The INTAMSYS FUNMAT PRO 610HT is an industrial FFF 3D printer with a 610 × 508 × 508 mm build volume, a 300 °C heated chamber and build plate, and dual 500 °C extruders for high-performance polymers like PEEK, PEKK, PEI, and PPSU. It achieves 12.5 µm XY and 1.25 µm Z accuracy for high surface quality and uses a dual-nozzle system with auto-cleaning and water-soluble support compatibility for complex parts. Designed for aerospace, automotive, medical, and high-tech industries, it includes intelligent features like filament reloading, jam detection, and safety controls for reliable 24/7 production.

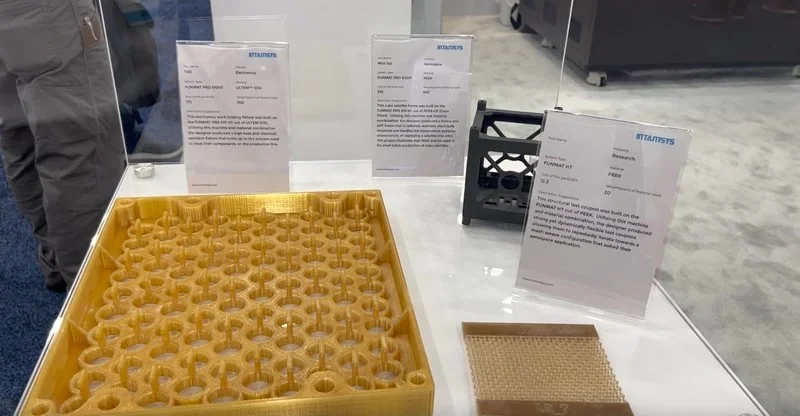

The INTAMSYS FUNMAT PRO 610HT achieves layer heights down to 50 µm, with 12.5 µm XY and 1.25 µm Z resolution for high dimensional accuracy and surface quality in complex geometries. The precision is maintained through a closed-loop servo system and ball screw drives, ensuring accurate positioning even at high print speeds, with sub-micron resolution in the X and Y axis. For example, below are three prints samples (left to right): a 700-gram ULTEM 1010 fixture for electronics, a 400-gram PEEK satelite frame, and a 20-gram PEEK mesh weave test coupon printed on the Funmat Pro 610HT.

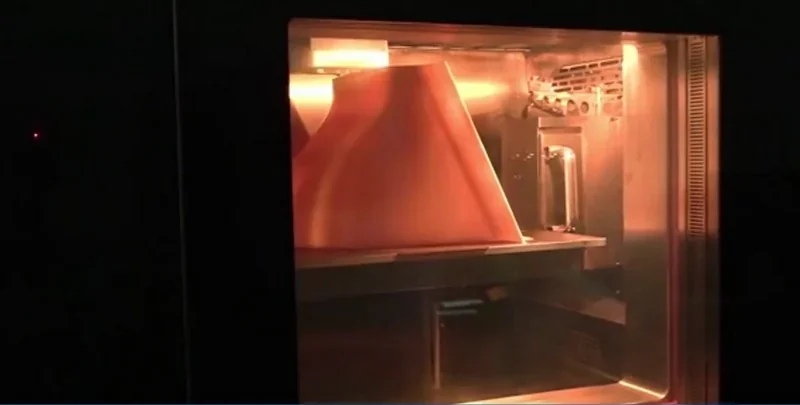

The FUNMAT PRO 610HT enhances print performance with an all-metal hotend and dual extruders reaching 500 °C, paired with a uniformly heated 300 °C chamber for stable processing of high-performance filaments like PEEK, PEI, and PPSU without warpage. For example, JLC, a prototyping and 3D printing service with over 100 machines, uses six Intamsys Funmat Pro 610 HT systems for large ABS and PC parts over 25 cm. The 610 HT ensures warp-free results with 0.2–0.3 mm accuracy and runs 24/7 with high reliability.

The FUNMAT PRO 610HT supports travel speeds up to 500 mm/s (XY) and 50 mm/s (Z), with typical print speeds of 30–100 mm/s depending on material.

