The Mingda MD-1000D is a large-format industrial FDM 3D printer with a 1000 mm³ build volume, dual extruders, and high-speed performance up to 300 mm/s. Built with HIWIN guides, CNC parts, and Klipper firmware, it delivers precise, high-quality prints using engineering-grade materials like carbon fiber and nylon. Designed for industries like automotive, aerospace, and medical, it supports complex multi-material projects and offers features like auto-leveling, remote monitoring, and power-loss recovery to streamline workflows for building functional prototypes, factory fixtures and molds.

The Mingda MD-1000D offers high print quality with ±0.1 mm accuracy, 300 mm/s speed, and a 40 mm³/s flow rate. Its Klipper-based vibration compensation, flow control, and 0.01 mm “Baby step” nozzle adjustments ensure consistent extrusion and flawless first layers. A dual cooling system and enclosed chamber maintain part quality and prevent warping, while dual extruders enable precise multi-material printing with breakaway supports for smooth surface finishes.

Print Sample: A black PET-CF toolbox (575×335×94 mm) with mounting holes and embossed branding was printed in 1 day 12 hours.

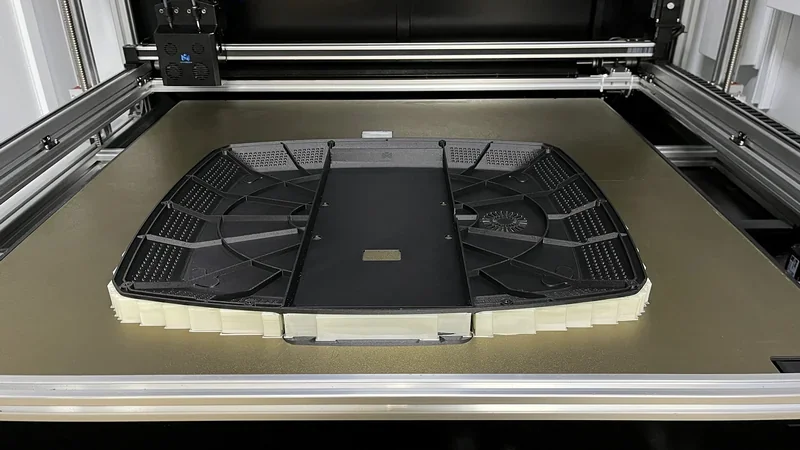

Print Sample: A full-scale PLA-HF car seat (800×800×1000 mm) was printed in 3 days at 200 mm/s, showing a 5× speed advantage over standard FDM printers.

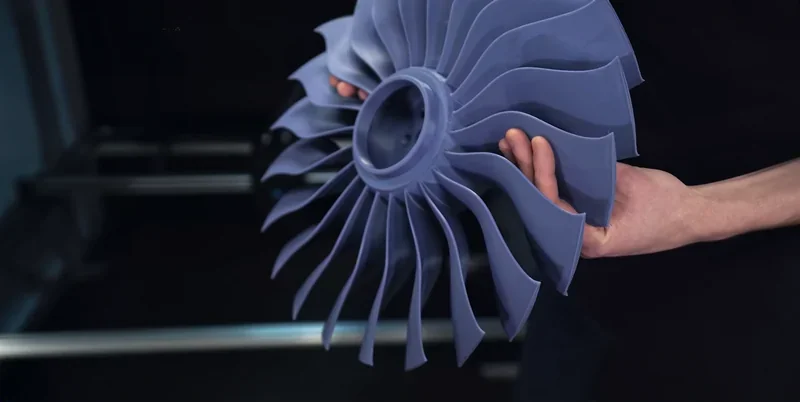

Print Sample: A dark blue impeller with 16 curved blades and a central hub bore, printed with smooth transitions and consistent geometry for fluid dynamics use.

Case Study: PATAK MOTORS cut prototyping lead times from weeks to days using the MINGDA MD-1000D with PET-CF filament, enabling faster iteration, less waste, and independence from traditional workshops.

The MD-1000D supports 12+ materials, including PLA, TPU, PETG, PET-GF, PET-CF, PA12-CF, HtPA-GF, HtPA-CF, ABS-GF25, ABS-CF20, HtPA-GF25, and HtPA-CF25. The MD-1000D’s dual extruders support multi-material printing with PVA, S-Multi, and S-HtPA, enabling complex parts with overhangs and hollow structures while leaving clean surfaces. As an open system, it works with both Mingda and third-party filaments.

