The Intamsys Funmat HT Enhanced is a desktop industrial 3D printer designed for high-performance thermoplastics like PEEK and ULTEM, offering industrial-grade parts at a lower cost. It features a 90°C chamber, 160°C heated bed, 450°C extruder, and upgrades like auto bed leveling and a glass-ceramic build plate for strong adhesion and reliability. With a 260 x 260 x 260 mm build area and 50-micron resolution, it delivers accurate, durable prints ideal for industries needing heat- and chemical-resistant parts.

The Funmat HT Enhanced prints at 50–300 microns with XY accuracy of 12.5 microns and Z accuracy of 1.25 microns. The calibration model below displays high dimensional accuracy, absence of fissures and cracks that can happen due to under-extrusion, as well as high print quality of the fine details.

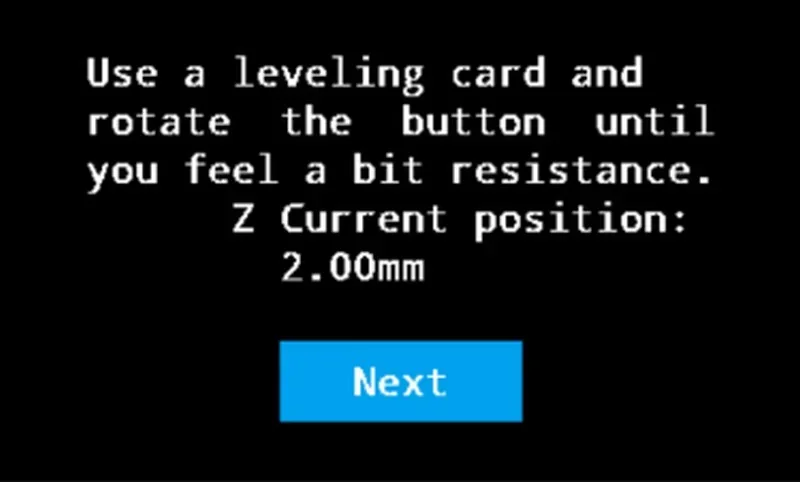

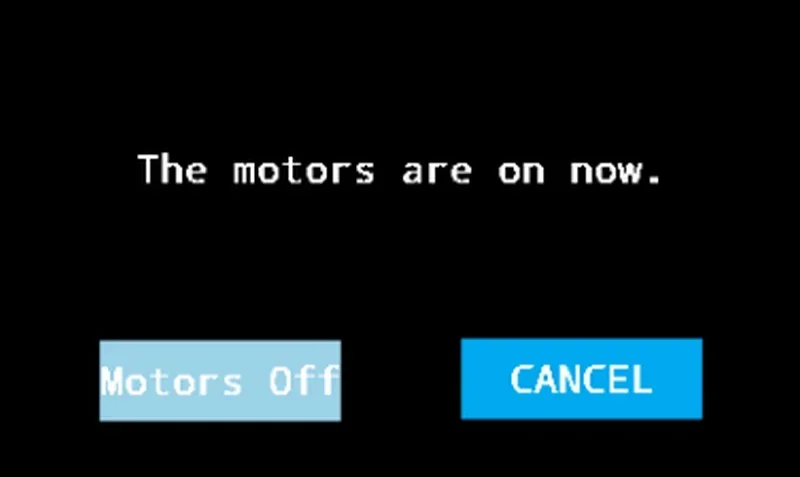

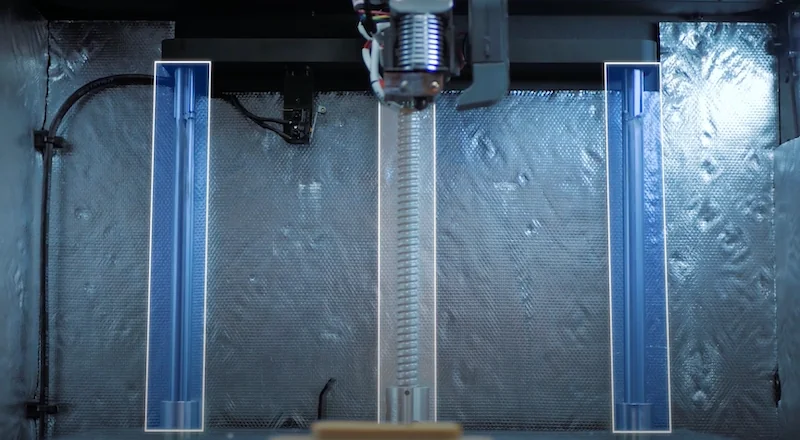

Four independent drive motors and automated bed leveling ensure precise positioning and consistent first-layer adhesion across the 260 × 260 mm build surface, essential for high-performance filaments like PEEK and ULTEM. The ceramic glass platform with PI sheet improves adhesion and part removal.

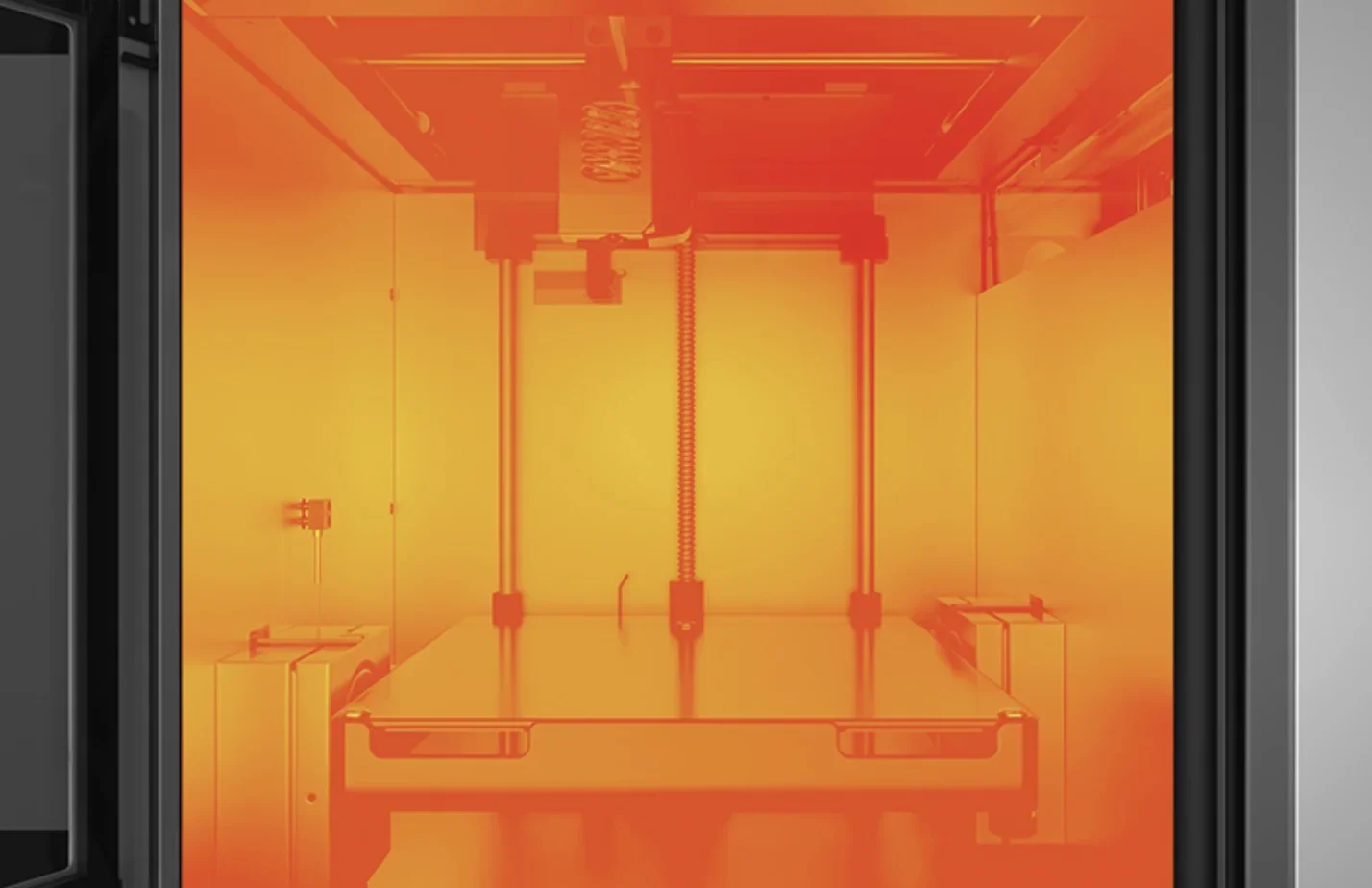

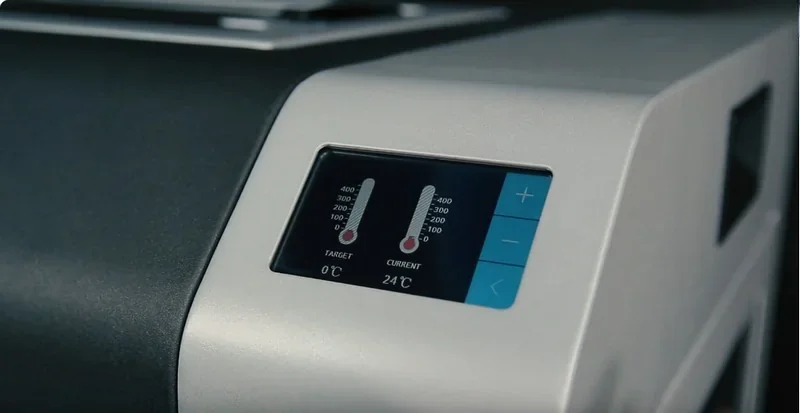

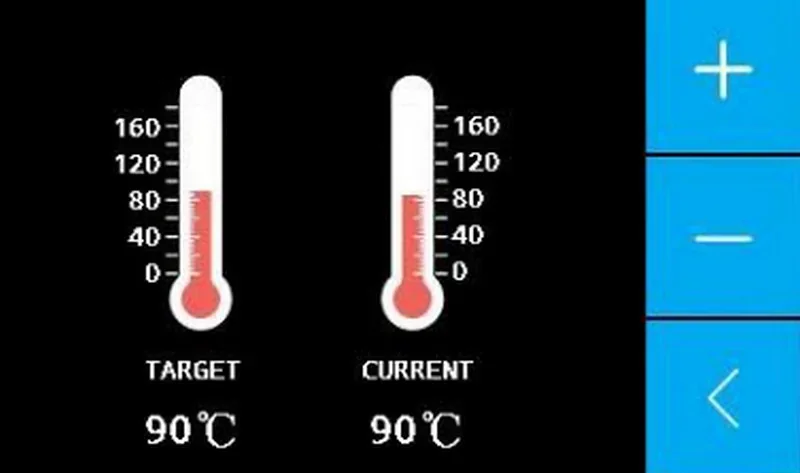

The Funmat HT Enhanced prints up to 300 mm/s, combining speed with precision. Its 90°C heated build chamber, 160°C build plate, and 450°C extruder with an all-metal hotend maintain stable conditions, preventing warping and delamination in sensitive filaments. For example, the 116x114x13 mm aircraft mount below was printed in PEEK in 4 hours and 10 minutes.

The Funmat HT Enhanced prints up to 300 mm/s, combining speed with precision. Its 90°C heated build chamber, 160°C build plate, and 450°C extruder with an all-metal hotend maintain stable conditions, preventing warping and delamination in sensitive filaments. For example, the 116x114x13 mm aircraft mount below was printed in PEEK in 4 hours and 10 minutes.

