The Mass Portal D600 is an FDM professional 3D printer. It is a delta-style, closed-frame machine composed of precision hardware. Its quality thermal design allows for high-temperature printing. It comes with a heated chamber, integrated dual filament dryers, built-in camera, automatic feeding switching, and optional compressed air part cooling. You can build your custom Mass Portal D600 according to your needs. Indeed, you can customize its configuration by choosing the functional systems you prefer. For example, it offers multiple hotend options based on both Bowden and Direct Drive mechanism. You are free to pick the system you prefer according to your application. The printer supports remote control and monitoring and is widely accessible from Wi-Fi and Cloud. It’s successfully used in prototyping and small-scale manufacturing. For example, it was used by several companies to print high performance, functional parts. Continue reading the review to find out more.

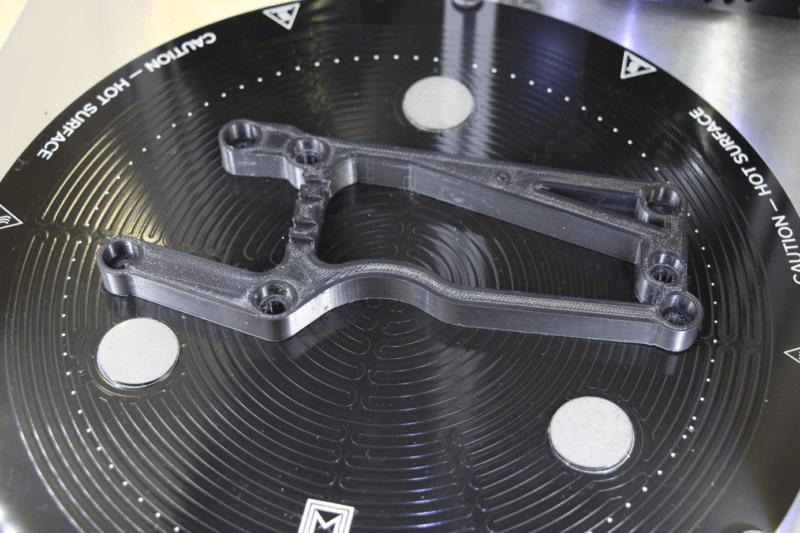

Ten Kate is the Official Honda World Superbike Team. Their R&D engineers adopted the Mass Portal 3D printers to produce some parts for their racing bikes. Made with ABS Fusion+, the printed products ensure the flexibility and the resistance the team was searching for.

The Mass Portal additive manufacturing technologies allow for creating useful tools to improve the quality of life. For example, they have been used to 3D print stork leg orthoses.