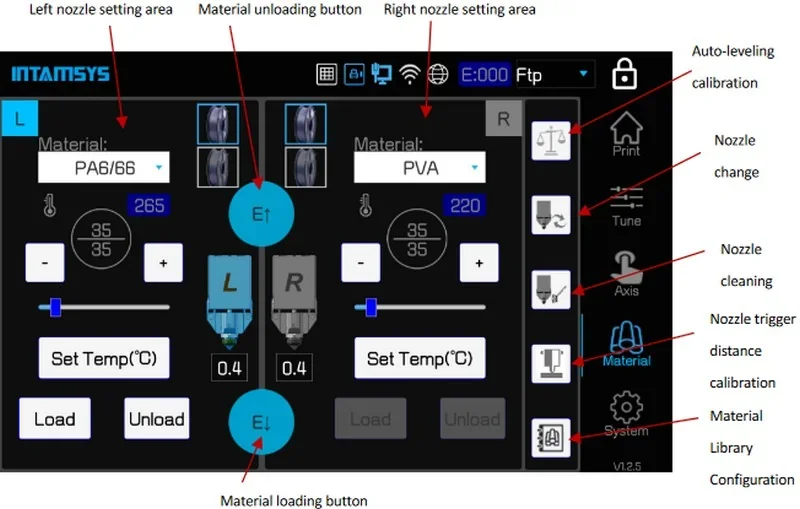

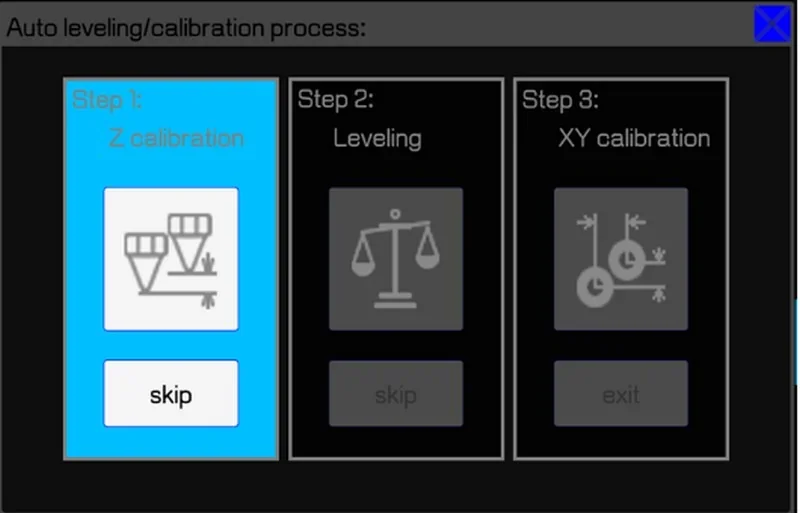

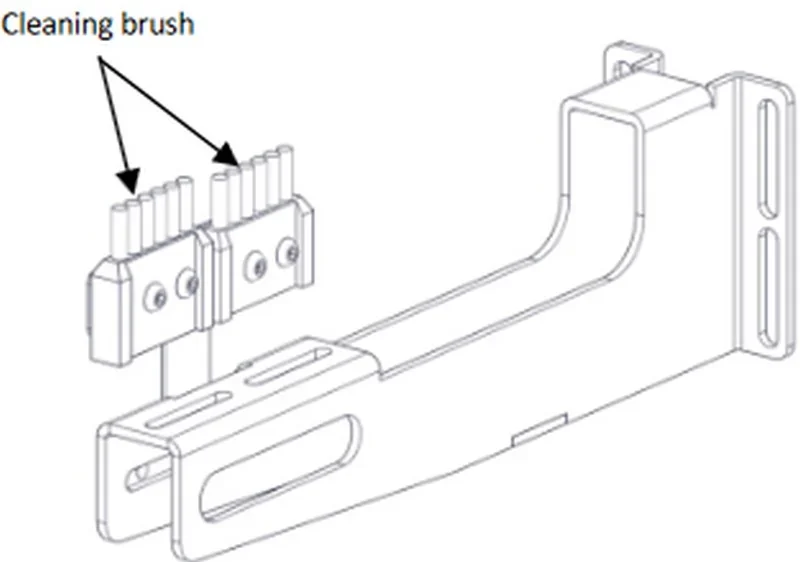

The FUNMAT PRO 610HT integrates features for consistent print quality, including fully automatic bed leveling with real-time Z compensation, liquid-cooled extruders to prevent jamming, and automatic nozzle cleaning for reliable operation. Dual nozzles with support filament capability further ensure smooth surface finishes on complex geometries.

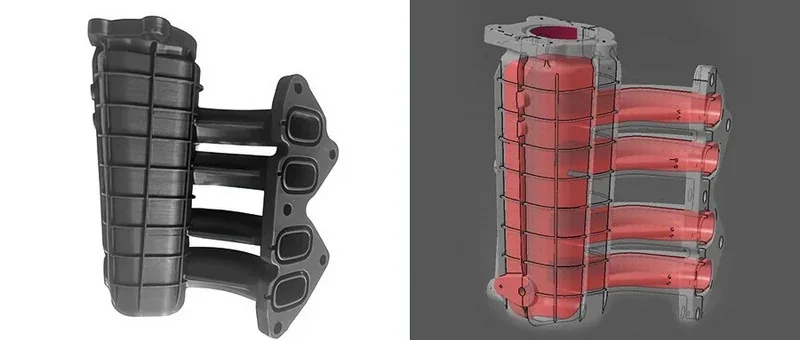

Produced at the Institute of New Industrial Materials in Dezhou, the 3D-printed manifold (218.4 × 216.4 × 95.4 mm) achieves 30% weight reduction with 1.7 mm walls, ±0.2 mm accuracy, 100 MPa strength, and heat resistance to 144 °C. Compared to traditional production costing $30,000 and six weeks, additive manufacturing delivers the part in one piece at one-tenth the cost within 4–7 days.

The printer ensures 24/7 reliability with monitoring features such as jam detection, absence sensors, and safety controls. Its 610 × 508 × 508 mm build volume supports full-size functional parts in a single print, eliminating assembly and preserving uniform material properties. For example, Horizon Aircraft produced over 780 3D-printed components for its Cavorite X5 eVTOL prototype, including propeller blades. The aircraft is 4.5 m long with a 6.5 m wingspan, a 225 kg takeoff weight, and exceeds 280 km/h in horizontal flight.

Over four years of real-world use, Deepvolt’s Intamsys FUNMAT Pro 610 HT 3D printer has supported continuous printing cycles of up to 30 days, producing both large and small parts in ABS and HIPS for applications in ATMs, smart safes, and kiosks.

CNES uses a stratospheric drone structure printed in one batch from ULTEM 9085 on the Funmat Pro 610HT. Built for balloon missions, it was tested in near-vacuum conditions, where both the structure and material were qualified for low outgassing, high strength-to-weight ratio, and thermal resistance.

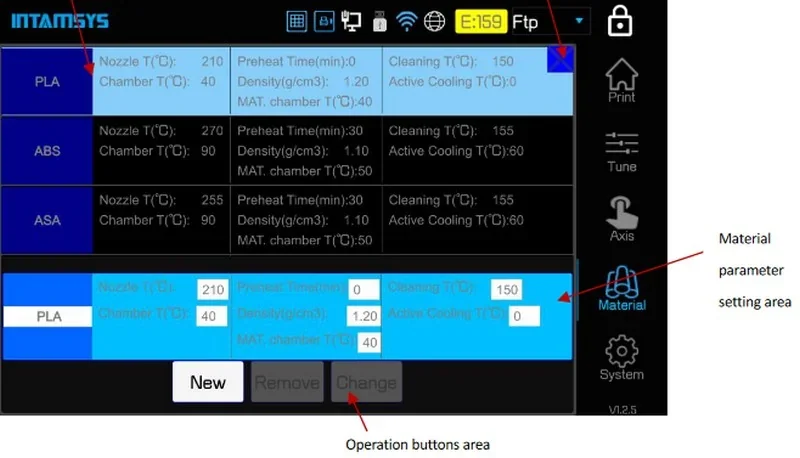

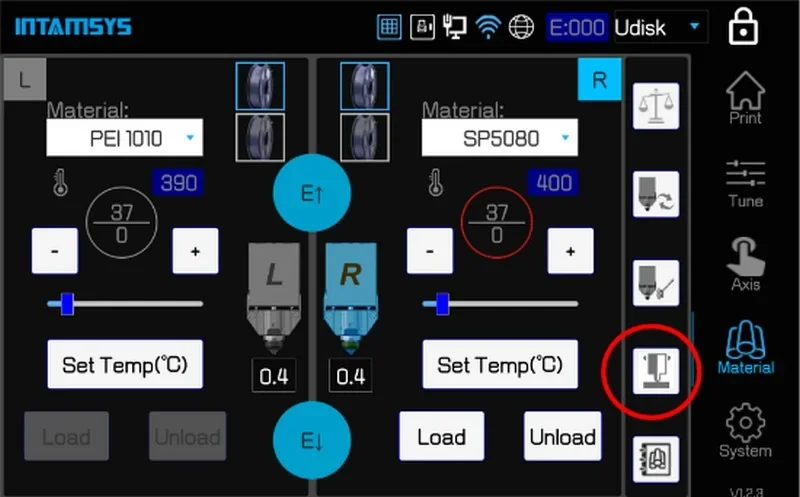

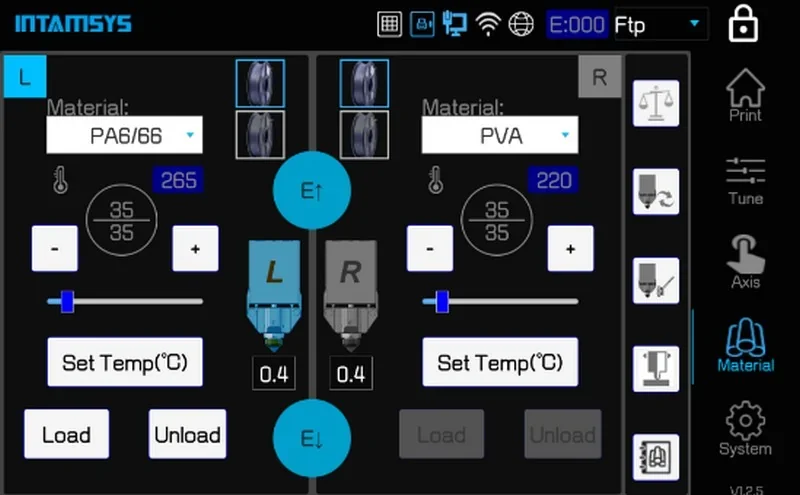

The INTAMSYS FUNMAT PRO 610HT FDM 3D printer supports over 36 filament types. This advanced thermal system enables reliable printing of demanding polymers such as PEEK, PEEK-CF, PEEK-GF, PEKK, PEI 9085, PEI 1010, PPSU, PC, PC alloys, PA, PPA-CF, ABS, ASA, PETG, ESD-safe types, HIPS, TPU and PLA. It also processes composites (carbon fiber-, metal-, and glass-filled) and water-soluble supports, eg. PVA for complex geometries with smooth finishes. All filaments are 1.75 mm in diameter.