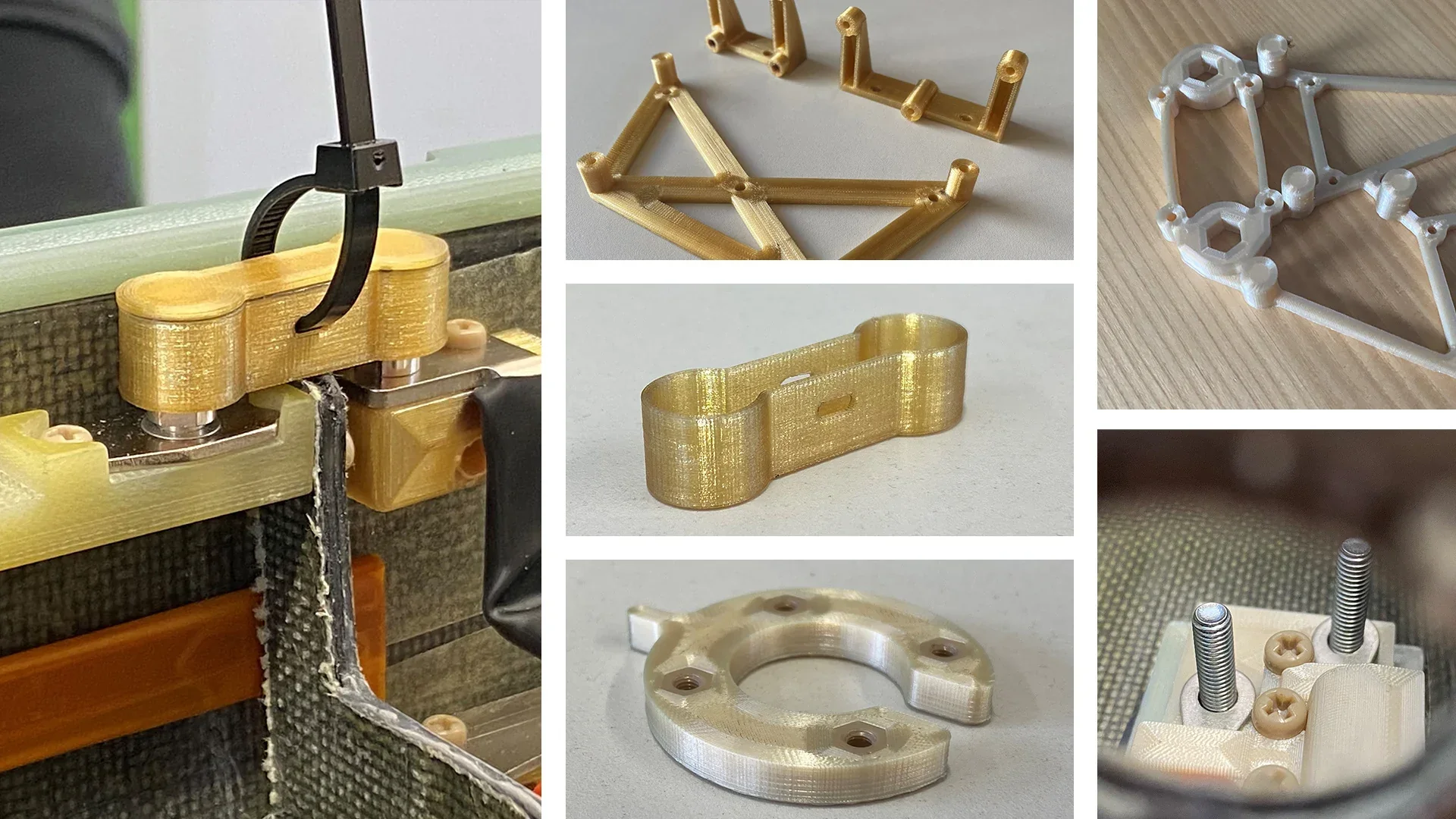

The enclosed, filtered chamber maintains stable conditions while reducing emissions. When properly calibrated, the printer delivers smooth, strong parts suitable for functional prototypes and end-use industrial applications. In case of a power outage, the backup power supply prevents print failures. For example, the Rennteam X0711-1 racing car uses 3D printed PEI, PC, and ABS parts from the INTAMSYS FUNMAT HT for structural molds, accumulator housings, power electronics mounts, wing ribs, and braking system components, leveraging its high-strength, heat- and fire-resistant polymers.

When properly calibrated, the printer delivers smooth, strong parts suitable for functional prototypes and end-use industrial applications. In case of a power outage, the backup power supply prevents print failures. For example, the Rennteam X0711-1 racing car uses 3D printed PEI, PC, and ABS parts from the INTAMSYS FUNMAT HT for structural molds, accumulator housings, power electronics mounts, wing ribs, and braking system components, leveraging its high-strength, heat- and fire-resistant polymers.

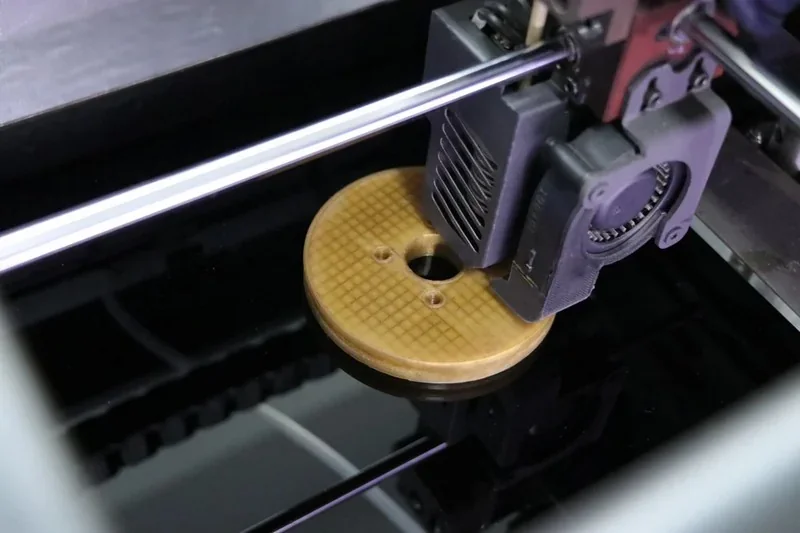

ABIGO Medical used the INTAMSYS FUNMAT HT to 3D print PEEK and Polycarbonate spare parts like pulley wheels, cutting lead times from eight weeks to immediate, lowering costs tenfold, and ensuring reliable pharmaceutical packaging line uptime.

INTAMSYS 3D printers use high-performance polymers like PEEK to create patient-specific implants, anatomical models, and surgical aids from CT data, enhancing orthopedic surgeries, training, and outcomes through strong, biocompatible, and durable materials.

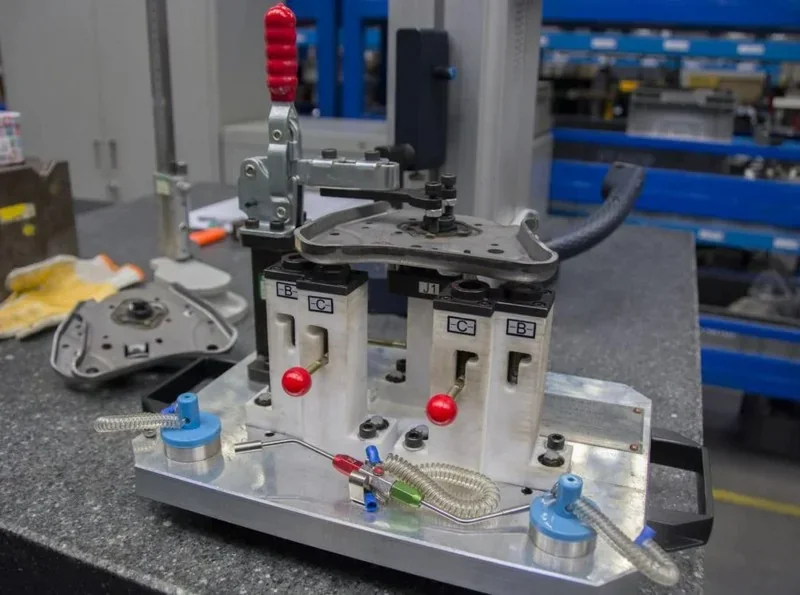

SAIC Yanfeng used the INTAMSYS FUNMAT HT with industrial polycarbonate to 3D print unibody 198 x 113 x 110 mm QC gauge units in two days, cutting development time while improving productivity, precision, and durability in automotive seating quality control.

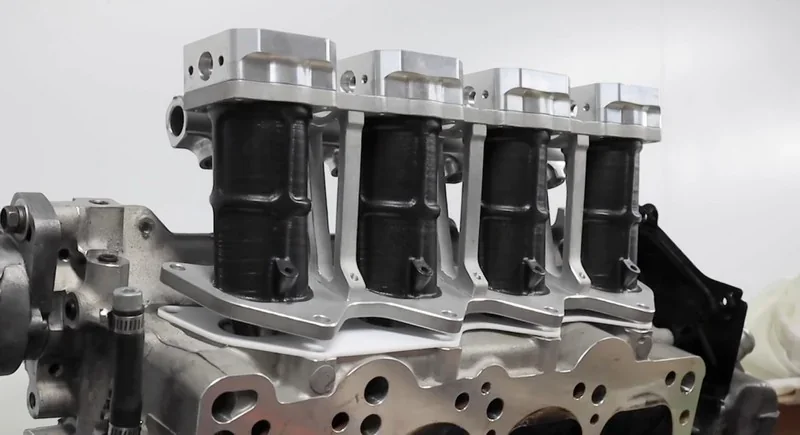

Hartley Engines and Motorsport used the INTAMSYS FUNMAT HT with carbon-fiber-reinforced nylon to 3D print engine parts like intake runners and trumpets, achieving 95% print success and improved efficiency, performance, and thermal properties through hybrid manufacturing and optimized geometries.

The University of Stuttgart’s GreenTeam used the INTAMSYS FUNMAT HT to 3D print high-performance polymer parts for the E0711-11 EVO electric race car, enabling rapid prototyping, functional testing, lightweight components, and custom accessories to accelerate EV innovation.

The Funmat HT Enhanced supports 16+ filaments, from standard to high-performance. It prints top-tier thermoplastics like PEEK, PEKK, ULTEM (PEI), PPSU, and reinforced blends (PEEK-CF, PEEK-GF). These materials are known for their excellent mechanical, thermal, and chemical resistance, and high melting point.

ULTEM 1010 3D Print Sample: A 92x92x12 mm automotive gear printed in 4 hours 13 minutes.

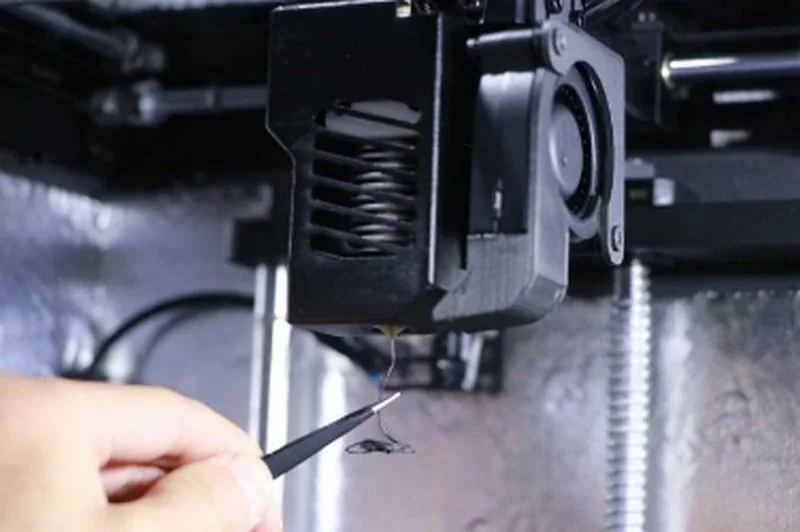

In the video, Intamsys removes SP5080 breakaway support from an ULTEM 1010 part in under 5 minutes.

PEKK Print Sample:A 69 x 69 x 55 mm PEKK compressor turbine printed in 3 hours 07 minutes

The Intamsys Funmat HT also handles engineering filaments such as PC, PC-ABS, PC-FR, PC-PBT blends, Nylon (PA, PA-CF), ABS, ASA, PETG, ESD-safe, and TPU, along with standard PLA and soluble PVA supports.