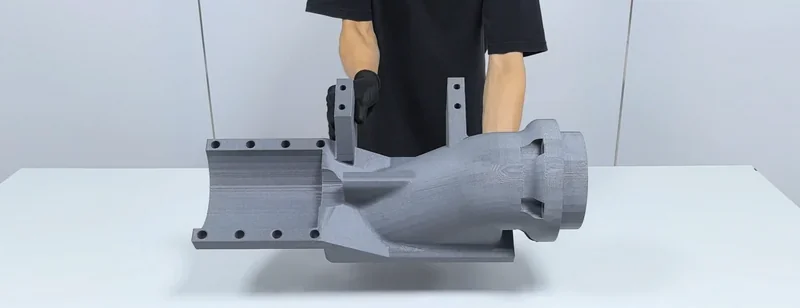

HTPA & S-HTPA Print Sample: A dark gray automotive bumper with mounting flanges, ribs, and a hexagonal aperture, printed with precise contours for use on a vehicle. HtPA materials handle 150°C, making them suitable for high-performance uses.

PET-CF Print Sample: A 974 x 329 x 246 mm black automotive part, printed with smooth finish and sharp edges.

PLA-HF Print Sample: A full-size helmet with red, yellow, and gold segments, angular contours, visor cutouts, and fine surface texture from fused filament deposition.

PET-CF 3D Print Sample: A black multi-spoke automotive wheel rim with five-bolt hub and radial spokes, printed with visible layer lines and uniform wall thickness for strength.

PET-CF Print Sample: A dark gray toilet tank housing with four mounting holes, a threaded inlet port, and side latches, printed with uniform layer lines and precise geometry for plumbing assembly.

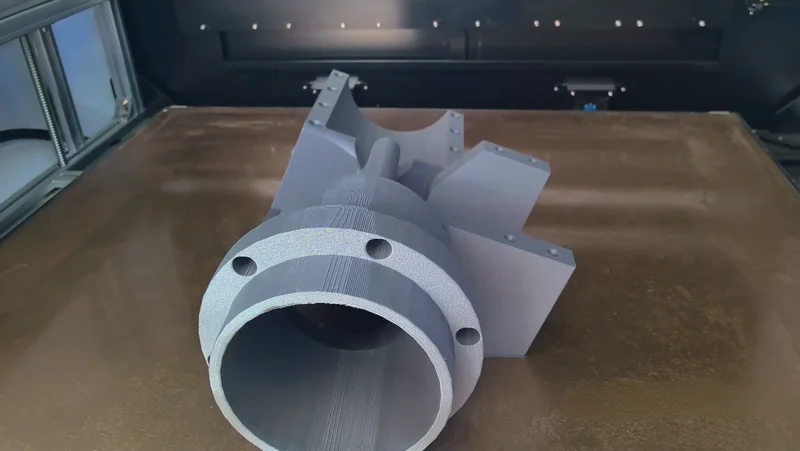

PPS-GF Print Sample: A gray industrial housing with flanged base, bolt holes, and cylindrical outlet port, printed with visible striations and reinforced geometry for high-temperature applications.

