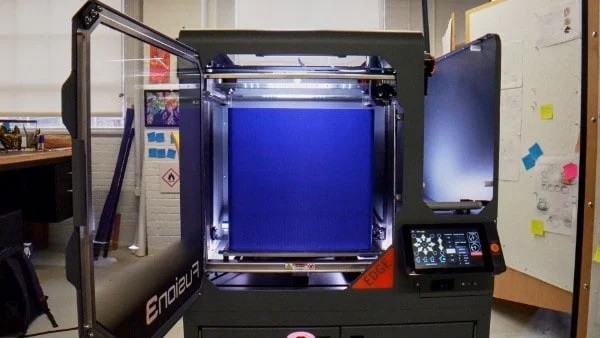

The Fusion3 Edge is a professional FFF 3D printer for affordable, effective, and completely safe use in business and education. The machine boasts durable construction with reliable kinematics and powerful control system. It can be equally deployed by novice and experienced users in various environments.

The Fusion3 Edge is engineered with a large build area of 368 x 368 x 343 mm that meets most manufacturer’s printing needs. Its enclosed design, 320 °C extruder, multi-zone heated bed, and passively heated chamber (max. 70 °C) allow for a wide range of materials with temperature-sensitive and engineering properties. With the minimum layer height at 20 microns, the machine is able to rapidly produce high-quality parts in fine detail. Its print speed reaches 250 mm/s. All these peculiarities make the new Edge model a highly efficient tool in terms of its price and performance.

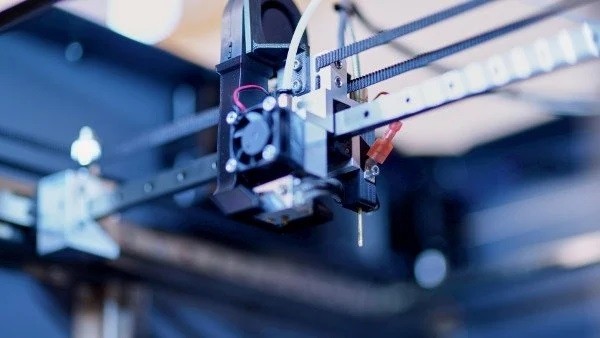

The device offers multiple advanced features, such as a fast 3D printing mode for certain materials (200 mm/s, 0.4 mm tube), new mesh bed leveling system with an ultra-light touch probe, upgraded V3 extruder with active cooling and improved grip, remote management tools, intuitive software with optimized material profiles, door interlock function, optional HEPA and Carbon air filters, low operating noise of only 37.5 db, and optional heavy-duty rolling cart.

The Fusion3 Edge is perfect for educational and professional use in manifold spheres, including aerospace, automotive, metal fabrication, and other major industries.

Read on to find out more about the printer.

The Fusion3 Edge can print layers at 20 microns. With it, you can produce parts with smooth exterior surfaces, complex geometry, and detailed composition.

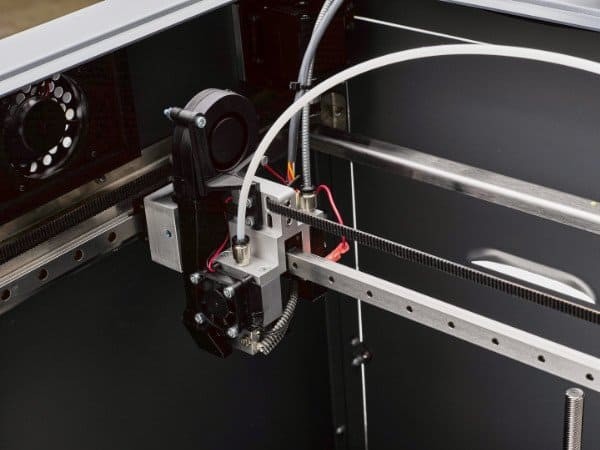

Thanks to the reliable F-Series Platform with upgraded motion control components, such as new linear rails, Gates 2GT2 belts, and specially tuned stepper motors, the machine boasts increased printing stability, tight tolerances, and impressive speed of production at 250 mm/s.

