The INTAMSYS FUNMAT PRO 410 is an industrial dual-extrusion 3D printer with a 305 × 305 × 406 mm build volume and high thermal control (500°C nozzle, 160f°C bed, 90°C chamber) for engineering materials like PEEK, PEKK, ULTEM, PPSU, PC, and carbon-fiber composites. It supports soluble supports for complex parts and includes features like auto bed leveling, jam detection, power-loss recovery, and self-cleaning nozzles. Connectivity options and a built-in camera enable remote monitoring, making it suited for prototyping, testing, and small-batch production with high-temperature filaments.

The FUNMAT PRO 410 prints high-temperature filaments with 50-micron precision and strong layer adhesion, producing durable, chemically resistant parts with fine details and smooth finishes. It handles materials like PEEK and reinforced composites, supporting industrial-scale output—WEERG used it to produce up to 25,000 complex components per day.

Benchmark tests show the FUNMAT PRO 410 achieves high dimensional accuracy, with an average offset of 0.112mm and a low 0.0415mm deviation across prints. It maintains circular precision as well, producing 100mm parts within 99.78–100.12mm, or 99.6% accuracy.

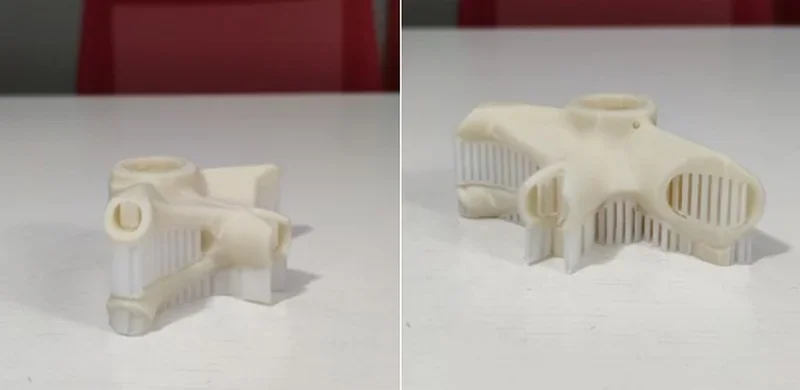

Image Credit: 3DPrintingIndustry.com

The FUNMAT PRO 410 handles demanding tests with ease, printing PEEK overhangs up to 50° without supports and bridging spans up to 20mm before distortion. Its strong retraction control minimizes stringing, maintaining accuracy and surface quality with high-temperature materials. Overall, it scored 77/100 in print performance.

Image Credit: 3DPrintingIndustry.com

The FUNMAT PRO 410 reliably prints complex PEEK parts with fine features, strong layer adhesion, and precise dimensions.

The FUNMAT PRO 410’s thermal system — 90°C chamber, 160°C bed, and liquid-cooled dual extruders — ensures consistent results with tough filaments. The Royal Netherlands Navy uses it to replace metal valve wheels with durable polymer parts and to print PEKK-CF brackets that withstand 20 kg loads in extreme heat and humidity, maintaining performance where standard filaments fail.

A Chinese aerospace institute used the FUNMAT PRO 410 with PEEK to accelerate CubeSat development, cutting costs and time versus molding while enabling greater design freedom and faster structural optimization for space missions.

The FUNMAT PRO 410 supports 30 filaments, from common plastics like PLA, PETG, TPU, ABS, ASA and PC to high-performance materials like PEEK, PEKK, PAEK, and PPS. Its 500°C nozzle, 160°C bed, and 90°C chamber ensure consistent, high-quality prints. The dual-extrusion system also works with water-soluble PVA and INTAMSYS support filaments.

3D Print Samples (from left to right): POM (2 parts), CF-ABS and HIPS, CF-ABS, PC and HIPS, ULTEM.

ULTEM 3D Print Sample: A part made of ULTEM, clearly showing how densely the walls are printed.

DMI 3D prints custom orthotics for the Royal Netherlands Navy using PEKK, ABS, or PP from mobile scans. The devices ensure anatomical fit, structural strength, and feature adjustable straps and complex geometries for comfort and performance.

PEEK 3D print samples from WEERG include a complex mechanical assembly and a precision mounting bracket.

POM 3D Print Sample: This part used a combination of POM and corresponding support filament.

CF-ABS and HIPS Sample: This part was printed from carbon-filled ABS with HIPS supports.

CF-ABS: Part made of ABS + carbon fiber composite.

PC and HIPS: Complex geometry parts made of Polycarbonate + HIPS.

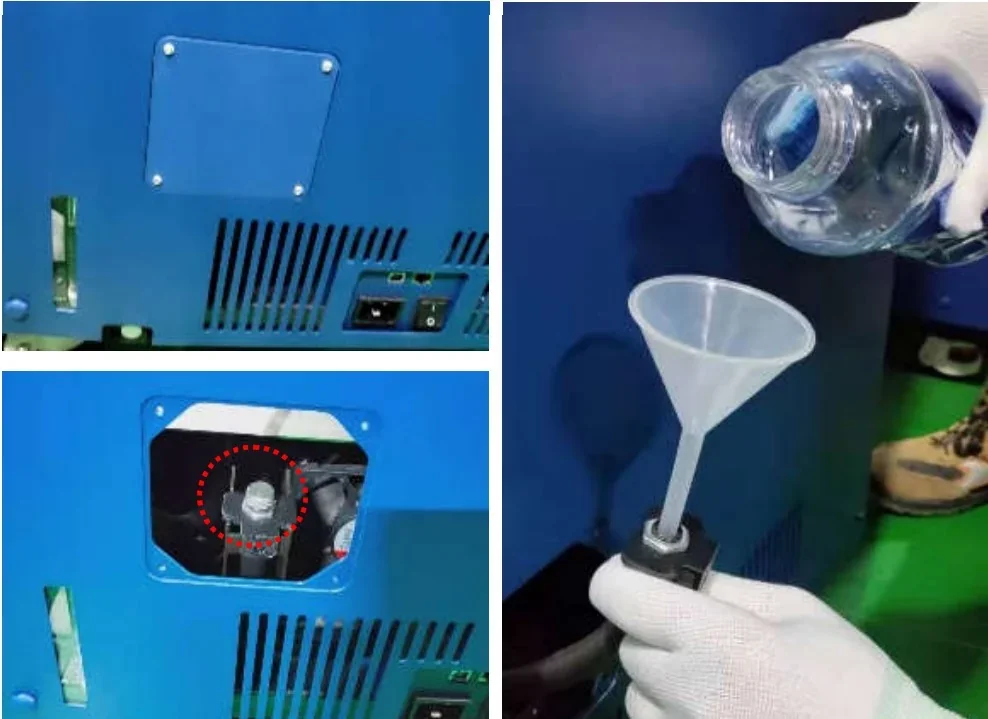

The SP5000 support filament is designed for high-temperature materials like PEEK, PEKK, ULTEM, and PPSU. It provides rigidity during the printing process and dissolves in ethyl acetate for easy removal from complex geometries. The SP3000 series, used for engineering-grade filaments, dissolves in water within 30 minutes.

A significant advantage of the FUNMAT PRO 410 is its open filament system, which is not locked to proprietary filaments. INTAMSYS explicitly designs the printer to work with third-party 1.75mm filaments.

The INTAMSYS FUNMAT PRO 410 offers a 305 x 305 x 406 mm (12 x 12 x 16 inches) build volume.