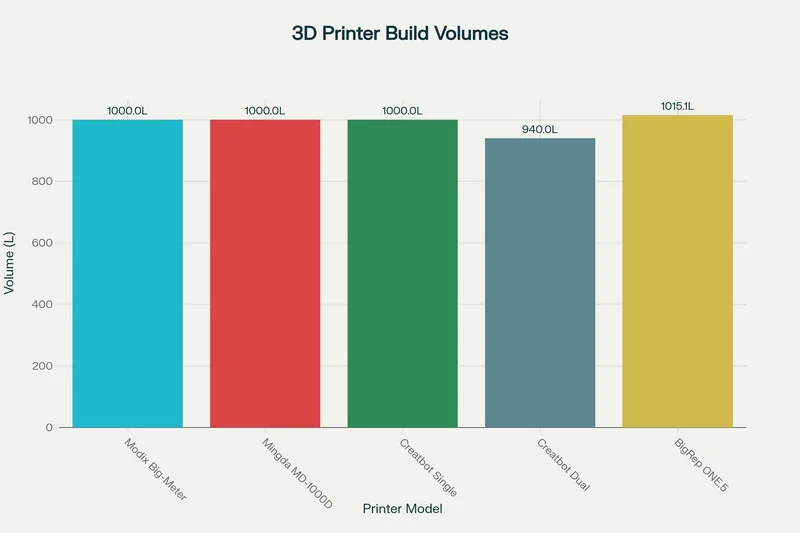

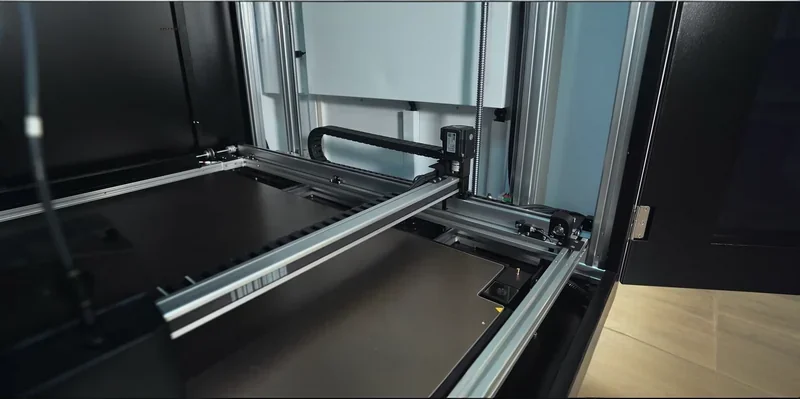

The MD-1000D features a 1000 × 1000 × 1000 mm build volume, among the largest enclosed FDM printers. It prints full-size parts without splitting, reducing post-processing and preserving strength, while guide rails and closed-loop motors maintain precision across the entire workspace.

Mingda’s strengths are turnkey assembly and included dual (non-IDEX) extrusion at a mid-tier price; its trade-offs are no active chamber, lower peak flow (~40 mm³/s) than Modix Ultra and Creatbot, and smaller build volume than MAKEiT.

In contrast:

| Specification | Mingda MD-1000D | Modix Big-Meter | Creatbot D1000 HS | BigRep ONE (ONE.5) |

|---|---|---|---|---|

| Price (USD) | $32,999+ | $20,000+ | $35,999+ | $49,900+ |

| Build volume (mm) | 1000 × 1000 × 1000 | 1000 × 1000 × 1000 | 1000 × 1000 × 1000 (Single); 940 × 1000 × 1000 (Dual) | 1005 × 1005 × 1005 |

| Enclosure / chamber | Enclosed; No active heated chamber. | Enclosed; No active heated chamber. | Enclosed, Active Heated chamber: 60 °C | Open frame; no heated chamber |

| Extruders / IDEX | Dual extruders, not IDEX | Single; IDEX optional | Dual, not IDEX | Single/Dual/Twin (IDEX) modes available |

| Max nozzle temp (°C) | ≤ 350 (rec ≤ 320) | Components rated 500 (tested to 340) | 420 | 280 |

| Max bed temp (°C) | 110 | 110 | 100 | 80 |

| Volumetric flow (mm³/s) | 40 | Std ~30; High-Flow 45–60; Ultra 160 | 90 | n/s |

| Rated output (g/h) | n/s | Std ~93.8; Ultra >500 | n/s | ~72 |

| Assembly | Assembled | Self-assembly kit (assembly services available in the US/EU) | Assembled | Assembled |

