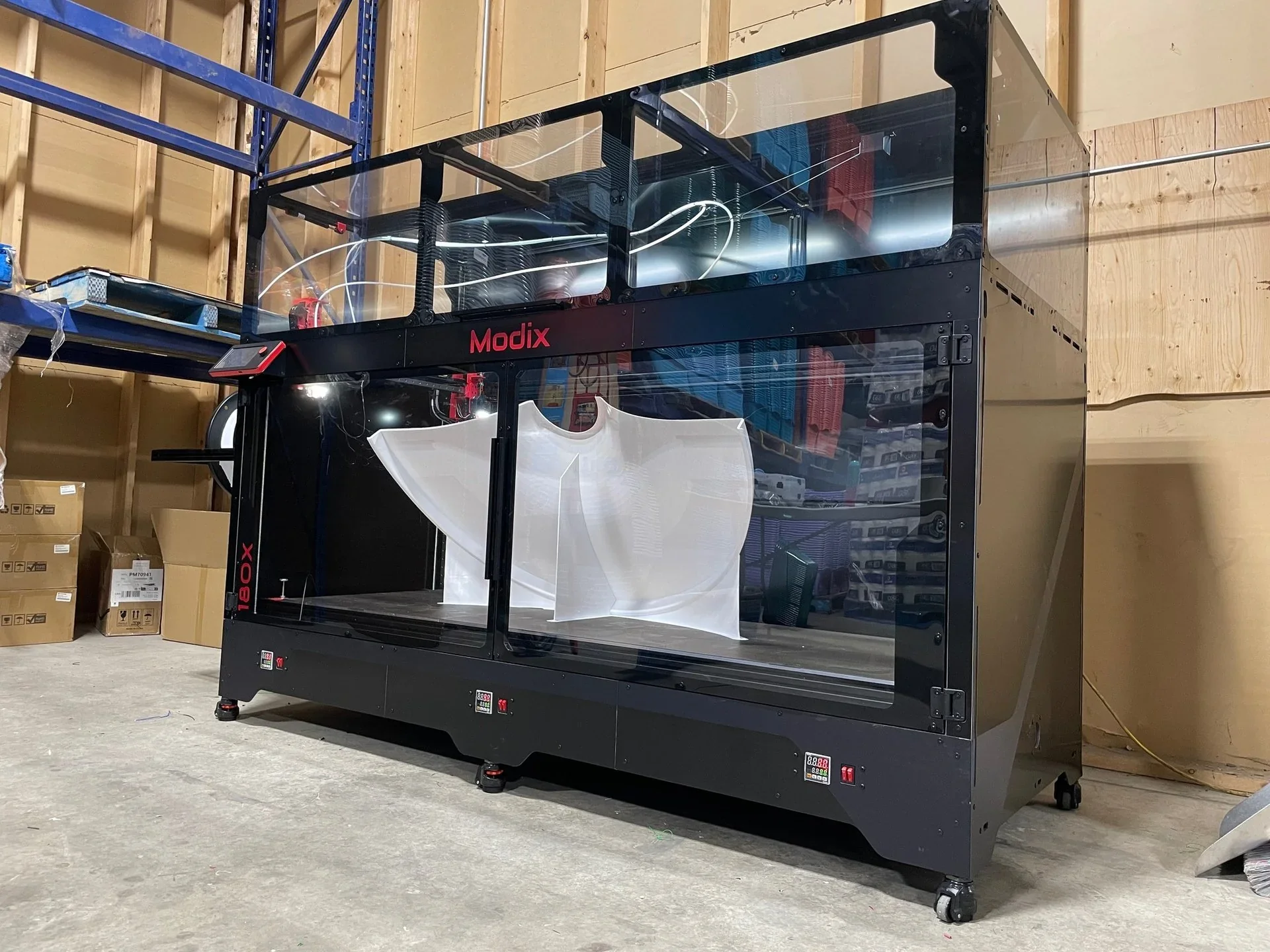

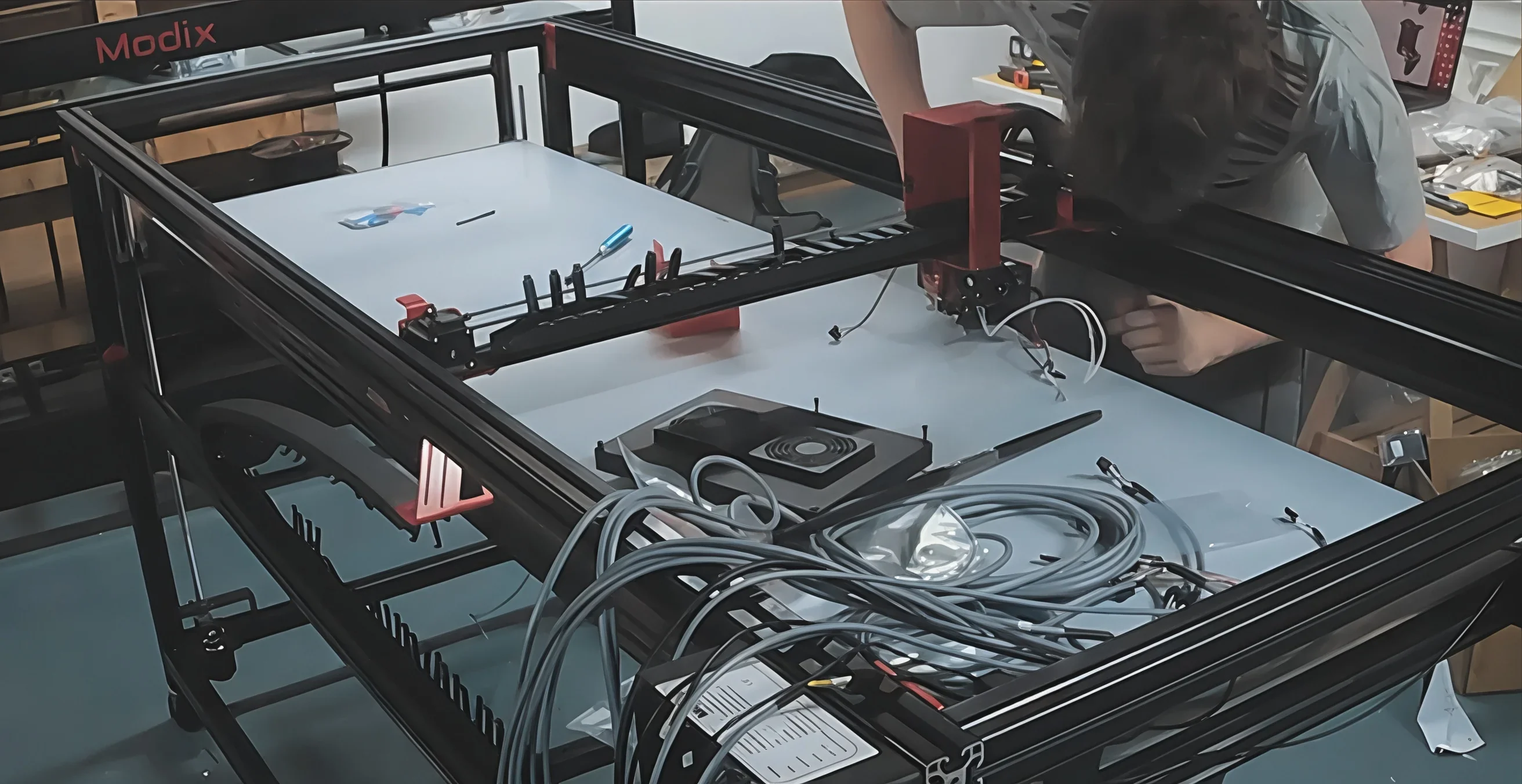

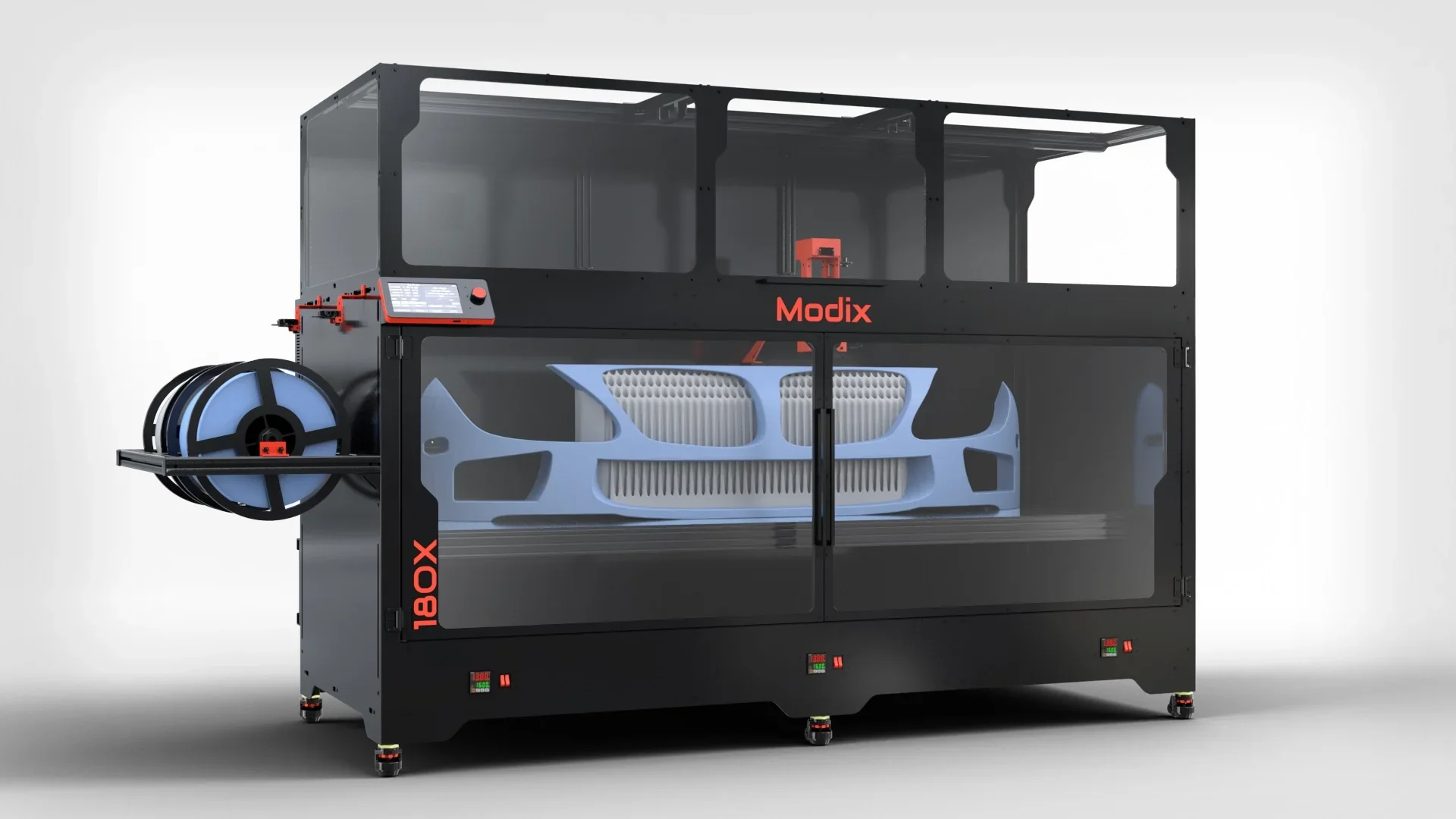

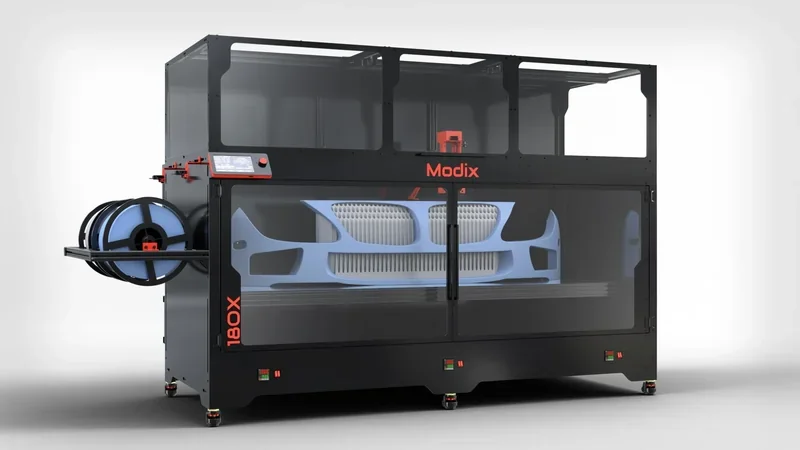

The Modix BIG-180X V4 is a large-format industrial FDM printer with a 1800×600×600 mm build volume, designed for full-scale parts in sectors like automotive, aerospace, and architecture. It features the high-flow Griffin print head (Bondtech extruder + Modix hotend, up to 450 °C) and upgraded Nema-23 motors for speeds up to 250 mm/s. The Duex 5 board enables automated calibration, including bed leveling and gantry alignment. Compatible with any 1.75 mm filament, it supports materials like PLA, ABS, Nylon, TPU, and composites. An optional IDEX add-on enables dual-material and multi-color printing, ideal for prototyping and production.

The Modix BIG-180X V4 delivers high print quality with a 40 μm minimum layer height, producing smooth surfaces and fine details. A demo shows a 64-hour print of a full-size chair (330 × 330 × 450 mm) using 3.8 kg of PLA at 0.4 mm layers with a 0.8 mm nozzle, maintaining dimensional accuracy and layer adhesion at 25 mm/s outer and 50 mm/s infill speeds — without shifts or thermal drift common in long large-format prints.

