The Korean Hanwha manufacturer produces a series of collaborative robots (cobots) aimed at streamlining any manufacturing process. The series includes the HCR-3, HCR-5, and HCR-12 models. Their names depend upon the maximum payload they can lift up, respectively 3 kg, 5 kg, and 12 kg. The HCR cobots are small, sleek, and lightweight. They feature smart sensors, safety functions, and rounded edges. Thus, they can safely and effectively interact alongside humans. The leading model, the HCR-5, comes with a Cleanroom certification (ISO class 5).

Composed of six-articulated arms, the HCR-3, the HCR-5, and the HCR-12 grant optimal space utilization requiring only minimal space installation. The HCR-5 and HCR-3 can be mounted to a wall or ceiling or can be installed on the floor. The HCR-12 can only be mounted to a wall or installed on the floor. They are a perfect fit for every small workspace difficult to reach by an operator.

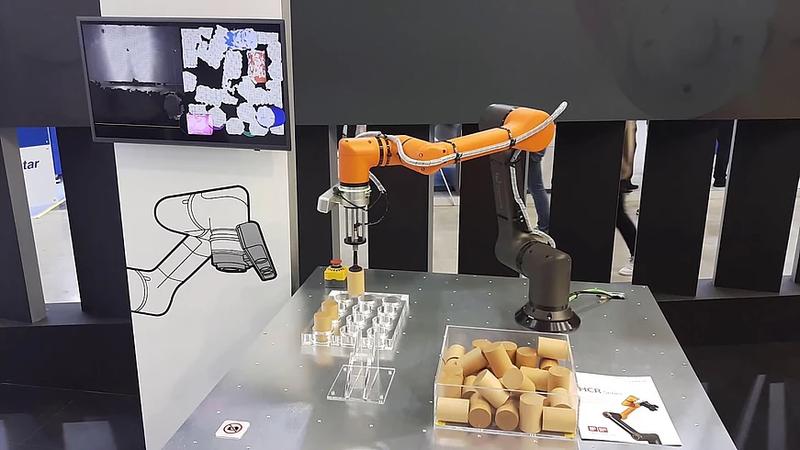

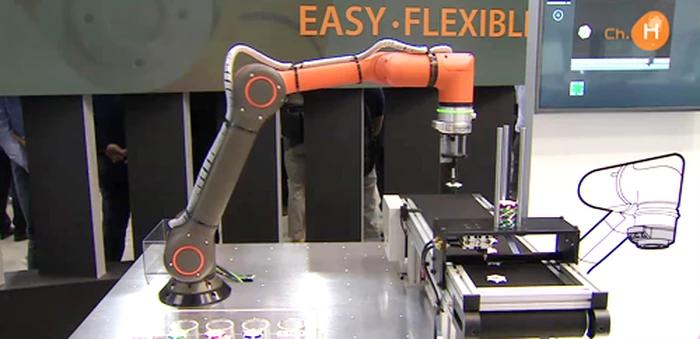

Hanwha HCR cobots are easy-to-install and use even by unskilled operators. They are an effective yet flexible solution for the automation of repetitive and dangerous tasks. Also, they can be easily redeployed to diverse applications. By adopting a Hanwha HCR cobot, you will conveniently cut the operating costs boosting your productivity.

Their end joint supports infinite rotation making them perfect for assembly applications, polishing, screw driving as well as pick-n-place and palletizing. Continue reading to find out more about the series.

Hanwha HCR devices are effective collaborative robots. They adopt a six-axis articulated arm, which is extremely simple to operate. It can reach a distance of up to 1,300 mm (HCR-12). The initial joints can rotate at 360°, while the end wrist is capable of infinite rotation.

They are packed with an interesting safety feature-set. It includes collision detection, impact mitigation to prevent jamming, rotation and speed secure limits. It also features a smart safety stop that comes into operation after 10 seconds. This gives you the possibility to push the arm out of the way. Then, after resuming the software, the cobots automatically reset the arm to the starting position.

Hanwha precision HCR machinery can be applied to a variety of industries. They are ideal to perform dull jobs, repetitive tasks or dangerous operations. They can safely work side-by-side with human operators maximizing productivity and creating a safer environment. The HCR series is adopted in several fields to perform a range of applications. Such as:

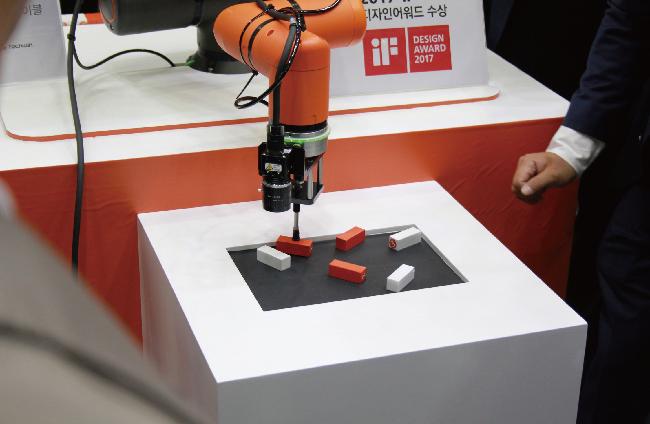

The collaborative robots can effectively perform monotonous tasks, such as pick & place in small-batch production. Indeed, they can easily transfer and load products of diverse angles and positions.

They can directly load and unload processed items in pressing or milling. The ability to place each product in the most accurate position grants optimal accuracy.

Machine tending is a dangerous job. The use of a cobot improves your productivity while reducing the risk of accidents.

The infinite rotation makes them ideal for assembly applications and polishing. For example, they are a useful solution for screwing and assembling components, providing accurate positioning and uniform strength. They can be configured with a range of tools to suit different processes.

With a dedicated tool, they can polish various surfaces granting uniform position and pressure. Thus, they are capable of delivering high, uniform finish quality.

The advanced technology adopted by the HCR-5 makes it ideal for collaborative work. It is able to pack various items in a fast and precise way improving the stability of the packaging lines.

Along with the other cobots, HCR-3 and HCR-12, it can even stack the products in a row onto dedicated pallets. The cobots are able to load the items in the exact position reducing the risk of human error.

Painting, dispensing and quality inspection are also other tasks the HCR series can easily perform.

The robots can be controlled using the proprietary operation software, Rodi. Its intuitive icon-based GUI lets anyone efficiently control both the device and peripheral systems. It enables easy programming with hand-guided teach function or conventional programming.

A LED light ring keeps you constantly updated about the robot status.

The 12-inch teaching pendant lets you easily call up the programs of each installed accessory. You can access them via a simple I / O digital or analog connection.

For some items, package content may change. In case of any questions, please get in touch.

Hanwha HCR series shows a black and orange arm. Its stylish, sleek look makes it ideal for several industries, including small-to-medium enterprises, medical businesses, and mid-scale companies producing different items in small batches (plastic, machine, electronics, and research).

Each arm has a footprint of Ø 5.1 inches (Ø 130 mm). The HCR-3 arm weighs 28.5 lb (13 kg) without cable and can reach up to 630 mm. The HCR-5 arm weighs 46.3 lb (21 kg) without cable and can reach up to 915 mm. The HCR-12 arm weighs 116 lb (53 kg) without cable and can reach up to 1300 mm.

To learn the current price of cobots, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now