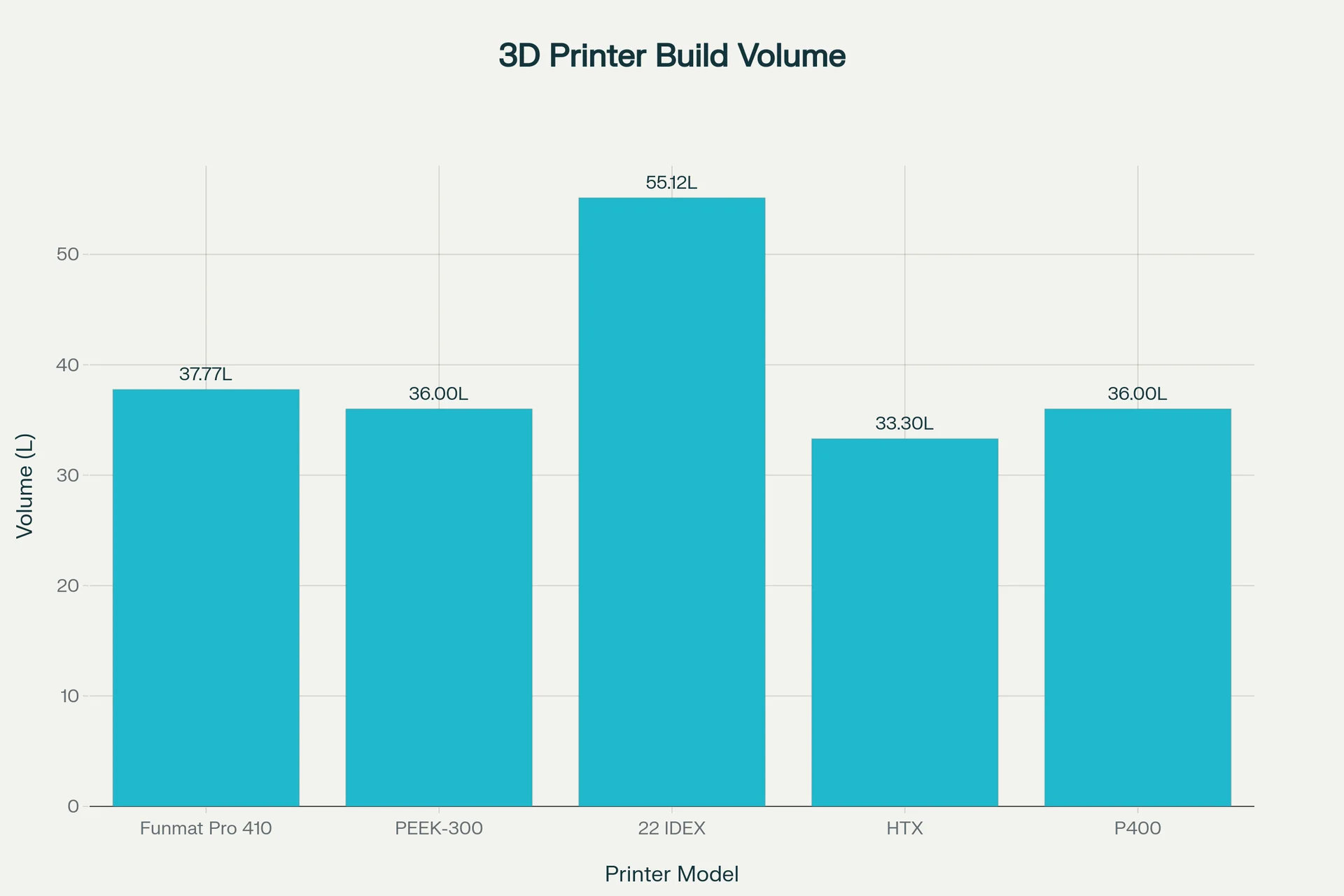

The Intamsys Funmat Pro 410 offers balanced, water-cooled high-temp additive manufacturing (500 °C nozzle, 90 °C chamber) with US/EU support, making it a solid mid-cost choice for those regions. The Apium P400 is the premium solution with enterprise-level support and adaptive zone heating > 500 °C that performs in-situ annealing during printing (no separate post-anneal step). CreatBot PEEK-300 is more affordable with water cooling and a 120 °C chamber, but China-only support slows service in the US/EU. VisionMiner 22 IDEX and 3DLabs HTX are low-cost and open-materials friendly but use air cooling, limiting thermal stability for long PEEK/PEKK jobs. Overall, the Funmat 410 offers reliable high-temp performance and local support without the high price tag.

| Feature | Intamsys Funmat Pro 410 | Creabot PEEK-300 | VisionMiner 22 IDEX | 3DLabs HTX | Apium P400 |

|---|---|---|---|---|---|

| Build Volume (mm) | 305 × 305 × 406 | 300 × 300 × 400 | 350 × 350 × 450 | 370 × 300 × 300 | 400 × 300 × 300 |

| Build Volume (L) | 37.77 | 36.00 | 55.12 | 33.30 | 36.00 |

| Chamber (°C) | 90 | 120 | 100 | 100 | Adaptive heater operates at >500 °C target |