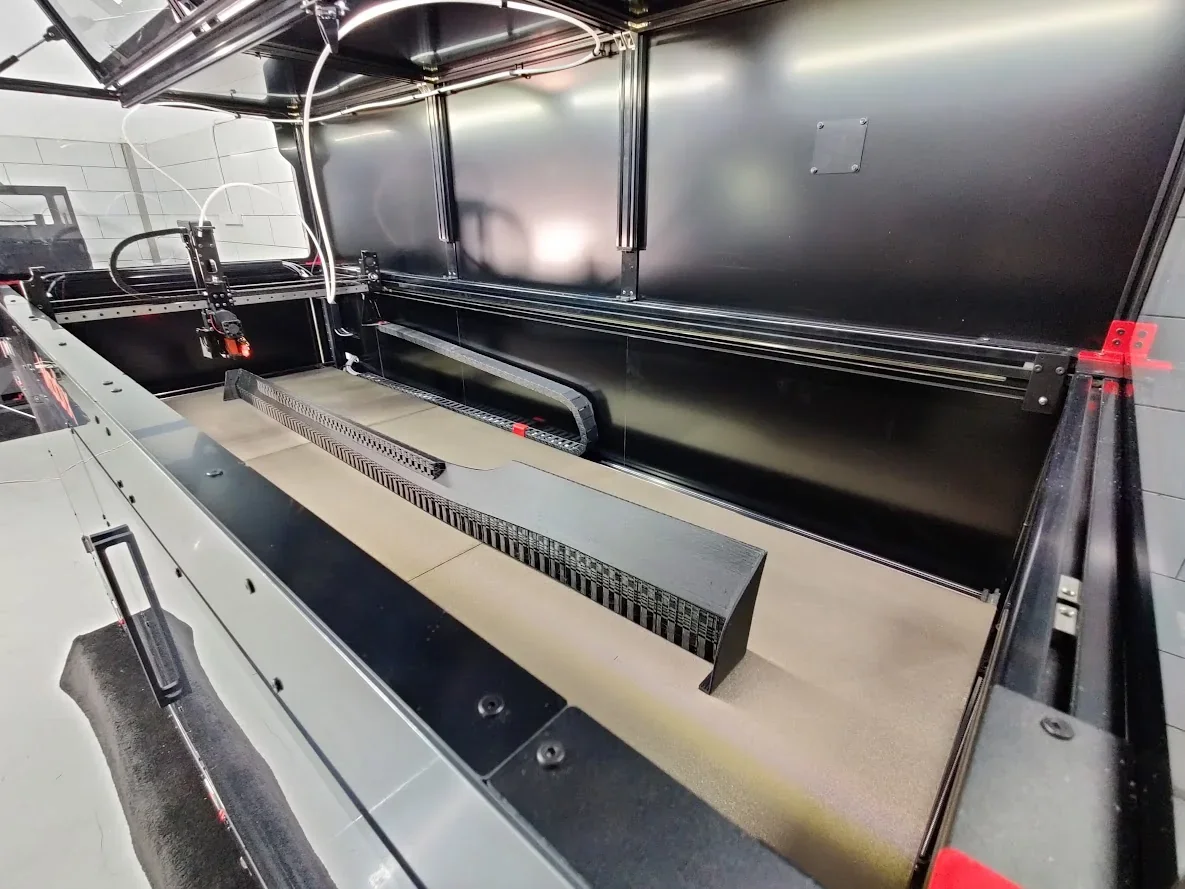

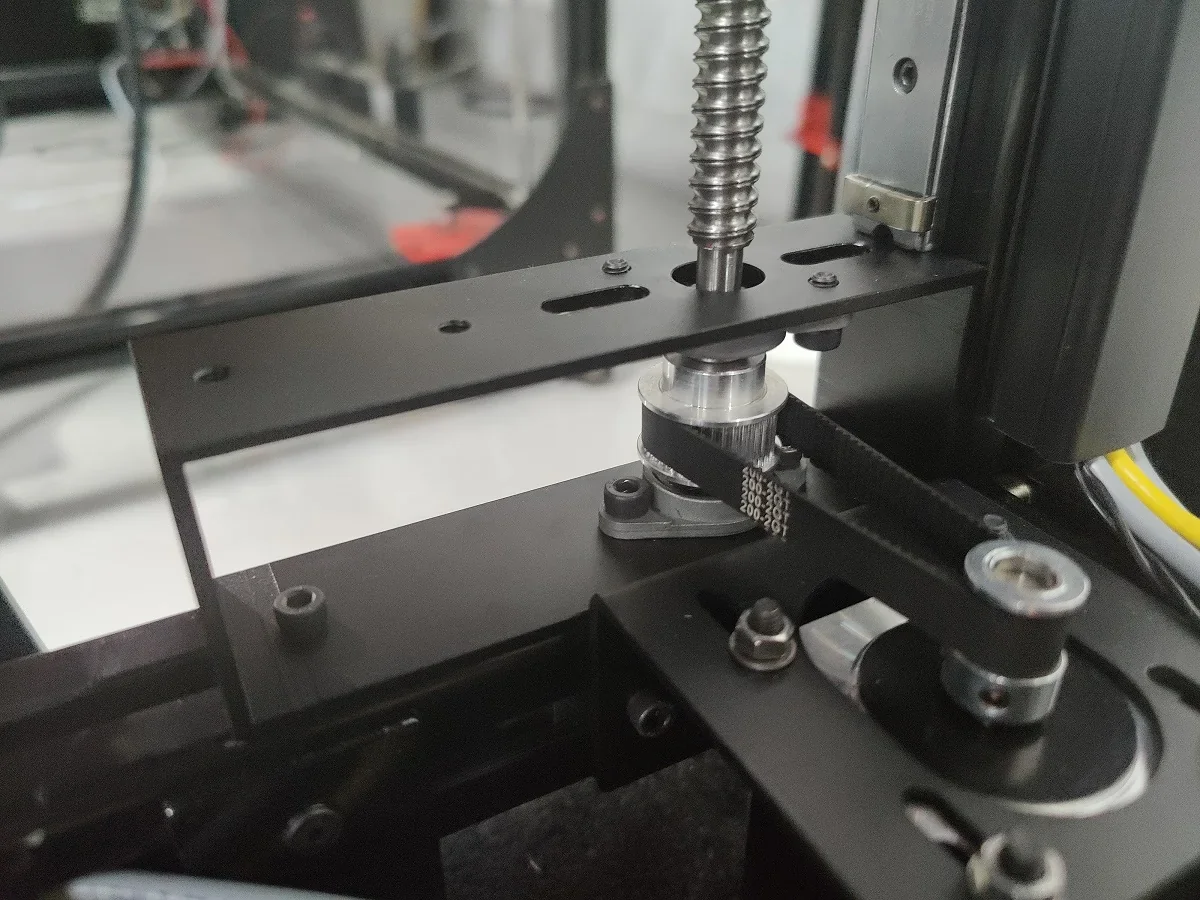

The upgraded Z-axis with Nema-23 motors and CNC brackets improves print accuracy and stability across the full 1800 × 600 × 600 mm build volume. A demo shows the printer producing a full-size hockey stick, nearly spanning its entire width, highlighting the precision of its 300-point bed leveling and four independent Z-axis motors for consistent layer adhesion and dimensional accuracy.