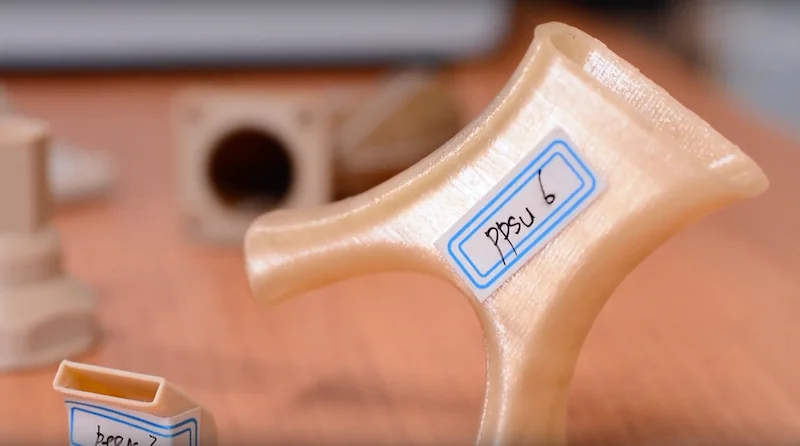

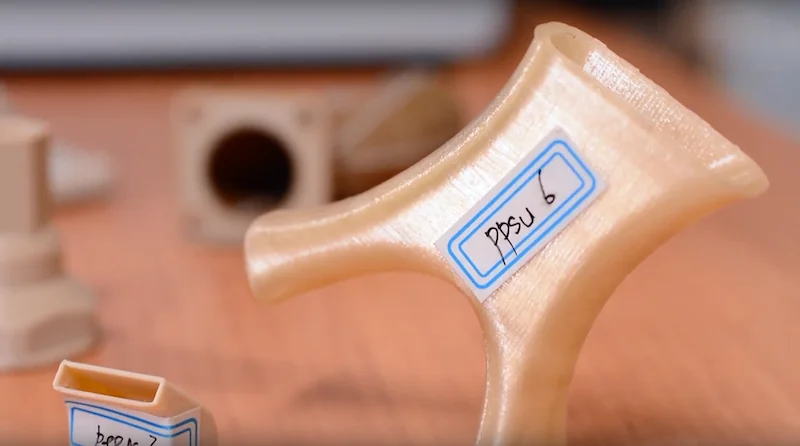

PPSU 3D Print Sample:

PC 3D Print Sample:A 198 x 113 x 110 mm PC auto-part inspection gauge printed in 9 hours 33 minutes.

PC 3D Print Sample:

PPSU 3D Print Sample:

CF-Nylon 3D Print Sample:

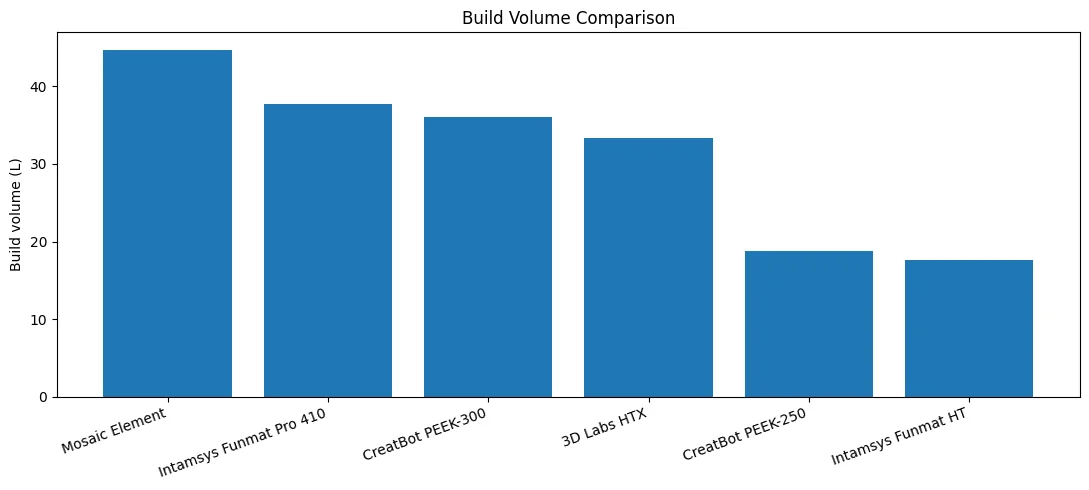

The Funmat HT Enhanced offers a 260 × 260 × 260 mm build volume (17,576 cc). Its height supports tall, rigid components, while the square plate ensures even thermal distribution and dimensional stability — crucial for warp-prone materials like PEEK and ULTEM.

The Intamsys Funmat HT Enhanced offers the most affordable entry into industrial high-temperature 3D printing, reliably handling PEEK and PEKK. Though it has a smaller build and lower heat specs than pricier models like the CreatBot PEEK-250 or 3D Labs HTX, its low price point and reliability make it ideal for labs, startups, and schools. Alternatives like the Mosaic Element HT add advanced automation, but sacrifice chamber temperature, and require a higher price. Higher-end options like the Funmat Pro 410 and CreatBot PEEK-300 offer dual extrusion and larger builds at a higher cost. The Funmat HT Enhanced strikes the best balance of performance, reliability, and value for users focused on ease and cost-efficiency.

| Feature | Intamsys Funmat HT | CreatBot PEEK-250 | CreatBot PEEK-300 | 3D Labs HTX | Intamsys Funmat Pro 410 | Mosaic Element |

|---|---|---|---|---|---|---|

| Build Volume (mm) | 260 × 260 × 260 | 250 × 250 × 300 | 300 × 300 × 400 | 370 × 300 × 300 | 305 × 305 × 406 | 355 × 355 × 355 |

| Chamber Temp (°C) | 90 | 200 | 120 | 100 | 90 | 80 |

| Direct Annealing | No | Yes | Yes | No | No | No |

| Nozzle Temp (°C) | 450 | 480 | 480 | 500 | 500 | 500 |

| Bed Temp (°C) | 160 | 200 | 200 | 220 | 160 | 120 |

| Extruder | Single Direct Drive | Single Direct Drive, Water Cooled | Dual Direct Drive, Water-Cooled | Dual Direct Drive | Dual Direct-Drive, Water-Cooled | Single Direct Drive |