PEEK 3D Print Sample: Pump housing for a small high-performance engine

ULTEM 1010 3D Print Sample: A test sample with a smooth finish.

PEEK+CF 3D Print Sample: Drone air intake

PEEK-CF 3D Print Sample: Exhaust manifold

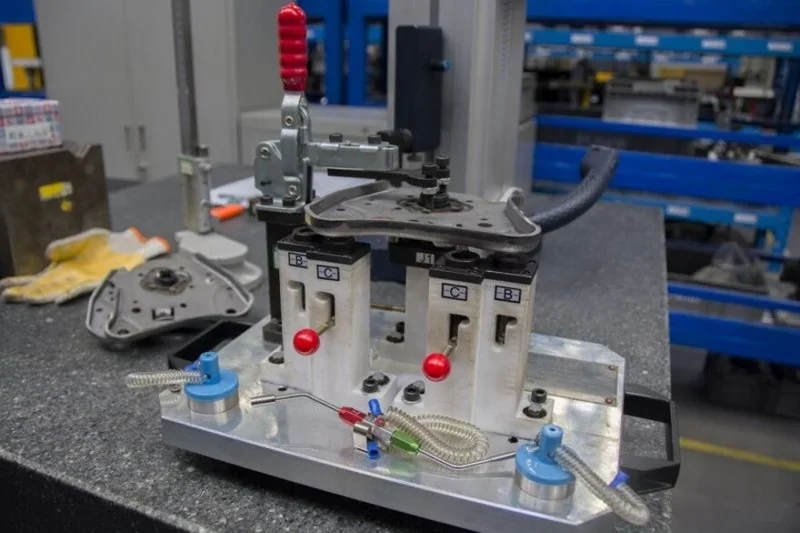

PC 3D Print Sample: Custom fixture for quality control and product standardization in automotive seat manufacturing

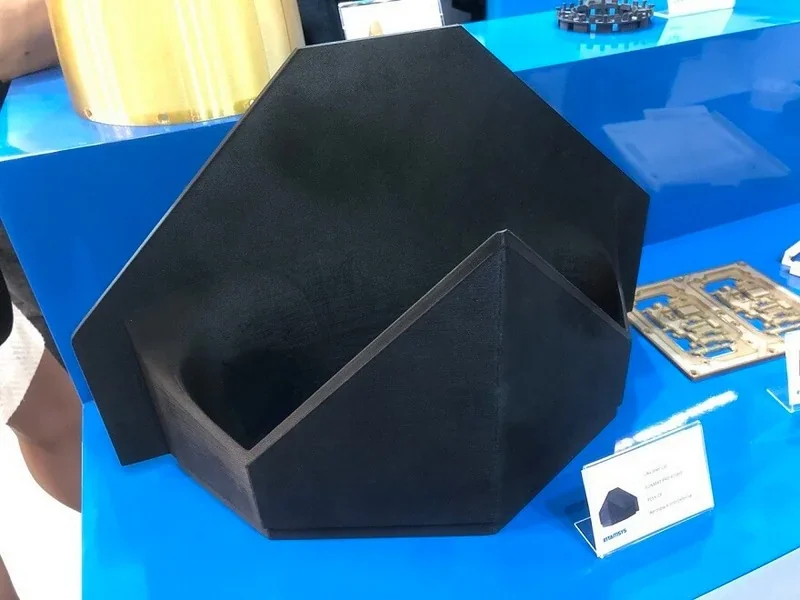

ASA 3D Print Sample: Compass cover

PA-CF 3D Print Sample: Lamp housing

The FUNMAT PRO 610HT uses an open filament system compatible with both INTAM™ and third-party materials, reducing costs by up to 50%.

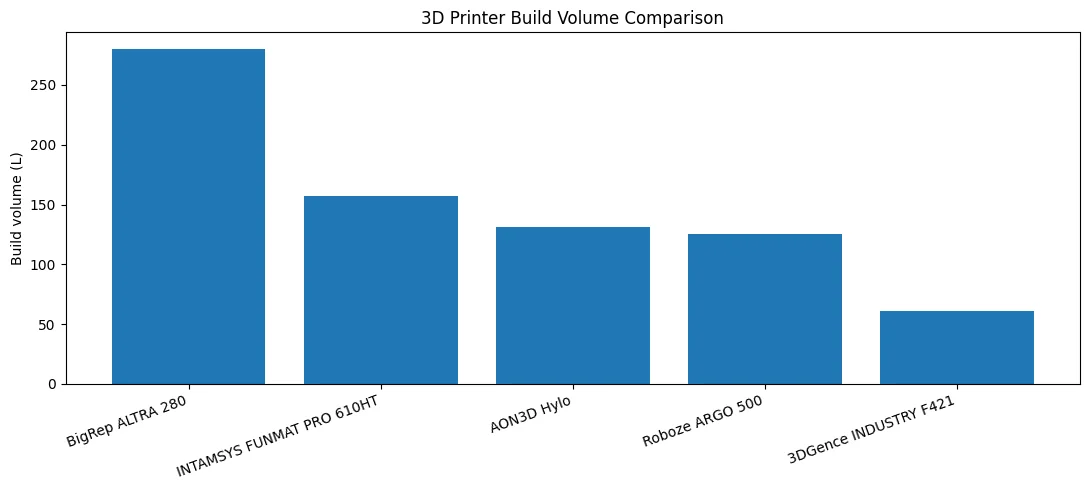

The INTAMSYS FUNMAT PRO 610HT PEEK 3D printer offers a 610 x 508 x 508mm build volume (157.4 L), making it a large-format industrial 3D printer capable of producing full-scale functional parts in a single run. Its capacity eliminates the need for multi-part assemblies, ensuring uniform material properties across entire structures.

INTAMSYS FUNMAT PRO 610HT — very large 610×508×508 mm platform with 500 °C nozzle and a class-leading 300 °C chamber (for uniform, high-heat builds) at a $139,500 mid-tier price among industrial systems.