| Nozzle (°C) | 500 | 480 | 500 | 500 | 540 |

| Bed (°C) | 160 | 200 | 250 | 220 | 200 |

| Price (USD) | $27,995+ | $13,999+ | $9,700+ | $15,499+ | $125,000+ |

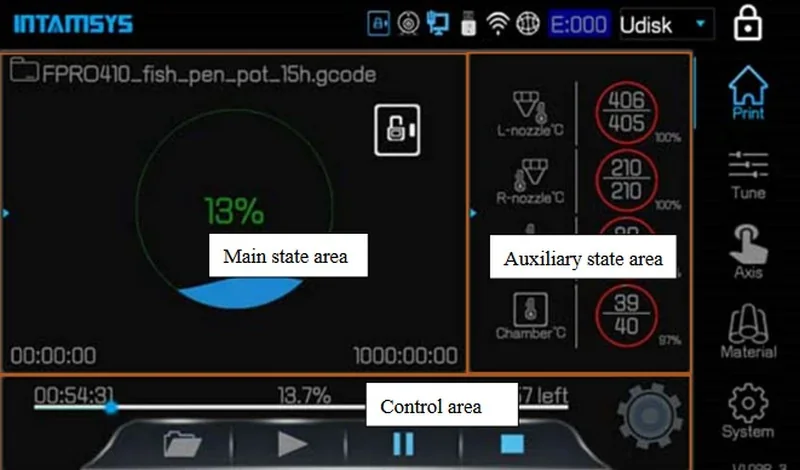

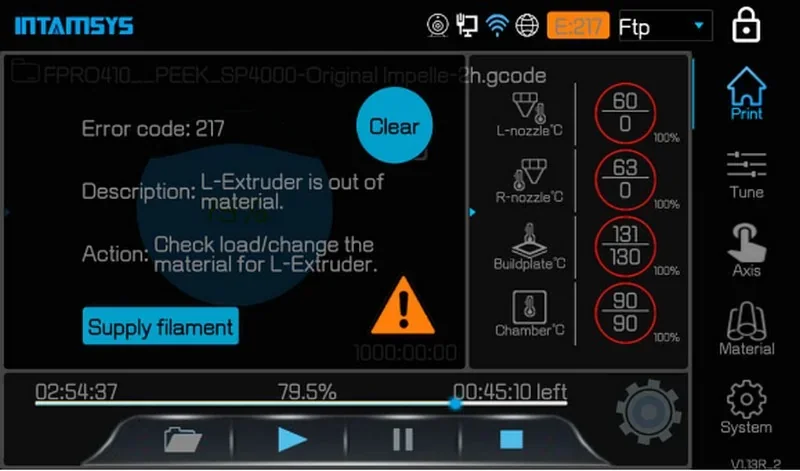

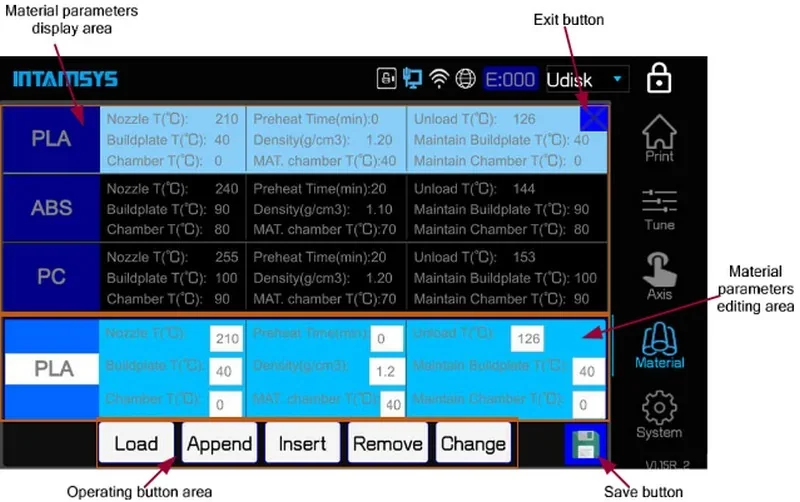

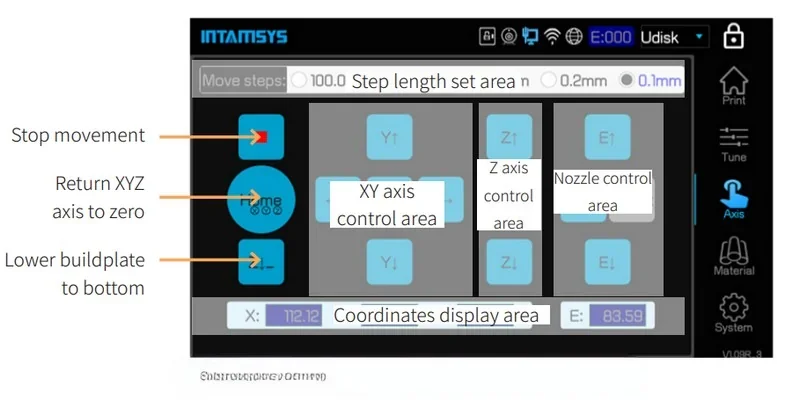

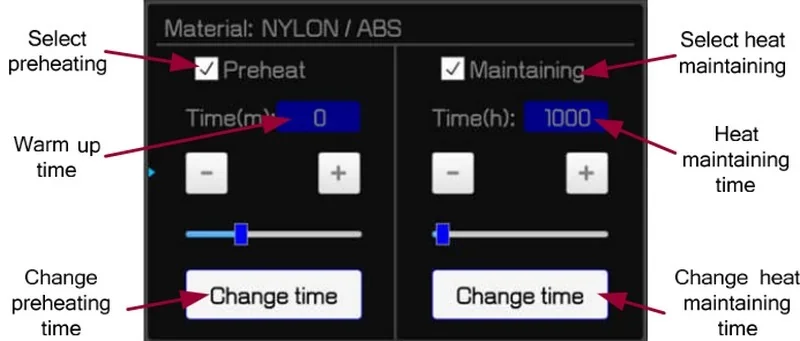

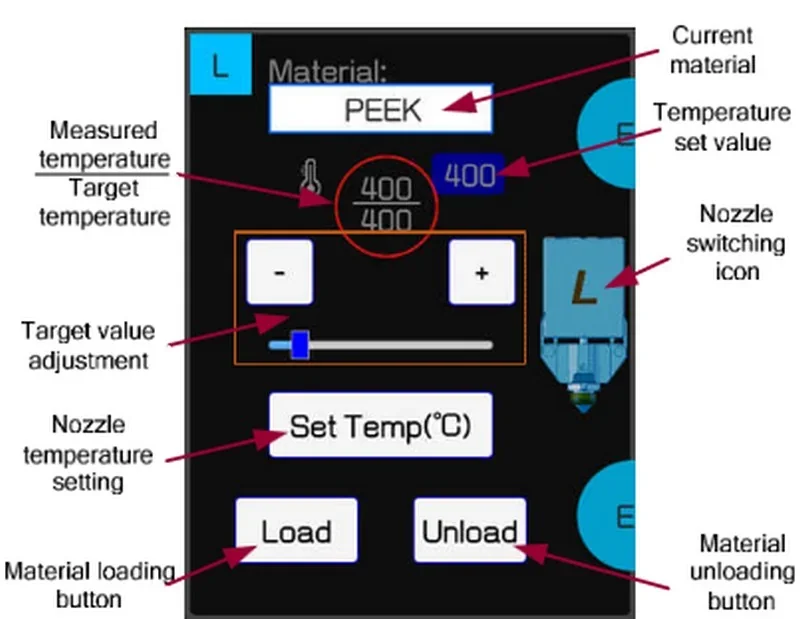

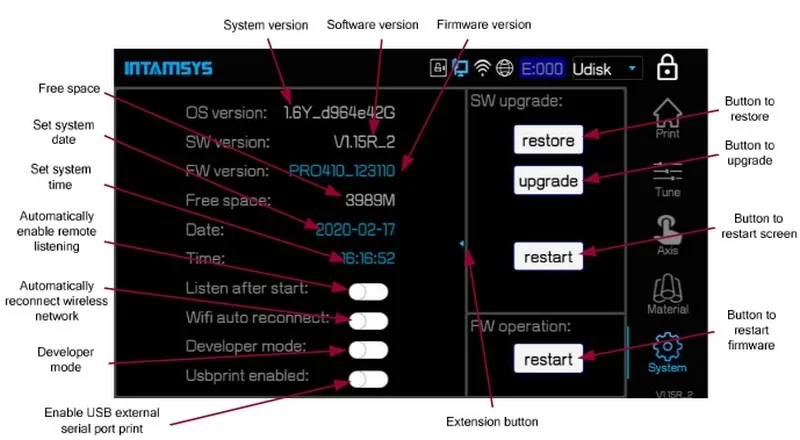

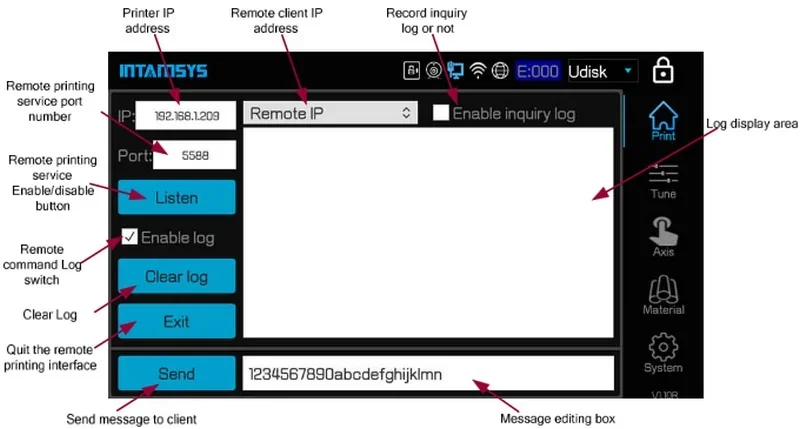

The INTAMSYS FUNMAT PRO 410 has a 7-inch full-color IPS touchscreen with a 170° viewing angle for full print control. Its menus cover print management, temperature, and system settings, including Tune for heating elements, Axis for bed and head movement, and Filament for material parameters. A front-panel light shows status—blue for standby, green for ready, yellow for printing.

Physical Controls (4 categories):

Touchscreen Controls (6 categories):

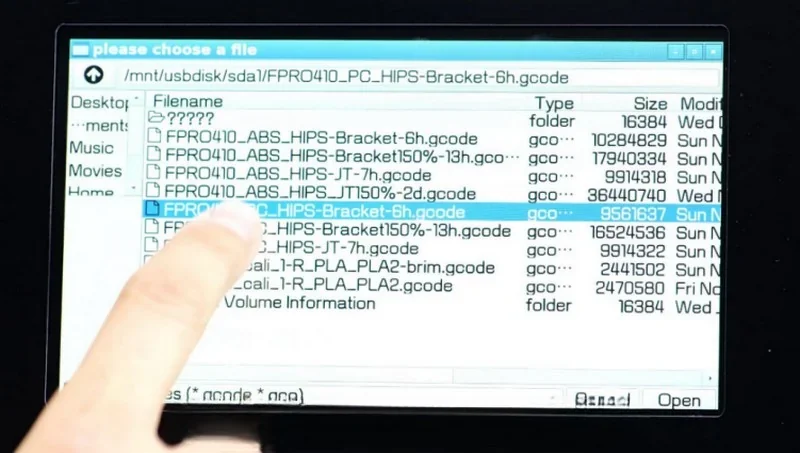

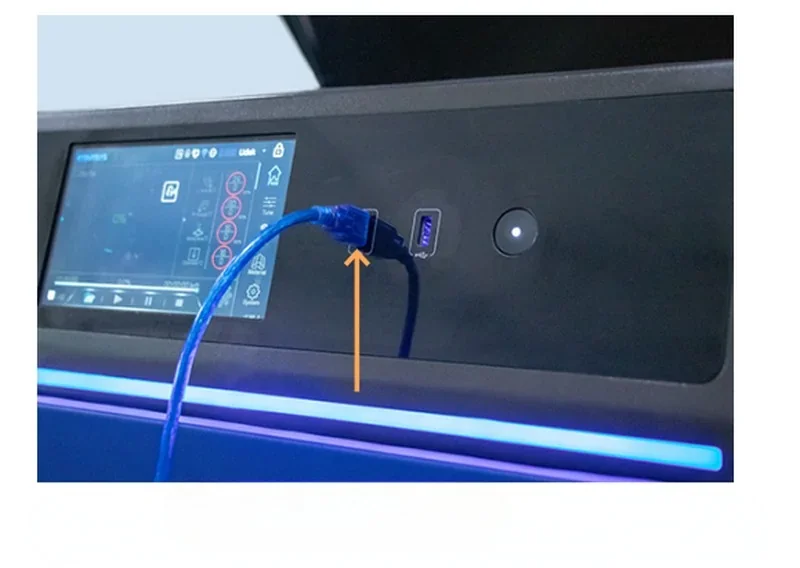

The INTAMSYS FUNMAT PRO 410 supports Wi-Fi, Ethernet, USB, and SD card connectivity, with offline printing via SD card. It includes a camera for remote monitoring and uses INTAMSUITE software on Windows, Linux, and Mac. Power-failure recovery and filament warnings add reliability for industrial use.

The INTAMSYS FUNMAT PRO 410 uses INTAMSUITE, a Cura-based slicer with profiles for high-performance filaments and dual-extrusion settings. INTAMSUITE NEO adds a CAD-style interface, project comparison, and remote monitoring. The printer also supports third-party slicers like Simplify3D, Cura, and Slic3r for flexibility.

