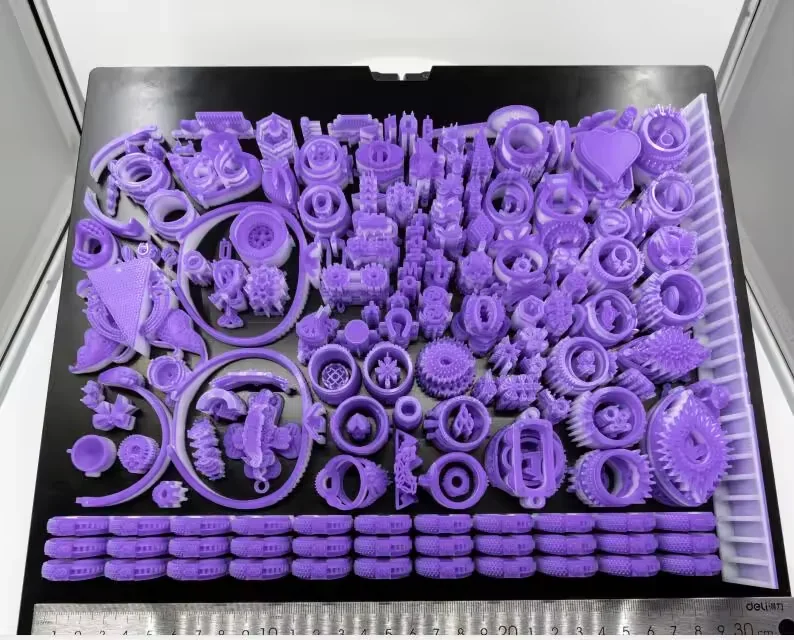

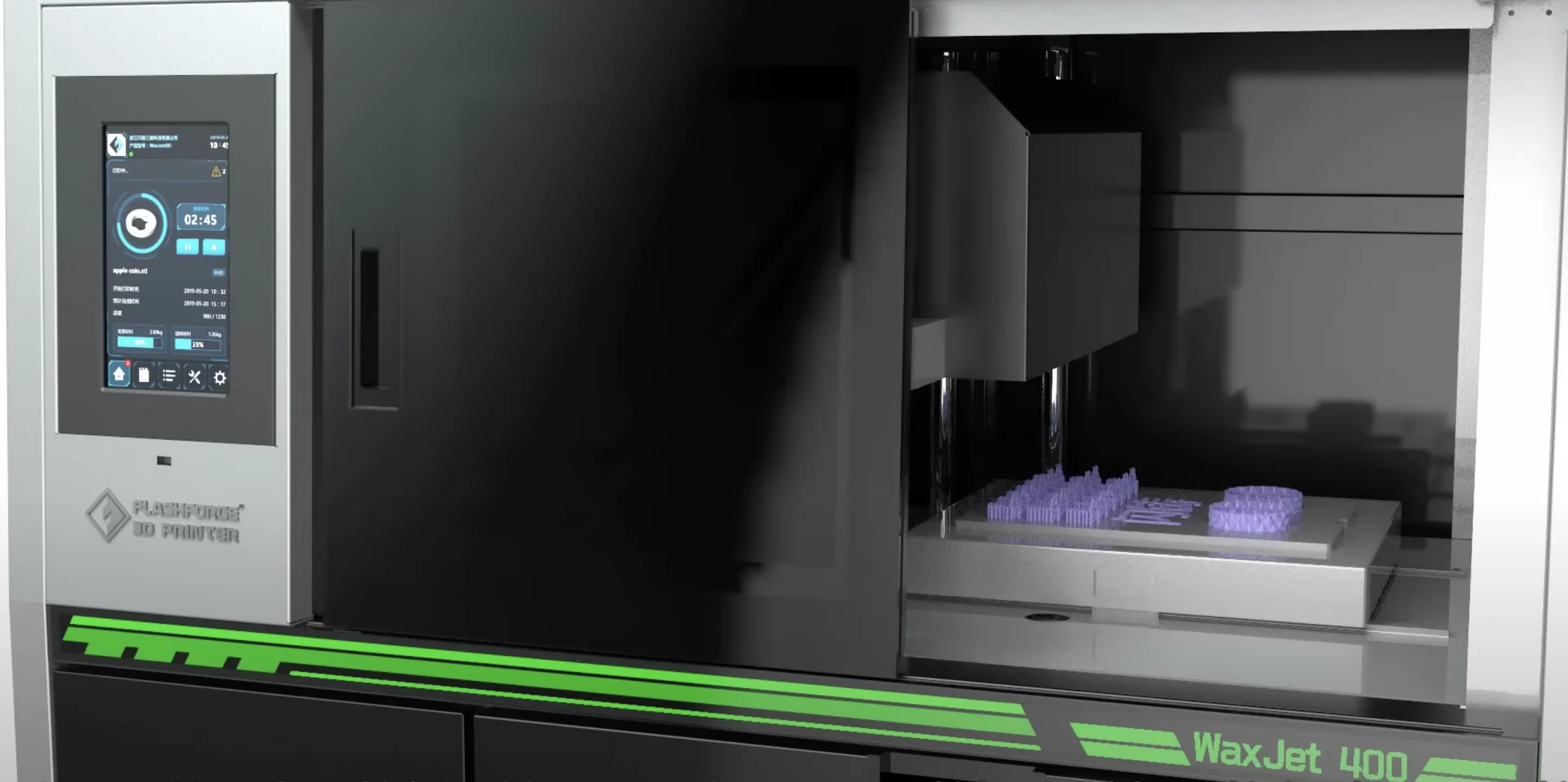

The Flashforge WaxJet 400 is an industrial Multi-Jet 3D printer designed for high-precision wax pattern production, offering ±0.04 mm accuracy, 16-micron layers, and a 1200 x 1200 x 1600 dpi printhead. With a 289 x 218 x 150 mm build volume and automated features like one-button 3D printing, material reloading, and layout optimization, it supports up to 10 kg of monthly output. Ideal for jewelry, precision casting, and art foundry applications, it reduces jewelry production costs by 30% and delivery times by half. It uses three proprietary wax materials—FFWJ1100, FFWJ1200, and FFMS3100—for versatile, detailed, and support-enabled casting.

