The Mingda MD-600D is a high-speed, dual-extruder FDM 3D printer with a large 600 x 600 x 600 mm build volume, capable of 3D printing engineering-grade materials at up to 300 mm/s and 10,000 mm/s² acceleration—five times faster than similar models. Its 350°C hotend, Klipper firmware, and advanced cooling system enable accurate multi-material prints with minimal warping. Powered by a 64-bit motherboard with a 6-core CPU and 32GB memory, it supports industries like automotive, medical, and prototyping. Features like 100-point auto leveling, PEI build plate, filament detection, resume printing, Wi-Fi, and camera monitoring make it ideal for professionals managing multiple printers or scaling for mass production.

The Mingda MD-600D achieves ±0.1 mm precision with smooth finishes, even at high speeds. Its closed-loop stepper motors ensure fast response without missed steps, while cutting heat and noise compared to open-loop systems. Combined with an all-metal enclosure and modular guide rails, the printer maintains stability and accuracy throughout printing.

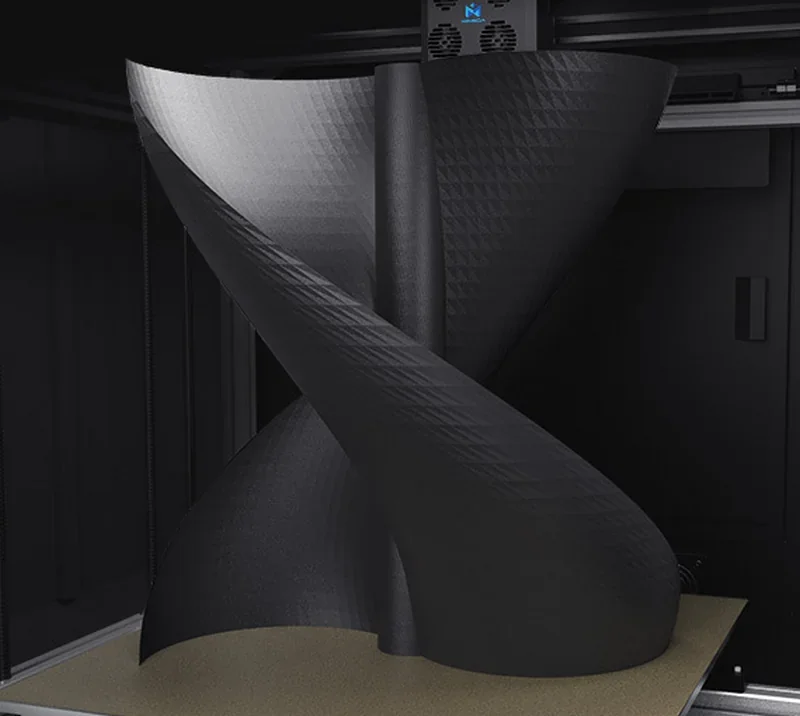

Print Sample: Black curved automotive duct with smooth surfaces and open cylindrical ends.

Case Study: A racing car company in Estonia used the MINGDA MD-600D to produce waterproof, pressure- and heat-resistant parts. Optimized printing and material choices improved reliability, replacing expensive metal welding and injection molding.