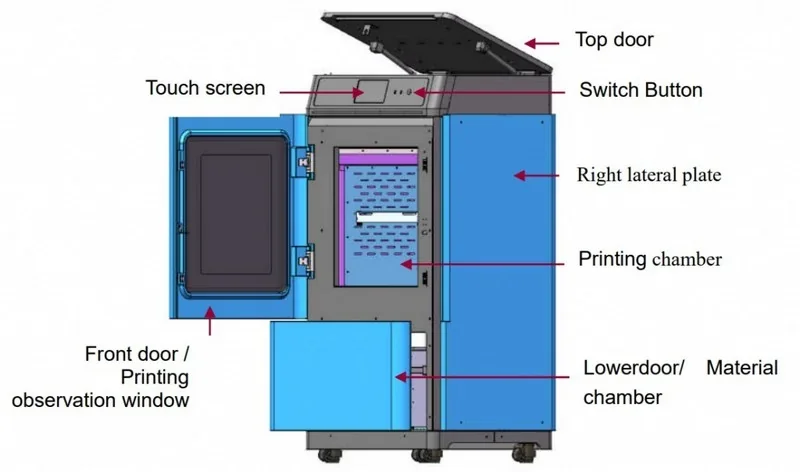

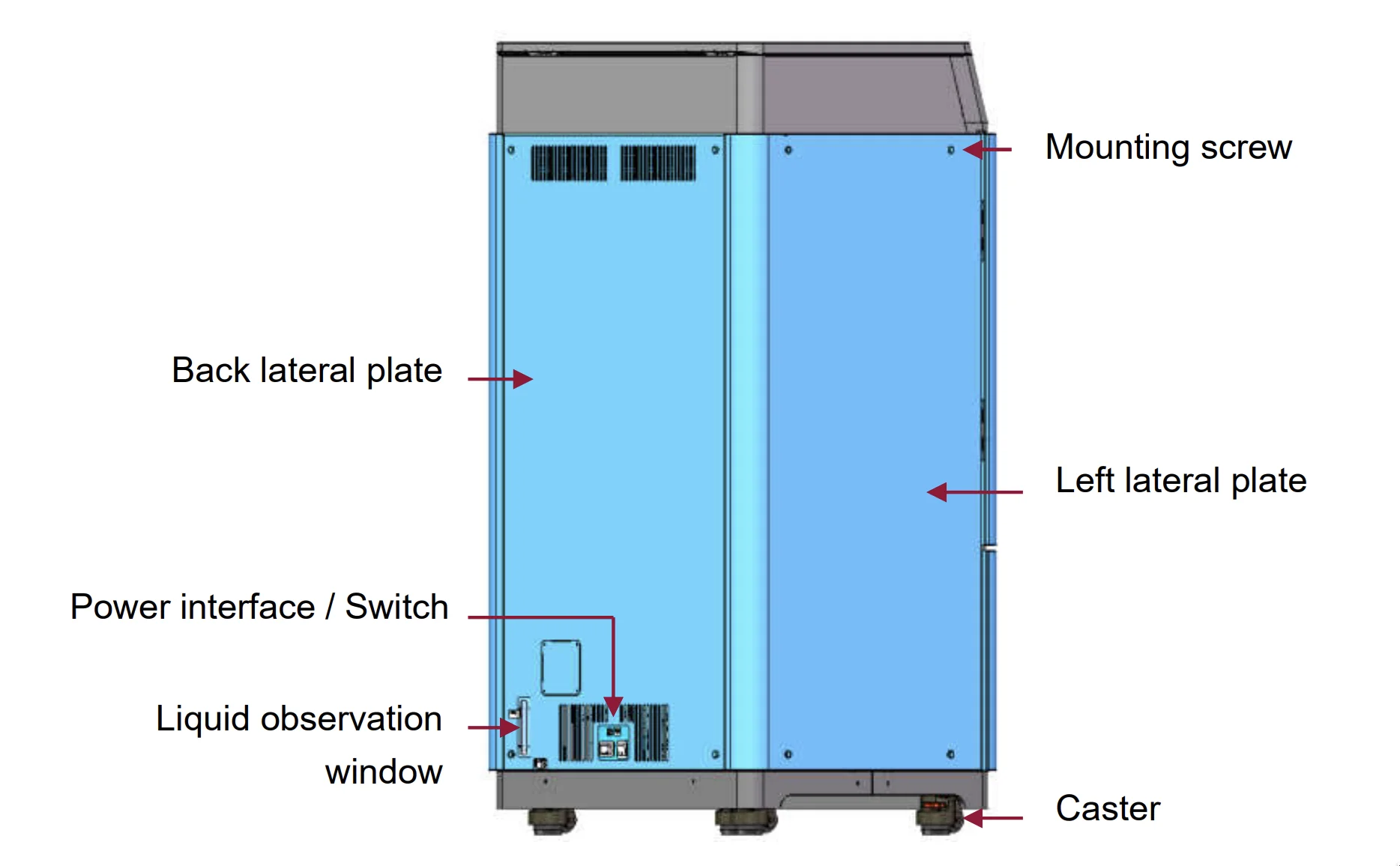

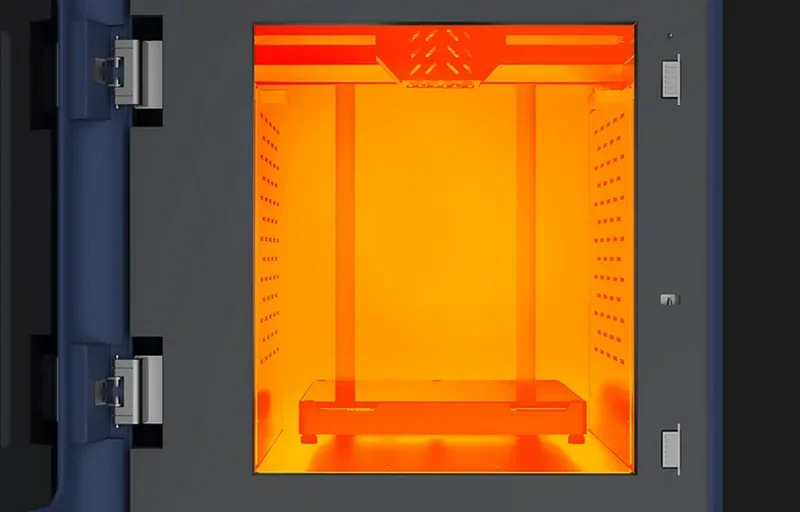

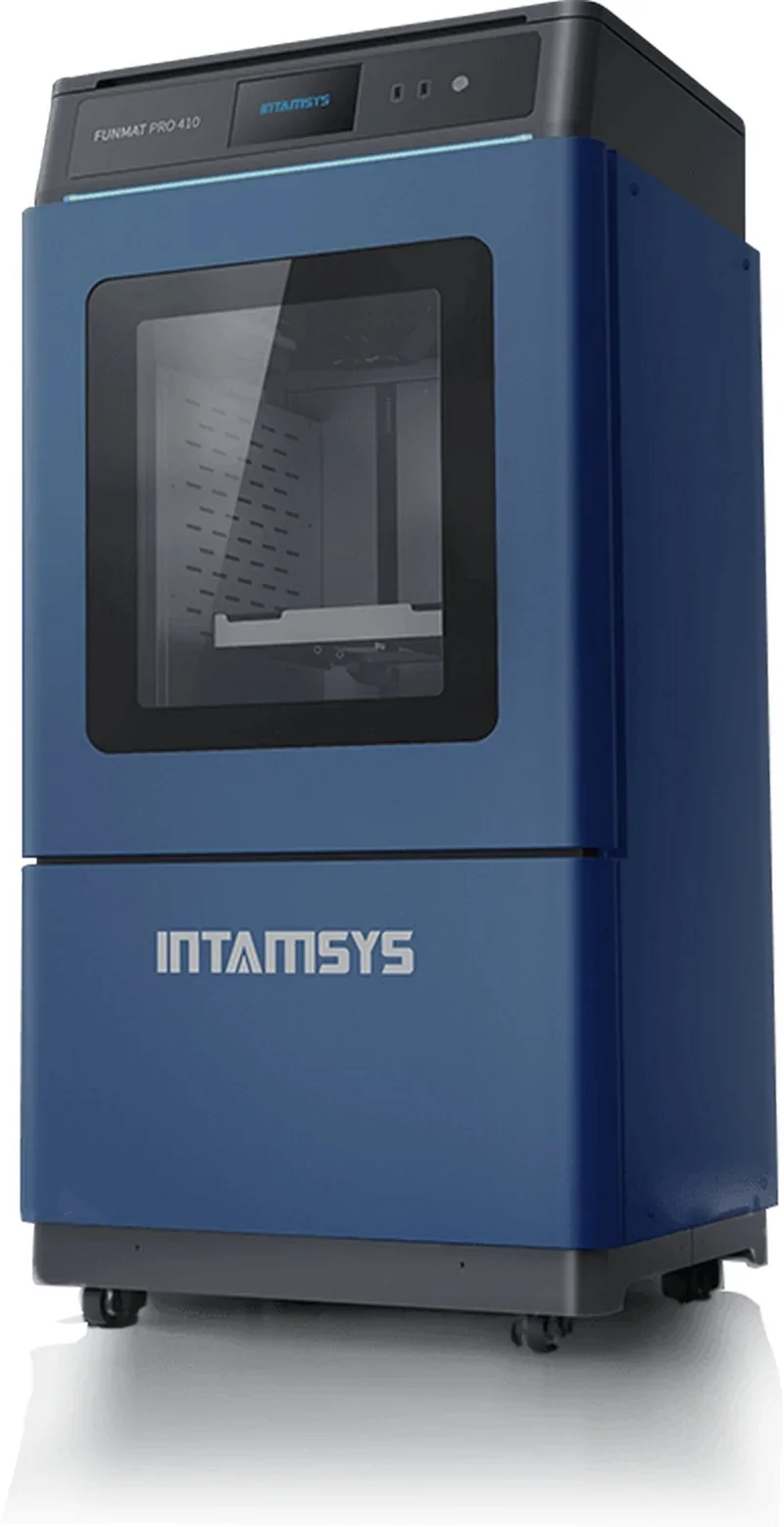

The Intamsys Funmat Pro 410 is a fully enclosed industrial 3D printer, measuring 720 × 670 × 1460 mm, weighing 200 kg, and finished in dark blue powder coat for a professional look. Its three-zone layout includes bottom filament storage, a central heated chamber with large observation windows, and a top control interface.

The printer sits on a wheeled, lockable base for easy repositioning.

The chamber features magnetically sealed doors with safety interlocks, a gas-spring top access door, dual-pane windows, an active carbon H13 HEPA filter for safe indoor operation, and LED lighting for safe operation and clear print monitoring.