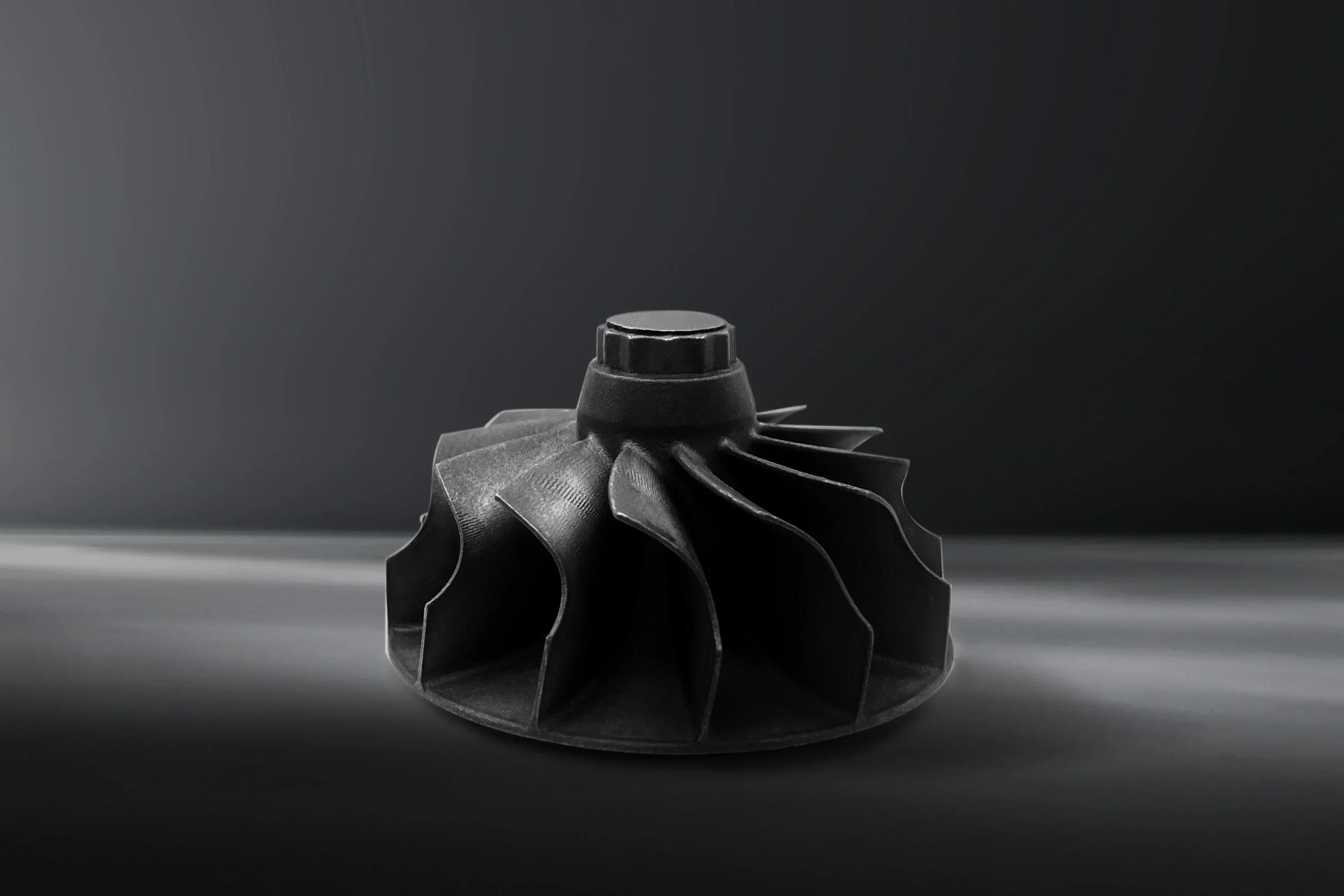

The Flashforge WaxJet 400 uses MultiJet Printing (MJP) to produce wax patterns with 16-micron layers and flawless finishes. Its industrial printhead achieves 1200 x 1200 x 1600 dpi resolution and ±0.04 mm accuracy per 20 mm, ensuring precise, reliable results for investment casting and precision manufacturing.