| Price | $7,000+ | $11,999+ | $15,000+ | $15,500+ | $28,000+ | $10,000+ |

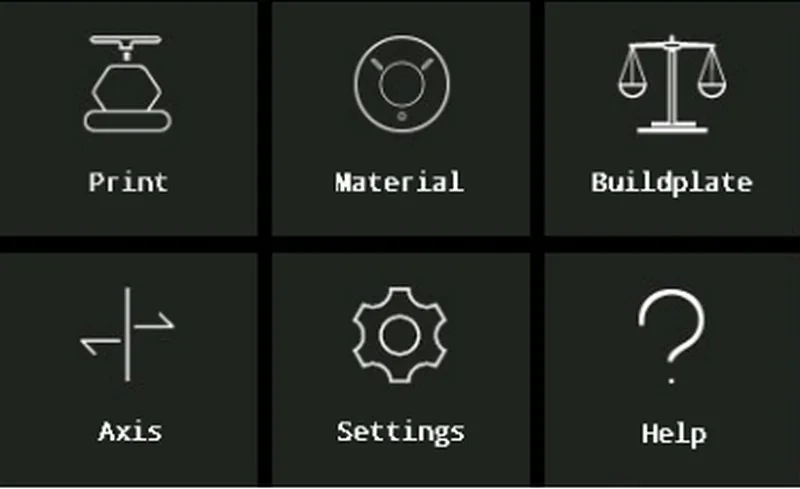

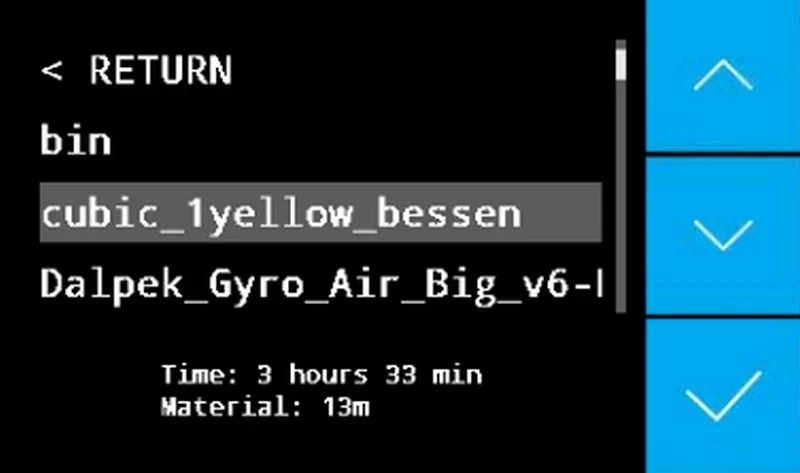

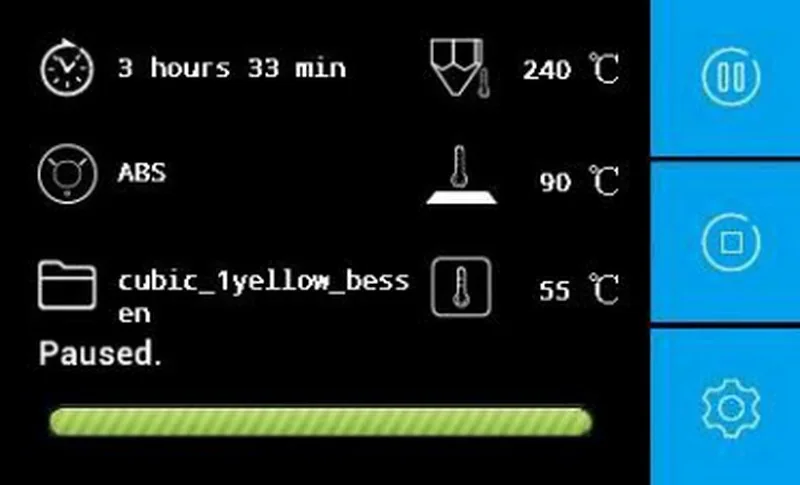

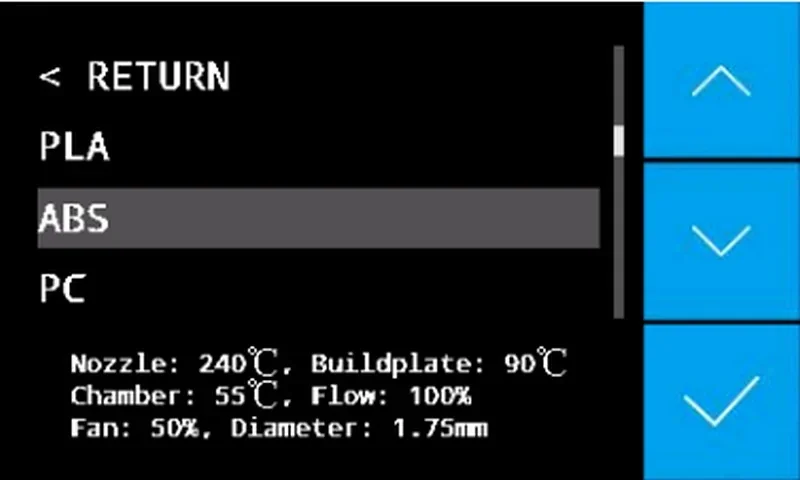

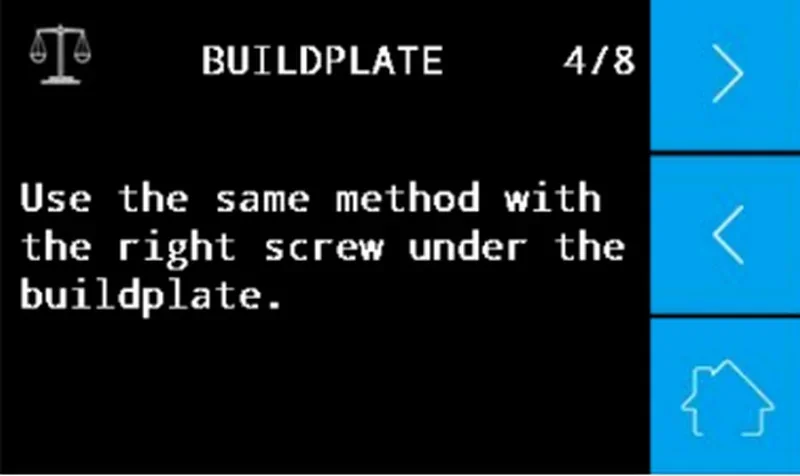

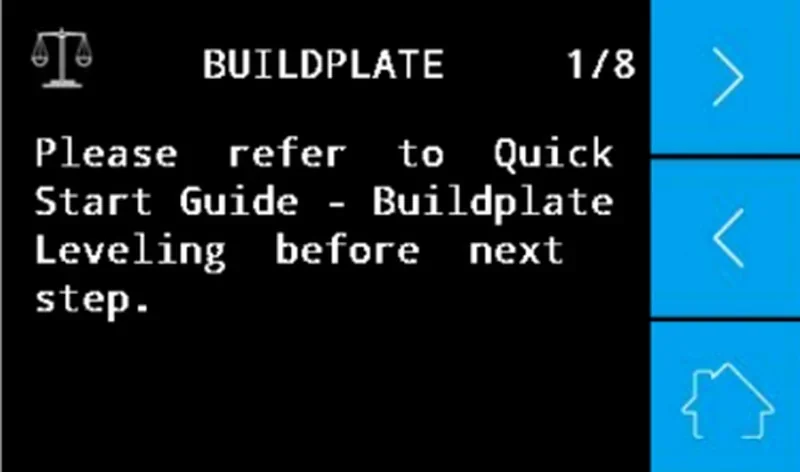

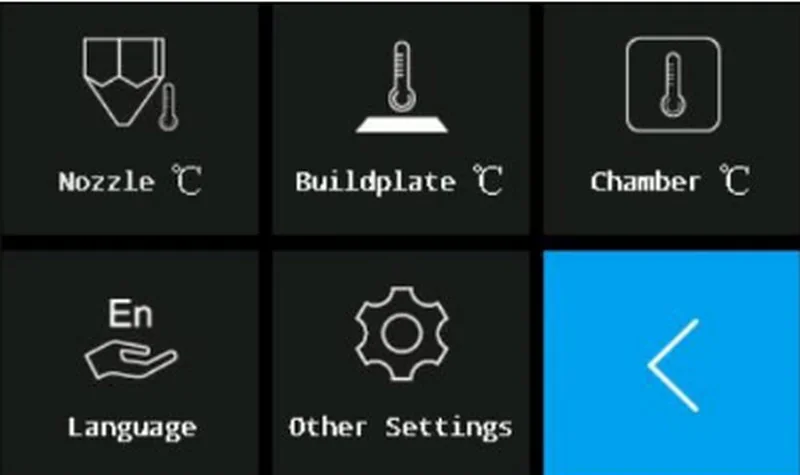

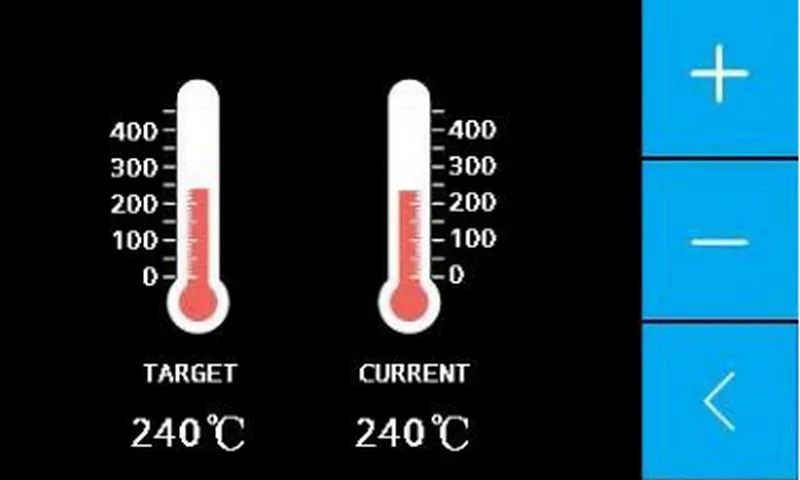

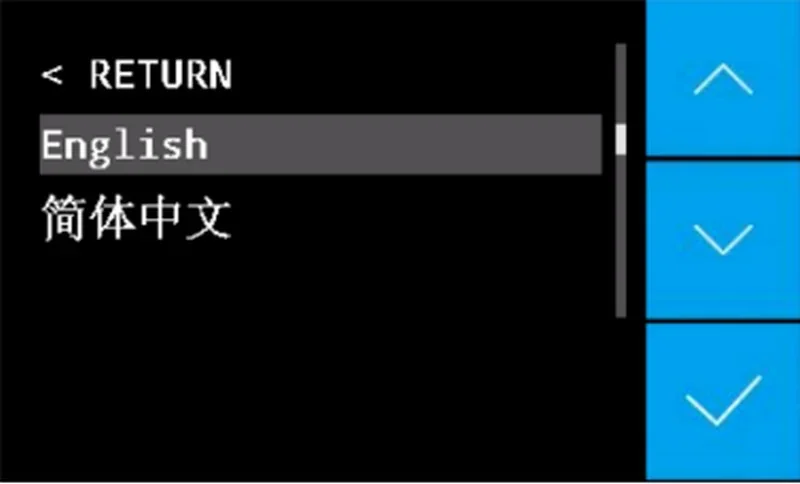

The Funmat HT Enhanced is operated via 4 physical controls, and a full-color touchscreen with menus for Print, Material, Buildplate, Axis, Settings, and Help.

Physical Controls (4):

Touchscreen Controls (6 categories):

The Funmat HT Enhanced connects via Ethernet, SD card, or USB. SD cards are the primary method for transferring sliced files from INTAMSUITE, while USB handles firmware updates and maintenance. A WiFi camera enables remote monitoring, with updates managed through the touchscreen via USB.

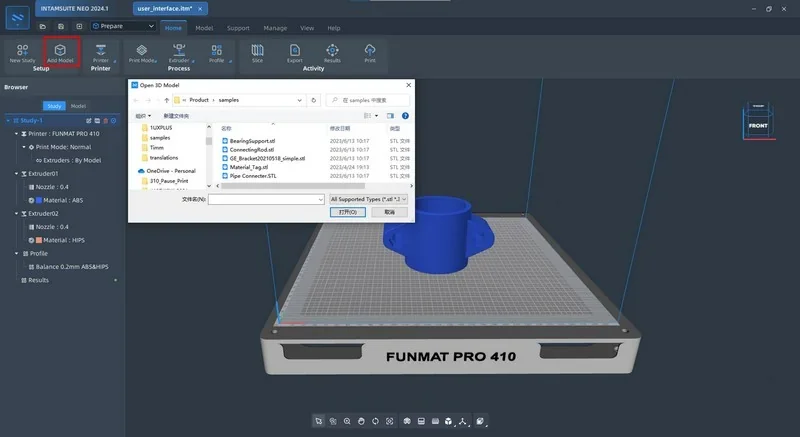

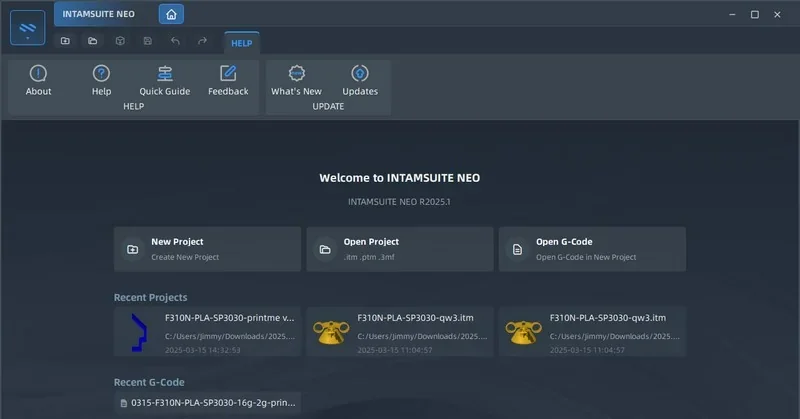

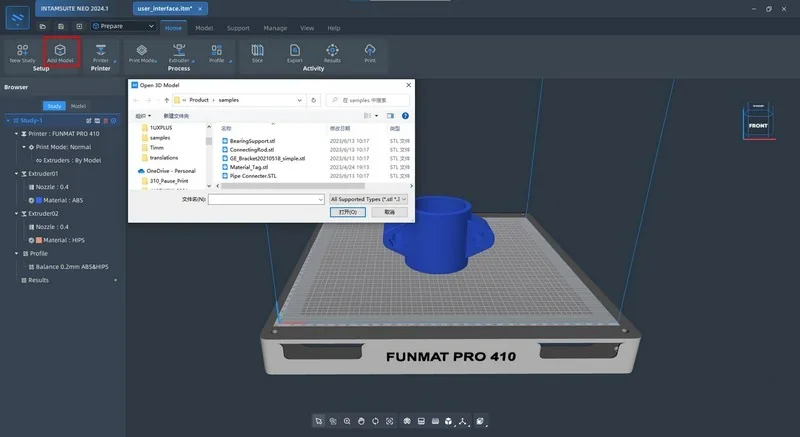

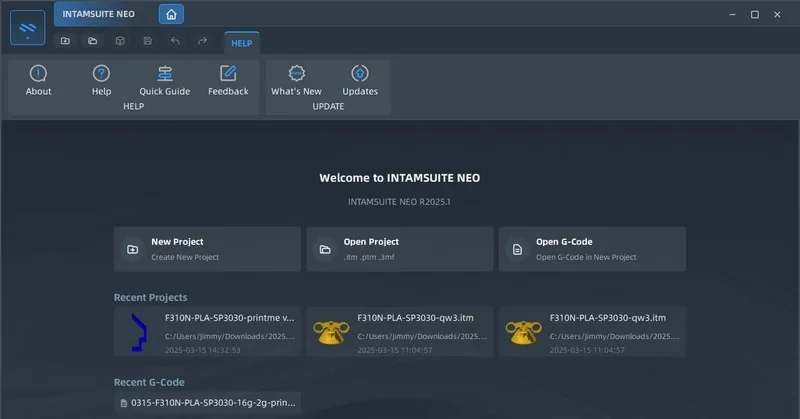

The Funmat HT Enhanced includes INTAMSUITE, which offers optimized filament profiles, craft packages for difficult materials like PEEK and ULTEM, and supports file formats such as STL, OBJ, X3D, 3MF, STP, and IGES without conversion. It is also compatible with third-party slicers like Cura and Simplify3D. Firmware updates are handled via USB, with independent paths for the control board and touchscreen (INTAMTOUCH).

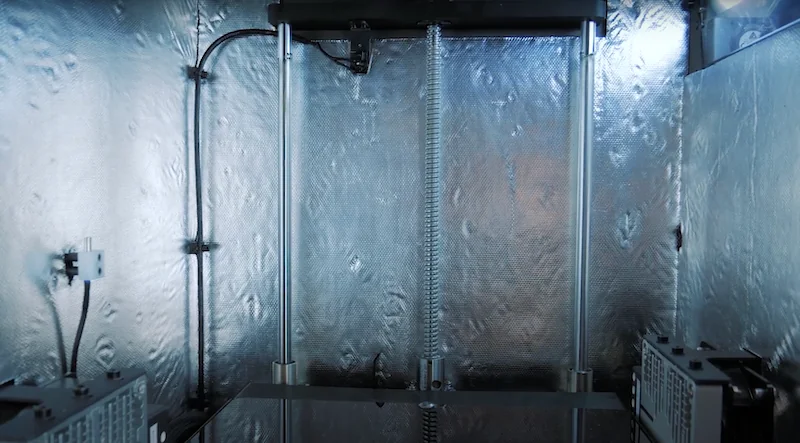

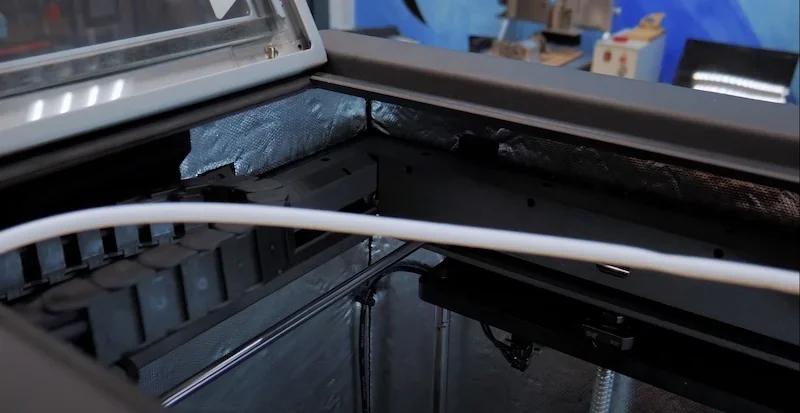

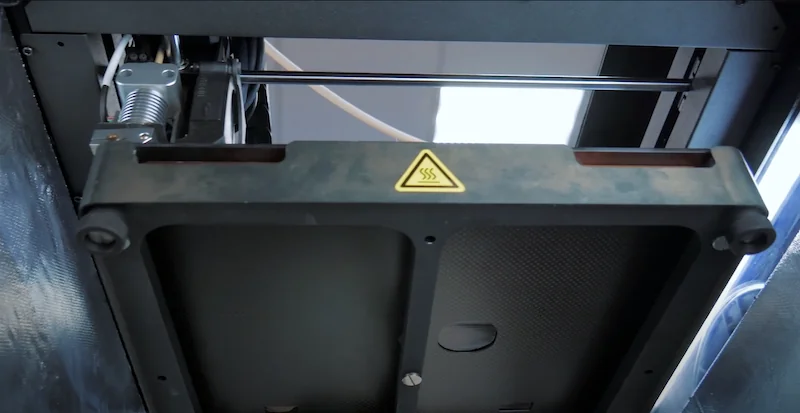

The Intamsys Funmat HT has a solid, industrial-grade appearance. The Funmat HT features a fully enclosed steel chassis with metal doors. Its enclosure features three double-glazed viewing windows with sealed latches, maintaining internal temperatures up to 90°C and minimizing heat loss for engineering-grade prints. The printer's external dimensions are 543 x 501 x 645 mm, and it weighs 63 kg (139 lb).