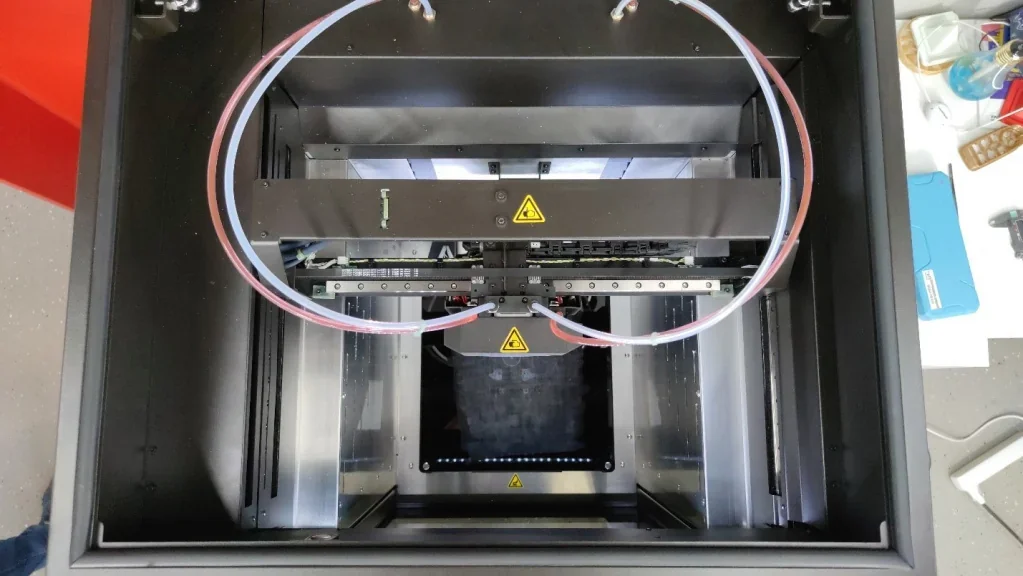

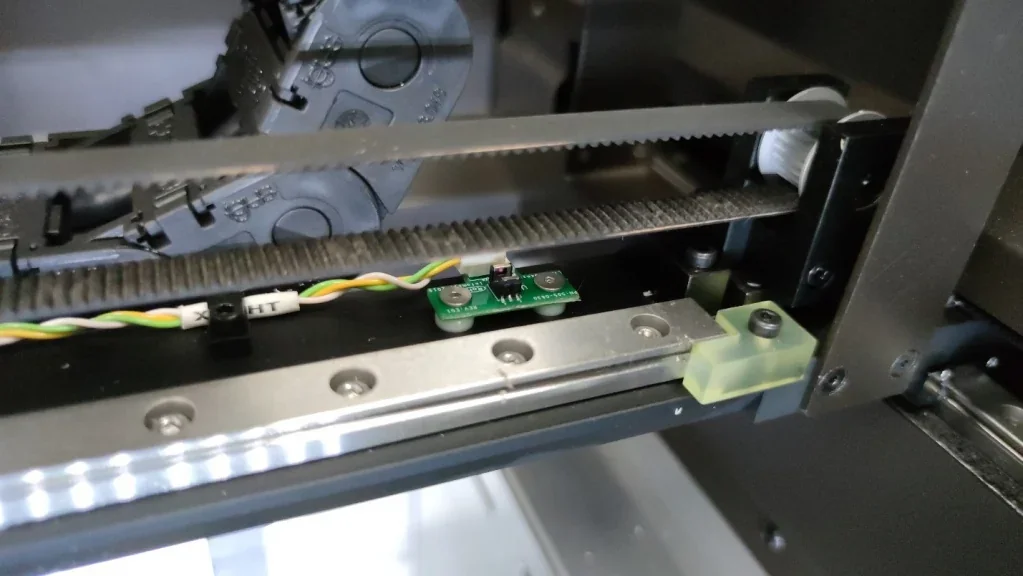

The Funmat Pro 410 uses a Cartesian kinematic system built with industrial-grade components. The X/Y axes run on linear guide rails with Gates LL-2GT timing belts driven by 1.4 N·m stepper motors, ensuring reliable motion even under high-temperature conditions.

The Z-axis employs dual cylindrical linear guides with a ball screw drive and coupling buffer to minimize backlash, plus polyurethane bumpers for added protection.

All axes feature optical endstops for precise homing, while motion is powered by Leadshine motor drivers under a System 32 architecture, providing robust command processing and coordinated movement.

Y-Motor:

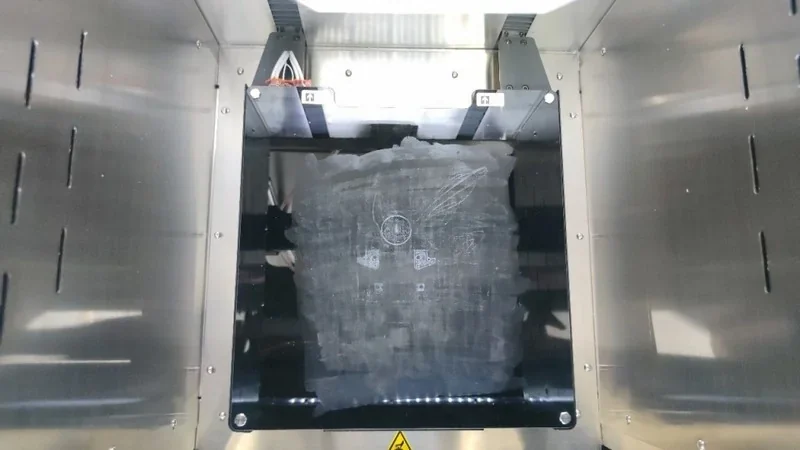

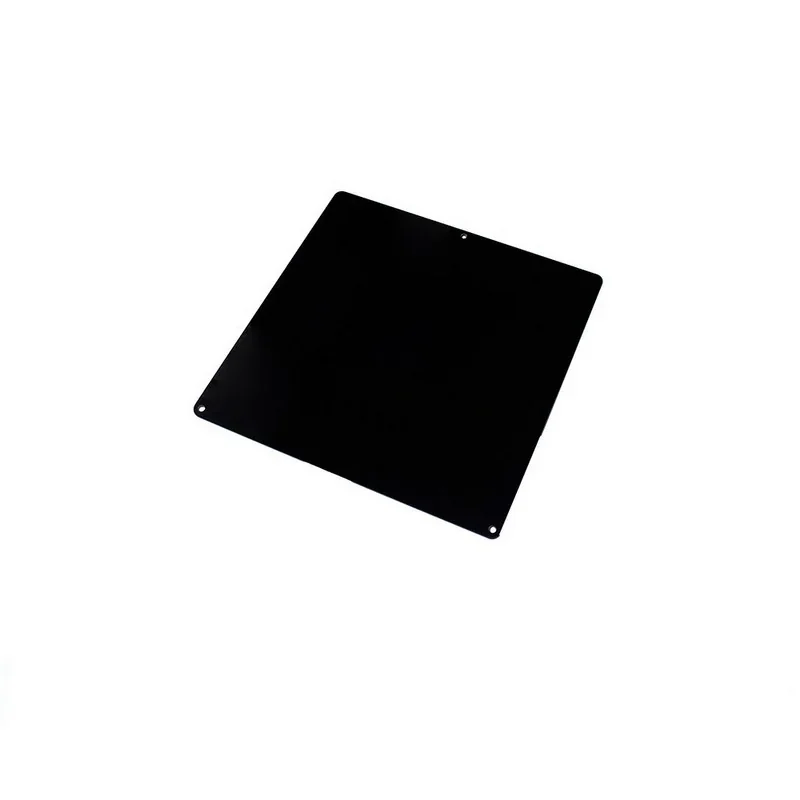

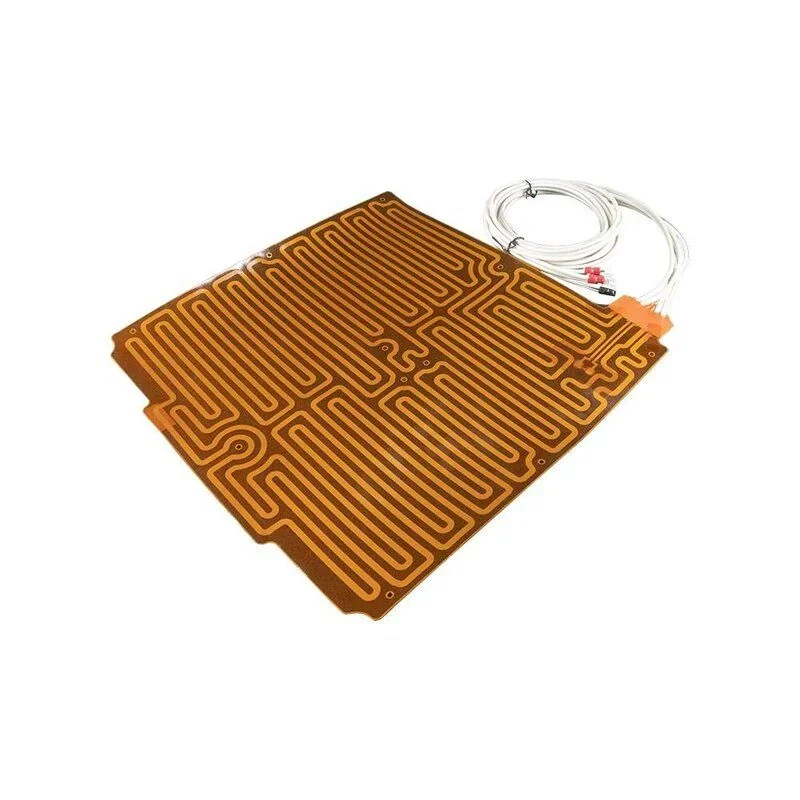

The Funmat Pro 410 provides a 305 × 305 × 406 mm build volume for large industrial parts. Its heated platform reaches 160 °C and uses interchangeable glass build plates. Two plate types are included: glossy glass for standard materials and matte high-temperature glass for engineering thermoplastics. Plates are mounted with four magnets securing them to the heated aluminum bed.

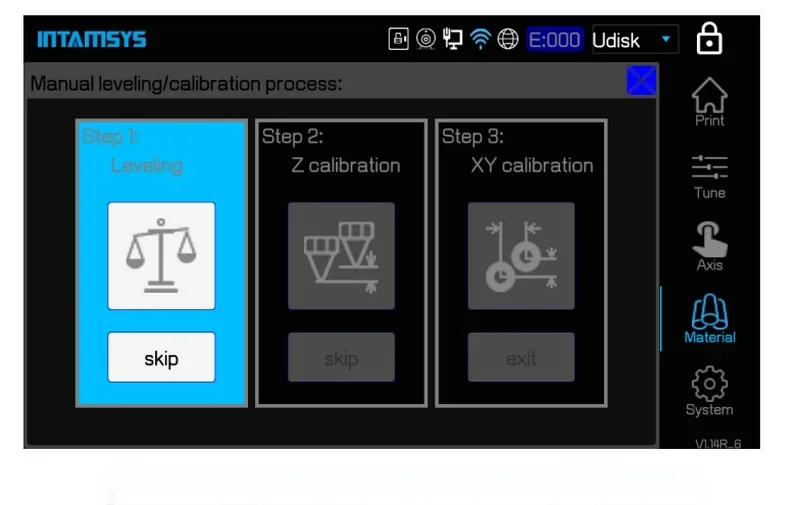

Bed leveling is handled manually with four adjustment screws and a 0.2 mm feeler gauge, or automatically via a sensor integrated into the left extruder.