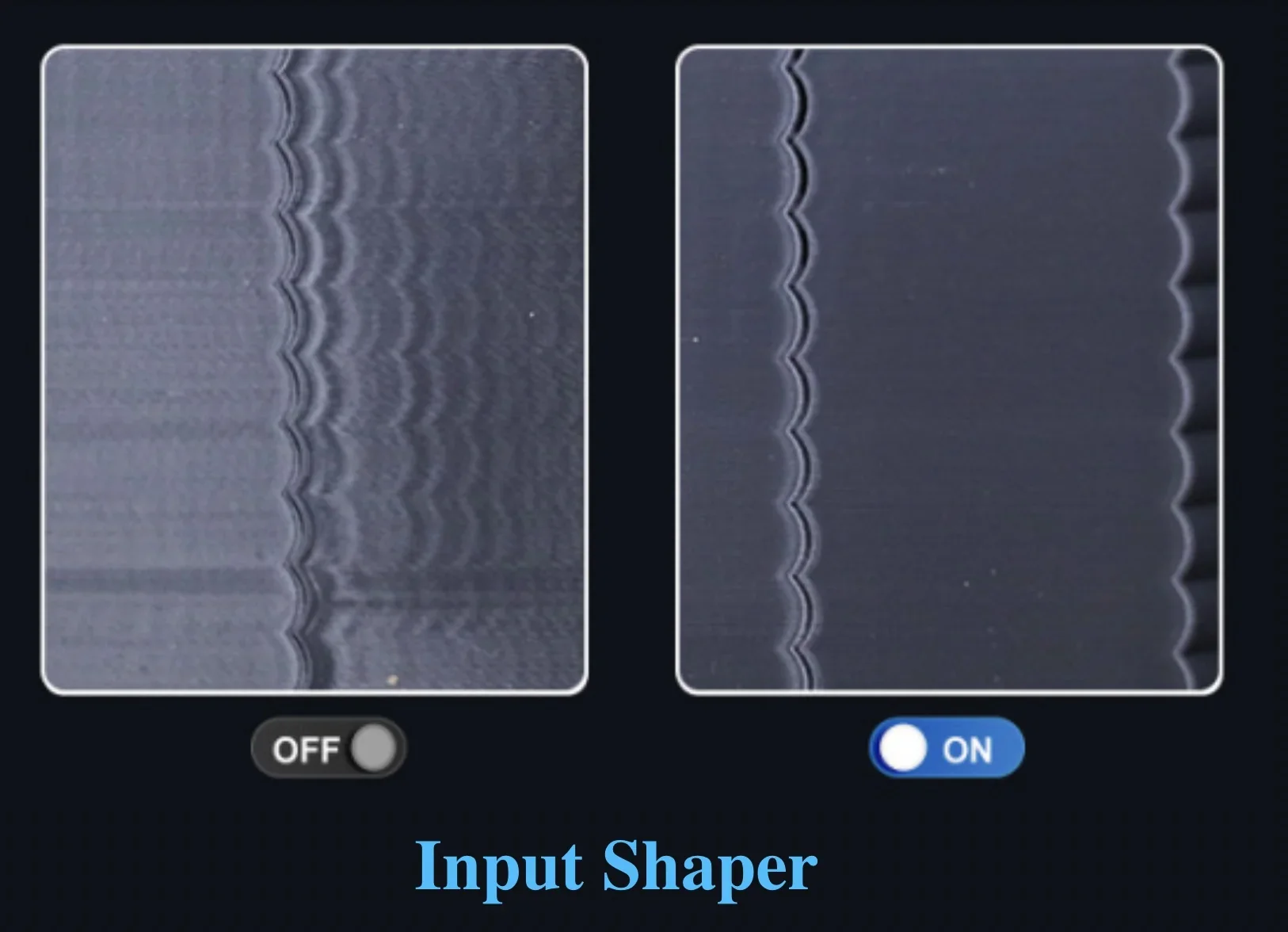

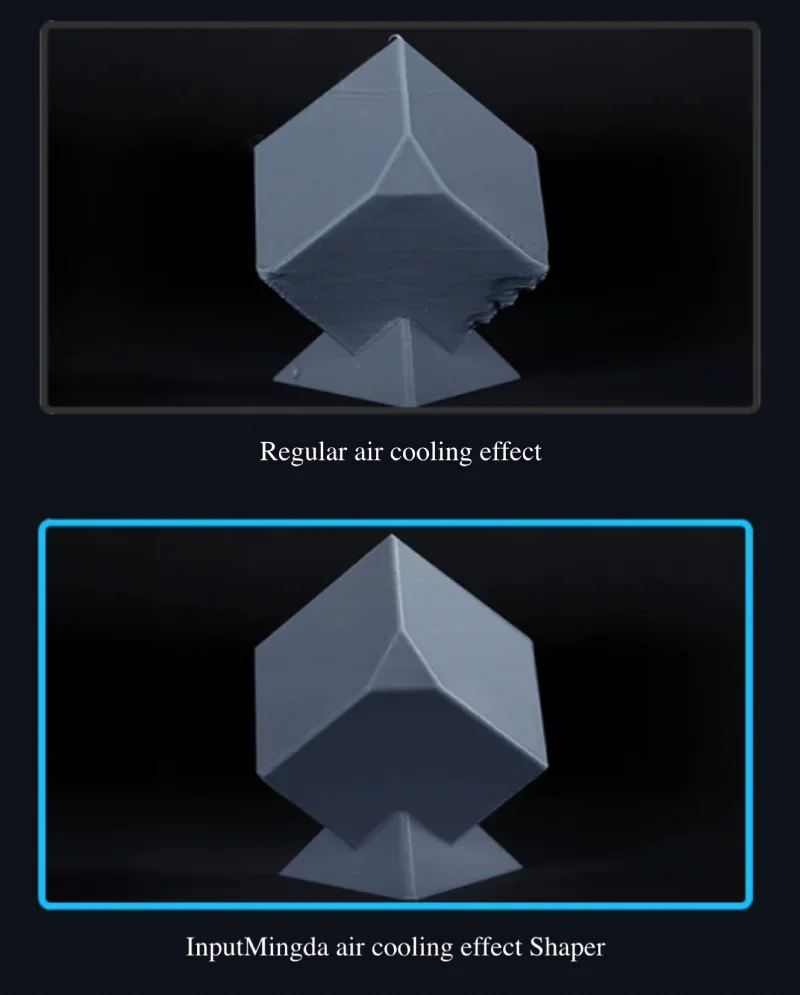

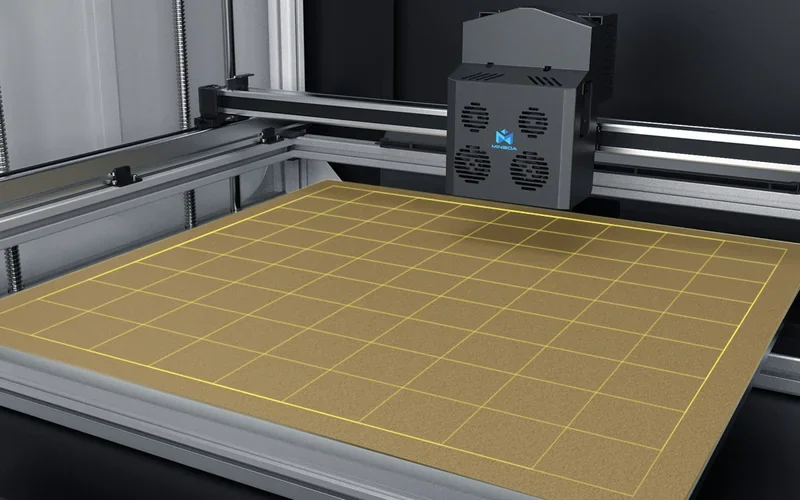

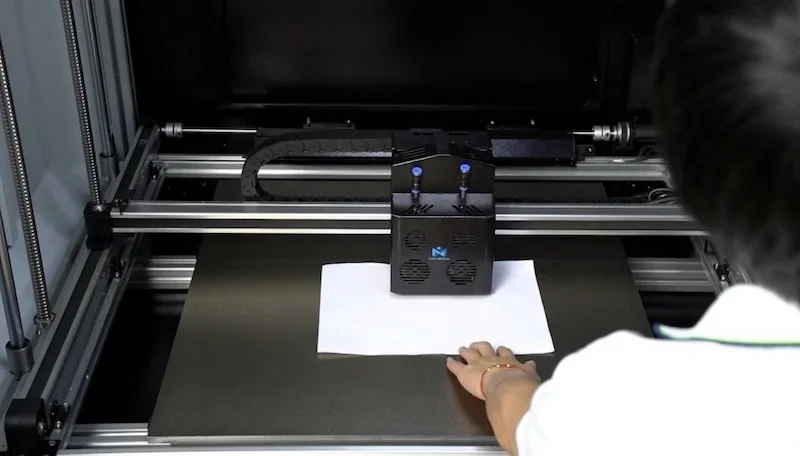

The Mingda MD-600D enhances print quality with auto 100-point bed leveling for stability, vibration reduction to prevent ghosting at high speeds, and flow control for precise extrusion, avoiding print defects and ensuring sharper detail.