Advanced Thermal Insulation:

Heating elements are 3-layered, consisting of a fan, a heater, and a radiator:

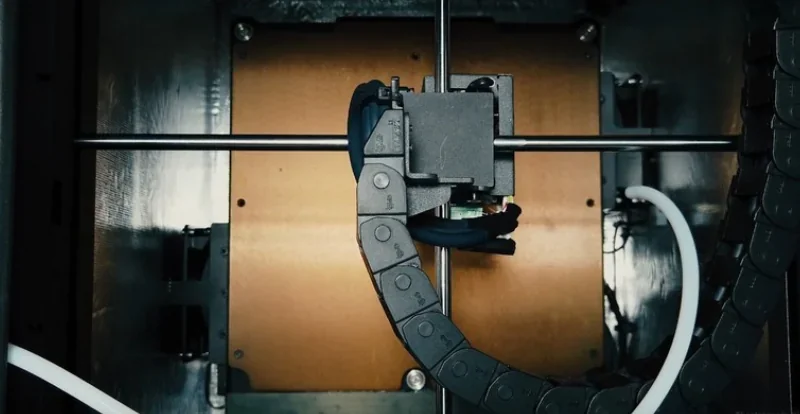

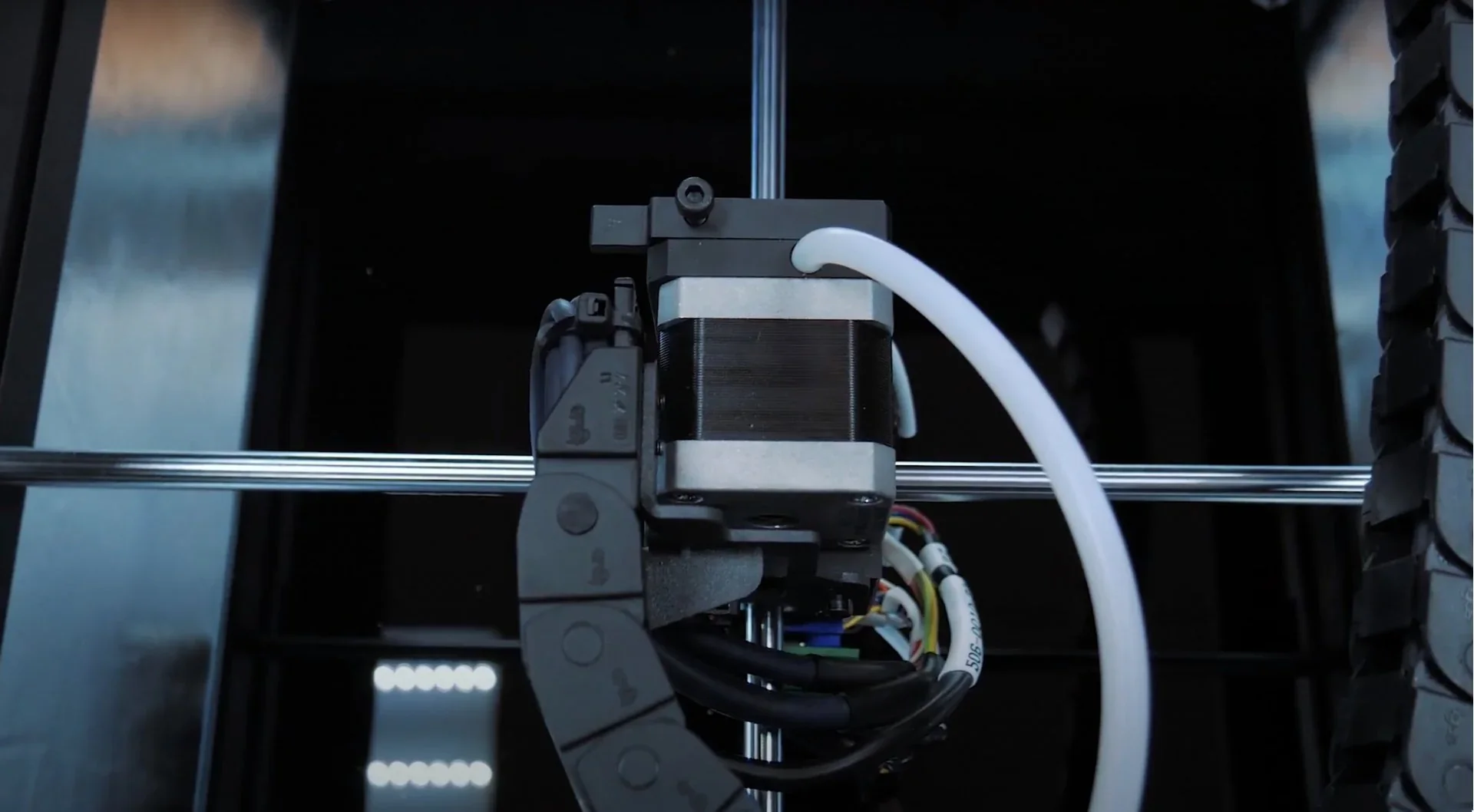

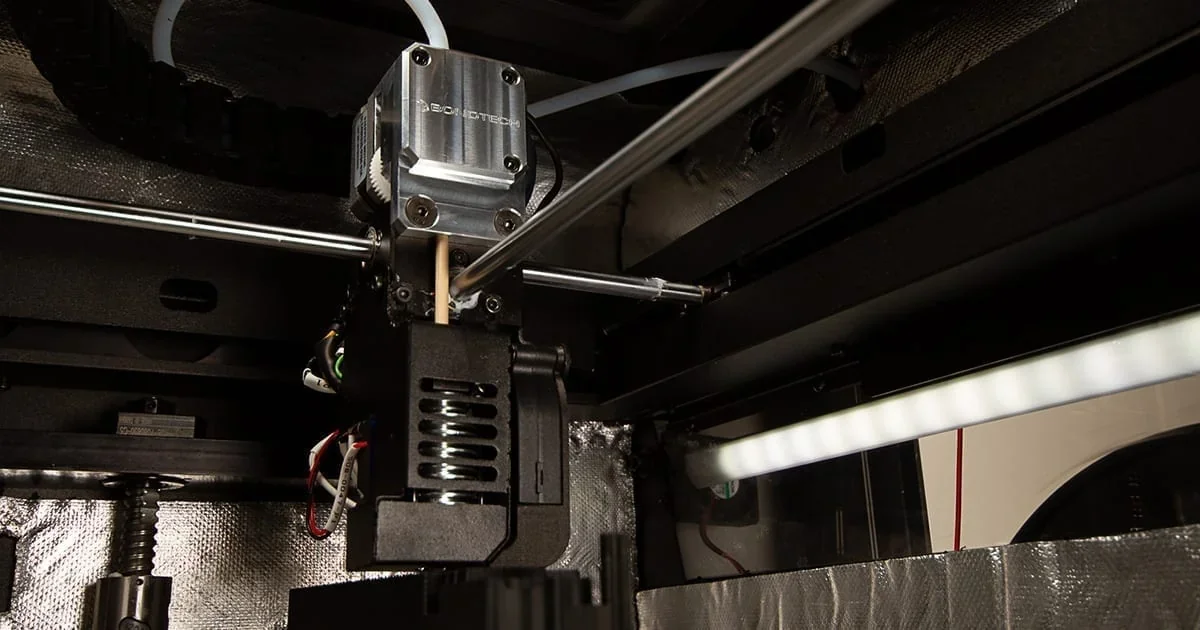

The Intamsys Funmat HT uses an Ultimaker-style motion system with intersecting linear guides for X and Y.

The Z-axis uses a ball screw with dual side guides for platform movement.

All kinematic components are from HIWIN. Position accuracy is XY: 0.025 mm, Z: 0.0025 mm.