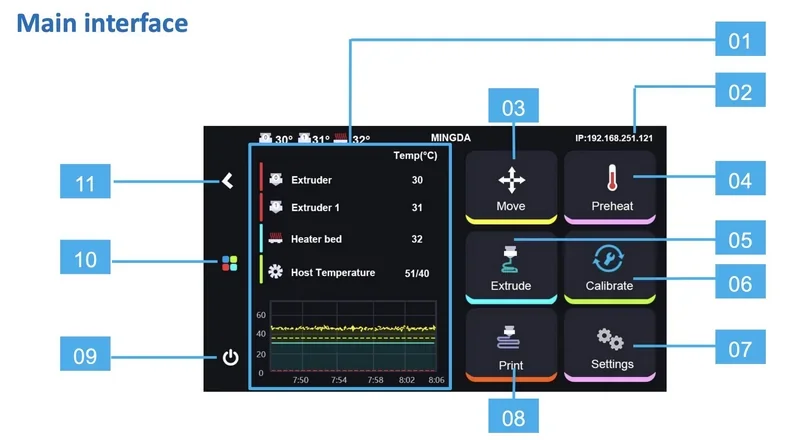

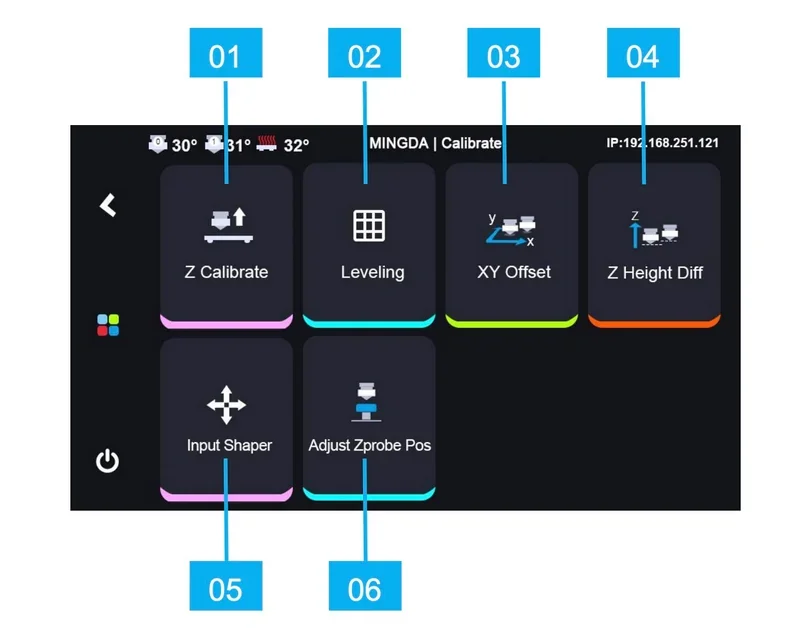

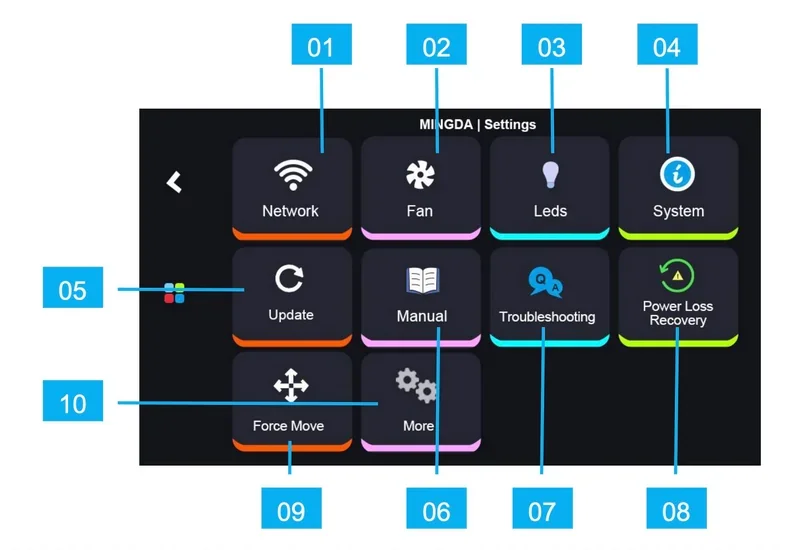

The Mingda MD-1000D features 27 on-device controls accessible through its 10-inch IPS high-definition computer screen.

Main Interface Controls

Calibrate Secondary Interface Controls

Settings Secondary Interface Controls

Printing Interface Controls

During active printing, additional controls become available:

LAN-Based Controls

When connected via network, the MD-1000D provides 6 additional web-based controls accessible through a browser interface:

In total, the Mingda MD-1000D offers 33 printer controls: 27 on-device controls through the touchscreen interface and 6 additional LAN-based controls for remote operation.

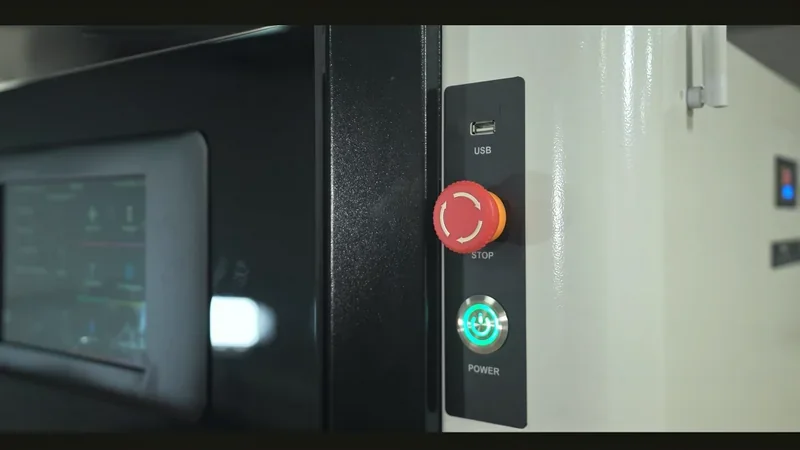

The Mingda MD-1000D supports 4 connectivity options: USB, SD card, WiFi and Ethernet. Direct connections are via USB ports, SD card slot, and U-disk support, enabling file transfers without needing a constant computer link.

For network use, the MD-1000D supports Wi-Fi and Ethernet, enabling remote printing, real-time webcam monitoring, and multi-machine control for mass production. Wi-Fi allows wireless access from computers or mobile devices, while Ethernet provides secure connections for sensitive environments.