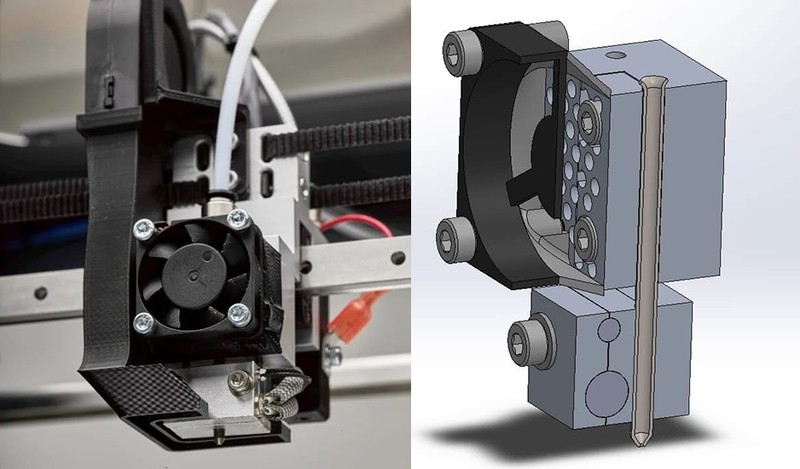

The fast printing comes with an exceptional level of detail due to the Fusion3’s patent-pending Anvil printhead system. It features interchangeable surgical steel print tubes used instead of the traditional screw-in 3D printer nozzles. Being inexpensive, easy to swap, and wear-resistant, these tubes increase accuracy and speed of printing as well as reduce the risk of leakage inherent to traditional nozzles.

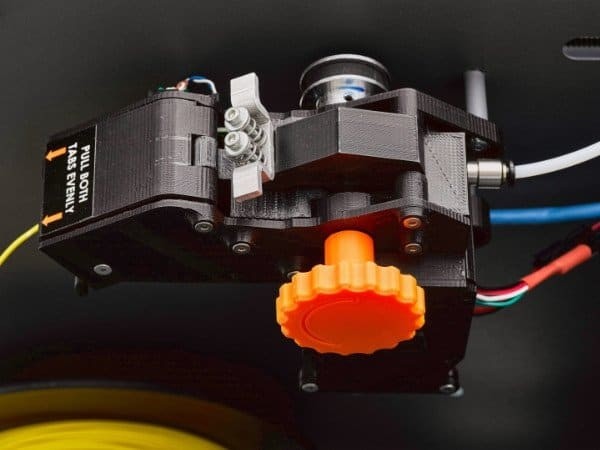

Finally, the Fusion3 Edge offers an upgraded V3 extruder that uses a belt drive system and a filament detection monitor to make printing smoother and easier. Alongside with the new linear rail system, quality build plate, and automated bed leveling ensuring a near-perfect first layer, the machine presents an increasingly durable system for work in the most demanding environments.

The Fusion3 Edge uses standard 1.75 mm filament, providing you with a wide choice of consumables from a variety of suppliers.

Due to the three extruder options (0.4, 0.6, and 0.8 mm) and passively heated enclosed build chamber (up to 70 °C), the printer supports different types of materials, including high-temperature, engineering-grade filaments with the highest melt temperature at 320 °C.

Overall, with the standard aluminum build plate with glass print surface, the machine supports the following materials: PLA, ABS, ASA, Carbon Fiber, Kevlar, Fiberglass, Flexible, Nylons, PET/PETG, Polycarbonate, and more. Additionally, the optional magnetic plate allows printing with Polypropylene, PVDF, and 316L Stainless Steel.

The massive build area of 14.5 x 14.5 x 13.5 inches (368 x 368 x 343 mm) lets you print a single large model or simultaneously produce several smaller ones.

The Fusion3 Edge is equipped with a 7" full color touchscreen with enhanced sensitivity featuring a clear user-friendly interface with all necessary information and robust remote management tools, including maintenance reminders.

The printer’s connectivity options include USB and Ethernet for the Secured Version (for companies, government, military, and similar organizations with strict information security guidelines) as well as additional Bluetooth and Wi-Fi options for the Standard one. Moreover, the Secured Edge provides offline activation of the operating software, which does not require Internet connection for updating.

The machine uses the proprietary Fusion3 Reactor slicer. It has many standard tools for 3D printing plus several unique features, such as streamlined interface, adaptive printing algorithms, flexible settings for different parameters, real-time updates, and optimized profiles for each material. The program works with the STL and OBJ file formats. The Reactor software runs on Windows only.

The Fusion3 Edge 3D printer is available in gray. Its stylish look makes it ideal for small businesses, rapid manufacturing, end-user production, and education.

The printer dimensions are 25.9 x 28.3 x 25.2 in (657 x 720 x 640 mm). It weighs 65 lb (38.56 kg). The filament spool holder is mounted on the side internally.

To learn the current price of the Fusion3 Edge 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now