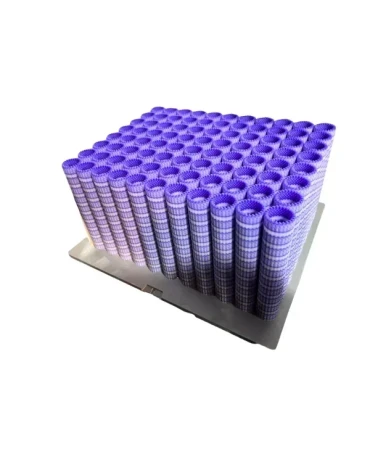

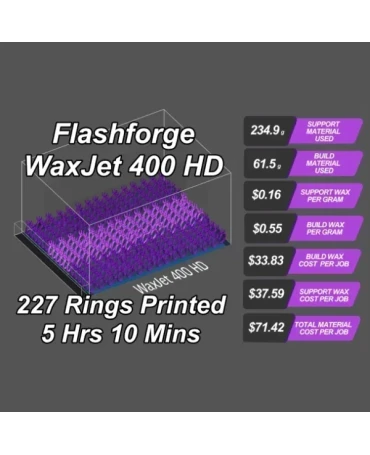

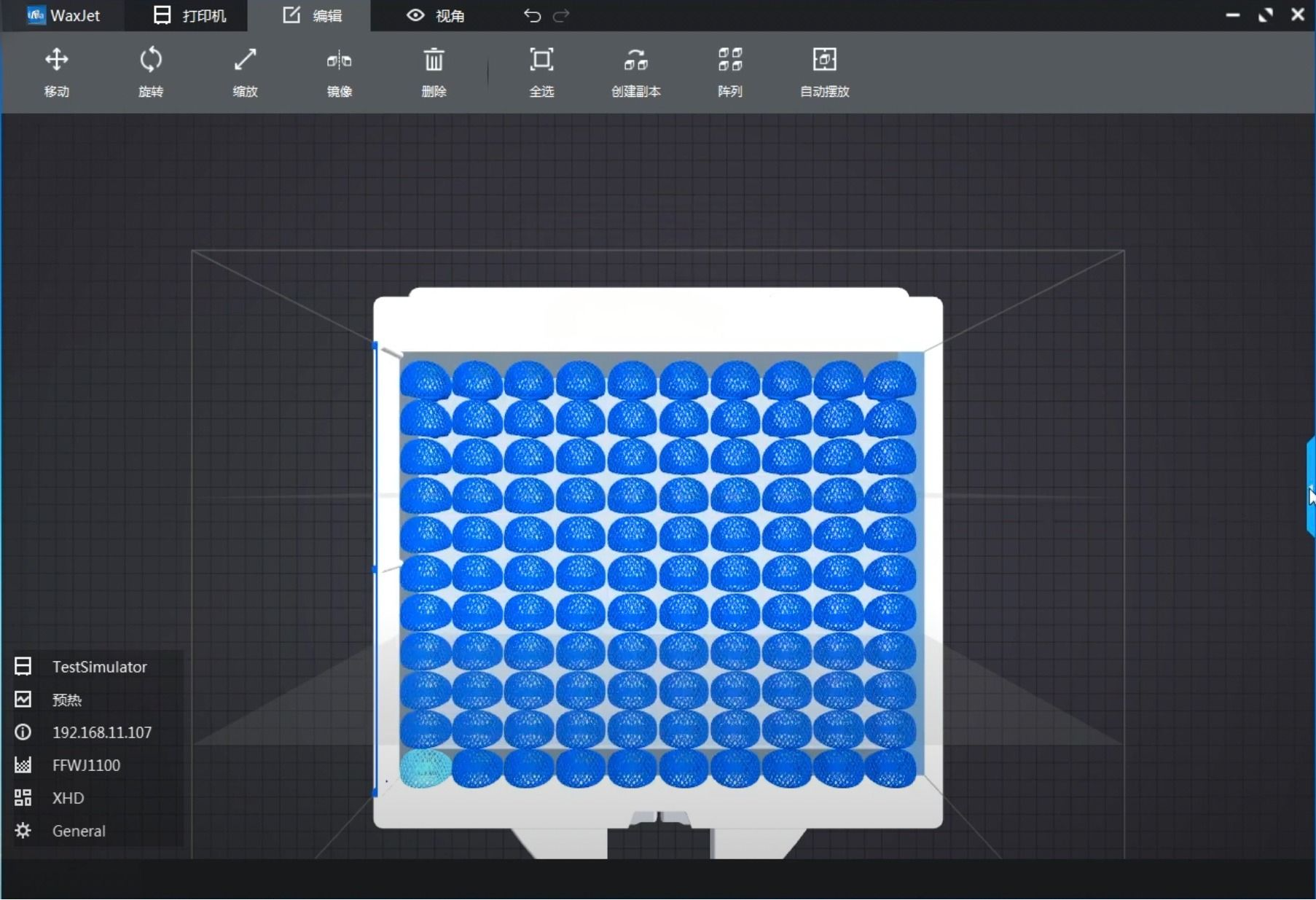

The WaxJet 400 balances quality with efficiency, producing up to 10 kg of wax patterns monthly. Its automated workflow and 3D layout optimization maximize build plate use, boosting throughput while maintaining high standards.

The WaxJet 400 uses three proprietary materials: FFWJ1100 (general-purpose, high stability), FFWJ1200 (dental-specific), and FFMS3100 (dissolvable support). Together, they enable complex geometries with overhangs and internal features while ensuring smooth surface quality.

The WaxJet 400 demonstrates real-world performance by printing a complex 4 cm wheel with curved blades in under 5 hours. Its speed and resolution make it especially valuable for jewelry manufacturing, cutting costs by 30% and delivery times by over half compared to traditional methods.

The WaxJet 400 uses three non-toxic materials: FFWJ1100 (general-purpose), FFWJ1200 (dental), and FFMS3100 (dissolvable support). Designed for MJP technology, they ensure high print quality and compatibility with casting processes.

Each WaxJet 400 material has a defined role: FFWJ1100 (purple) is the primary structural wax for jewelry, precision casting, and aerospace; FFWJ1200 (pink) is tailored for dental casting; and FFMS3100 (white) acts as a dissolvable support, removed in a wax wash during post-processing.

WaxJet 400 materials are engineered for casting with controlled melting points (68°C FFWJ1100, 80°C FFWJ1200, 55°C FFMS3100), low shrinkage (1.10% and 0.90%), and ash content below 0.01%. These properties ensure consistent print quality and reliable casting results.

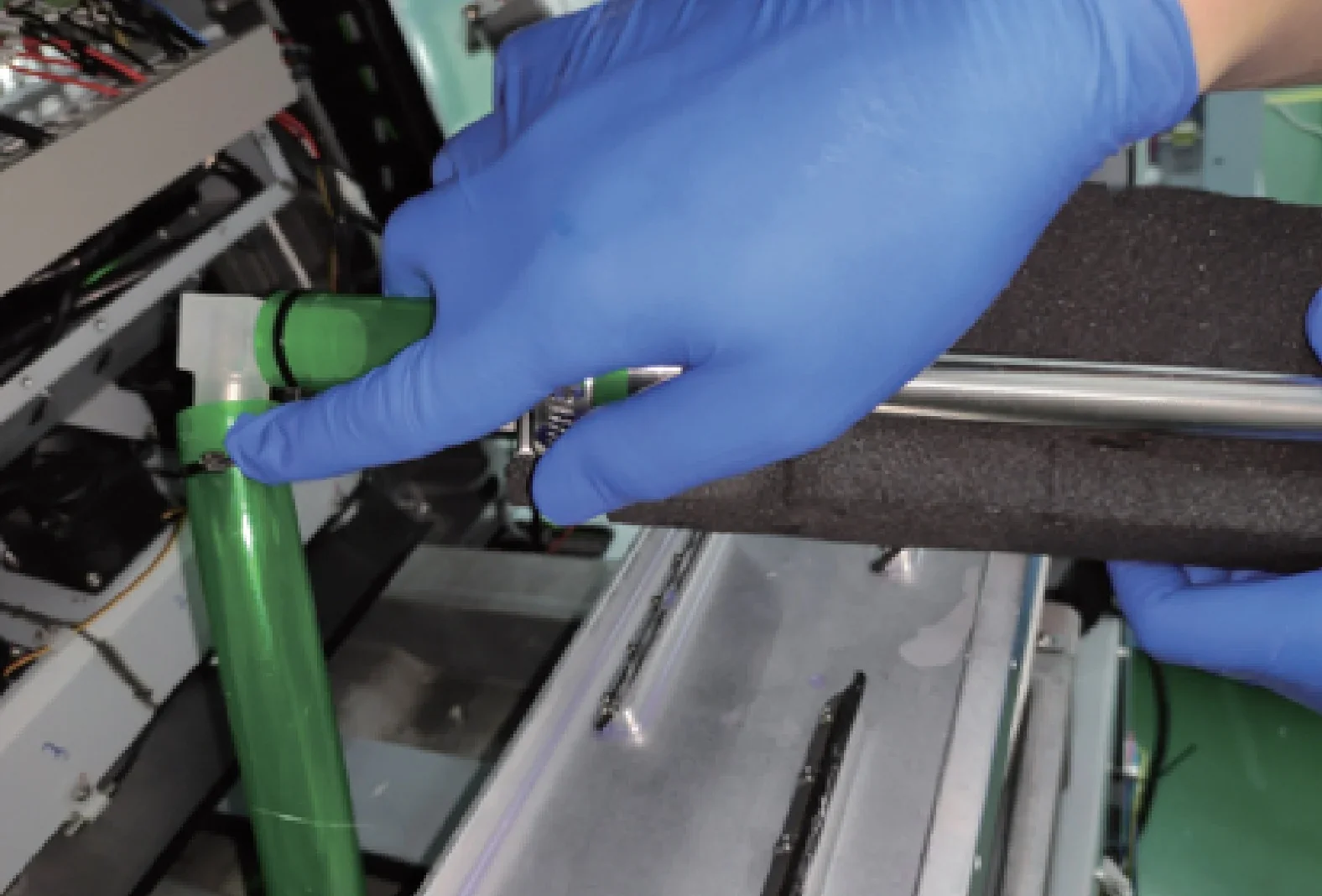

The WaxJet 400’s material management system uses a 2×2 cartridge setup with automatic switching, level monitoring, and low-supply alerts. Built-in warming maintains optimal flow, ensuring consistent material deposition and reliable printing.