The Mingda MD-1000D supports multiple slicers, including MingDa OrcaSlicer (user-friendly with expert mode, print-time/material estimates, and presets for Mingda materials), PrusaSlicer, and self-developed Mingda Cura (optimized Cura fork).

The MD-1000D has a fully enclosed industrial design with a metal frame, transparent acrylic doors, and a 1680 × 1365 × 1665 mm footprint at 480 kg. It features a 50 °C heated chamber, carbon-filtered air system, sealed filament storage, and a 10-inch multilingual LCD touchscreen.

The MD-1000D uses a Cartesian kinematic system. The X-axis runs on a belt-driven stepper motor, the Y-axis on a motor with synchronized rods, and the Z-axis on four 16 mm ball screws with a modular guide rail structure and closed-loop feedback.

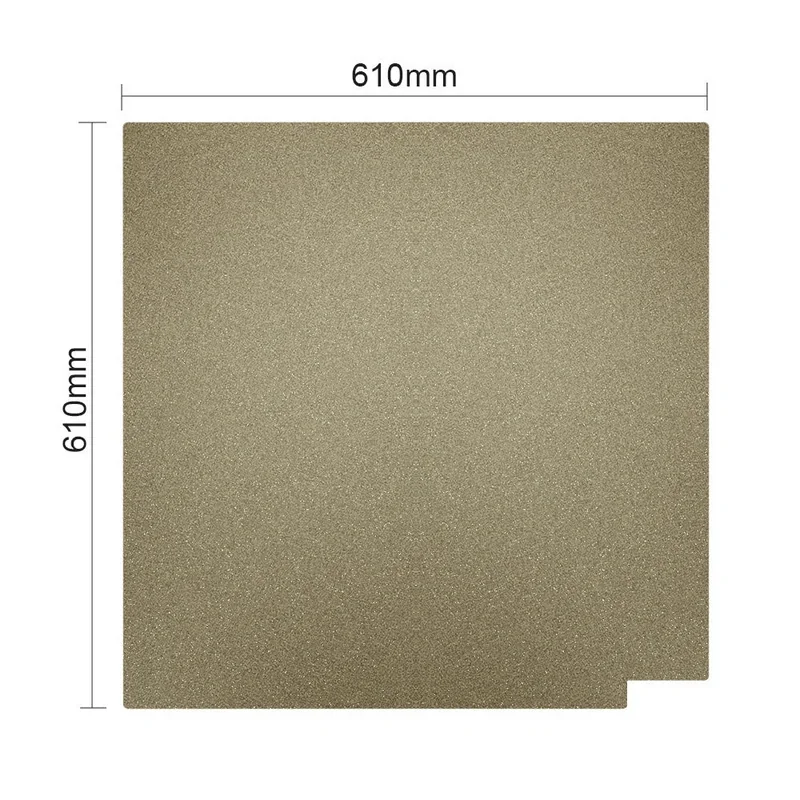

The MD-1000D offers a 10 mm aluminum heated bed (up to 110 °C, 60 °C in 75 s). It uses a flexible magnetic PEI-coated sheet for strong adhesion and easy removal, plus a recessed calibration zone for nozzle offset setup.