The MD-600D’s dual cooling system with aerodynamic ducts ensures fast, even layer cooling at high speeds.

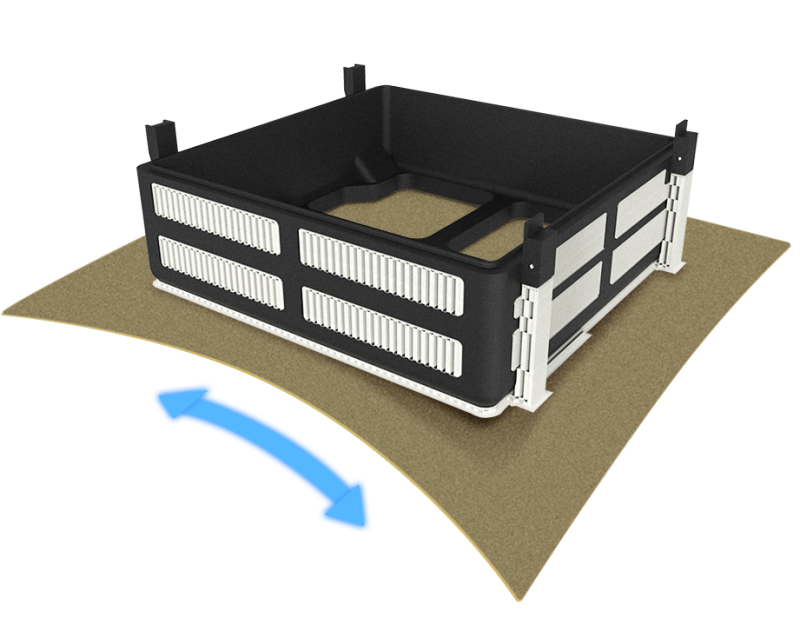

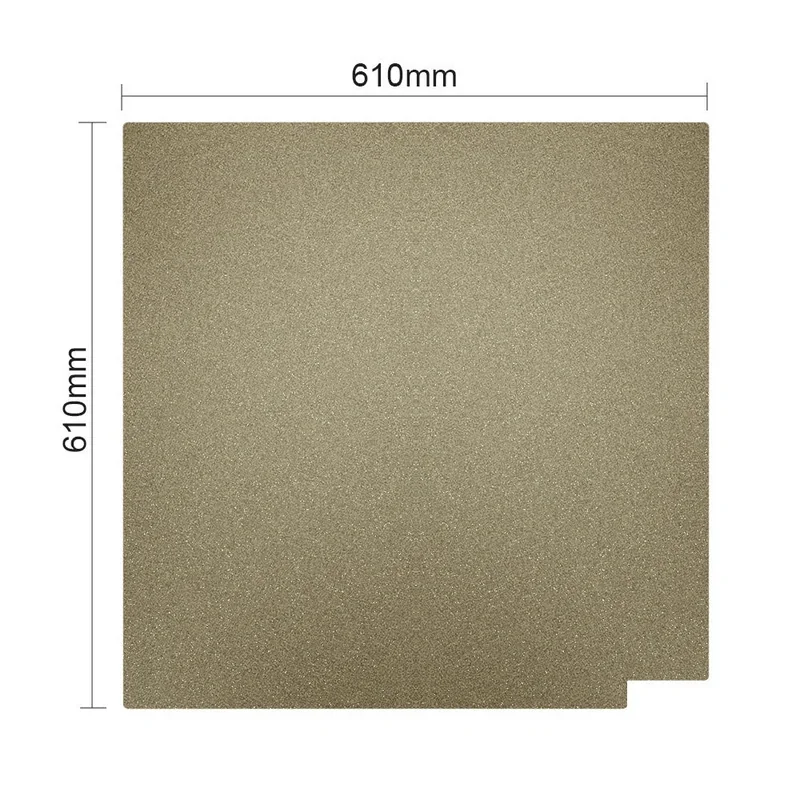

Its flexible PEI build plate provides strong adhesion, resists heat, prevents warping, and allows easy part removal.

