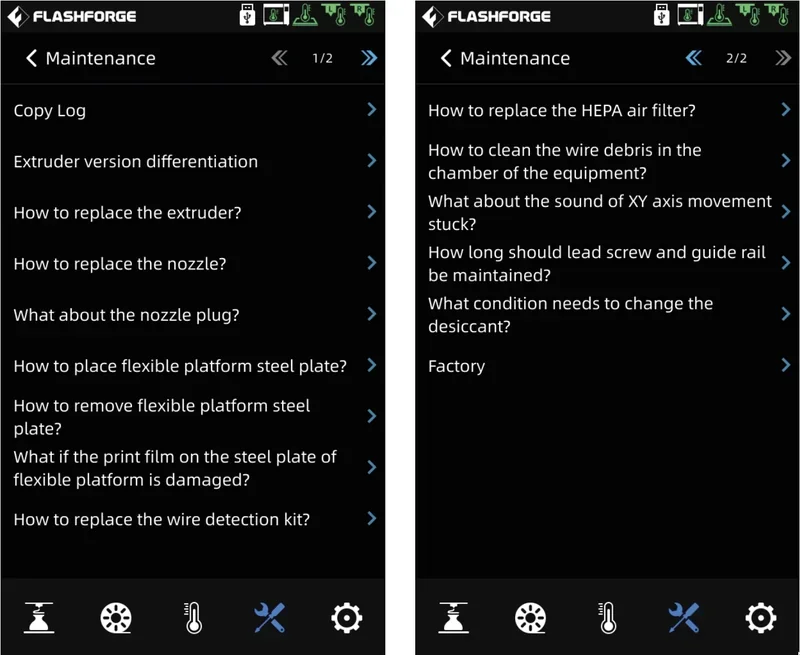

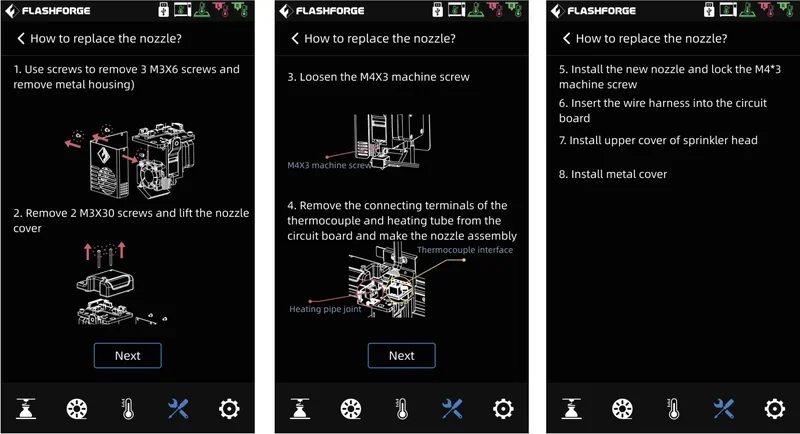

FlashForge provides lifelong free technical support for Creator 4 owners via email (Mon–Sat). Engineers offer remote guidance for complex issues, while the printer’s maintenance screen helps users troubleshoot common problems like nozzle clogs.

Top 3D Shop supports Creator 4 buyers with pre- and post-purchase assistance. Each printer includes a detailed user guide covering setup, operation, maintenance, and troubleshooting. For complex issues, their team coordinates with FlashForge technicians for quick resolution.

Full warranty terms: https://www.flashforge.com/pages/warranty-and-return-policy

The FlashForge Creator 4 3D printer starts at $10,999.00, with final cost depending on configuration. It features IDEX dual extrusion, a massive build volume, and a 65°C heated chamber. The Creator 4A includes a 320°C extruder for engineering plastics, while the Creator 4S uses a 360°C extruder for carbon fiber composites.

For a detailed quote on configuration, service, and installation, contact the Top 3D Shop team.

Update your browser to view this website correctly. Update my browser now