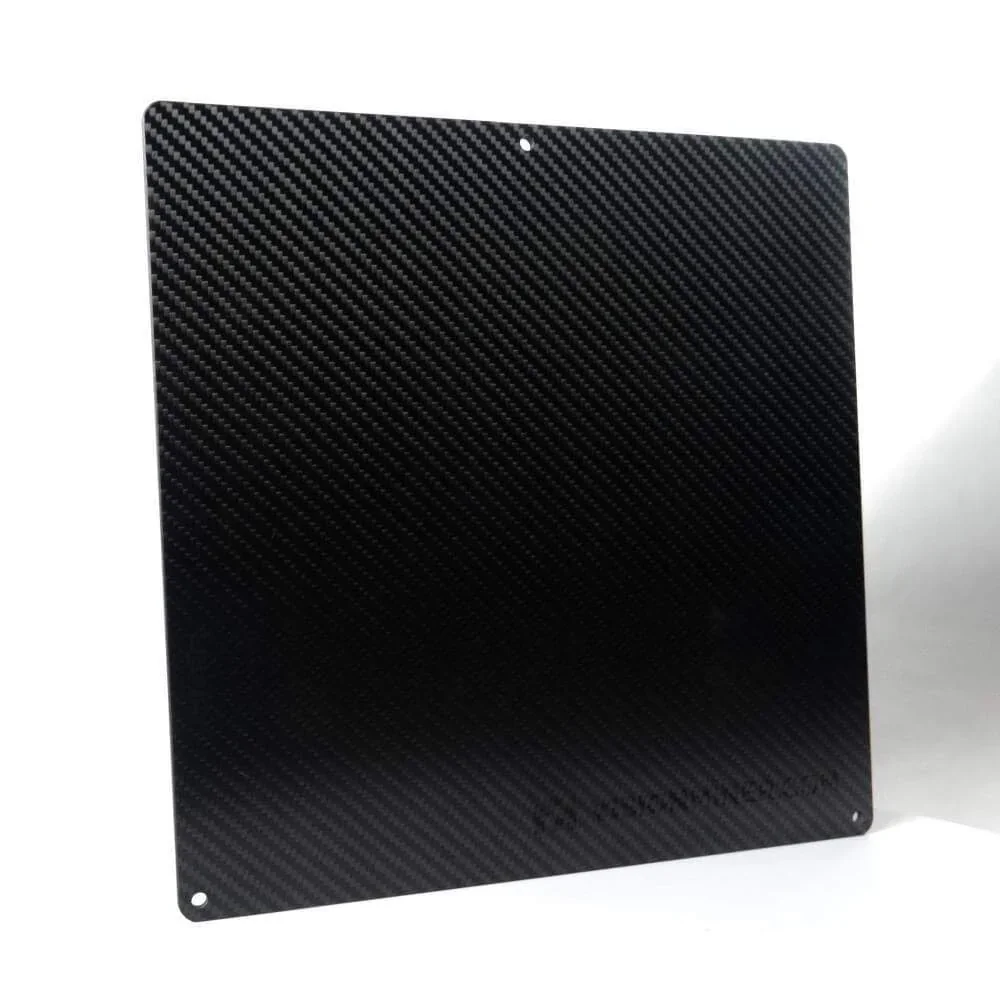

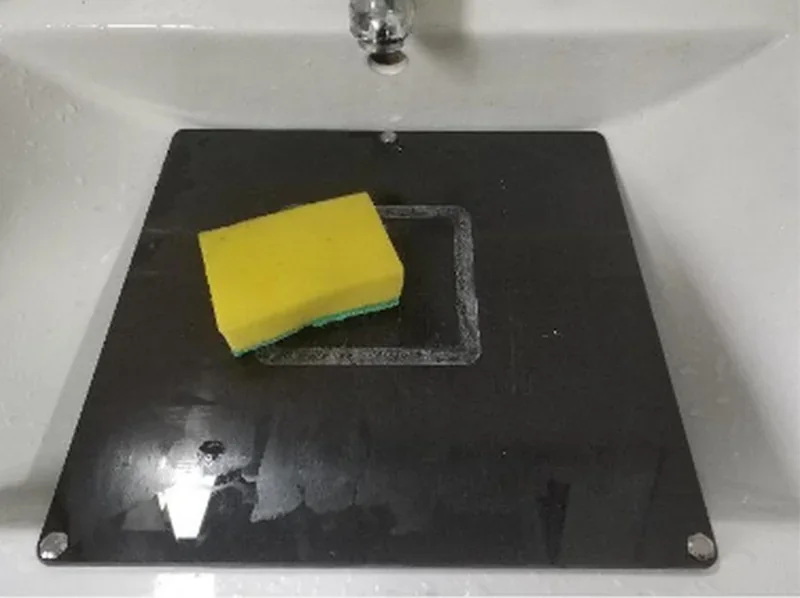

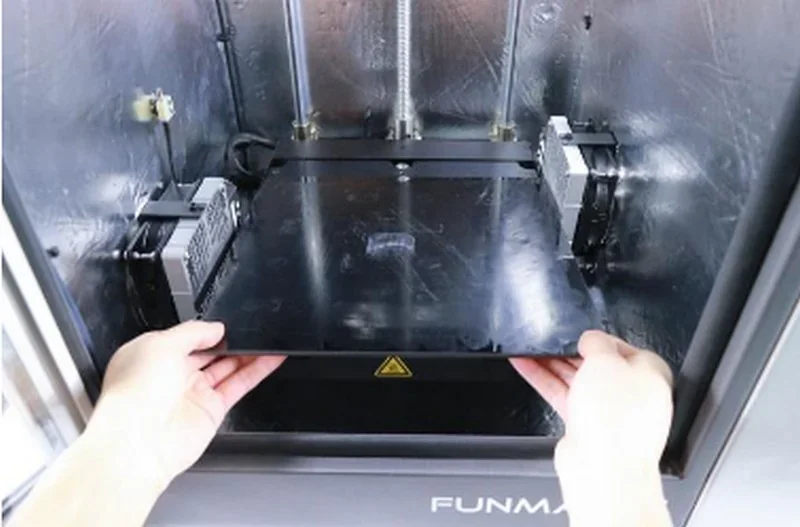

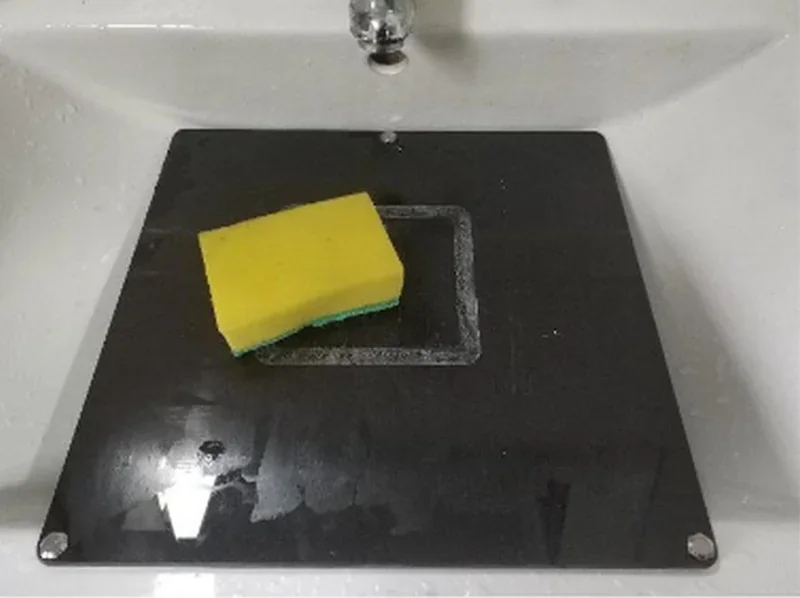

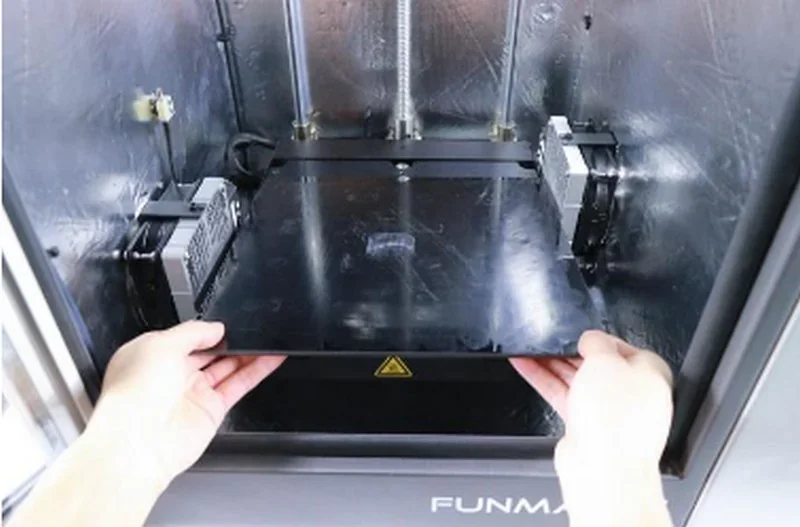

The Intamsys Funmat HT offers a 260 × 260 × 260 mm build volume. Its heated platform reaches 160°C and has a three-layer design: carbon insulation, heating plate, and adhesive glass top.

Carbon Insulation:

The magnetically held glass has a glossy side for PLA/ABS and a matte side for high-temp filaments like PEEK and Ultem.