The WaxJet 400 has the largest build volume in the series at 289 × 218 × 150 mm, offering greater capacity for mass production and larger patterns. Compared to the WaxJet 510 and 530 (289 × 208 × 100 mm), it provides 10 mm more width and 50 mm more height.

| 3D Printer Model | Build Volume |

| WaxJet 400 | 289 x 218 x 150 mm |

| WaxJet 510 | 289 x 208 x 100 mm |

| WaxJet 530 | 289 x 208 x 100 mm |

The WaxJet 400’s 3D automatic layout optimizes build plate use by arranging parts horizontally and vertically with 0.5 mm spacing (0.5–1 mm when stacked). This maximizes capacity and boosts throughput by fitting more parts into each job.

The WaxJet 400 comes with two build plates, enabling continuous production. While one plate undergoes post-processing, the other can be used for the next job, reducing downtime and increasing output.

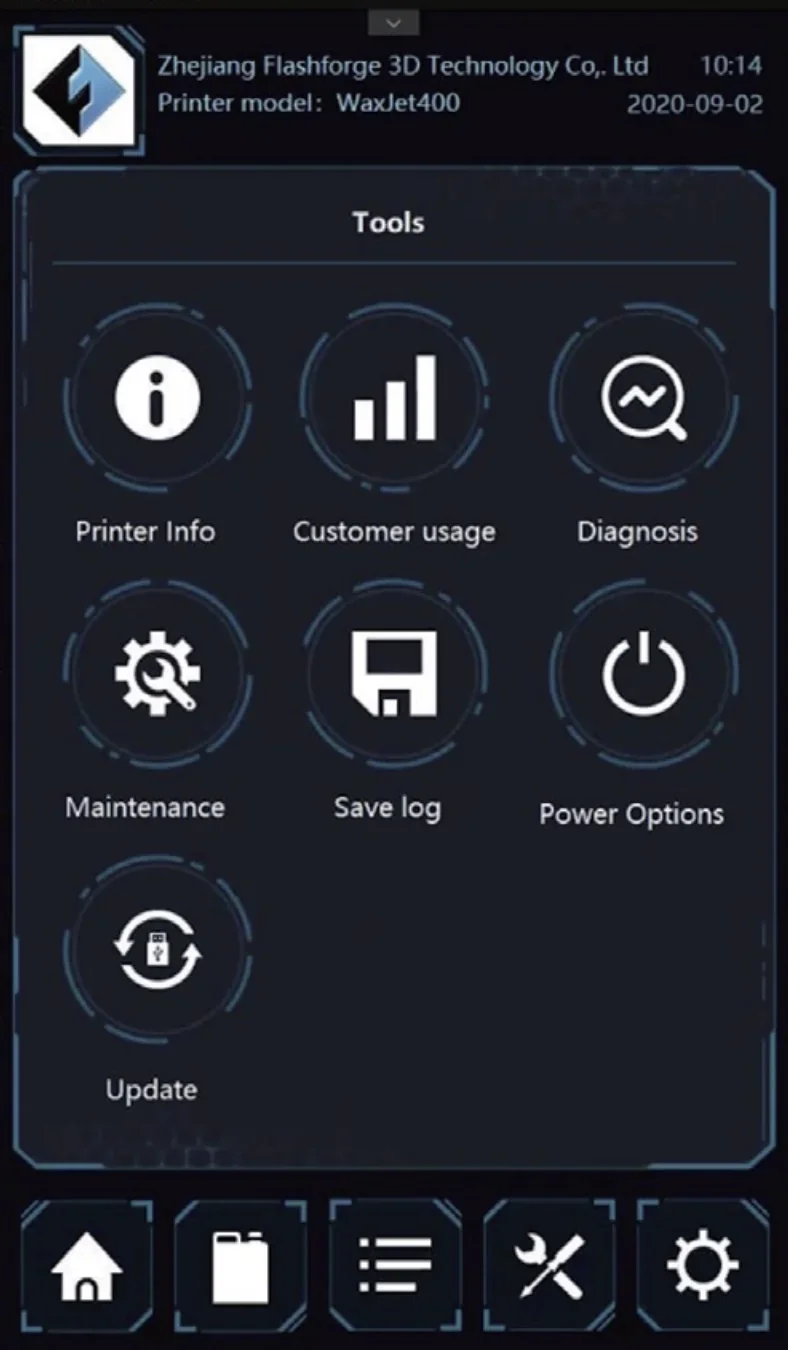

The Flashforge WaxJet 400 features over 25 controls accessible via a 10.1-inch color touchscreen, including print status functions like pause/stop and material level tracking, material cartridge management with four independent bottles, print queue handling for multiple jobs, and diagnostic and maintenance tools such as Z-axis tests and firmware updates.

Print Status (8):

Material Info Controls (3):

Printing List (6):

Tools Interface Controls (7+):