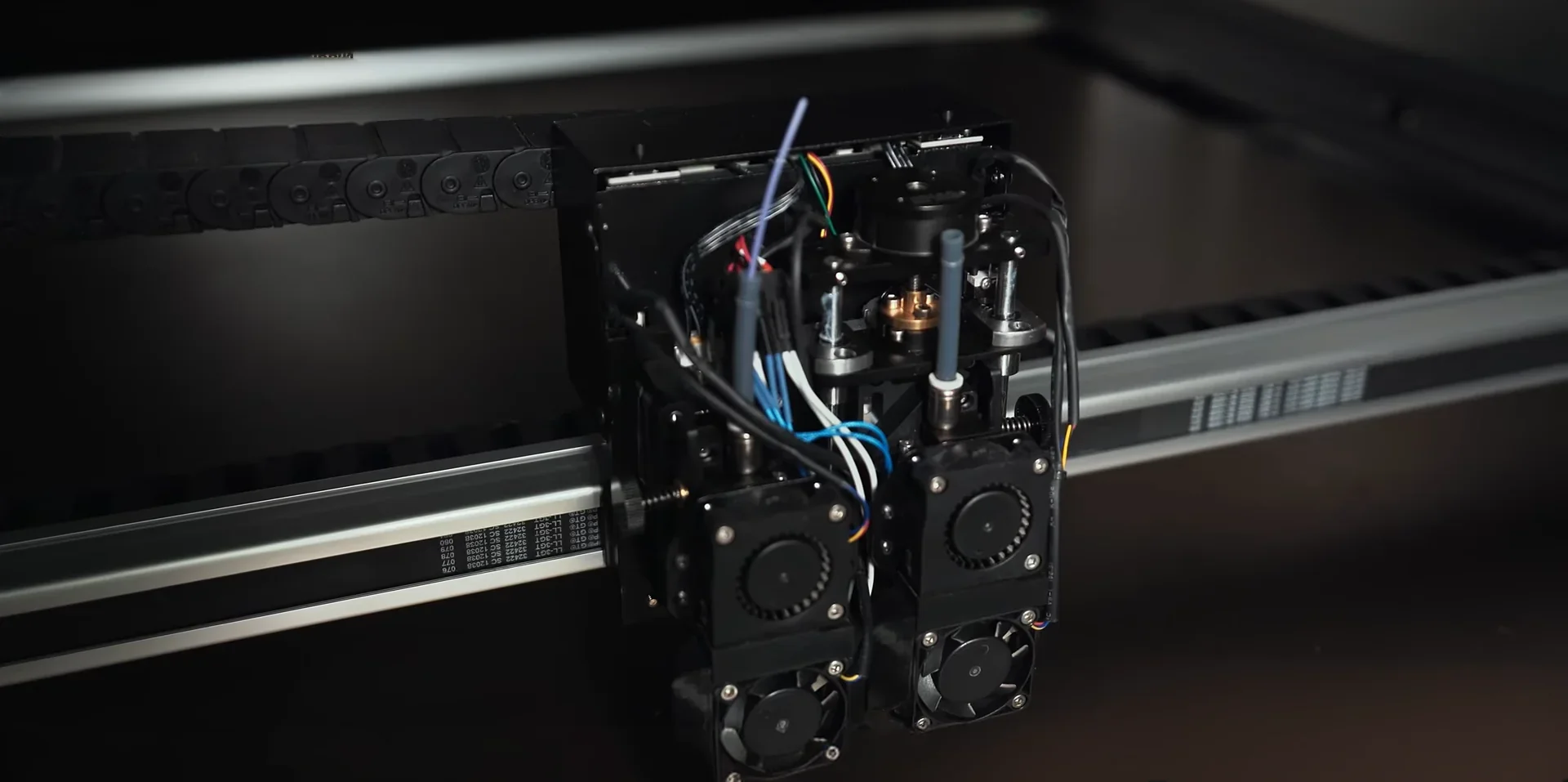

The MD-1000D has two dual-gear direct-drive extruders with dual-gear grips, supporting 1.75 mm filament and nozzle temps up to 350 °C. Hotends use interchangeable nozzles — 0.4 mm hardened steel (standard), plus 0.6, 0.8, or 1.0 mm in brass, hardened steel, or DLC-coated steel. Each extruder includes part-cooling fans and a rear auxiliary fan.

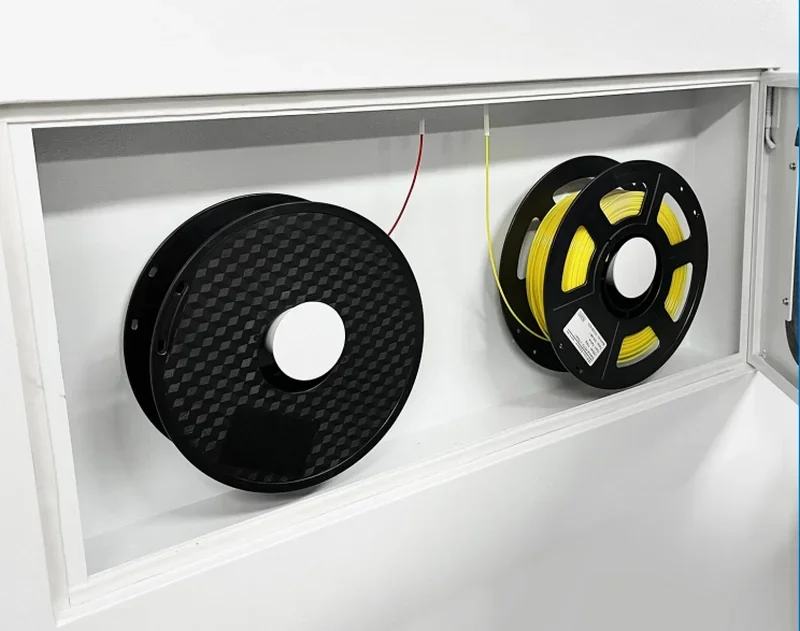

The MD-1000D has a sealed, heated filament chamber on the left side for two 2 kg spools of 1.75 mm filament. Filament feeds through PTFE tubes with tensioned cables and is monitored by runout sensors at the chamber exit and extruder inlet. Insertion triggers automatic feeding, with manual load/unload available via the touchscreen Extrude menu.