In contrast:

| Specification | INTAMSYS FUNMAT PRO 610HT | 3DGence INDUSTRY F421 | Roboze ARGO 500 | BigRep ALTRA 280 | AON3D Hylo |

|---|---|---|---|---|---|

| Build Volume (mm) | 610 × 508 × 508 | 380 × 380 × 420 | 500 × 500 × 500 | 500 × 700 × 800 | 650 × 450 × 450 |

| Nozzle Temp (°C) | 500 | 500 | 500 | 450 | 500 |

| Chamber Temp (°C) | 300 | 195 | 180 | 180 | 250 |

| Bed Temp (°C) | 160 | 190 | – | 180 | 250 |

| Print Speed | Up to 160 mm/s | Up to 400 mm/s | High speed (dual-pinch feeder) | Up to 350 mm/s | Up to 500 mm/s |

| Materials | PEEK, PEKK, PEI 9085/1010, PPSU, PC, ABS, Nylon, CF/GF composites | ABS, ASA, PC, PEKK, ULTEM 9085, PEEK, PEEK-CF | PEEK, PEKK, Carbon PEEK, Carbon PA, ULTEM AM9085F, ABS, Nylon | ABS, ASA, PC, PEKK, PPSU, ULTEM 9085, PA6/12 + CF/GF, TPU | Open system: PEEK, PEI 9085/1010, PEKK, PPSU, PC, Nylon, ABS, TPU, CF/GF/Kevlar composites |