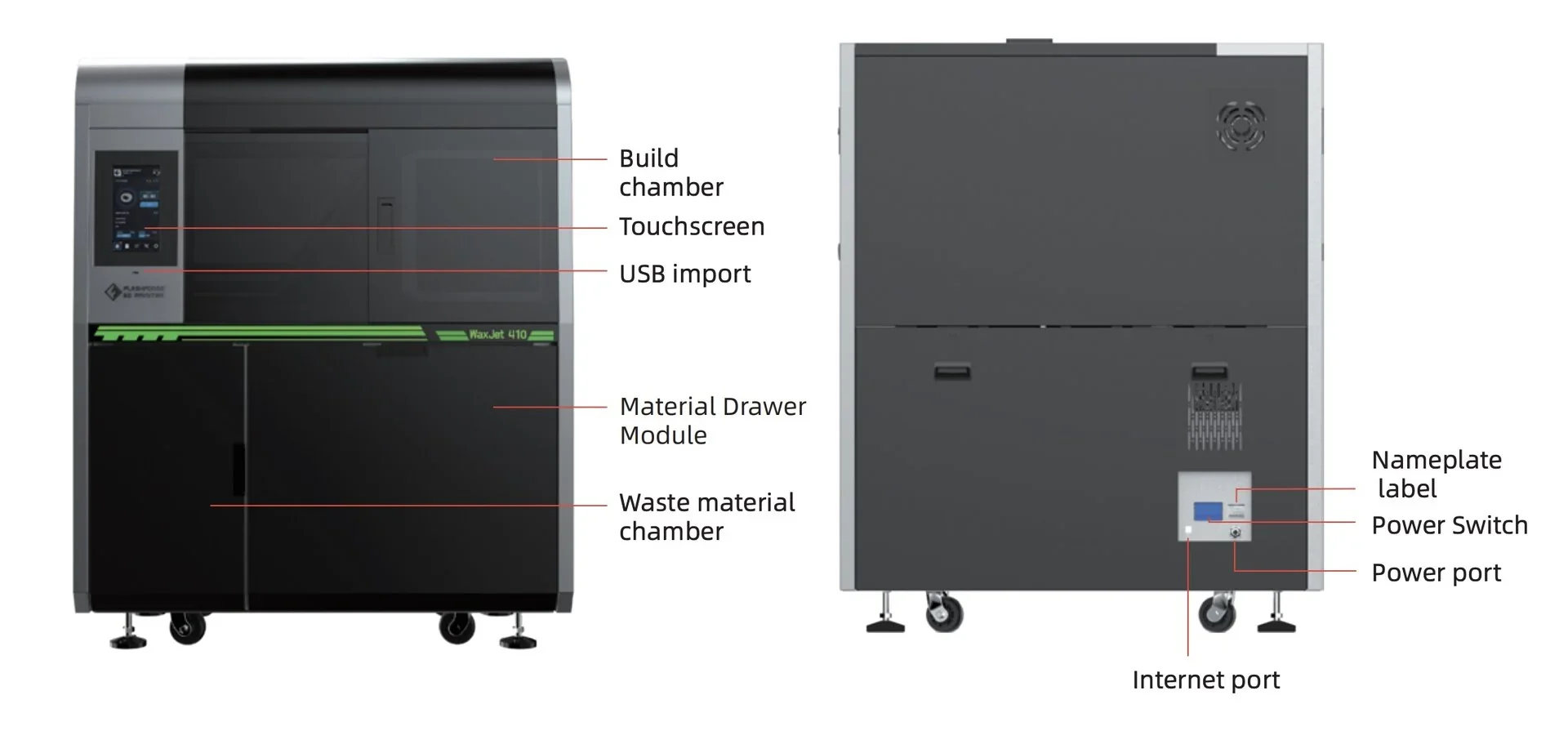

The WaxJet 400 supports USB and Ethernet connectivity. A 10/100/1000 Ethernet port on the back allows direct file transfer from WaxJetPrint software, with a 2 m network cable included for quick setup.

The WaxJet 400’s USB port supports file transfer from storage devices and firmware updates via the Tools menu. An email notification system can alert up to four recipients about job completion, errors, or maintenance needs, keeping operators informed remotely.

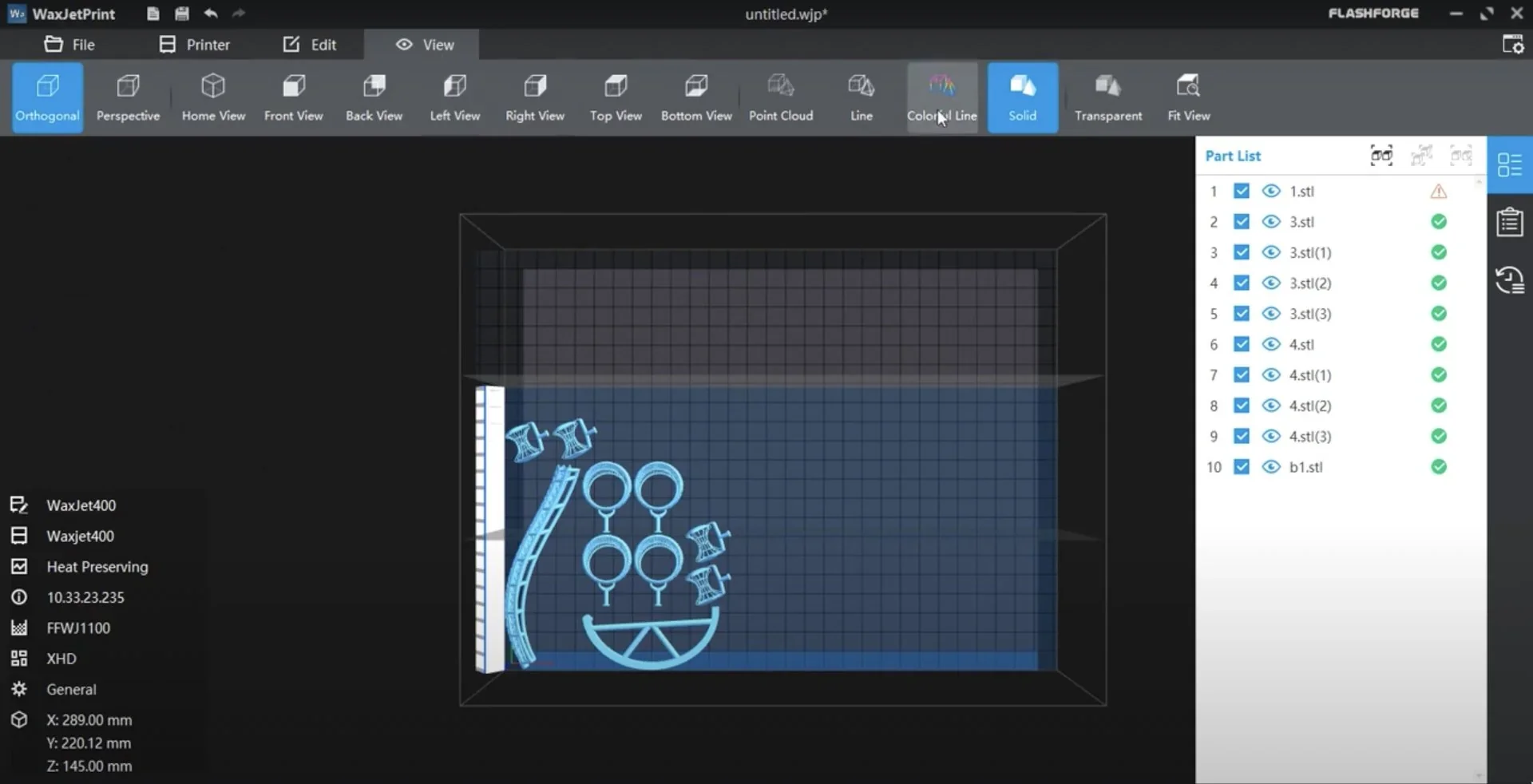

The WaxJet 400 uses WaxJetPrint software, built for its MJP technology. It converts STL and SLC files into WJS format and offers automatic 3D layout placement for optimized part positioning. Users can batch import models, adjust attributes, and select areas for auto-placement.