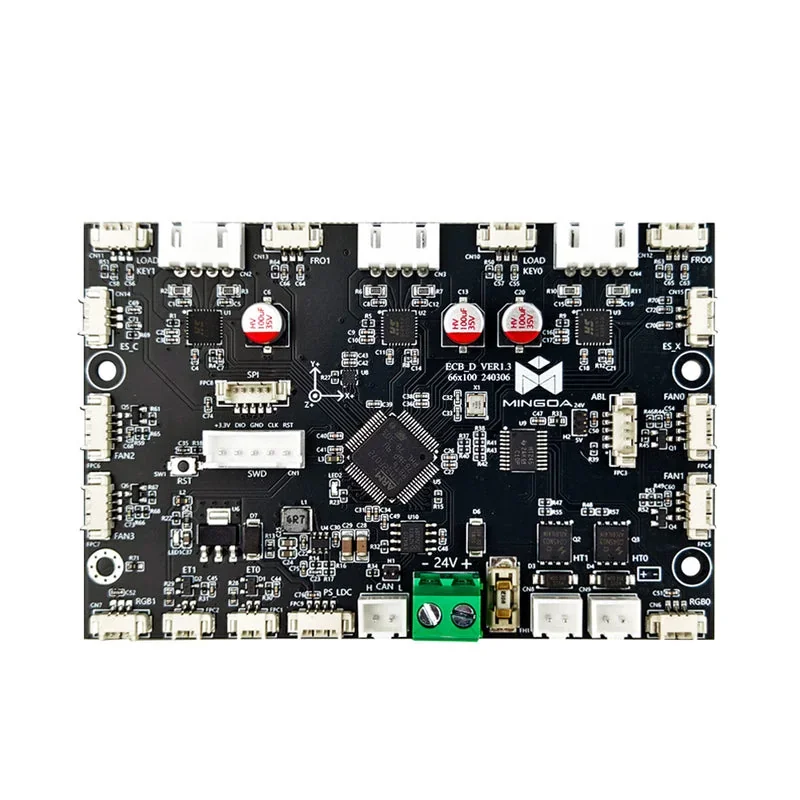

The MD-1000D runs on a proprietary 64-bit six-core controller with 32 GB of storage and Klipper firmware. It features input shaping for vibration compensation and flow control algorithms for consistent print quality.

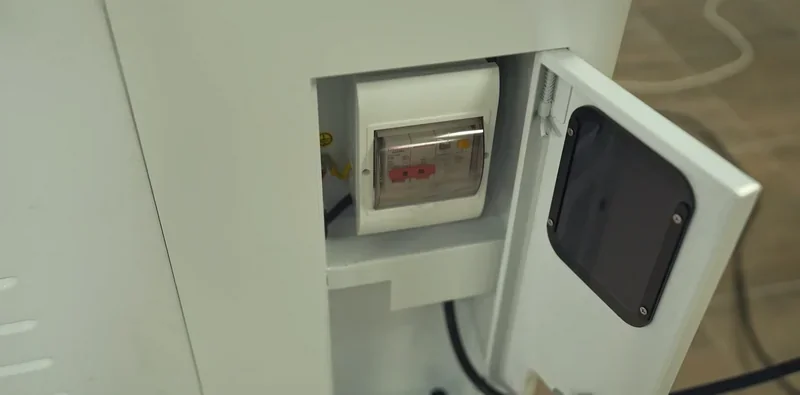

The MD-1000D runs on 100–240 V AC, 50/60 Hz, with 2700 W rated power. It includes a UPS to pause and resume prints during outages and an RCCB safety breaker in the rear panel.

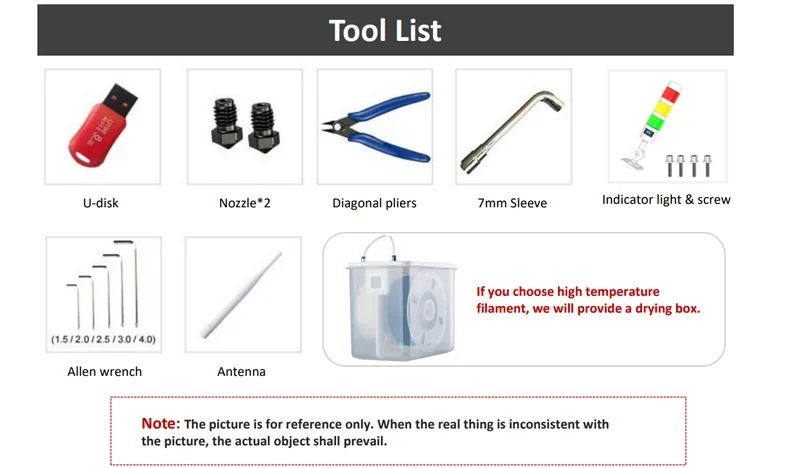

The MD-1000D ships fully assembled and factory calibrated, needing only the indicator light and antenna installed before powering on. A USB flash drive includes the manual, videos, and slicing software. The PEI flexible platform ensures strong adhesion and easy part removal, while the drying box keeps filament in optimal condition for high-temperature materials.

