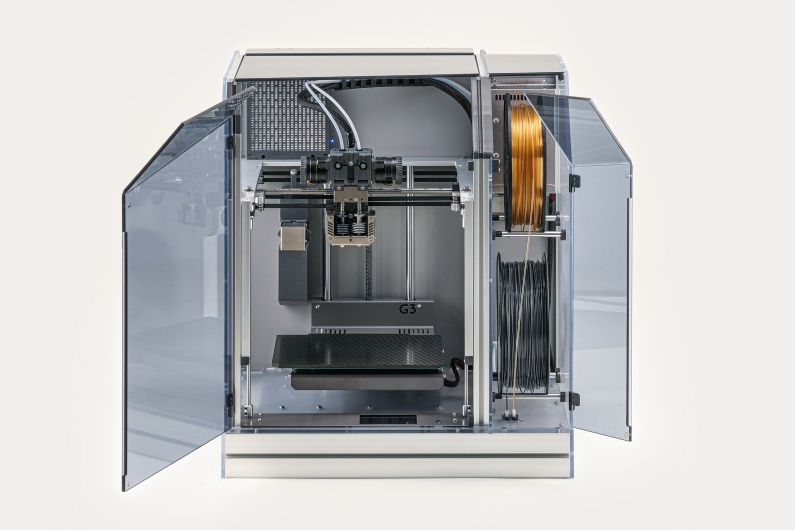

The LUGO G3 is a professional desktop FDM 3D printer featuring dual extrusion system, wide material compatibility, and excellent value-to-price ratio. The G3 is the latest model from the Korean manufacturer LUGOLABS, which has produced 3D printers for the domestic market since 2013 under the Former’s Farm brand.

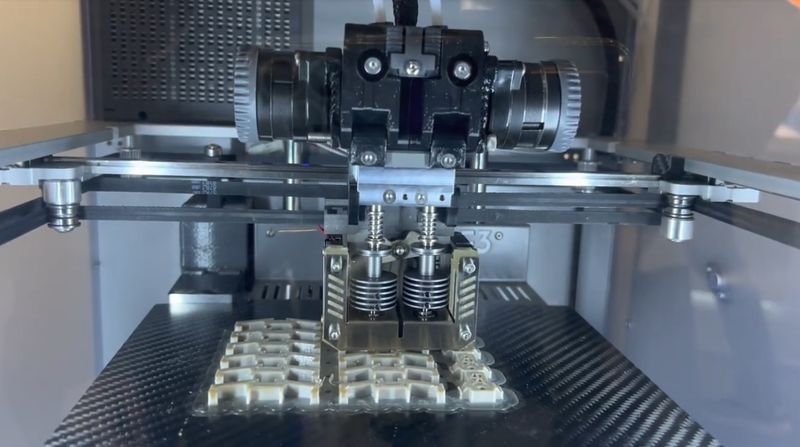

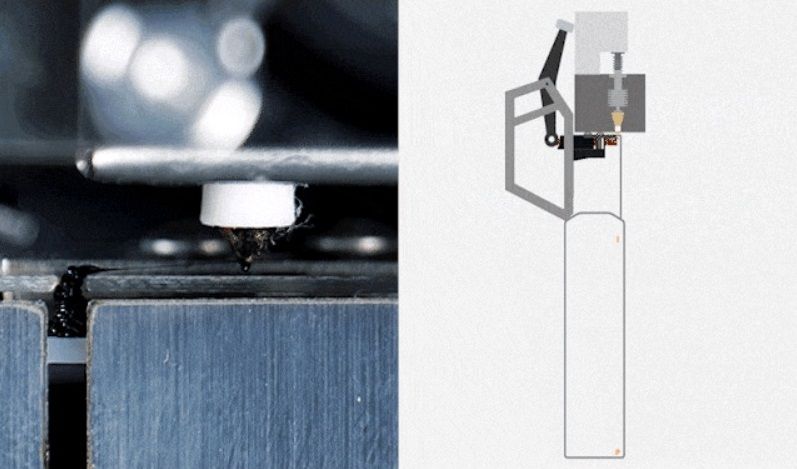

One of the key features of the LUGO G3 is its proprietary DCH (Dual Cone-shaped Head) print head eliminating the need for dual calibration and allowing for precise temperature control for each nozzle. This opens wide possibilities for dual-material printing with filaments requiring different print temperatures, and expands the scope of printer’s applications.