| Price (USD) | $139,500 | $90,000 | $260,000 | $180,000 | $156,000 |

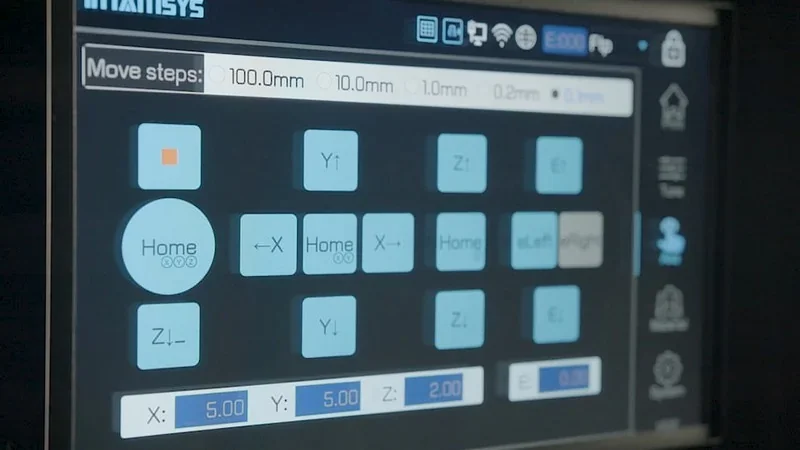

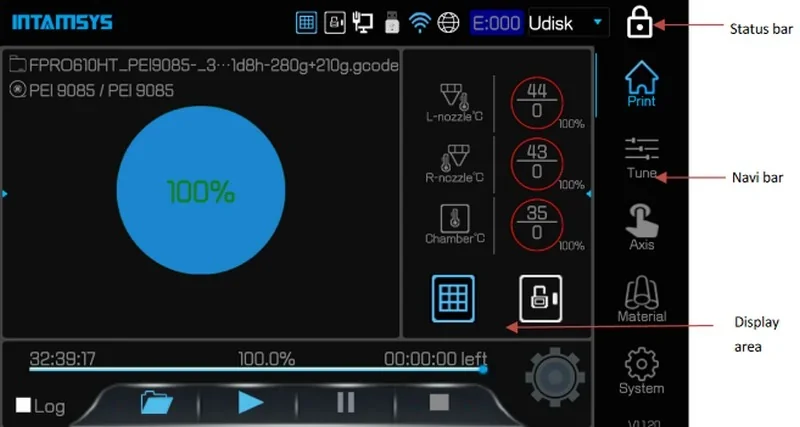

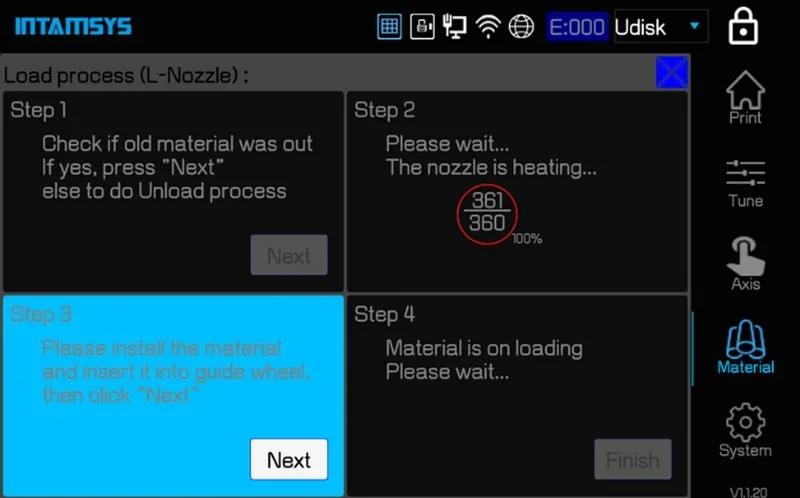

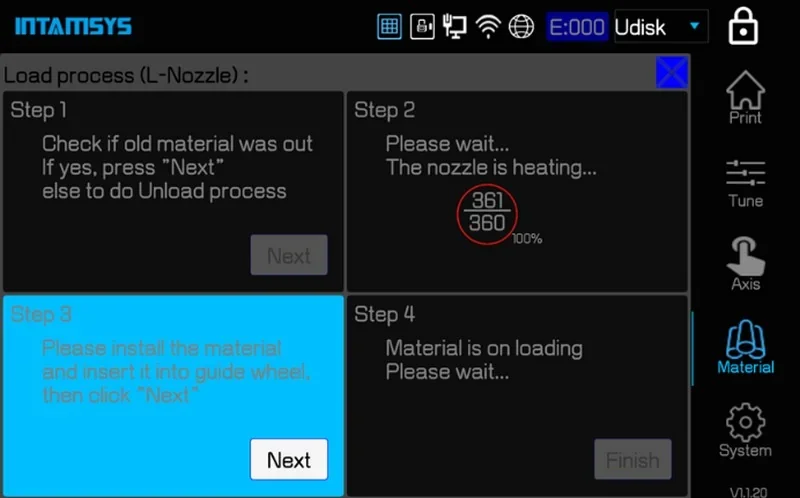

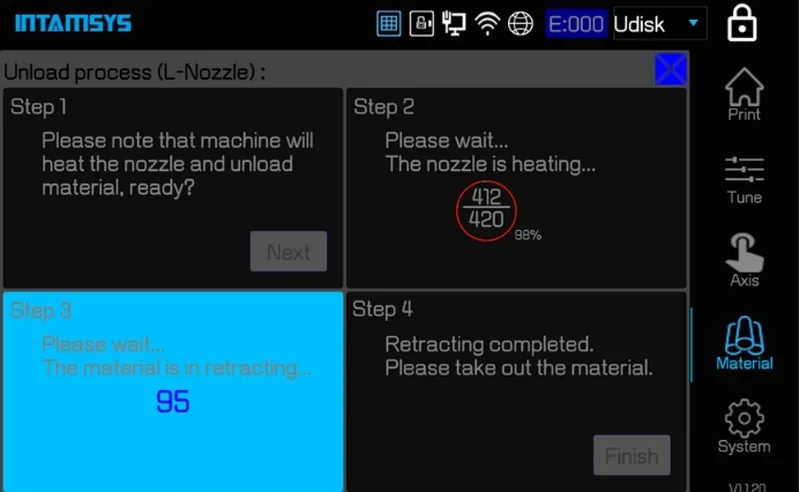

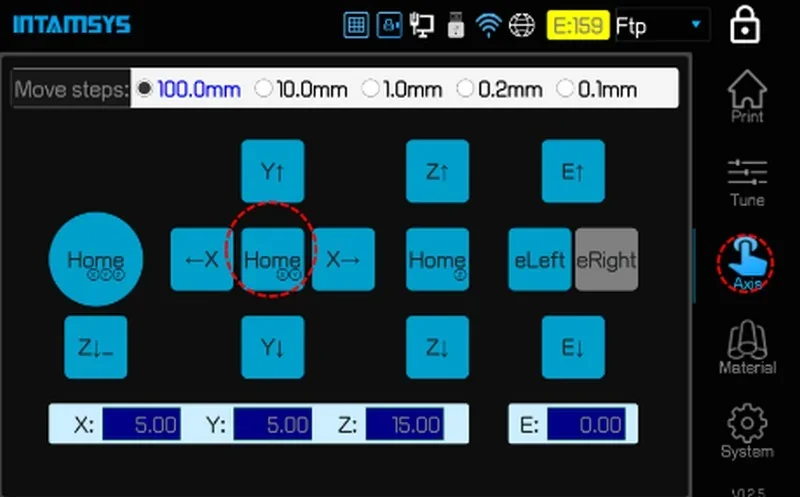

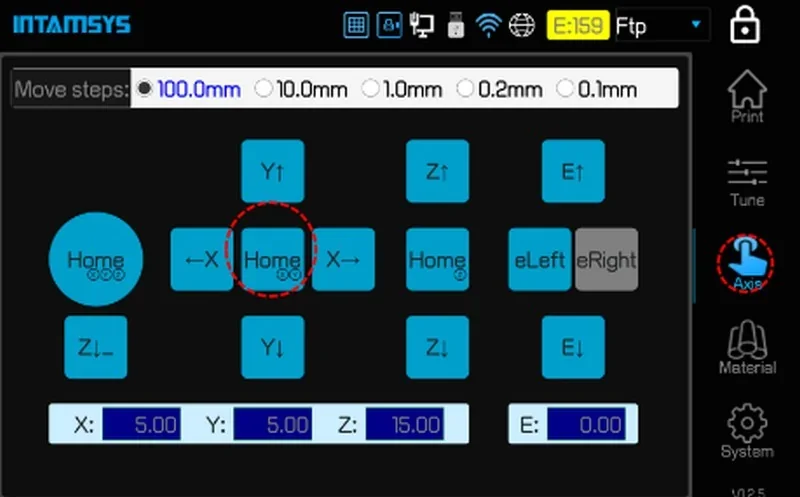

The INTAMSYS FUNMAT PRO 610 features a touchscreen interface for print management, temperature control, filament loading/unloading, calibration (auto leveling and Z-offset), system settings, and network configuration.

Physical Controls (4 categories):

Touchscreen Controls:

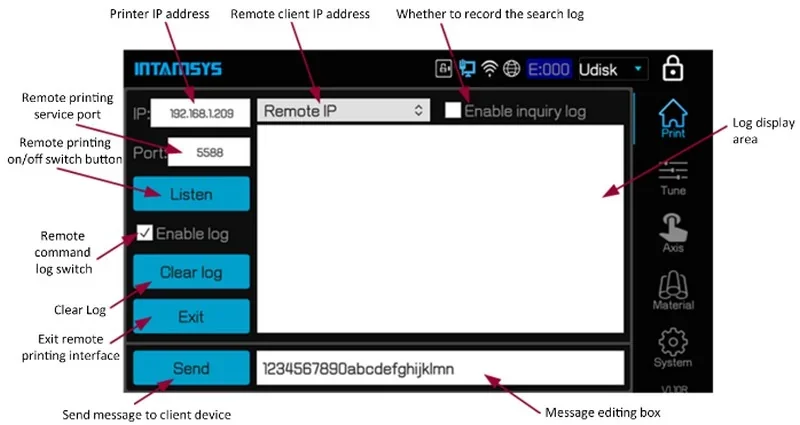

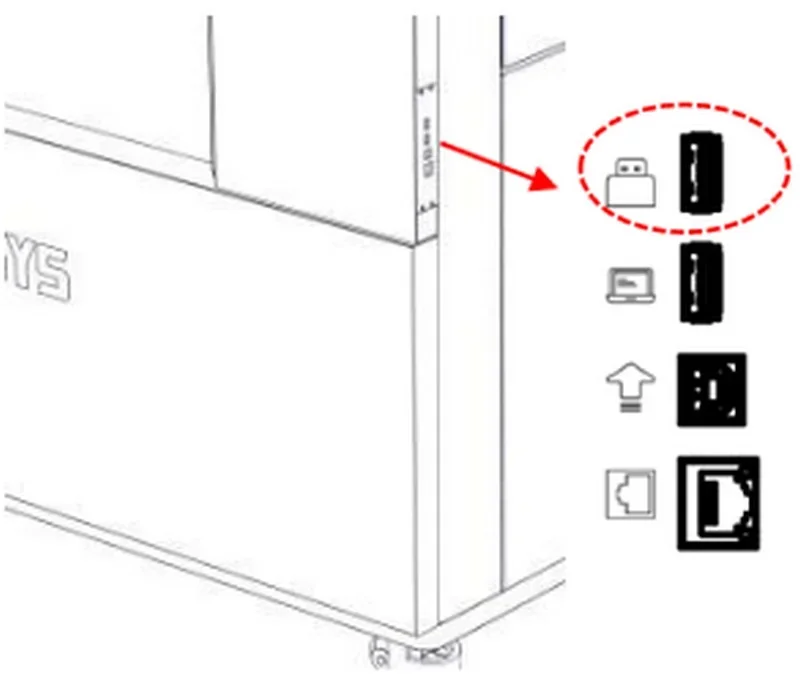

The INTAMSYS FUNMAT PRO 610HT supports USB, Ethernet, and Wi-Fi for direct file transfers. Network setup is handled via touchscreen with static/dynamic IP options and diagnostics. It enables remote printing and monitoring through networked computers, including camera-based progress tracking.

The INTAMSYS FUNMAT PRO 610HT comes with INTAMSUITE NEO, a free slicing software designed for INTAMSYS printers. Its CAD-style interface supports multi-project workflows, side-by-side setting comparisons, and optimized profiles for materials like PEEK, PEI, and PPSU. It accepts formats like .stl, .obj, .3mf, .stp, and .iges, and includes features like adaptive supports and material-specific recommendations.

Beyond slicing, the FUNMAT PRO 610HT supports remote printing over a local network, including G-code uploads, print control, and camera-based progress tracking. Firmware and the INTAMTOUCH interface can be updated via USB with documented upgrade paths. While INTAMSUITE NEO offers the best workflow integration, the printer also works with third-party slicers like Cura and Simplify3D using standard G-code.