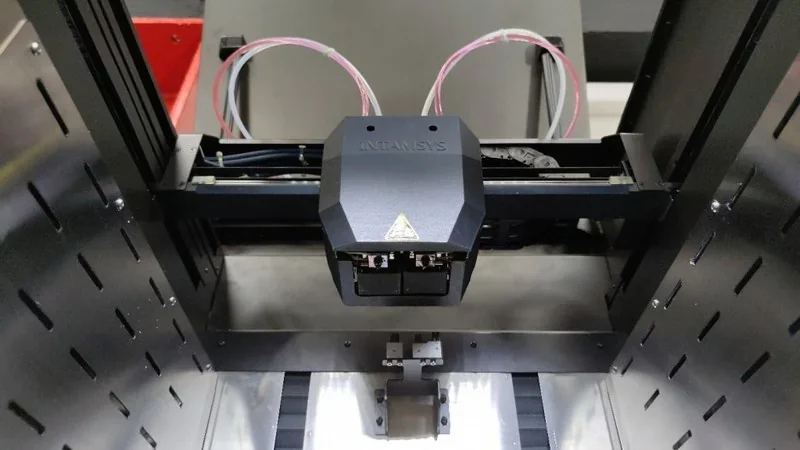

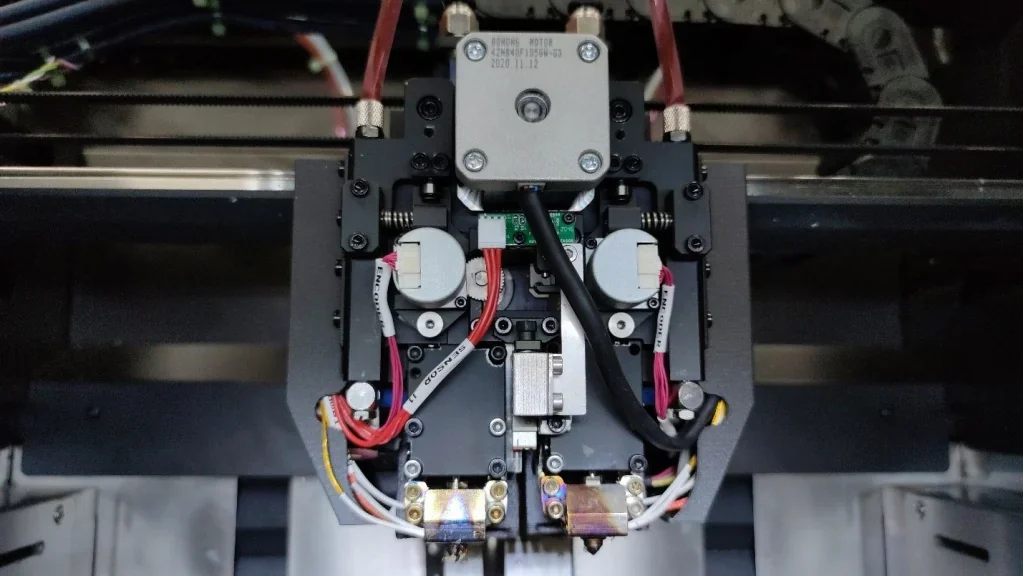

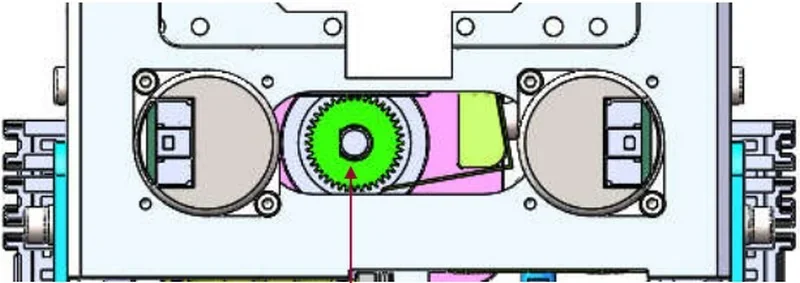

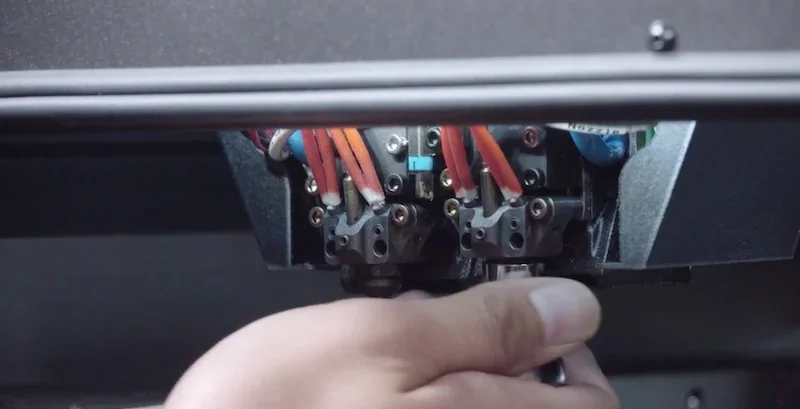

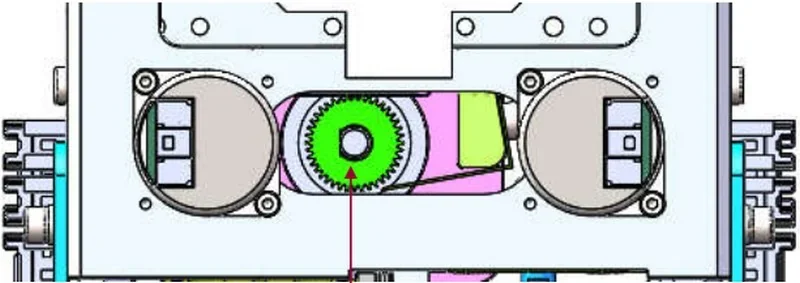

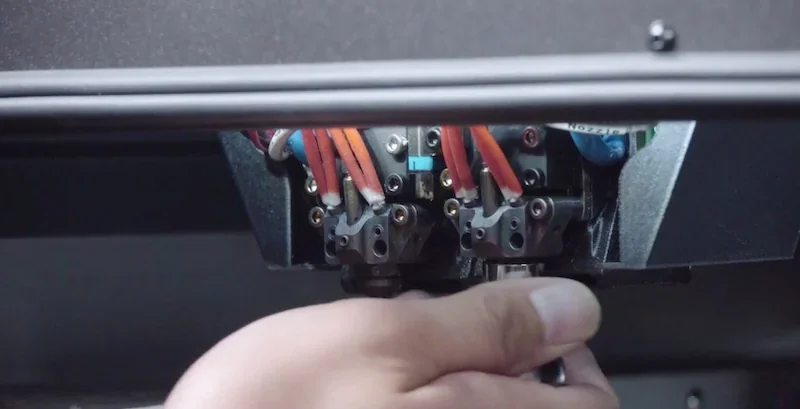

The Funmat Pro 410 uses a dual-extruder system with independent temperature control. The primary high-temperature hotend reaches 500 °C for engineering thermoplastics, while the secondary extruder supports materials up to 260 °C. Both are driven by a direct-drive mechanism with a single stepper motor and switching system.

The assembly is liquid-cooled with dedicated cooling blocks to stabilize the cold zones.

Each extruder includes filament runout and feed monitoring sensors for triple-redundant flow control. The hotends use proprietary all-steel nozzles, supplied with interchangeable 0.4 mm tips as standard.

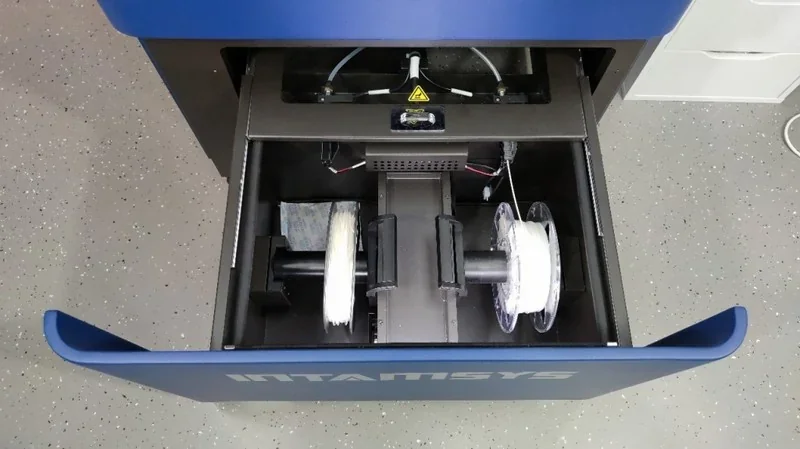

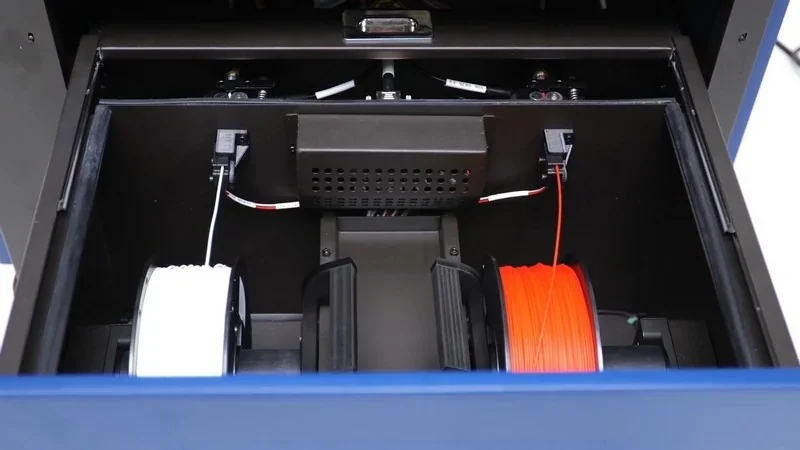

The Funmat Pro 410 features a heated filament chamber up to 70 °C for material drying. It accommodates two 0.5–2 kg spools with weight monitoring, presence sensors, and auxiliary feed mechanisms for reliable delivery. The chamber includes automatic lighting, a sliding magnetic door for humidity control, and secure mounting hardware for stable spool placement.

The Funmat Pro 410 operates on a System 32 architecture. The control system separates processing for the touchscreen interface and motion coordination. Developer modes allow custom G-code execution and diagnostics.

The Funmat Pro 410 operates on 200–240 V AC, 50–60 Hz input and powers multiple heating zones, including dual extruders, heated bed, chamber, and filament storage. Dual power controls consist of a main AC disconnect and a front panel power button.

The INTAMSYS FUNMAT PRO 410 package includes:

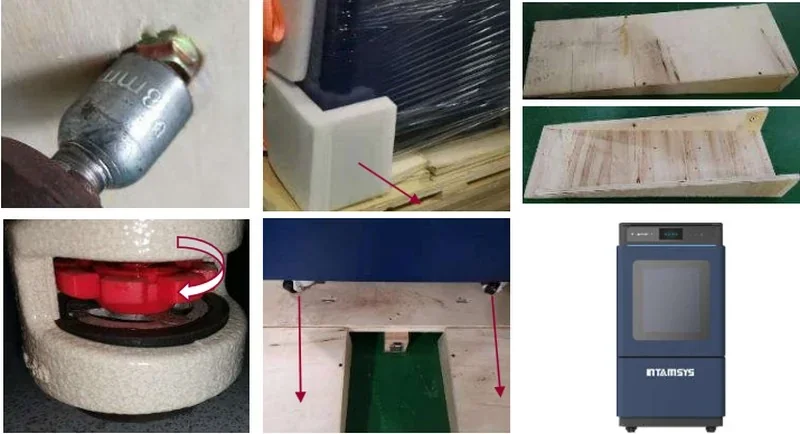

The INTAMSYS FUNMAT PRO 410 ships in a sturdy wooden crate, fully assembled and factory-calibrated for quick setup. It includes a tool kit for maintenance and nozzle changes, plus two glass build plates for standard and high-temperature printing. Users can start printing immediately with the supplied PLA or high-performance polymers without extra accessories.

Please Note: Package contents are determined by the manufacturer anotice. To confirm the current items included with this product, please contact a Top3DShop sales representative before placing your order.