WaxJetPrint supports shrinkage compensation, letting users adjust X, Y, and Z values to correct dimensional changes in wax printing. Default values for FFWJ1100 are 100.9% (X), 100.6% (Y), and 100% (Z). The software runs on Windows 7/10 (64-bit), connects via network for direct file transfer, and works with the printer’s USB firmware update function.

Download it here: https://eu.flashforge.com/blogs/download-firmware/wax-jet-400

The WaxJet 400 has an industrial build measuring 1352 × 775 × 1600 mm and weighing 480 kg. Its black-and-gray design suits professional settings. Four casters provide mobility, while leveling feet lock and stabilize the printer for precise operation.

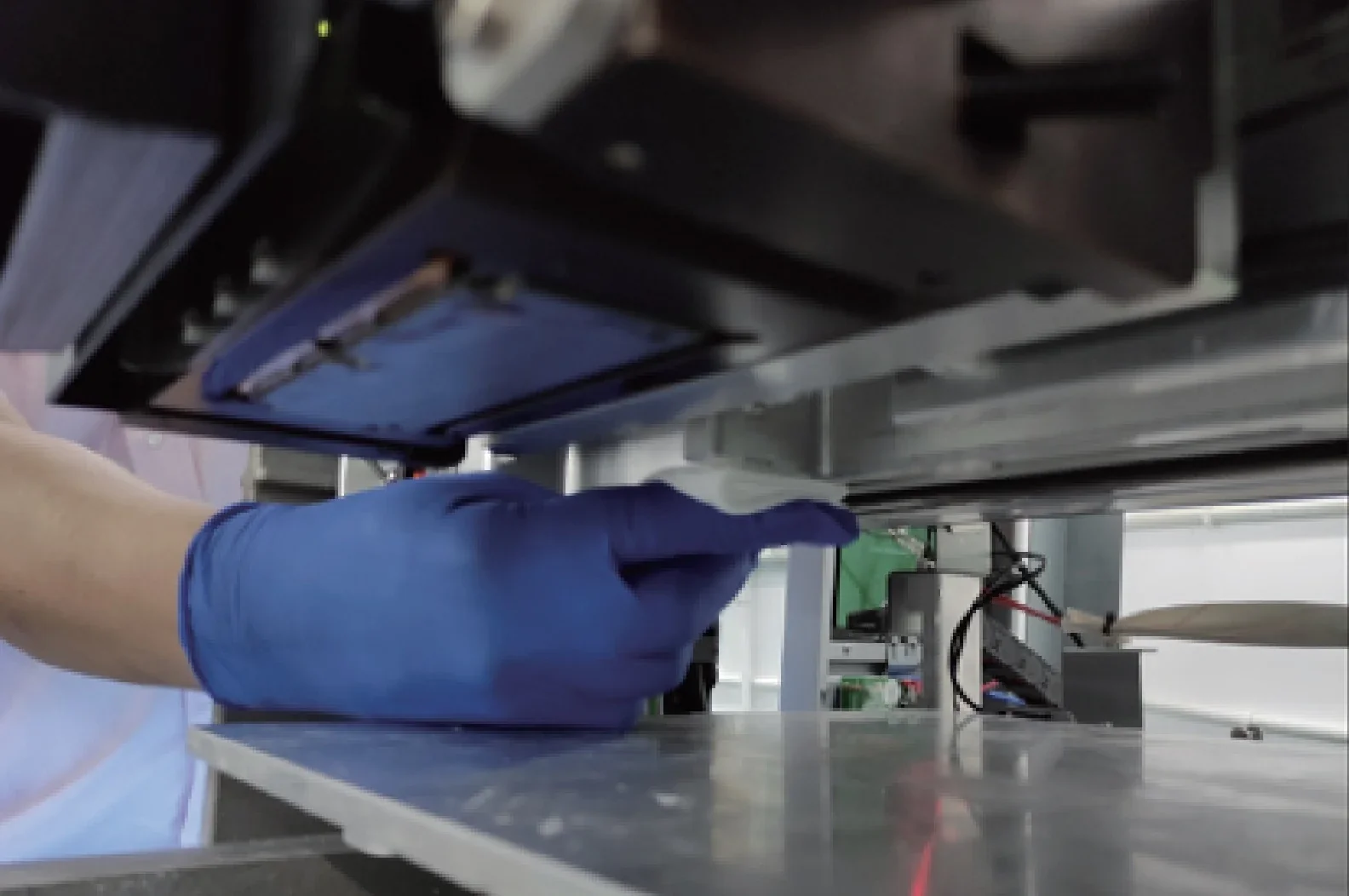

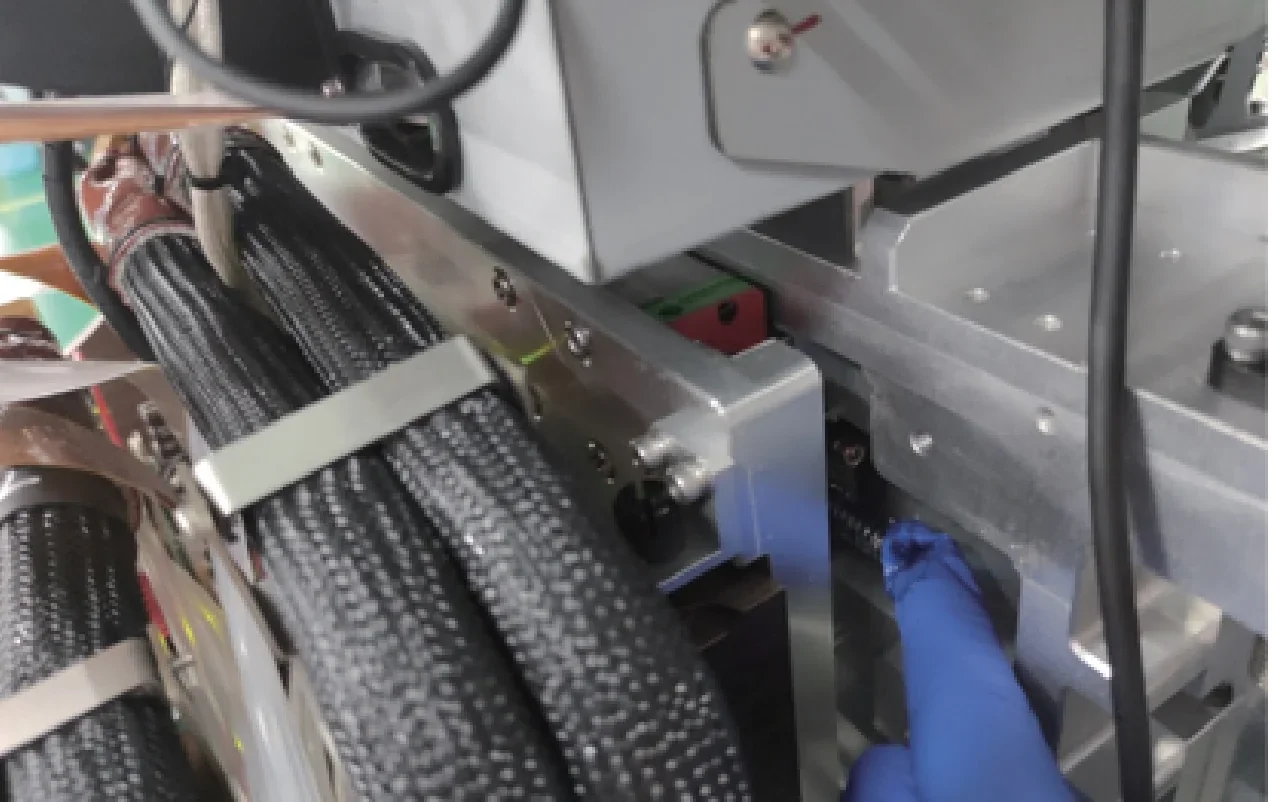