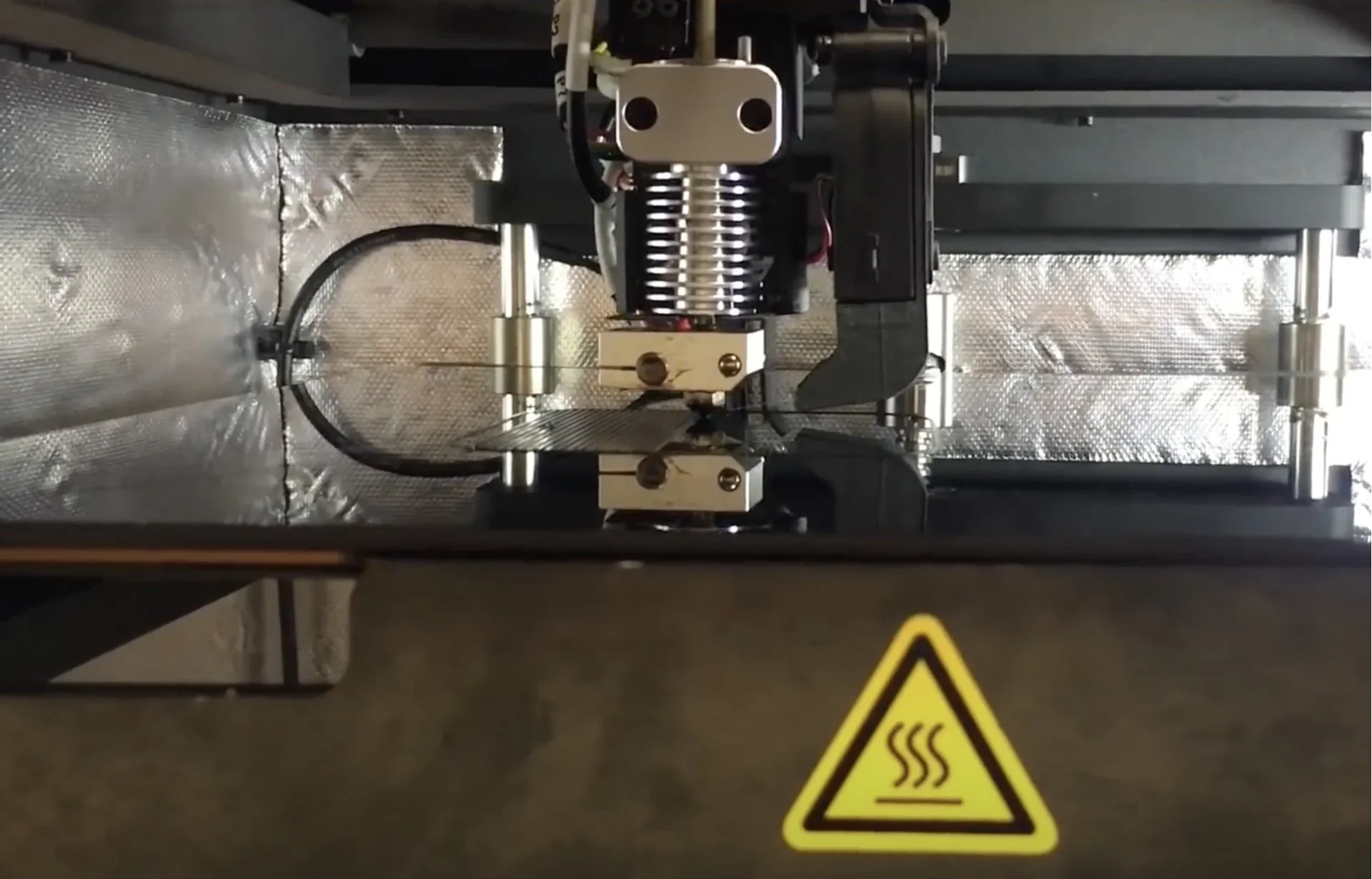

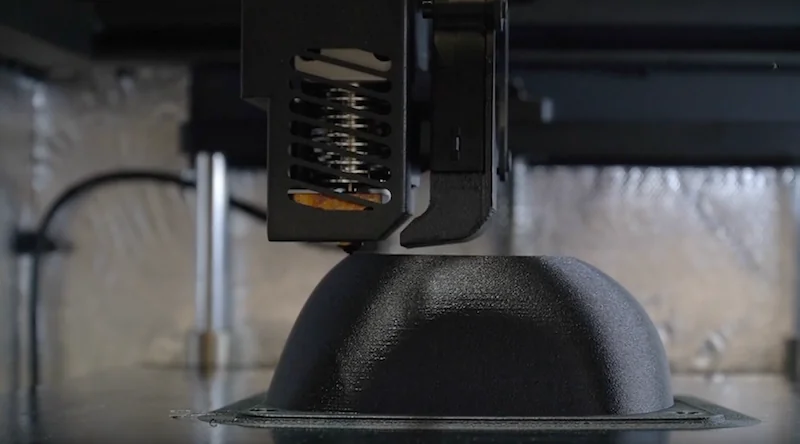

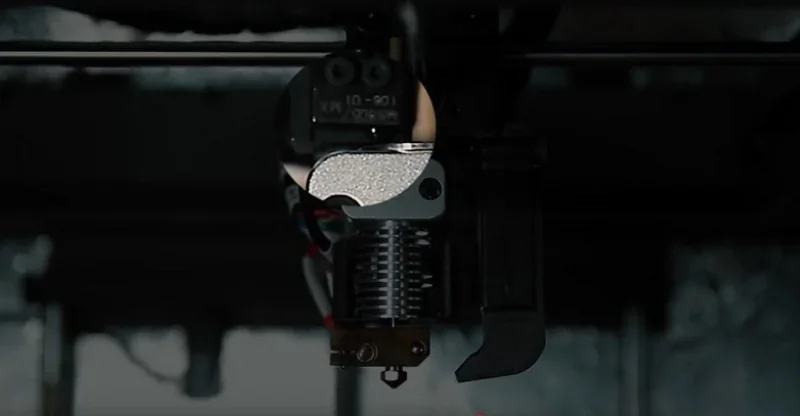

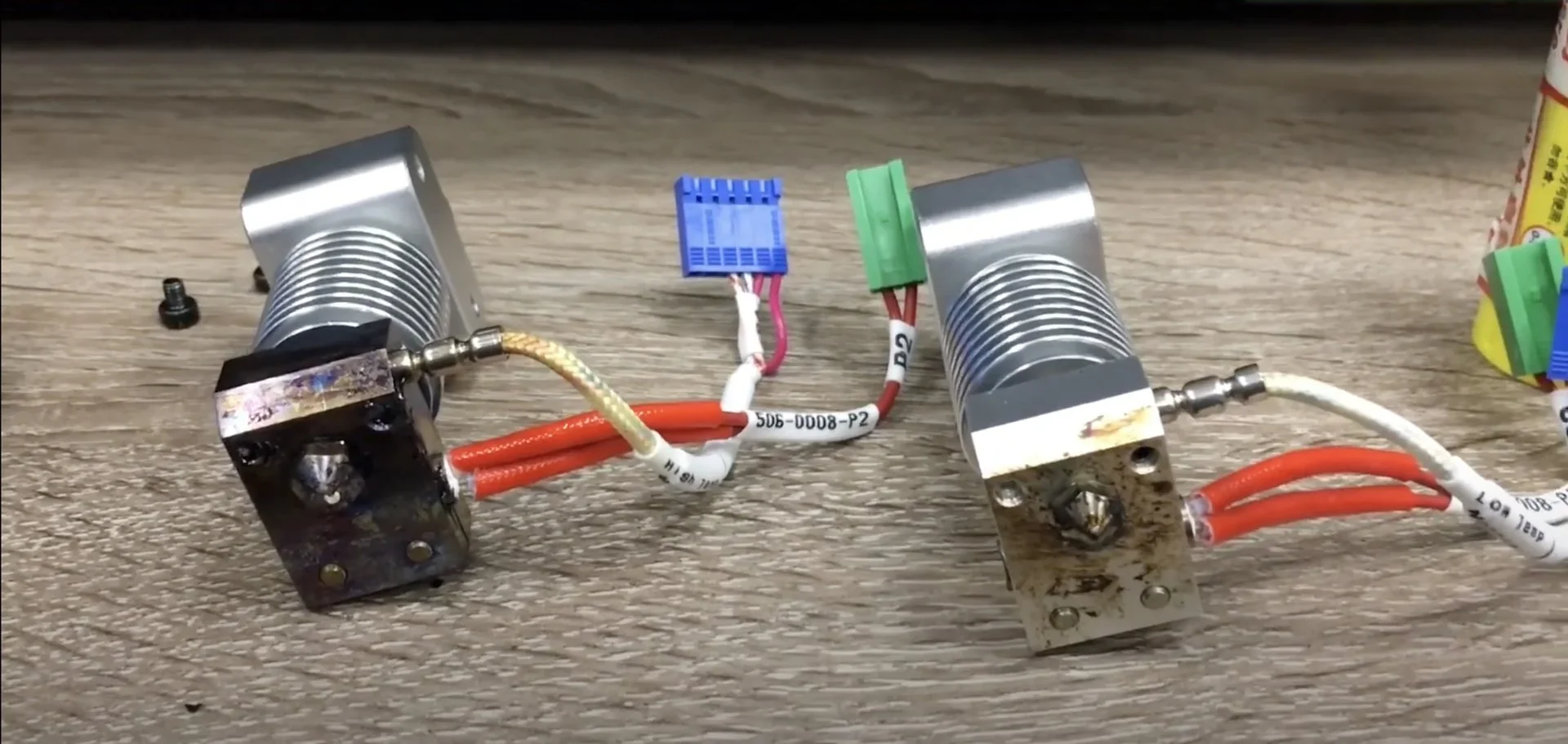

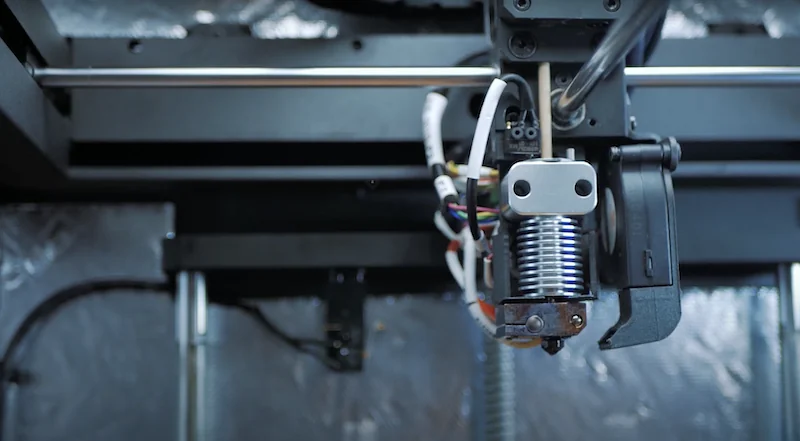

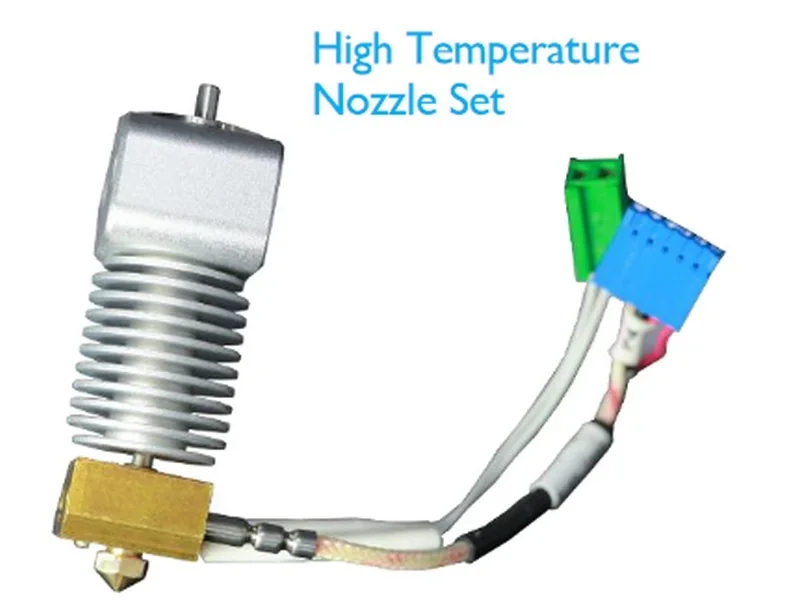

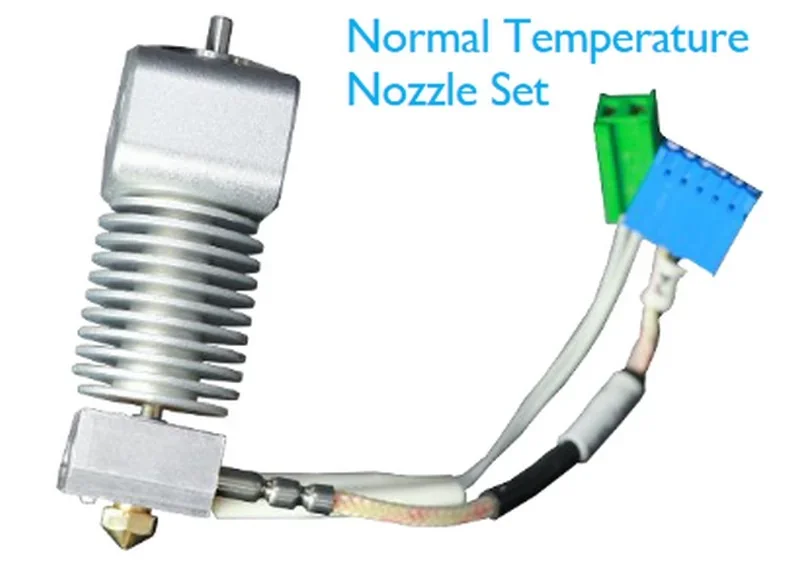

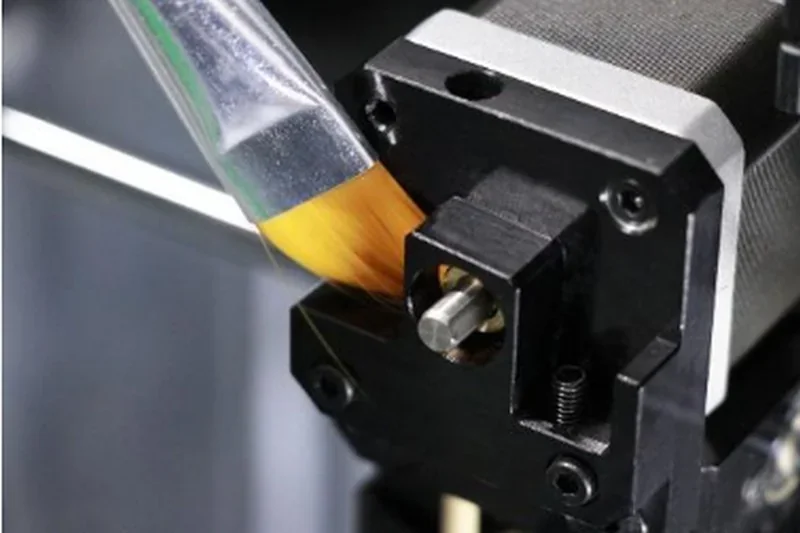

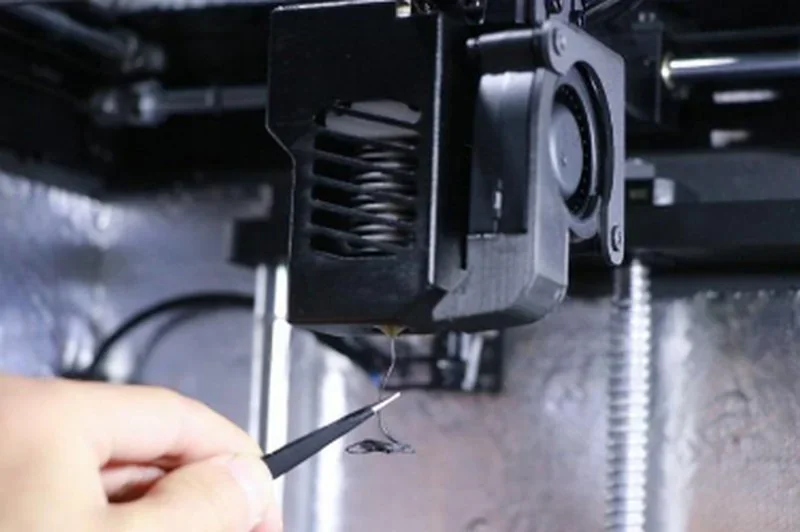

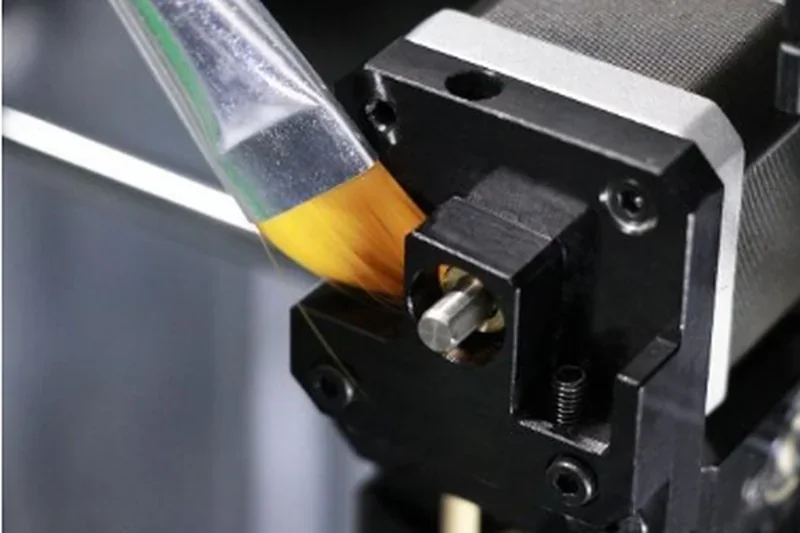

The Intamsys Funmat HT features a single direct-drive high-temperature extruder system. Users can switch between low (up to 260°C) and high (up to 450°C) temperature E3D-style hotends. Swappable nozzles come in 0.25–0.8 mm sizes, with a 0.4 mm nozzle standard. Extruders can be swapped in under five minutes using the included tools.