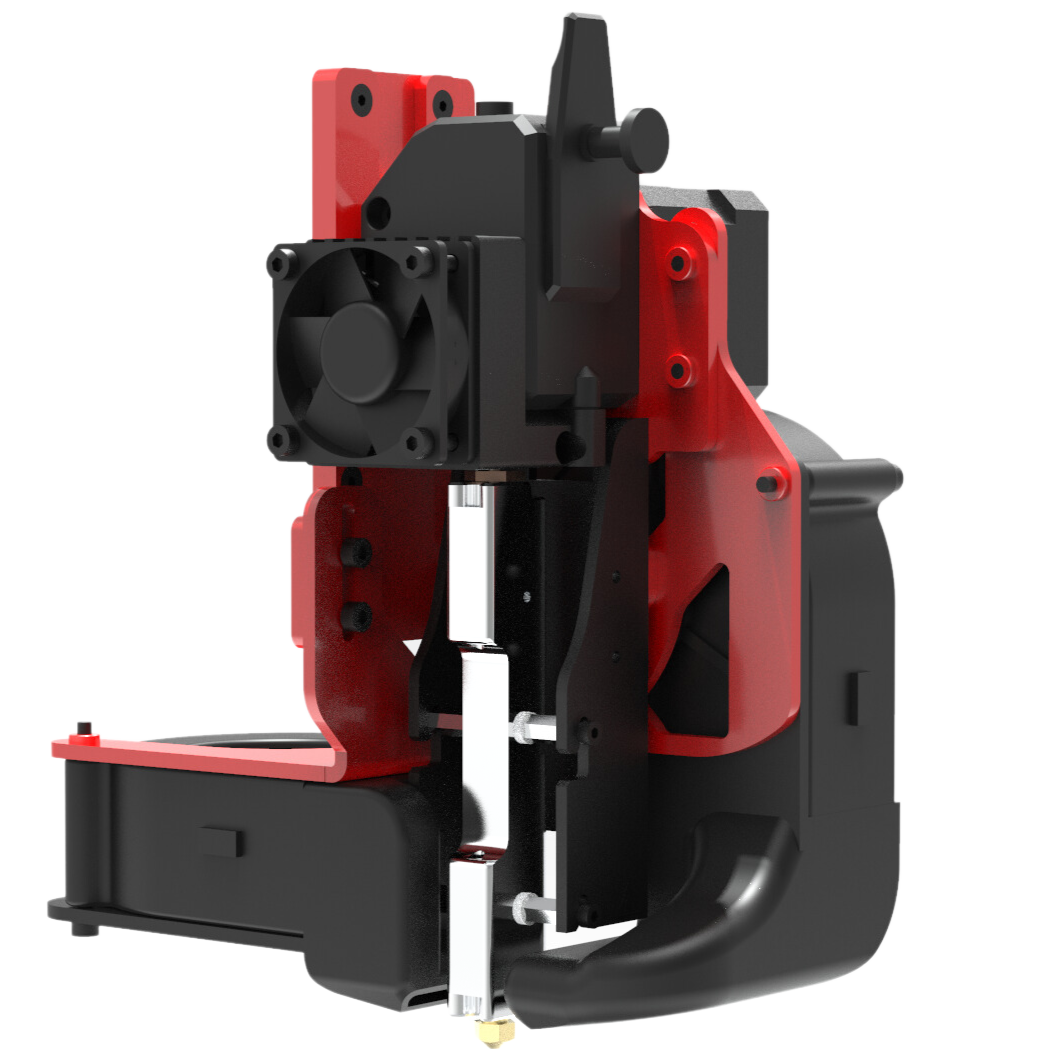

The productivity of the large Modix 3D printers depends on the extruder, with Griffin variants ranging from ~46.9 g/h (High-Resolution) to over 500 g/h (Ultra), driven by differences in hotend length, melt path design, and heater power.

| Feature / Spec | Griffin (Standard) | Griffin High-Resolution | Griffin High-Flow | Griffin Ultra |

|---|---|---|---|---|

| Use Case | All-purpose printing | Ultra-fine detail | High-speed, large prints | Maximum throughput, industrial use |

| Design | Standard hotend | 50% shorter for precision | Double-length for more melt volume | Extended dual-zone melt path (4× standard) |

| Flow Rate | ~30 mm³/s | ~15 mm³/s | ~45–60 mm³/s | ~160 mm³/s |

| Extrusion Rate | ~93.8 g/h | ~46.9 g/h | ~140.6–187.5 g/h | >500 g/h |

| Nozzles | Volcano-compatible; 0.4, 0.6, 0.8mm | Volcano-compatible; 0.4mm | Volcano-compatible; 1.0mm | Volcano-compatible; 1.6mm |

| Heater | 50W standard | 50W standard | 80W upgraded | Dual heaters (>80W) |

| Cooling | Standard fan | Standard fan | Standard fan | Dual XXL blowers |

| Max Temp | Tested to 340°C, supports up to 500°C | Tested to 340°C, supports up to 500°C | Tested to 340°C, supports up to 500°C | Tested to 340°C, supports up to 500°C |

| Build Volume Impact | None | None | None | Reduces X by 50mm; Y by 50mm (IDEX mode) |

The optional Griffin High-Resolution Extruder supports tight tolerances. For example, this video shows 50-micron layer height printing, producing two detailed 11.5mm bolt parts in 27 minutes. Printed in Glitter Gray PLA using a 0.4mm nozzle at 185°C, 55°C bed, 2.5mm retraction, 100% fan, 2 outer walls, and 7 top solid layers.

The optional Griffin Ultra hotend halves production time — a 1-meter statue printed in 21 hours vs. 47 with the standard Griffin Extruder.