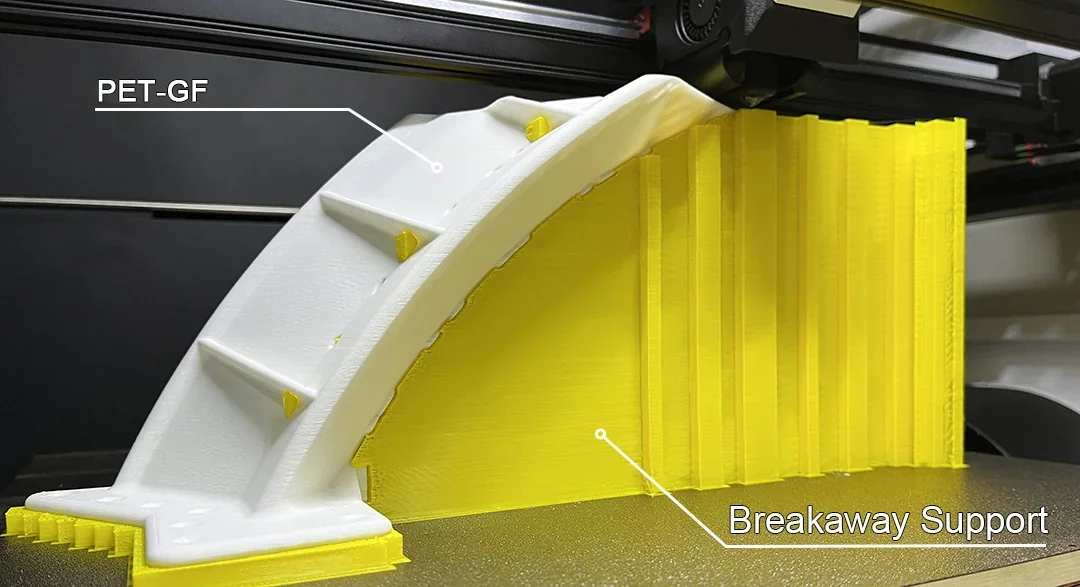

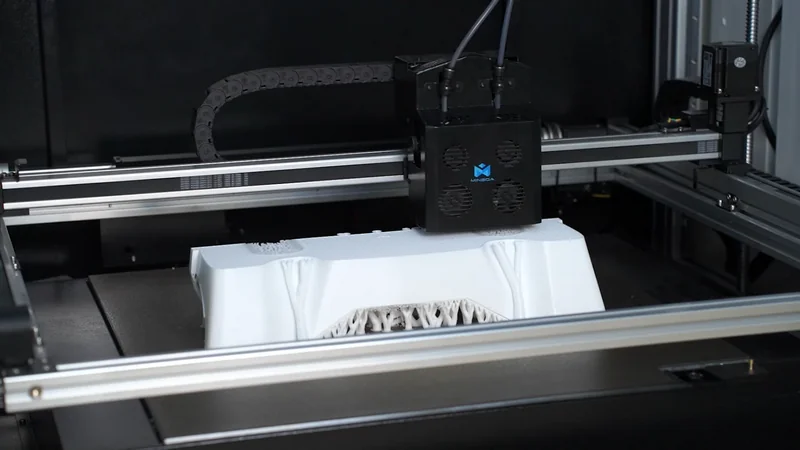

The dual-extruder setup supports water-soluble or breakaway materials for precise printing of complex overhangs, bridges, and hollow structures.

The MD-600D reaches speeds up to 500 mm/s, with optimal printing at 200–300 mm/s. Its 10,000 mm/s² acceleration enables it to hit 300 mm/s in just 0.02 seconds. For example, this 600×500×600 mm PLA-HF wind turbine housing was printed in 24 hours.

The MD-600D supports filaments with a processing temperature up to 350 ℃. These include standard materials like PLA, TPU, and PETG; engineering-grade composites such as PA-CF/GF, PET-CF/GF, HtPA-CF/GF, PA-GF25/CF25. Its dual-extruder setup also enable the use of water-soluble supports, making it easier to print and remove complex overhangs, bridges, and internal structures. As an open-material system, it works with any filament brand.

ABS-HF Print Sample: Heat treatment equipment shell with cylindrical body, mounting flanges, ventilation slots, and matte finish, built to endure high heat and mechanical stress.

PLA-HS Print Sample: Three decorative vases with striped and lattice patterns, showing sharp geometry and smooth surface transitions.

PETG-HF Print Sample: Black angular engineering part with mounting holes, curved cutout, and snap-fit tabs, showing high accuracy, smooth finish, and strong rigidity for assembly.

PLA-HF Print Sample: White car front bumper with aerodynamic contours, recessed channels, and mounting points, featuring sharp edges, consistent adhesion, and matte finish.