Another feature designed for user convenience is the Purge box in the G3, which removes filament residues from the nozzle when switching between the nozzles during printing. Prime towers, usually built for this purpose, take a lot of time and material, whereas using the Purge box solves the problem.

The LUGO G3 features a heated print bed with a double-sided spring build plate, one side of which is made from carbon fiber, and the other is a PEI sheet, for best adhesion results with various plastics.

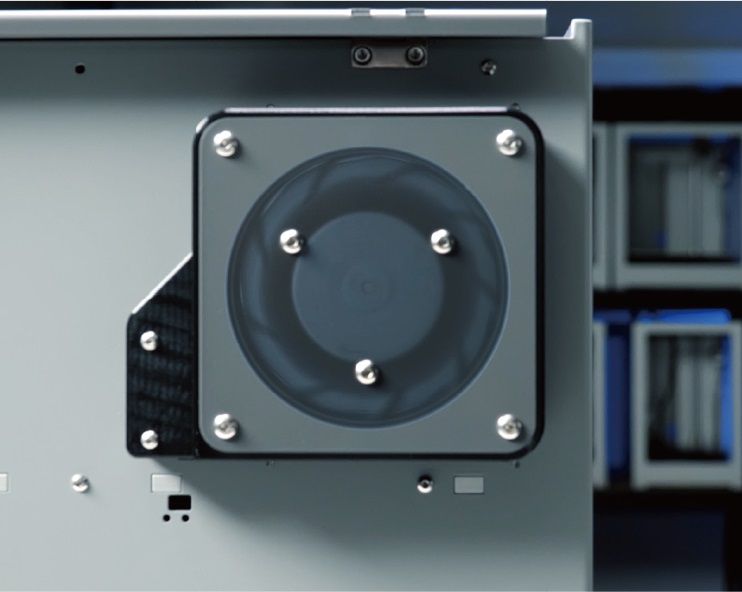

To prevent the risk of toxic fumes and ensure safe operation in any environment, the printer is equipped with an efficient H13 grade carbon-HEPA filter. The machine is fully enclosed, and the transparent front and side panels give it a stylish, futuristic look. All maintenance can be performed from the front, without the need to move the printer.

To keep the printing materials in the best condition, the LUGO G3 is equipped with the Fila-box, housing two spools of filament and capable of maintaining the humidity level below 15–20%.