Credit: @massportal / instagram

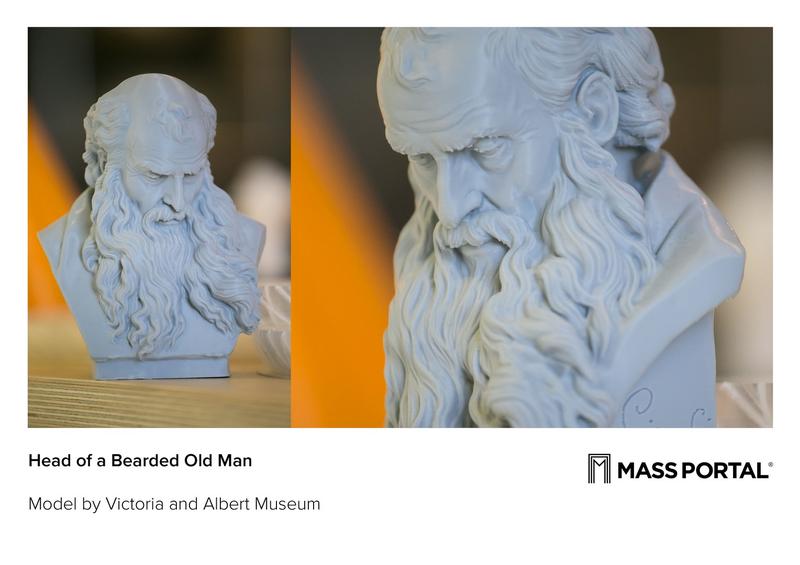

The Mass Portal D600 is an FDM 3D printer that can print high-resolution layers. Thanks to its engineering-grade design it allows for printing with a positioning accuracy of 6 microns and layer resolution up to 50 microns. This way you can produce parts with smooth exterior surfaces. The advanced extrusion, the automatic feeding switching, and the cooling system allow for continuous printing. They reduce warps, filament slip, and other common issues delivering reliable, high-precision prints.

The Mass Portal D600 comes with four different extrusion systems, Bowden Pro 1.75, Direct Pro 1.75, Bowden Dual HT 1.75, and Direct HT 1.75. The all-metal feeders reduce the risk of filament slipping and overheating.

This is a delta-type 3D printer with high print speed. Since there is minimal vibration of the print bed, the print quality is high.

Mass Portal D600 prints with ABS, ASA, CPE, HIPS, PA, PEEK, PETG, PLA, PMMA, POM, PP, PVA, TPE, TPU, BVOH, PC, PEI, PET, PPSU, PVB, and other materials.

You can choose between four extrusion systems. The Bowden-type selection includes the Bowden Dual HT and the Bowden Pro. The Dual HT is a dual nozzle switching Bowden extruder that can reach up to 475°C. It is liquid-cooled and allows printing high-temp materials with ease. The Bowden Pro features a single nozzle and a fan-cooling system. It can heat up to 300°C. The Direct-Drive extruder comes in two versions, the HT and the Pro. The Direct HT adopts a single nozzle, direct-drive, liquid-cooled hotend. As the Dual HT, it reaches 475°C. The Direct Pro employs a single nozzle that can heat up to 300°C. It comes with a fan for cooling the 3D model. You’ll only have to pick the best extruder that suits your design needs.

The cooling system has been designed to reduce warping and stringing. It generally makes for higher quality prints.

Unlike many FDM printers, the Mass Portal D600 has a heated print bed and closed print chamber, which means it can reliably print with ABS-type materials. The controlled build chamber comes with dedicated air filtration and circulation system which reduce fume emissions.

The extruder has a maximum working temperature of 887 °F (475 °C), which means it can print high-temperature materials like PEEK, ABS/PC, PEI, carbon fiber and glass fiber.

The Mass Portal D600 prints with 1.75 mm filament, providing you with a wide choice of materials. The dual filament dryers and feed switchover improve process stability and allow for easy printing moisture-sensitive materials.

The build area is 15.7 x 22.8 inches (400 x 580 mm). It enables to print large volume, functional objects without the need of splicing them into multiple parts. One-piece printing reduces both assembly and cleaning times.

The printer can be controlled either via PC or a fitted, 7-inch HD touchscreen. The onboard display lets you easily manage the device providing you with a complete overview of the printing settings. The printer is closely integrated with FabControl Additive Manufacturing Platform. It gives you extensive control and monitoring capabilities.

3D models can be printed from computer via USB 2.0, Ethernet, and Wi-Fi. You can keep an eye on things via the printer’s high-definition built-in camera.

When purchasing the printer, you get a full Simplify3D license. This easy-to-use 3D printing slicer supports a variety of 3D model formats, ensuring extreme versatility and compatibility. It is available for Windows, Mac OS, and Linux.

For some items, package content may change. In case of any questions, please get in touch.

Mass Portal D600 is available in a black and gray scheme. Its stylish look makes it ideal for professional use.

The printer dimensions are 28 x 28.7 x 71.3 inches (710 x 730 x 1810 mm). It weighs 549 lb (249 kg). The spool holder is mounted inside.

To learn the current price of the 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now