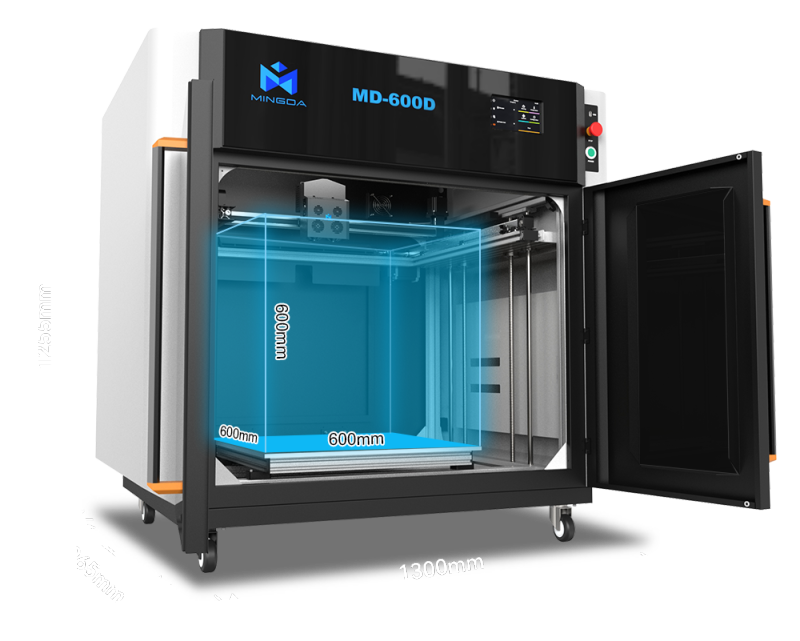

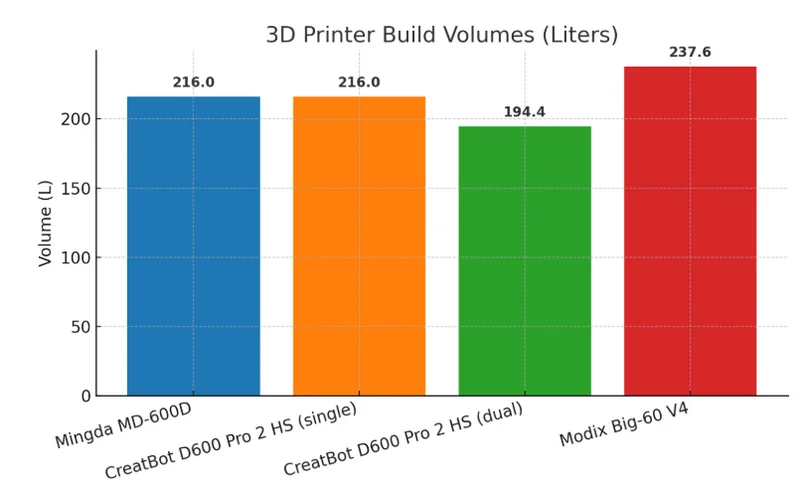

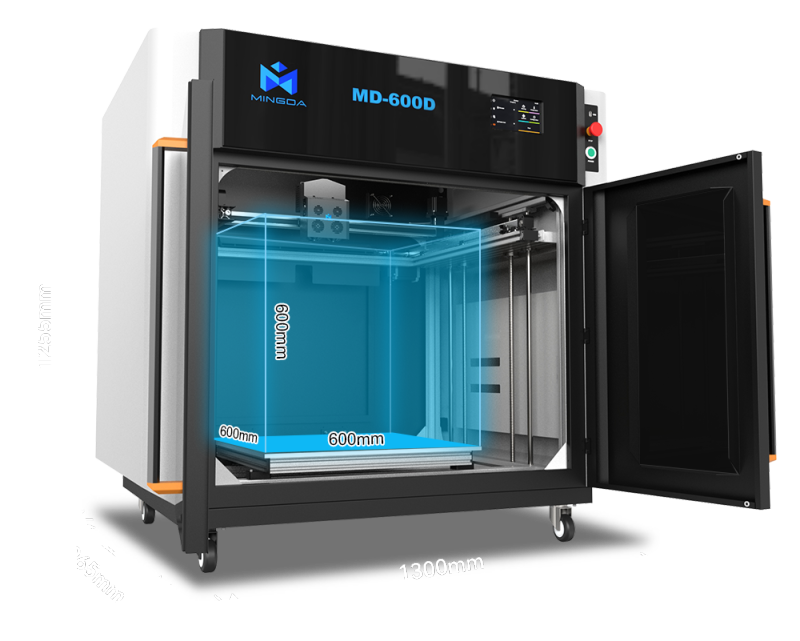

The MD-600D offers a 600 × 600 × 600 mm build volume (216,000 cm³), enabling large models without part-splitting for stronger, faster production. Its outer size of 1300 × 965 × 1255 mm makes it compact enough for studios, schools, and manufacturing sites.

Mingda MD-600D — assembled, dual-extruder (non-IDEX), 600 × 600 × 600 mm large-format workhorse with a 110 °C bed and ~40 mm³/s flow at $16,999+; enclosed (no active chamber) with a ≤350 °C nozzle.

In contrast:

| Specification | Mingda MD-600D | Modix BIG-60 V4 | Creatbot D600 Pro2 HS | MAKEiT 2X2 |

|---|---|---|---|---|

| Price (USD) | $16,999+ | $8,000+ | $16,999+ | $25,000+ |

| Build volume (mm) | 600 × 600 × 600 | 600 × 600 × 660 | 600 × 600 × 600 | 650 × 650 × 800 |

| Enclosure / chamber | Enclosed; No active heated chamber. | Enclosed; No active heated chamber. | Enclosed, Active Heated chamber: 60 °C | Optional, no heated chamber |

| Extruders / IDEX | Dual extruders, not IDEX | Single; IDEX optional | Dual, not IDEX | Single |

| Max nozzle temp (°C) | ≤ 350 (rec ≤ 320) | Components rated 500 (tested to 340) | 420 | 450 |

| Max bed temp (°C) | 110 | 110 | 100 | 110 |

| Volumetric flow (mm³/s) | 40 | Std ~30; High-Flow 45–60; Ultra 160 | 90 | n/s |

| Rated output (g/h) | n/s | Std ~93.8; Ultra >500 | n/s | n/s |

| Assembly | Assembled | Self-assembly kit (assembly services available in the US/EU) | Assembled | Assembled |