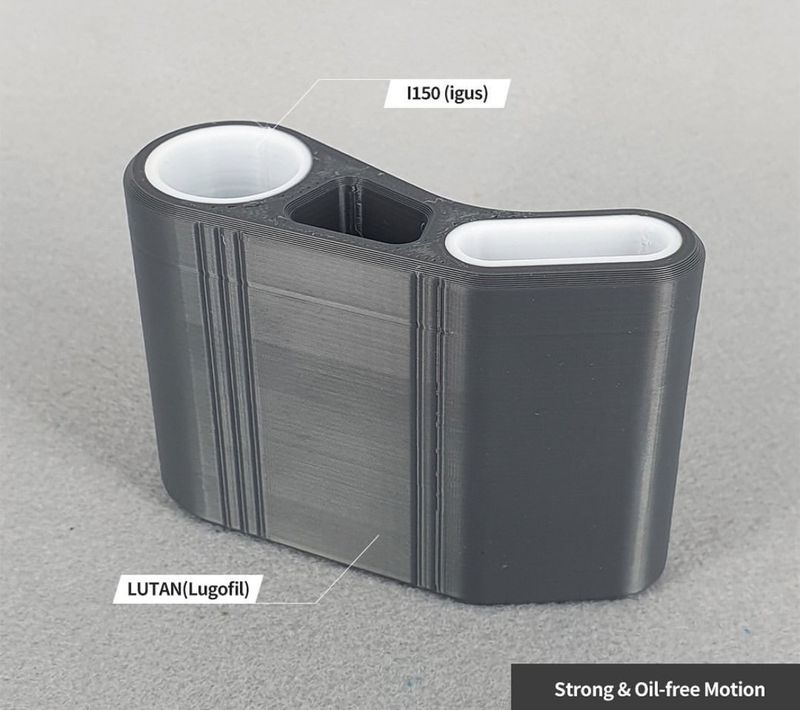

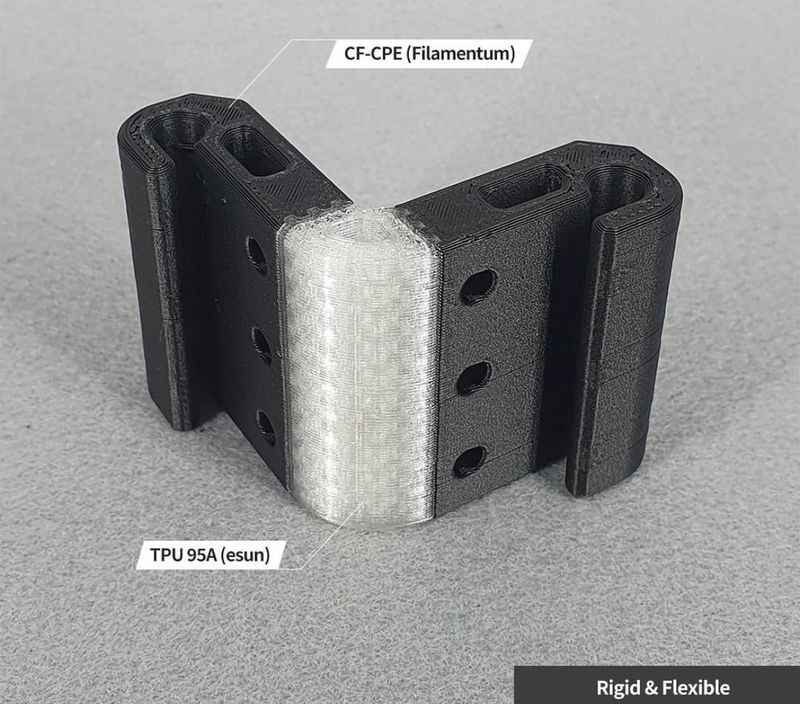

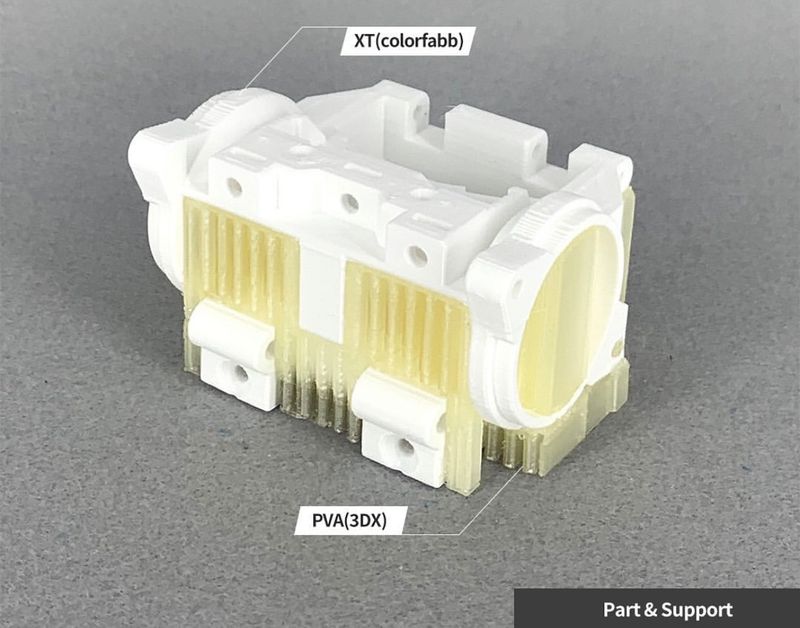

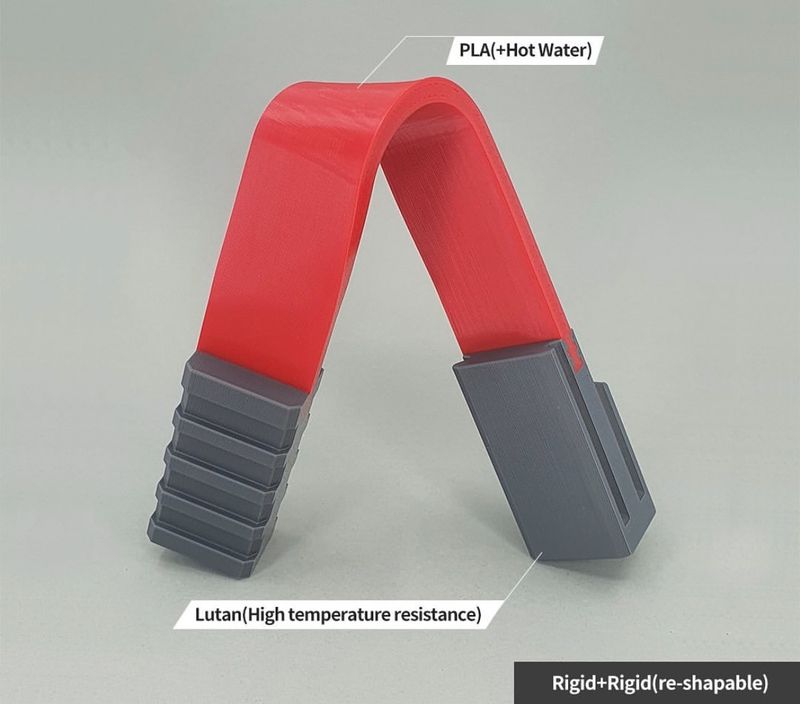

Below are examples of parts printed on the LUGO G3 using different materials.

The DCH head is equipped with two 0.4 mm nozzles that heat up to 285 °C, providing the ability to print with all consumer and some engineering-grade filaments. Dual extrusion allows for printing multi-material models with various properties in different areas, and building complex assemblies. The LUGO G3 prints dimensionally accurate precise models that maintain the best properties of the materials used for printing.

Credit: kickstarter.com

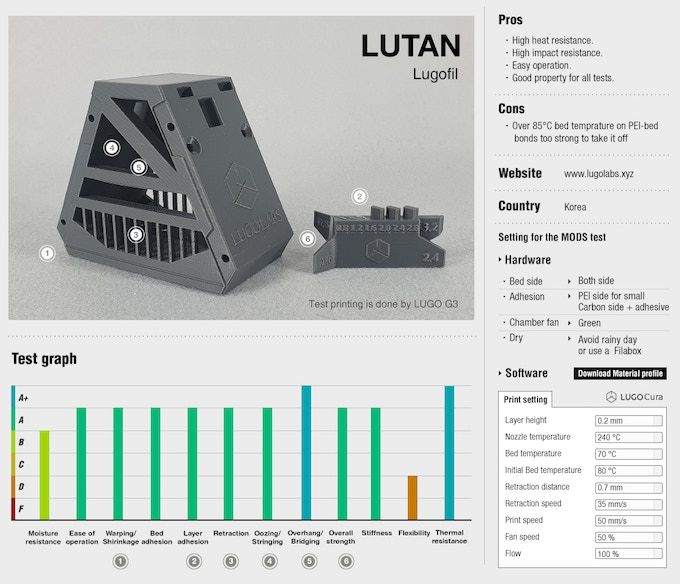

The LUGO G3 is compatible with a wide range of thermoplastics, including ABS, PLA, PC, PA, ASA, PETG, TPU, PP, PAHT, carbon and glass fiber composites, and others. It is an open material system and can print with any 1.75 mm filament up to 285 °C no matter the manufacturer. The LUGOLABS company is developing its own line of filaments called Lugofil. They recommend their Lugofil Lutan filament as a default material for the LUGO G3. It is made from PBT copolymer and shows good mechanical properties while being easy to print.

The build volume of the LUGO G3 is 190 x 165 x 180 mm, which is enough for printing small-to-medium parts. Larger models can be printed in parts and then assembled.

Credit: formnext.mesago.com

The built-in fan is used for temperature control in the build chamber. When the temperature is going too high, the fan speeds up to ensure fast cooling.

The LUGO G3 is operated via an LCD touchscreen with a quick response and a user-friendly interface.

The printer is compatible with the LUGO Cura slicer, optimized for DCH head and allowing for convenient settings adjustment for various materials.

For some items, package content may change. In case of any questions, please get in touch.

The LUGO G3 FDM 3D printer is available in gray with transparent doors and side panels. Its stylish look makes it ideal for any studio, workshop, or home use.

The machine dimensions are 18 x 14.6 x 21 in (457 x 370 x 532 mm). It weighs approximately 33.1 lb (15 kg).

To learn the current price of the LUGO G3, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now