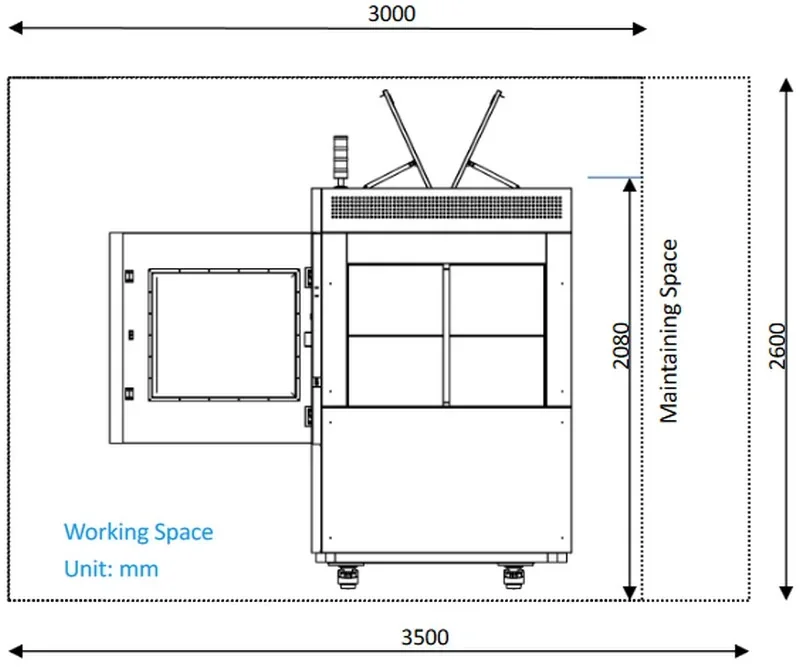

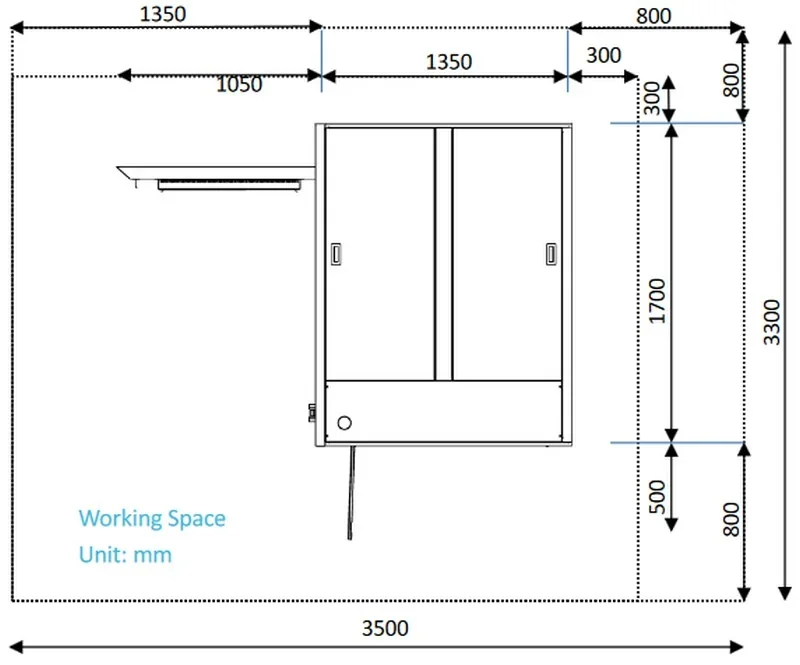

The FUNMAT PRO 610HT has an industrial design measuring 1710 × 1425 × 2080 mm, or 1710 × 1425 × 2350 mm with warning lights installed. Weighing 1450 kg, it reflects the heavy-duty build required for continuous high-temperature operation.

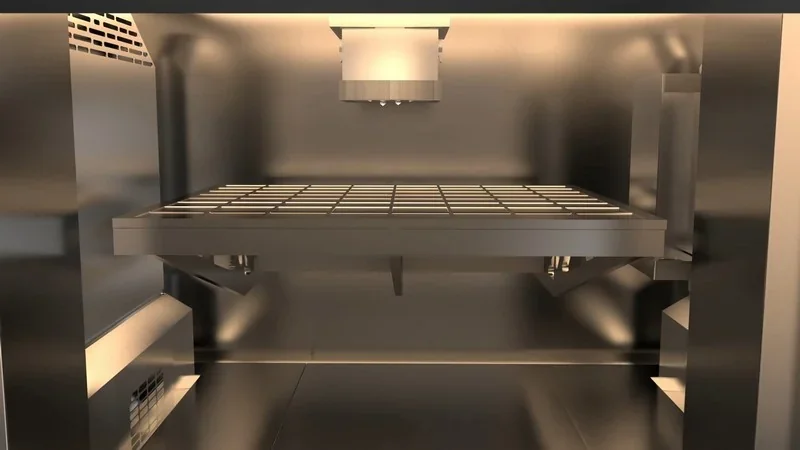

The FUNMAT PRO 610HT features a fully enclosed chamber heated to 300 °C with a clear viewing window for print monitoring. Its robust construction supports continuous high-temperature operation while providing easy access to the build area.

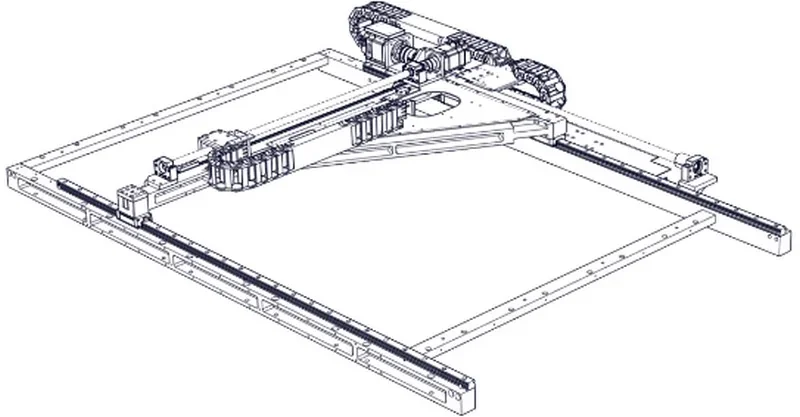

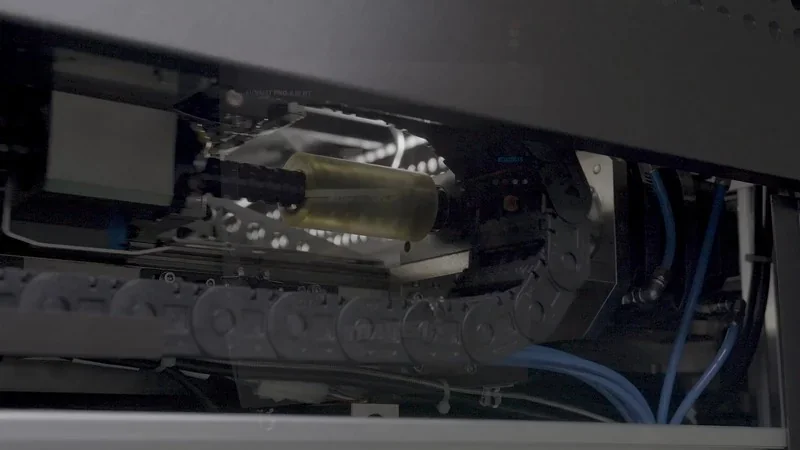

The FUNMAT PRO 610HT uses a closed-loop servo system with high-precision ball screws, achieving 12.5 µm XY and 1.25 µm Z accuracy.