The Funmat HT Enhanced supports more than 19 replacement components and accessories to extend functionality and ensure reliable performance with high-temperature filaments.

| Accessory | Function | Price (USD) | Image |

|---|---|---|---|

| INTAMSYS Pro 410 Ceramic Glass Plate V2 | Newer-generation ceramic-glass build plate for repeatable adhesion and stable heating; replacement/upgrade plate | $265 |  |

| INTAMSYS FUNMAT PRO 410 G1 Fixed Hardened Steel Nozzle 0.4/0.6 mm (right) | Wear-resistant fixed extrusion nozzle designed to hold diameter longer when printing abrasive filaments (e.g., filled composites) | $58 |  |

| INTAMSYS FUNMAT PRO 410 G1 Fixed Nozzle 0.4/0.6 mm (Cu/Cr/Zr, right) | Durable fixed extrusion nozzle for reliable material flow and stable printing performance (replacement right nozzle) | $47 |  |

| INTAMSYS FUNMAT PRO 410 G1 Retractable Hardened Steel Nozzle 0.4/0.6 mm (left) | Wear-resistant retractable nozzle used for bed calibration/leveling, improving probing reliability and long-term accuracy | $105 |  |

| INTAMSYS FUNMAT PRO 410 G1 Retractable Nozzle 0.4/0.6 mm (Cu/Cr/Zr, left) | Retractable leveling/calibration nozzle for consistent bed probing and repeatable first-layer results (replacement left nozzle) | $99 |  |

| INTAMSYS Pro 410 G2 Nozzle Assembly High Temp 0.4/0.6 mm | G2 print-head nozzle assembly for high-temperature setups; restores clean extrusion and consistent layer deposition | $89 |  |

| INTAMSYS Pro 410 G2 Nozzle Assembly Low Temp 0.4/0.6 mm | G2 print-head nozzle assembly for lower-temp setups; restores stable extrusion and predictable print quality | $89 |  |

| INTAMSYS Mini PC (Linux/WiFi) for FUNMAT PRO 410 | Main control/display module (UI + controller + Wi-Fi) that restores full printer operation and interface responsiveness | $1,330 |  |

| INTAMSYS 40×10 Cooling Fan Assembly (UI/SW board) | Dedicated electronics cooling for the UI/SW board to prevent overheating-related instability and failures | $40 |  |

| INTAMSYS 40×15 Cooling Fan Assembly (electrical cabinet) | Electrical-cabinet cooling fan that protects internal electronics from heat buildup for higher uptime/reliability | $25 |  |

| INTAMSYS 60 Cooling Fan Assembly (electrical cabinet) | Higher-capacity cabinet cooling for boards/controllers to maintain stable operating temperatures and reduce fault risk | $50 |  |

| INTAMSYS 42 Stepper Motor (Pro 410) | Replacement motion drive motor that restores accurate axis movement, positioning, and print dimensional consistency | $36 |  |

| INTAMSYS Backup Power (Pro 410) | Power-loss protection that buffers outages so prints can pause safely and resume, reducing failed builds and waste | $140 |  |

| INTAMSYS Buildplate Heater Sheet (Pro 410, 680W/24V) | Replacement heated-bed element that restores fast warm-up and even bed temperature for better adhesion/less warping | $105 |  |

| INTAMSYS Camera (Pro 410) | In-chamber monitoring for live progress checks and early detection of failures (remote supervision) | $71 |  |

| INTAMSYS Chamber Heating Tube (Pro 410) | Replacement chamber heater to maintain a stable heated environment, improving results on warp-prone engineering plastics | $24 |  |

| INTAMSYS FUNMAT PRO 410 Filament Tube | Filament guide tube that reduces friction and routing errors for smoother, more reliable feeding | $8 |  |

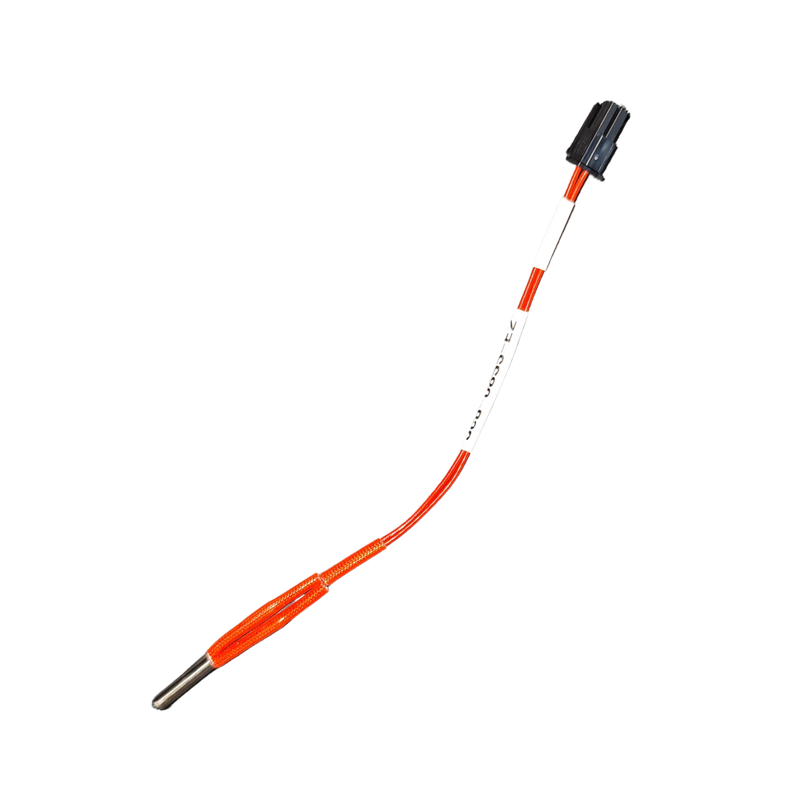

| INTAMSYS FUNMAT PRO 410 Nozzle Heater Assembly 2 | Hotend/nozzle heating component that restores proper melt temperature and extrusion stability | $51 |  |

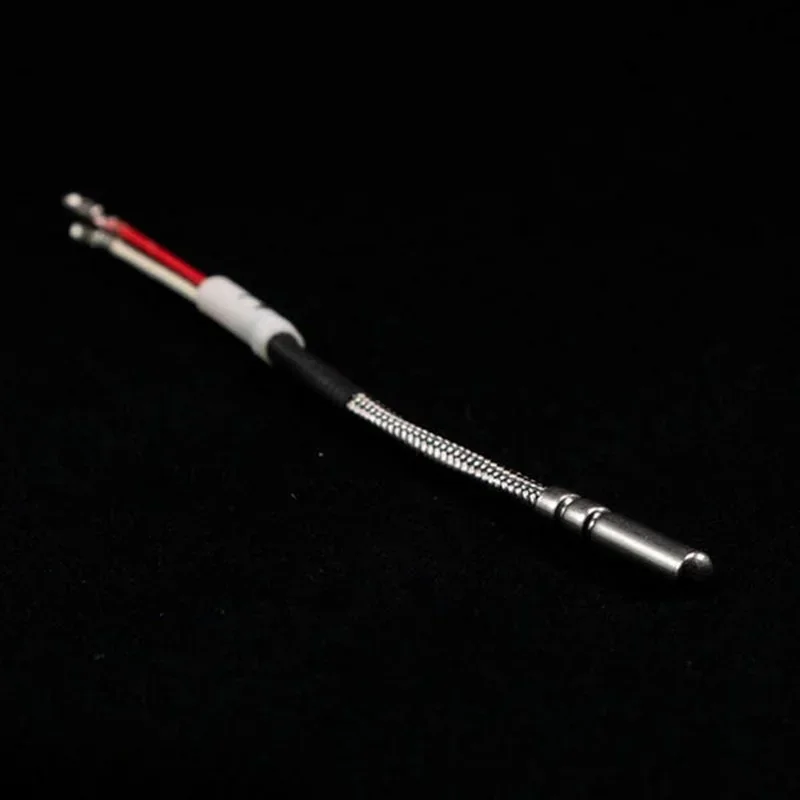

| INTAMSYS FUNMAT PRO 410 Nozzle Thermistor Assembly | Nozzle temperature sensor that restores accurate temperature readings/control and prevents temp-related print errors | $125 |  |

The FUNMAT PRO 410 requires scheduled maintenance to maintain print quality, material feeding, and thermal and mechanical performance.

Before Printing:Feeding gear positioning:

Every 6 Months:

Every 12 Months:

Every 2 Years (or per product specification):

Additional Notes:

Warranty Coverage:

Extended Warranty (Optional):

| Warranty Plan | Price (USD) |

| 1-Year Extension | 2000 |

| 2-Year Extension | 4000 |

Warranty Requirements:

Warranty is Void If:

Repair Works for User-Caused Damage:

Technical Support & Resources:

Email Support by Region:

Help Center Resources:

Authorized Distributor – Top 3D Shop:

The INTAMSYS FUNMAT PRO 410 is an industrial dual-extrusion 3D printer with a 305 × 305 × 406 mm build chamber for precise functional parts. Pricing varies by installation, service, and use case; quotes are available from Top 3D Shop. Built for demanding environments, it delivers advanced performance and reliability.

Update your browser to view this website correctly. Update my browser now