The Motor Driving Extrusion

The high-temperature hotend (on the left), the low-temperature hotend (on the right):

A PEEK guide tube handles high temperatures.

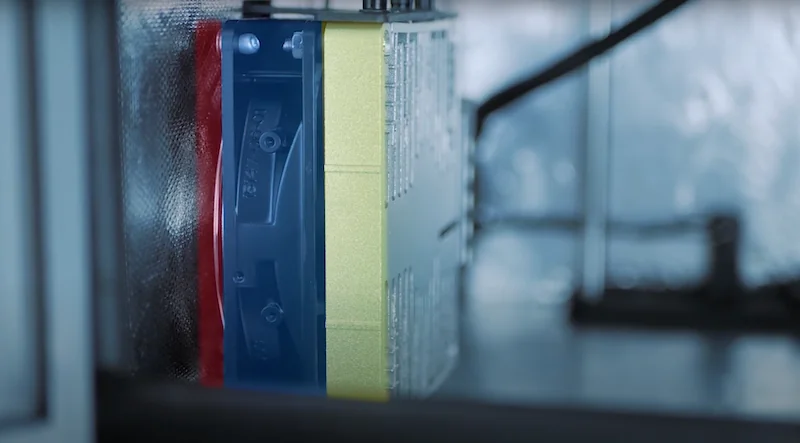

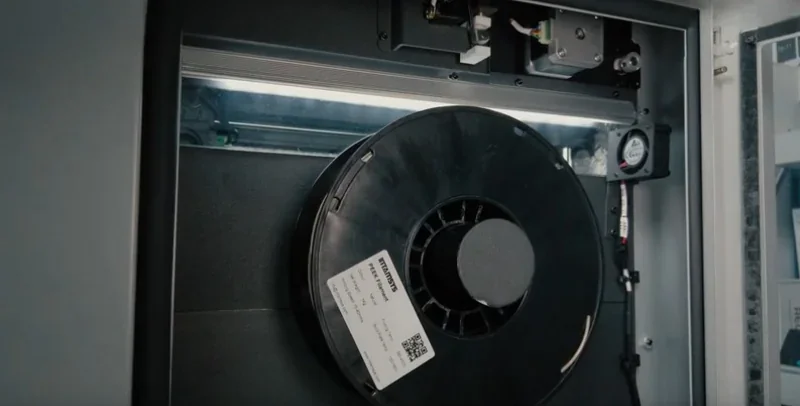

The Intamsys Funmat HT has a separate enclosed filament chamber with a spool bracket and a filament sensor.

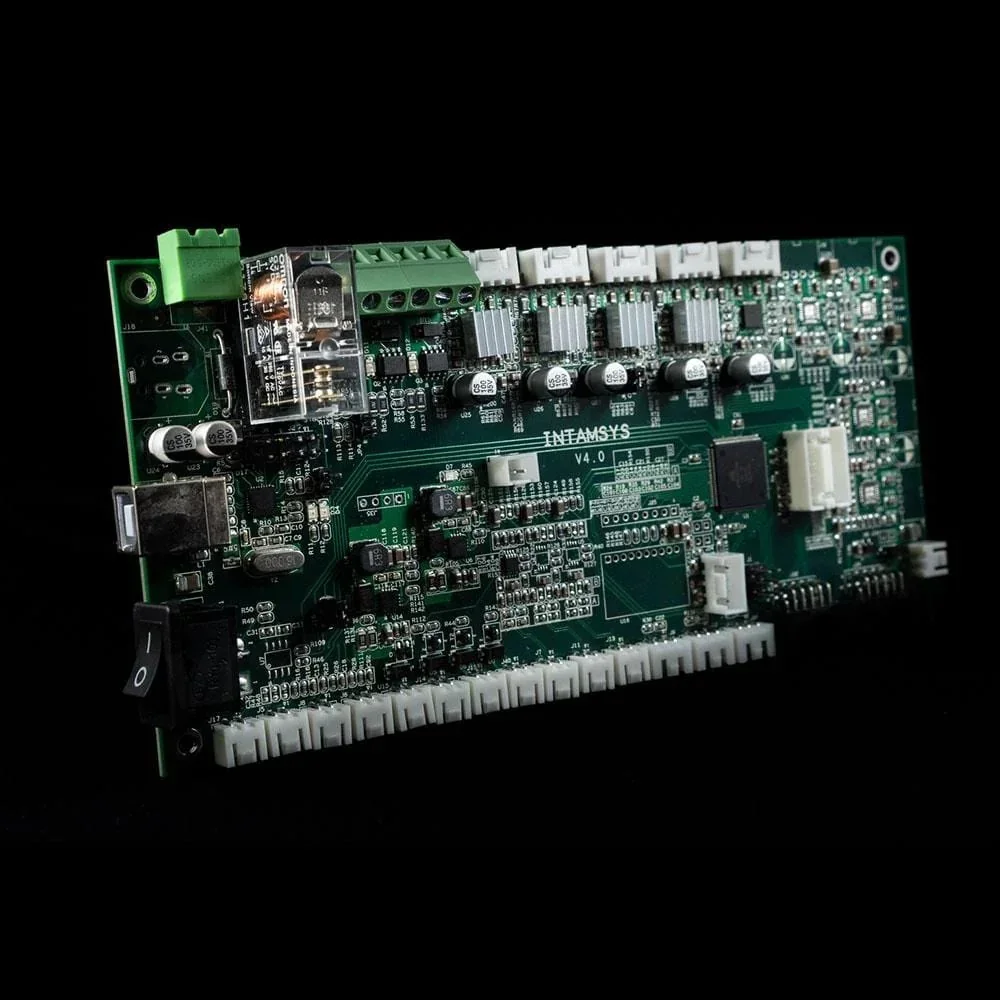

The Funmat HT control system uses distributed electronics, with separate controllers for the thermocamera, kinematics, and user interface. A labeled pin board (e.g., P2, P4, P7) allows modular connections for components like the extruder and sensors.

The Funmat HT uses a 1200 W power supply compatible with 100–120 V or 200–240 V AC at 47–63 Hz. It meets CE standards and includes protection against short circuits, overload, over-voltage, and overheating. Safety circuits cover all high-temperature and high-current components.

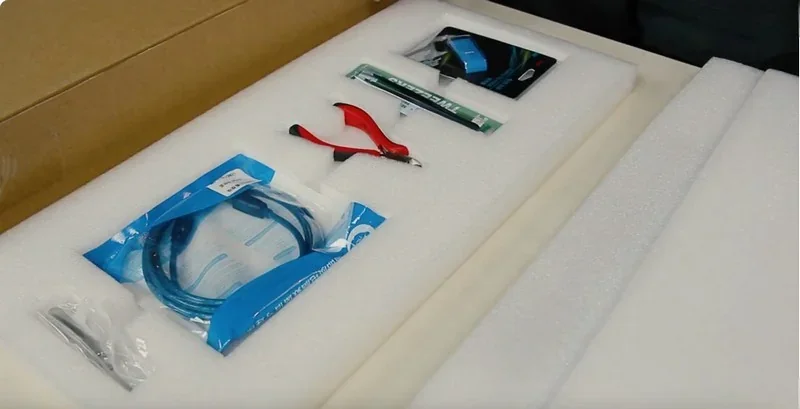

The Funmat HT Enhanced ships fully assembled and ready after calibration. It includes a tool kit for maintenance and nozzle cleaning, an SD card with INTAMSUITE slicing software, and a PI-coated ceramic glass plate for improved adhesion and part removal.

Note: Package contents may vary. Confirm details with Top3DShop before purchase.

The Funmat HT Enhanced supports 16 replacement components and accessories.

| Accessory | Function | Price (USD) | Image |

|---|---|---|---|

| Extruder and Filament Feeding Upgrades | |||

| BMG-HT for INTAMSYS FUNMAT HT | Extruder upgrade for higher-grip filament feeding (BMG-HT) | $520 |  |

| Hotend Heating Parts and Temperature Sensors | |||

| Nozzle Thermistor Assembly (Normal Temperature) for INTAMSYS FUNMAT HT | Replacement nozzle temperature sensor assembly for normal-temperature setup | $31 |  |

| Nozzle Thermistor Assembly (High Temperature) for INTAMSYS FUNMAT HT | Replacement nozzle temperature sensor assembly for high-temperature setup | $31 |  |

| Nozzle Heater Assembly for INTAMSYS FUNMAT HT | Replacement heater assembly that heats the nozzle/hotend | $15 |  |

| Hotend Heat Break Parts | |||

| Heat Break (High Temperature) for INTAMSYS FUNMAT HT | Heat break for high-temperature hotend configuration (thermal separation between hot and cold zones) | $12 |  |

| Heat Break (Normal Temperature) for INTAMSYS FUNMAT HT | Heat break for normal-temperature hotend configuration (thermal separation between hot and cold zones) | $8 |  |

| Nozzles and Nozzle Kits | |||

| Nozzle Brass 0.25 mm for INTAMSYS FUNMAT HT | Replacement 0.25 mm brass nozzle for fine-detail printing | $7 |  |

| Nozzle CuCrZr for INTAMSYS FUNMAT HT | Replacement CuCrZr nozzle (copper alloy) for high thermal conductivity (nozzle diameter is selectable on the product page) | $12 |  |

| Nozzle Steel for INTAMSYS FUNMAT HT | Replacement steel nozzle for improved wear resistance vs. standard brass (nozzle diameter is selectable on the product page) | $10 |  |

| Nozzle Set V3 (Normal Temperature) for INTAMSYS FUNMAT HT | Nozzle set for V3 hotend in normal-temperature configuration | $185 |  |

| Nozzle Set V3 (High Temperature) for INTAMSYS FUNMAT HT | Nozzle set for V3 hotend in high-temperature configuration | $205 |  |

| Build Plates and Print Surfaces | |||

| Glass Plate for INTAMSYS FUNMAT HT | Replacement glass build plate / print surface | $57 |  |

| Glass Ceramics Plate for INTAMSYS FUNMAT HT | Replacement glass-ceramic build plate / print surface (higher temperature-capable surface) | $145 |  |

| PEEK Tubes (Filament Path and Thermal Isolation) | |||

| PEEK Tube for INTAMSYS FUNMAT HT | Replacement PEEK tube used in the hotend/filament path (guidance + thermal isolation) | $21 |  |

| Upper PEEK Tube for INTAMSYS FUNMAT HT | Replacement upper-position PEEK tube for the hotend/filament path | $21 |  |

| Lower PEEK Tube for INTAMSYS FUNMAT HT | Replacement lower-position PEEK tube for the hotend/filament path | $21 |  |

Regular upkeep ensures consistent performance on the Funmat HT.

These steps reduce print defects, extend part life, and maintain stable quality.

Warranty Coverage:

Extended Warranty (Optional):

Warranty Requirements:

Warranty is Void If:

Repair Works for User-Caused Damage:

Technical Support & Resources:

Email Support by Region:

Help Center Resources:

Authorized Distributor – Top 3D Shop:

The Intamsys Funmat HT 3D printer starts at $6,995.00, offering advanced FFF printing with a 450°C hotend, 90°C heated chamber, and 260 × 260 × 260 mm build volume. It supports high-performance thermoplastics like PEEK and PEI, delivering consistent, repeatable, industrial-grade results with open-material compatibility. For tailored setups or service packages, contact Top 3D Shop for a custom quote. Buy Intamsys Funmat HT at Top3DShop for reliable support!

Update your browser to view this website correctly. Update my browser now