Funmat 610 XY movement system

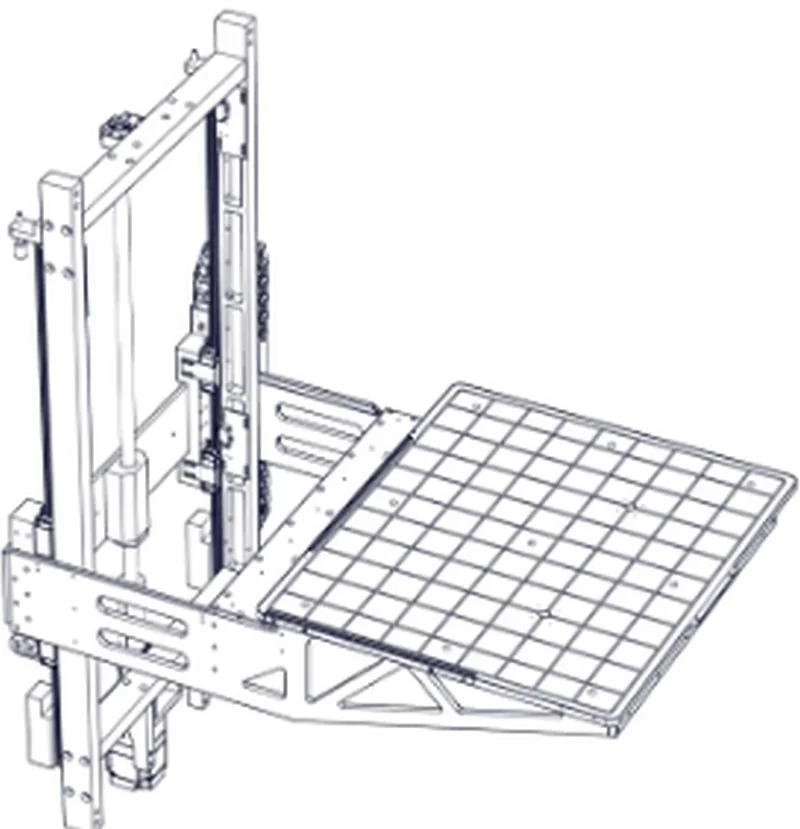

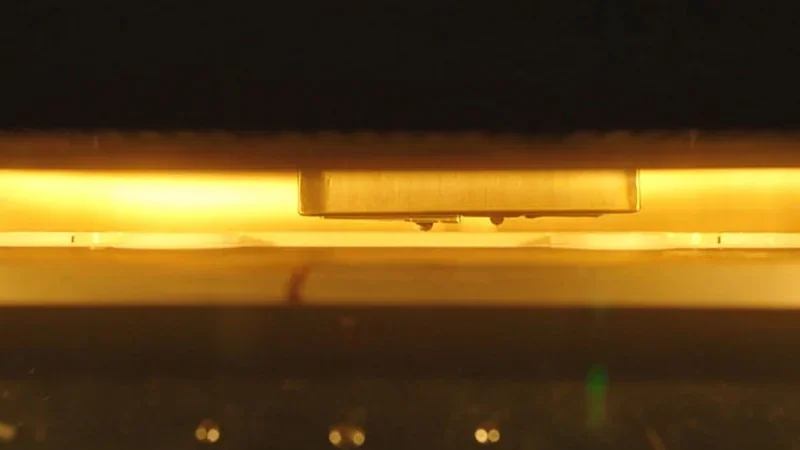

Funmat 610 Z movement system

The printer uses linear rails and high-end motor drivers for precision, with maximum speeds of 500 mm/s (XY) and 300 mm/s (Z). Typical print speeds range from 30–100 mm/s depending on material.

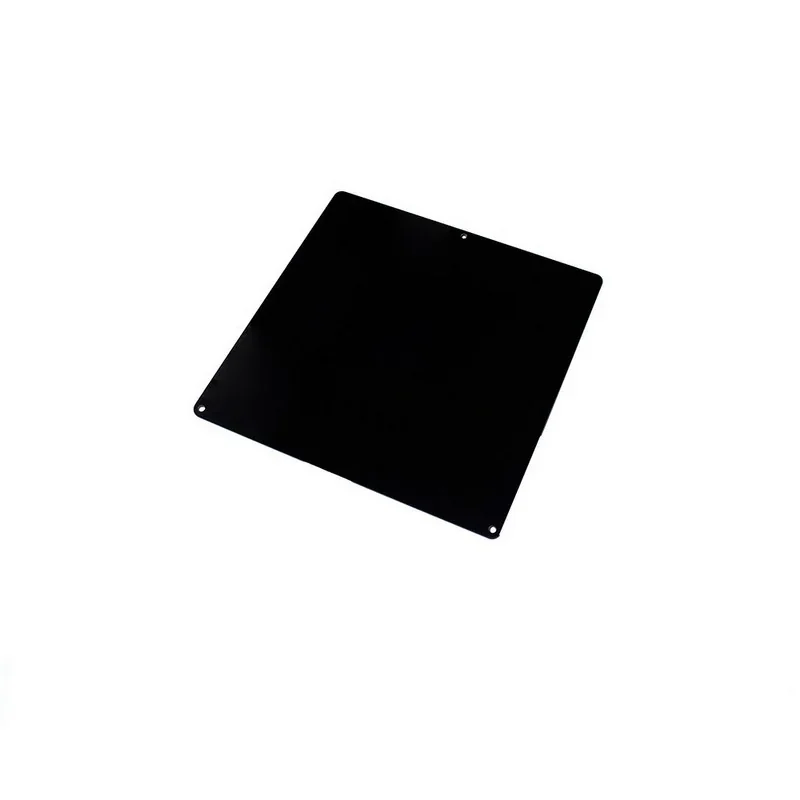

The FUNMAT PRO 610HT features a 610 × 508 × 508 mm build volume with a carbon fiber platform, silicone heater, and ceramic glass surface. Its heated bed reaches 300 °C and uses a 3-point auto-leveling system with manual adjustment. A magnetic glass-ceramic build plate provides strong adhesion for high-performance materials.

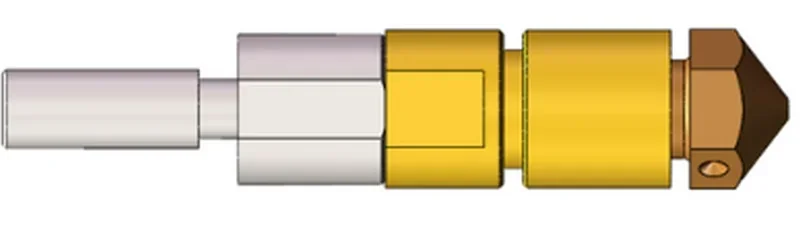

The FUNMAT PRO 610HT features dual all-metal direct drive extruders, each reaching up to 500 °C for consistent feeding and reliable printing with advanced materials.

The extruder supports proprietary nozzles in 0.1, 0.25, 0.4, 0.6, and 0.8 mm sizes, with automatic nozzle cleaning for consistent performance.