The WaxJet 400 is built with precision components for wax printing, including lubricated X, Y, and Z guide rails for smooth motion and easy maintenance access. Its 2×2 cartridge system uses push-to-open doors for secure, convenient material handling.

The WaxJet 400 includes efficiency-focused design features: a sealed, transparent build chamber door for visibility and temperature control, plus an accessible waste chamber with a removable box for easy cleaning.

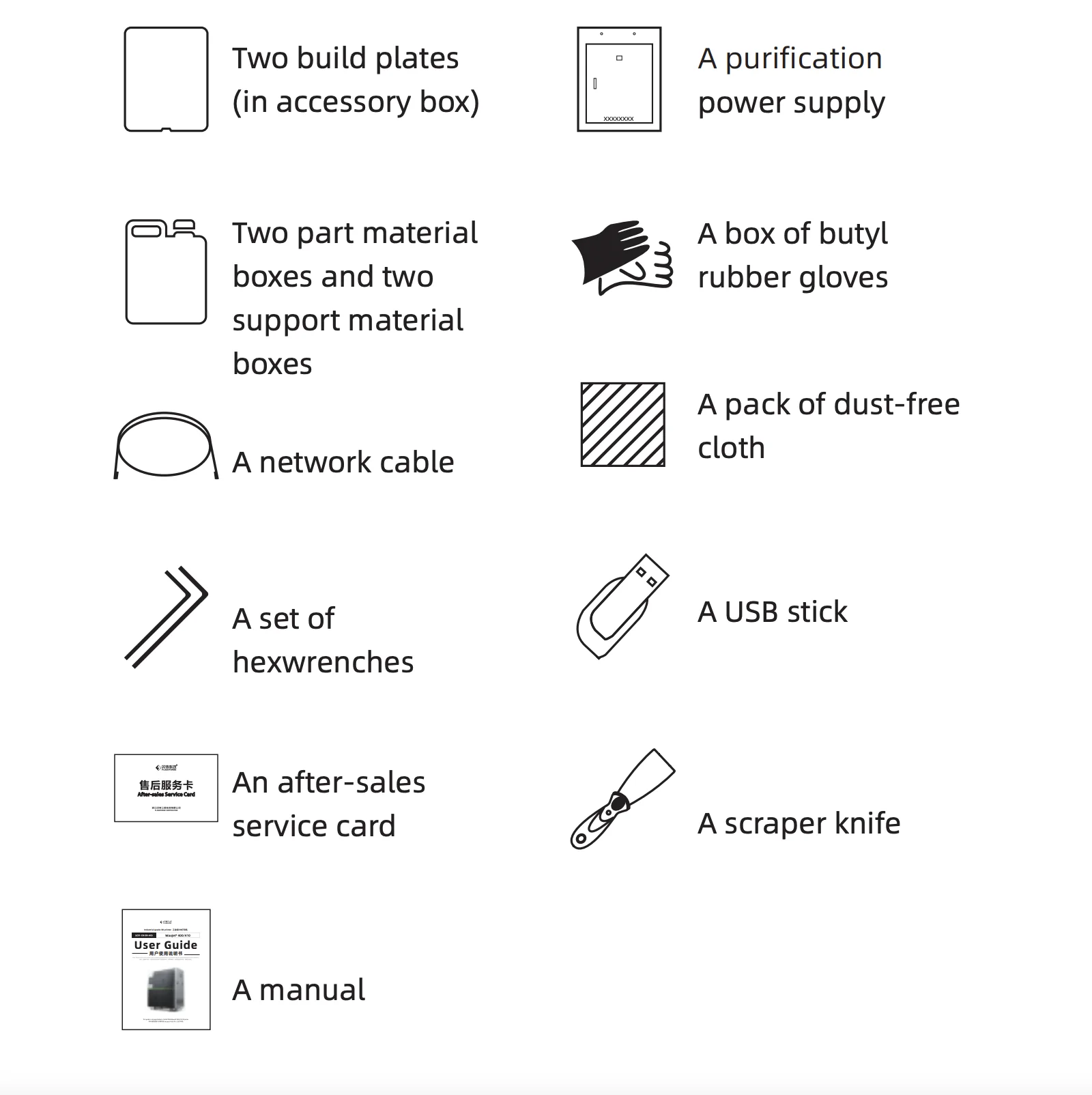

The WaxJet 400 ships production-ready with all essentials. Two build plates support continuous workflow, while starter supplies include two bottles each of FFWJ1100 and FFMS3100 for initial runs. A toolkit with gloves, dust-free cloth, and other accessories supports safe handling, maintenance, and post-processing.

Note: Package contents may vary by manufacturer without notice. Please confirm current inclusions with a Top3DShop sales representative before ordering.