Note: Package contents may vary by manufacturer. Confirm included items with a Top3DShop sales representative before ordering.

| Accessory | Function | Price (USD) | Image |

|---|---|---|---|

| Filament Storage & Smart Boxes | |||

| MingDa MD-F01 Filament Box (3-tier) | Smart filament storage box (3-tier) for large-capacity storage and continuous printing. | $3,599 |  |

| Printhead Nozzles (Integrated) | |||

| MD-1000D Integrated High-Coat Hardened Steel Nozzle (single) | Integrated hardened-steel nozzle for MD-1000D. | $60 |  |

| MD-1000D Integrated High-Coat Hardened Steel Nozzle (5 pcs) | 5 integrated hardened-steel nozzles for MD-1000D. | $230 |  |

| MD-1000D Integrated High-Coat Silicon Carbide Nozzle (single) | Integrated silicon-carbide nozzle for MD-1000D. | $90 |  |

| MD-1000D Hardened Steel Nozzle Set 0.4 mm (5 pcs) | 0.4 mm hardened-steel nozzles for MD-1000D (1 x 0.4 mm nozzle, 2 x 0.6 mm nozzles, 2 x 0.8 mm nozzles). | $80 |  |

| Hotend & Heating Assemblies | |||

| MD-1000D Integrated Hotend (complete) | Integrated hotend assembly for MD-1000D. | $250 |  |

| MD-1000D Hotend (complete) | Hotend assembly for MD-1000D. | $230 |  |

| MD-1000D Heater + Hardened Steel Nozzle Kit | Heater plus hardened-steel nozzle kit for MD-1000D. | $105 |  |

| Extrusion Drive & Filament Feeding | |||

| Extruder Drive Gear (Tool Steel) | Tool-steel extruder drive gear (filament feed gear). | $40 |  |

| Extruder Drive Gear (RNC Hardened Steel) | RNC hardened-steel extruder drive gear (filament feed gear). | $50 |  |

| MD-1000D Extruder (complete module) | Complete extruder module for MD-1000D. | $1550 |  |

| Build Platform Surfaces | |||

| MD-1000D PEI Build Surface Sheet (1010 × 1010 mm) | PEI build surface sheet for MD-1000D (1010 × 1010 mm). | $510 |  |

| Sensors, Cables & Electronics | |||

| MD-1000D Filament Detection Limit-Switch Cable (200 mm) | 200 mm filament detection limit-switch cable for MD-1000D. | $30 |  |

| MD-1000D Printhead Control Board | Printhead control board for MD-1000D. | $130 |  |

| Cooling | |||

| MD-4015 4-Wire Turbo Cooling Fan (for MD-1000D) | 4015 turbo cooling fan, 4-wire, for MD-1000D. | $45 |  |

After Each Print

Regular Maintenance

As Needed

The Mingda MD-1000D includes a 1-year limited warranty when purchased through Top3DShop. Core components — mainboard, display, power supply, and motors — are covered for 12 months, while extruder kits are covered for 3 months. Coverage applies only to defects under normal use and excludes damage from misuse, unauthorized modifications, improper handling, or uncertified third-party parts.

Mingda provides complimentary technical support for setup, operation, and troubleshooting, mainly via email (support@3dmingda.com) or Whatsapp (+8613530306290). Assistance includes remote diagnostics, software guidance, and issue resolution, with priority given to warranty-related cases.

Purchasing through Top3DShop adds dedicated reseller support on top of Mingda’s warranty coverage. The expert team is available Monday–Friday via phone, email, or live chat, offering guidance from unboxing and calibration to on-site installation.

Full warranty terms: https://3dmingdaofficial.com/pages/after-sales-service-polices

The Mingda MD-1000D is priced at $30,689.07, offering strong value for a fully enclosed industrial 3D printer with a 1000 × 1000 × 1000 mm build volume, dual extruders, high-temp material compatibility, and print speeds up to 5× faster than peers. Positioned competitively in the large-format market, it combines performance and advanced features at a mid-to-high price point. Top3DShop supports flexible purchasing through financing for eligible businesses and purchase orders for educational institutions, making the MD-1000D more accessible to professional users.

Update your browser to view this website correctly. Update my browser now