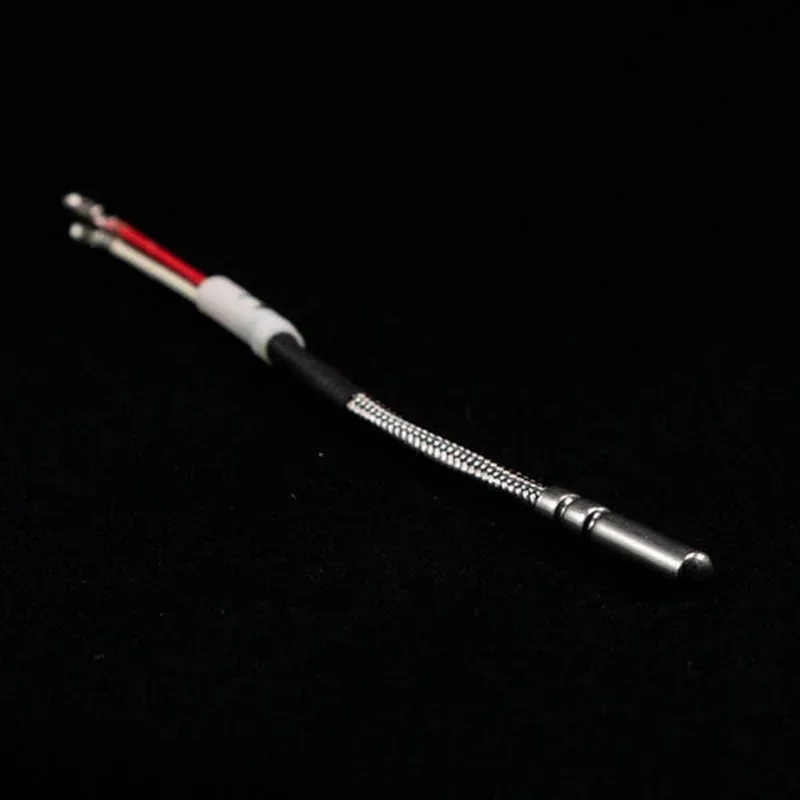

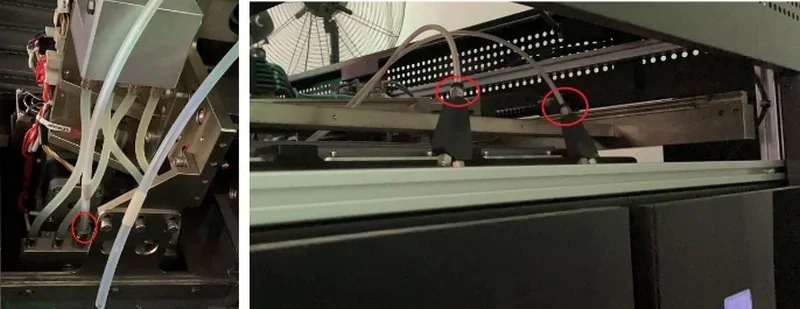

A liquid cooling system enhances heat dissipation, preventing jams and extending service life in high-temperature operation.

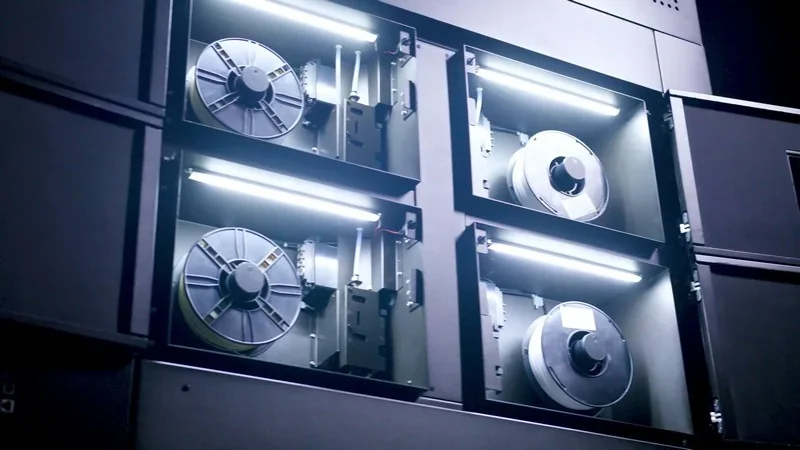

The FUNMAT PRO 610HT uses 1.75 mm filament and includes a heated filament box for optimal storage. Automated reloading boosts efficiency, while jam and absence warnings help prevent interruptions. Its open material system supports third-party filaments for greater flexibility and cost savings.

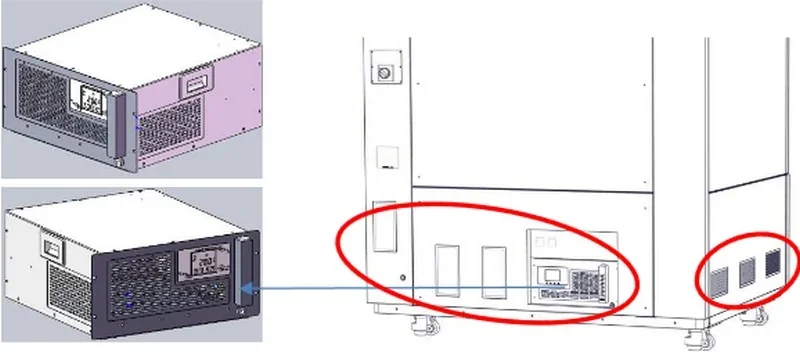

The FUNMAT PRO 610HT requires 380 V at 37 A and includes a backup power supply to prevent print failures. It operates between 15–30 °C with 30–70% humidity and can be stored at –10 to 50 °C with 10–85% humidity. The printer is CE, SGS, and FCC certified.

The INTAMSYS FUNMAT PRO 610HT package includes:

The INTAMSYS FUNMAT PRO 610HT ships fully assembled and factory calibrated, requiring minimal setup. Its components are optimized for high-temperature printing, including a 300 °C heated chamber and specialized print bed for engineering filaments. The package includes a toolkit with maintenance tools and a dial indicator for precise Z-offset calibration.

Note: Package contents may vary. Please confirm current inclusions with a Top3DShop sales representative before ordering.

Regular procedures ensure reliable operation, adhesion, and thermal accuracy.

After Each Print:

Periodic Maintenance:

Annual Maintenance:

Replacing Short Liquid Cooling Pipes – Print Head:

As Needed:

Warranty Coverage:

Extended Warranty (Optional):

Warranty Requirements:

Warranty is Void If:

Repair Works for User-Caused Damage:

Technical Support & Resources:

Email Support by Region:

Help Center Resources:

Authorized Distributor – Top 3D Shop:

The Intamsys Funmat Pro 610 HT is priced at $139,500.00. It provides a 610 × 508 × 508 mm build volume, dual high-flow extruders, and a fully enclosed heated chamber up to 300 °C for processing high-performance polymers like PEEK and PEI (ULTEM). Configurations with added industrial features—networking, extended service, and on-site installation—cost 20–25% more. For enterprise deployments, contact the Top 3D Shop team for a custom quote.

Update your browser to view this website correctly. Update my browser now