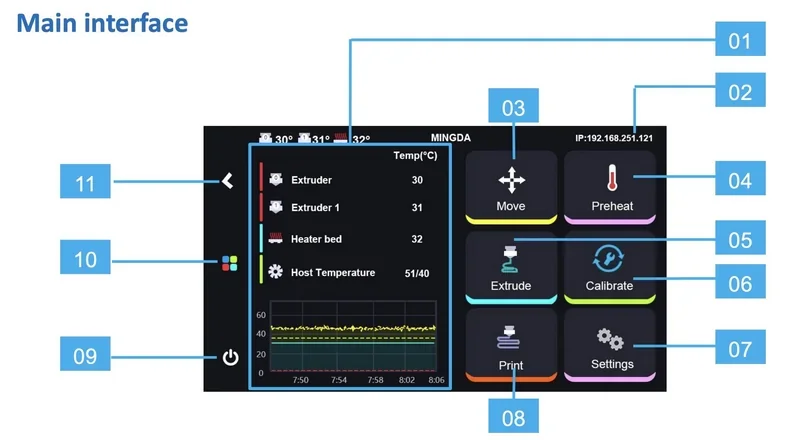

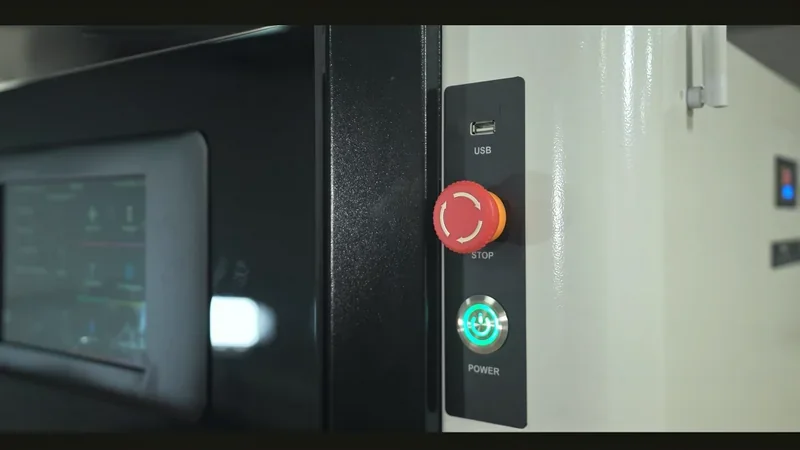

The Mingda MD-600D offers 33 printer controls: 27 on-device controls through its 10-inch IPS high-definition touchscreen interface and 6 additional LAN-based controls for remote operation.

Main Interface Controls

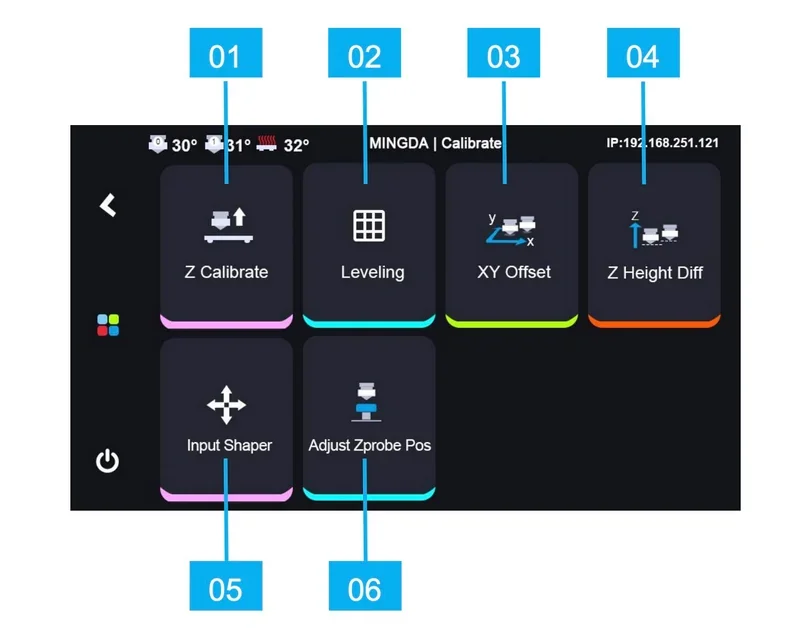

Calibrate Secondary Interface Controls

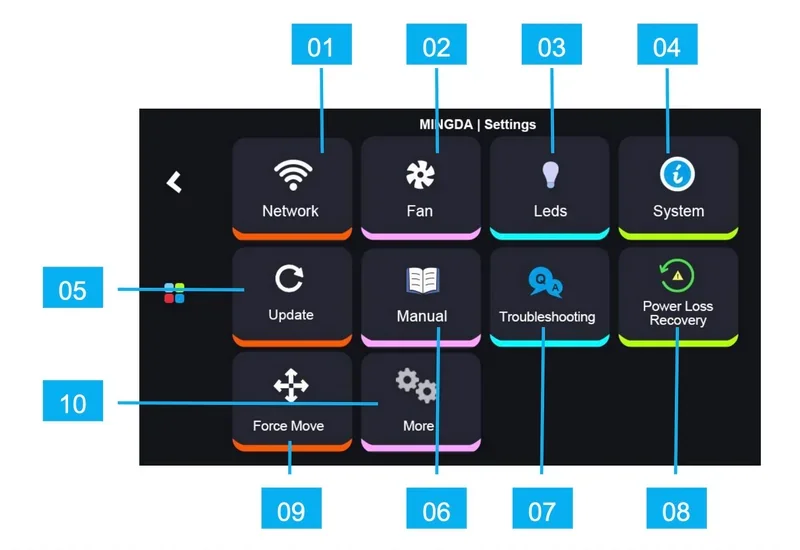

Settings Secondary Interface Controls

Printing Interface Controls

During active printing, additional controls become available:

LAN-Based Controls

When connected via network, the MD-600D provides 6 additional web-based controls accessible through a browser interface:

The MD-600D supports 4 connectivity options: SD card, U-disk, Wi-Fi, and Ethernet. Networked setup with software like Mingda OrcaSlicer lets users send jobs directly via IP, enabling remote printing, monitoring, and streamlined team workflows.

The Mingda MD-600D supports multiple slicers, including MingDa OrcaSlicer (user-friendly with expert mode, print-time/material estimates, and presets for Mingda materials), PrusaSlicer, and self-developed Mingda Cura (optimized Cura fork).

The MD-600D has a boxed design with black front and white side panels, dual front doors, caster wheels, and a light tower, measuring 1300 × 965 × 1255 mm, it features a fully enclosed build chamber.

The MD-600D industrial 3D printer uses HIWIN linear rails on all axes and closed-loop stepper motors for ±0.1 mm precision, stability, and fast response. Its modular guide rail system supports 10,000 mm/s² acceleration and 500 mm/s travel speeds under Klipper control, ensuring .

The MD-1000D has a 10 mm aluminum heated bed (up to 110 °C, reaching 60 °C in 75 s) with a printing size of up to 600mm cube. It uses a flexible magnetic PEI sheet for strong adhesion and easy part removal. A recessed calibration zone simplifies nozzle offset setup.

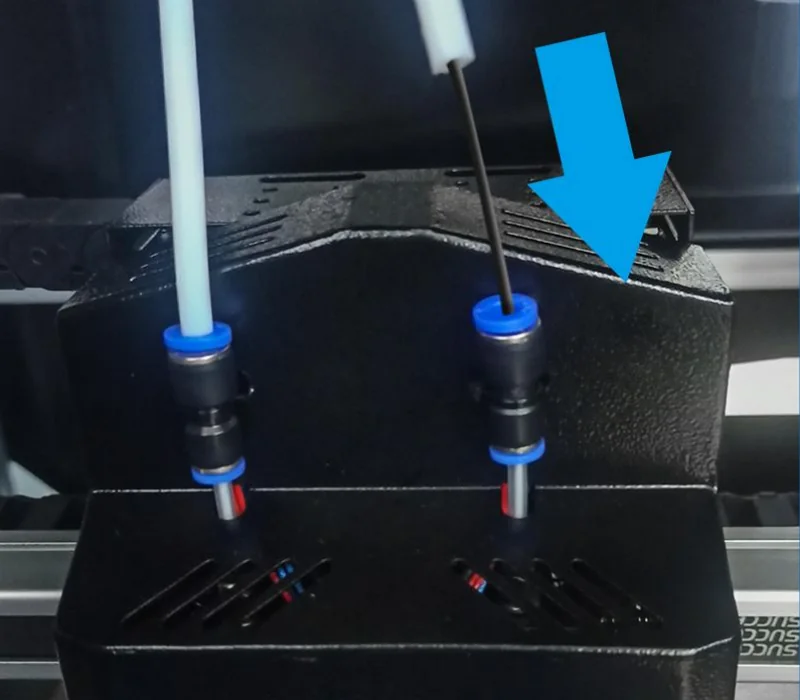

The MD-600D features a dual-gear direct extruder system with a max nozzle temperature of 350 °C and independent XY/Z offset calibration for each extruder.

The MD-600D has filament boxes on both sides for spool storage. Filament feeds through guide pipes into the extruders, with loading controlled via the touchscreen.