The WaxJet 400 uses proprietary waxes (68 °C, 80 °C, and 55 °C dissolvable support) along with maintenance items like build plates and filters, plus post-processing tools including magnetic stirrers, solvents, and lab containers for reliable printing and finishing.

| Consumable | Description | Application | Compatibility |

|---|---|---|---|

| FFWJ1100 | 100% wax, 68 °C melting point | General-purpose casting (jewelry, precision parts) | Fully compatible with WaxJet 400 |

| FFWJ1200 | 100% wax, 80 °C melting point | Dental casting | Fully compatible with WaxJet 400 |

| FFMS3100 | Dissolvable support wax, 55 °C melting point | Support structures for all applications | Fully compatible with WaxJet 400 |

Additional accessories for the WaxJet 400 include replacement build plates to support continuous production and consumable maintenance items required for optimal performance.

| Maintenance Item | Description | Purpose | Replacement Interval |

|---|---|---|---|

| Initial Filter | Filter element | Removes fumes/particles | Every 6 months |

| Dust-Free Cloth | Non-abrasive cloth | Cleans sensitive parts | As needed |

| Rubber Gloves | Nitrile gloves | Safe material handling | Single use |

Post-processing accessories support the WaxJet 400’s wax printing workflow, ensuring smooth cleaning and finishing of printed parts.

| Post-Processing Item | Description | Function | Compatibility |

|---|---|---|---|

| Magnetic Stirrer | Temp-controlled mixer | Keeps solvent at optimal temperature | Required for support removal |

| Wax Dissolution Solvents | Specialized cleaning solutions | Dissolves support material without harming parts | For FFMS3100 support wax |

| Beakers and Containers | Lab-grade vessels | Hold solvents during post-processing | Standard lab equipment |

For current pricing and availability of WaxJet 400 consumables and accessories, please contact our sales team.

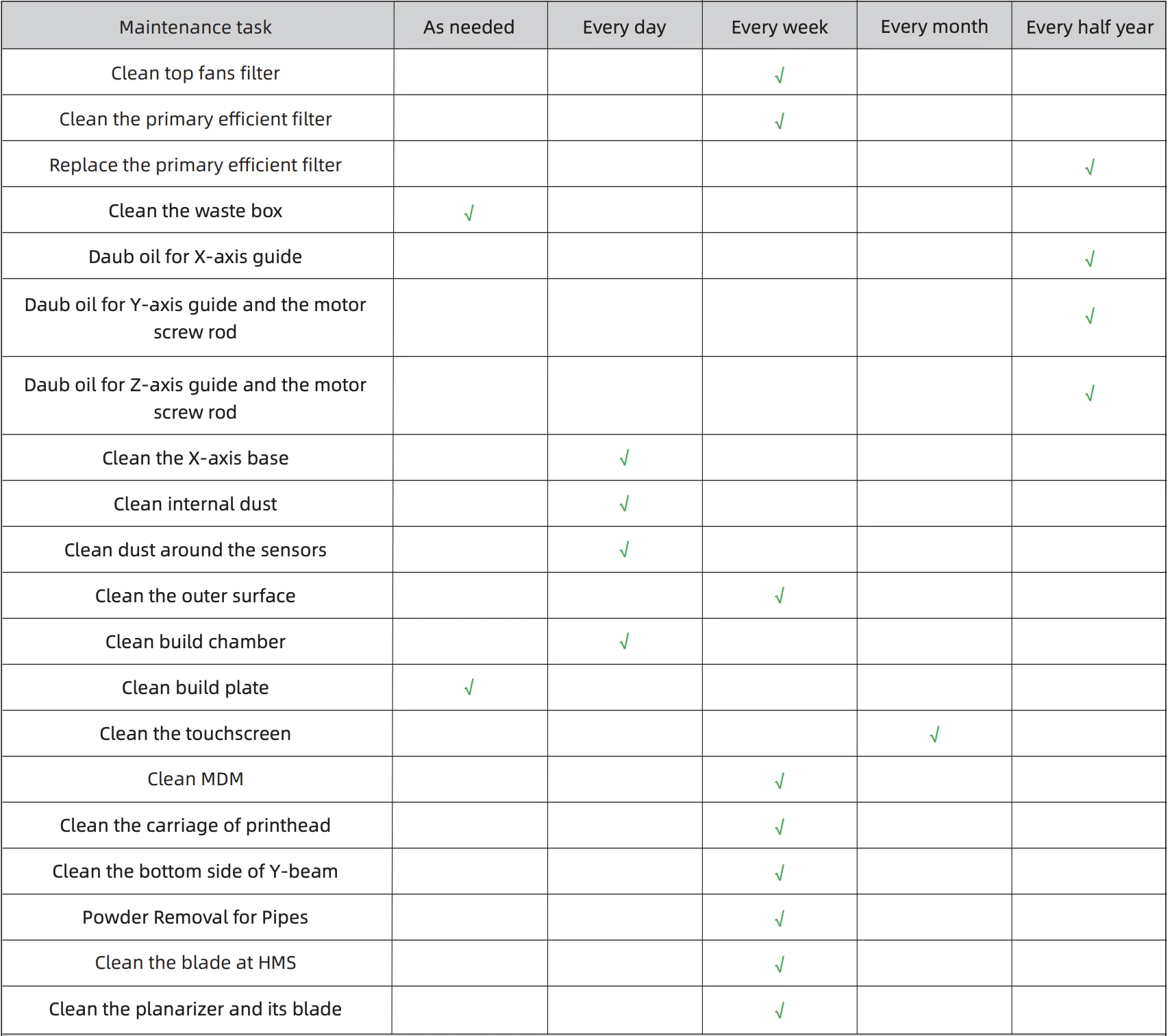

Daily:

Weekly (11 tasks):

Monthly:

Semi-Annual:

The WaxJet 400 ensures reliability with a diagnostic system and structured maintenance to prevent failures. It operates best at 18–24 °C and 30–70% humidity, with sensors monitoring 16 fault types such as printhead blockages and material issues. Automated recovery and built-in tools—like Z-axis tests, purge cycles, and printhead maintenance—help operators resolve problems without external support.

Reliability is further supported by targeted maintenance, such as printhead dredging with isopropanol wipes and automated purge cycles to clear blockages.

The WaxJet 400’s material system uses proper bottle installation and RFID tags to prevent errors. Troubleshooting guides cover print quality, material delivery, and mechanical issues with step-by-step recovery, reducing downtime and ensuring consistent output.

The WaxJet 400 includes a 12-month limited warranty from installation, covering defects and failures under normal use with free parts or repairs. Extruder components carry a separate 3-month warranty as consumable parts.

Support for the WaxJet 400 is available by phone (+86 579 82273989) or email (support@flashforge.com). The printer also saves operation logs, which can be shared with support teams for remote troubleshooting.

Buying the WaxJet 400 through Top3DShop adds local support via phone, email, and live chat (Mon–Fri). This complements Flashforge’s own service, giving customers both manufacturer expertise and local assistance.

The Flashforge WaxJet 400’s cost is available by quotation and is designed to reduce jewelry production expenses by 30% and delivery times by over 50%. For pricing, click Request a Quote and a Top3DShop representative will provide details on cost, installation, training, and support.

Update your browser to view this website correctly. Update my browser now