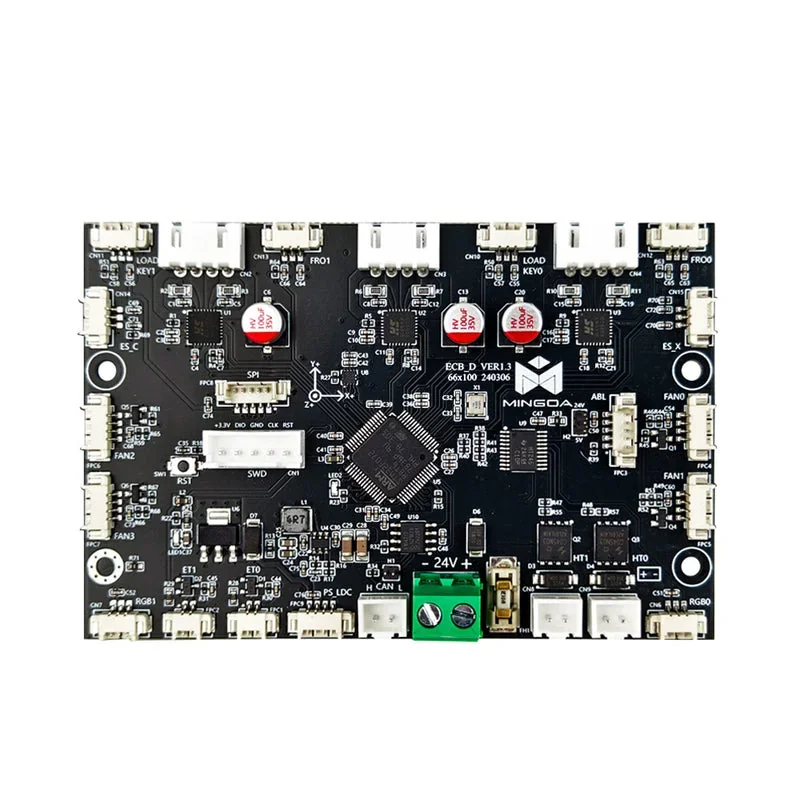

The MD-600D runs Klipper firmware on a proprietary 64-bit mainboard, powered by the 6-core CPU, ensures fast processing of data and rapid completion of 3D printing tasks.

The MD-600D runs on 100–240V AC, 50/60Hz, with a rated power consumption of 2000W.

The MD-600D ships fully assembled and calibrated, needing only basic startup before first use. It comes with essential tools, a USB drive with software and test files.

Note: Package contents may vary. Confirm included items with a Top3DShop representative before ordering.

| Accessory | Function | Price (USD) | Image |

|---|---|---|---|

| Filament Storage & Smart Boxes | |||

| MingDa MD-F01 Filament Box (3-tier) | Smart filament storage box (3-tier) for large-capacity storage and continuous printing. | $3,599 |  |

| Printhead Nozzles (Integrated) | |||

| MD-600D Integrated High-Coat Hardened Steel Nozzle (single) | Integrated hardened-steel nozzle for MD-600D. | $60 |  |

| MD-600D Integrated High-Coat Hardened Steel Nozzle (5 pcs) | 5 integrated hardened-steel nozzles for MD-600D. | $230 |  |

| MD-600D Integrated High-Coat Silicon Carbide Nozzle (single) | Integrated silicon-carbide nozzle for MD-600D. | $90 |  |

| MD-600D Hardened Steel Nozzle Set 0.4 mm (5 pcs) | 0.4 mm hardened-steel nozzles for MD-600D (1 x 0.4 mm nozzle, 2 x 0.6 mm nozzles, 2 x 0.8 mm nozzles). | $80 |  |

| Hotend & Heating Assemblies | |||

| MD-600D Integrated Hotend (complete) | Integrated hotend assembly for MD-600D. | $250 |  |

| MD-600D Hotend (complete) | Hotend assembly for MD-600D. | $230 |  |

| MD-600D Heater + Hardened Steel Nozzle Kit | Heater plus hardened-steel nozzle kit for MD-600D. | $105 |  |

| Extrusion Drive & Filament Feeding | |||

| Extruder Drive Gear (Tool Steel) | Tool-steel extruder drive gear (filament feed gear). | $40 |  |

| Extruder Drive Gear (RNC Hardened Steel) | RNC hardened-steel extruder drive gear (filament feed gear). | $50 |  |

| MD-600D Extruder (complete module) | Complete extruder module for MD-600D. | $1550 |  |

| Build Platform Surfaces | |||

| MD-600D PEI Build Surface Sheet (610 × 610 mm) | PEI build surface sheet for MD-600D (610 × 610 mm). | $300 |  |

| Sensors, Cables & Electronics | |||

| MD-600D Filament Detection Limit-Switch Cable (200 mm) | 200 mm filament detection limit-switch cable for MD-600D. | $30 |  |

| MD-600D Printhead Control Board | Printhead control board for MD-600D. | $130 |  |

| Cooling | |||

| MD-4015 4-Wire Turbo Cooling Fan (for MD-600D) | 4015 turbo cooling fan, 4-wire, for MD-600D. | $45 |  |

MINGDA 3D printers, developed since 2012, have been in operation for over 11 years, with each machine averaging over 35,000 hours of printing time, showcasing unparalleled stability.

After Each Print

Regular Maintenance

As Needed

The MD-600D includes a 1-year limited warranty from Top3DShop: 12 months for the mainboard, display, power supply, and motors, and 3 months for extruder kits, backed by Shenzhen Mingda Technology Co as the manufacturer. Coverage applies to defects under normal use, excluding misuse, modifications, mishandling, or uncertified parts.

Mingda provides complimentary technical support for setup, operation, and troubleshooting, mainly via email (support@3dmingda.com) or Whatsapp (+8613530306290). Assistance includes remote diagnostics, software guidance, and issue resolution, with priority given to warranty-related cases.

Purchasing through Top3DShop adds dedicated reseller support on top of Mingda’s warranty coverage. The expert team is available Monday–Friday via phone, email, or live chat, offering guidance from unboxing and calibration to on-site installation.

Full warranty terms: https://3dmingdaofficial.com/pages/after-sales-service-polices

The Mingda MD-600D FDM 3D printer is priced at $15,437.07, including the fully assembled dual extruder 3D printer, 350 °C hotends, 600 × 600 × 600 mm build volume, and essential accessories. It offers 5× faster printing, support for engineering-grade materials, and features like auto bed leveling, Wi-Fi, and remote monitoring. Buy the powerful professional-grade 3D printer MD-600D at Top3DShop for expert local support.

Update your browser to view this website correctly. Update my browser now