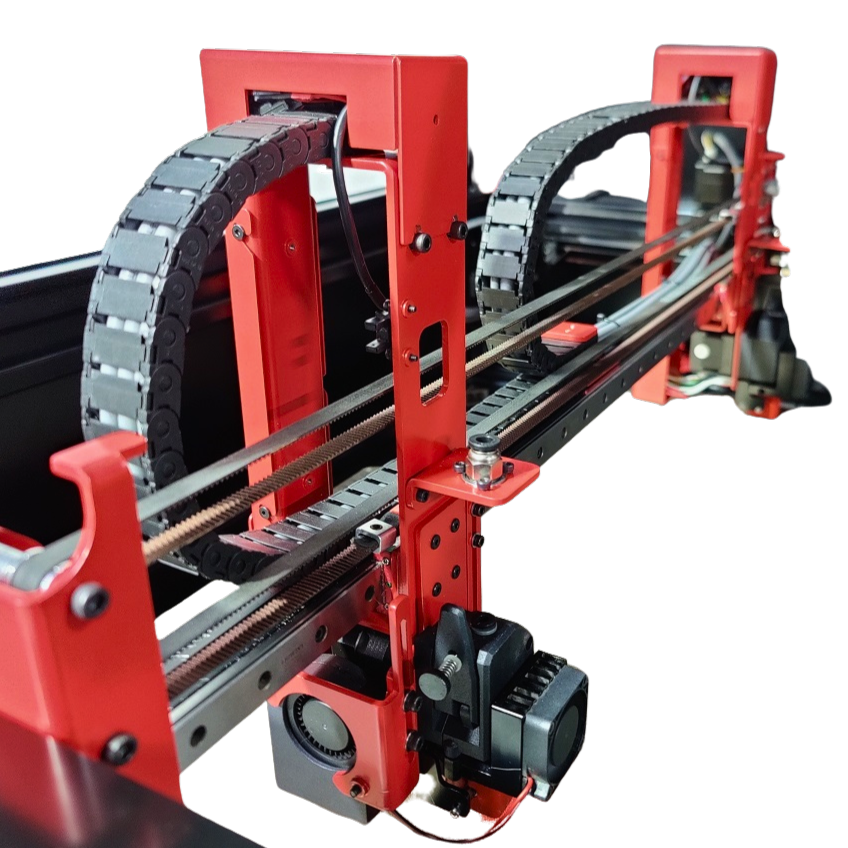

The BIG-180X V4 uses HIWIN linear rails for precise, fast, and reliable movement. The Duex 5 expansion board provides dedicated drivers for each Z and X motor, enabling full automated bed tilt, leveling, gantry alignment, and Z offset calibration for improved print quality.

Upgraded optical end-stop switches enhance accuracy and repeatability, improving print recovery after power outages.

The Griffin printhead’s modular design supports both speed and precision, with nozzle sizes from 0.4 mm to 1.2 mm. Hardened steel nozzles handle abrasive materials up to 450°C, while a bi-metal heat break and PT-1000 sensor enable printing at up to 500°C for high-temp industrial materials.

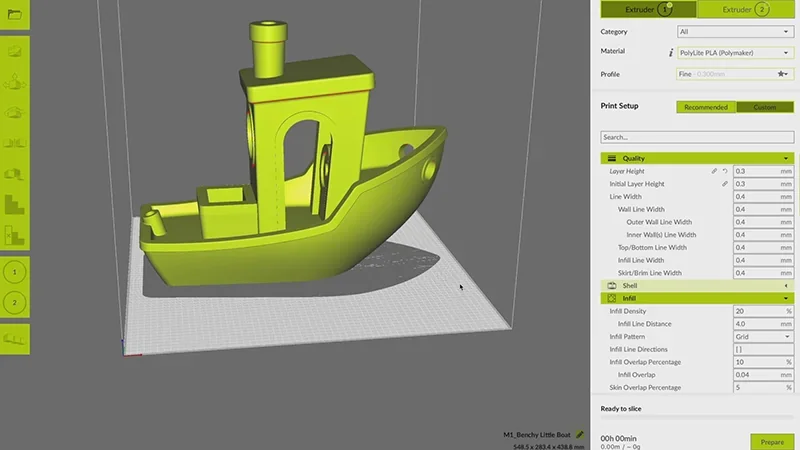

The Modix BIG-180X V4 supports over 15 filament types, including PLA, ABS, PETG, Nylon, TPU/TPE, and composites like carbon fiber, wood, and metal-filled filaments. With the optional PT-1000 upgrade, it can reach 500 °C, enabling high-temp engineering plastics. Its open material system works with any 1.75 mm third-party filament and is compatible with slicers like Simplify3D, PrusaSlicer, and Cura. The optional IDEX add-on allows multi-material, multi-color, and soluble support printing, while a built-in clog detector helps prevent print failures and material waste.

3D Print Sample: Breakaway support filament

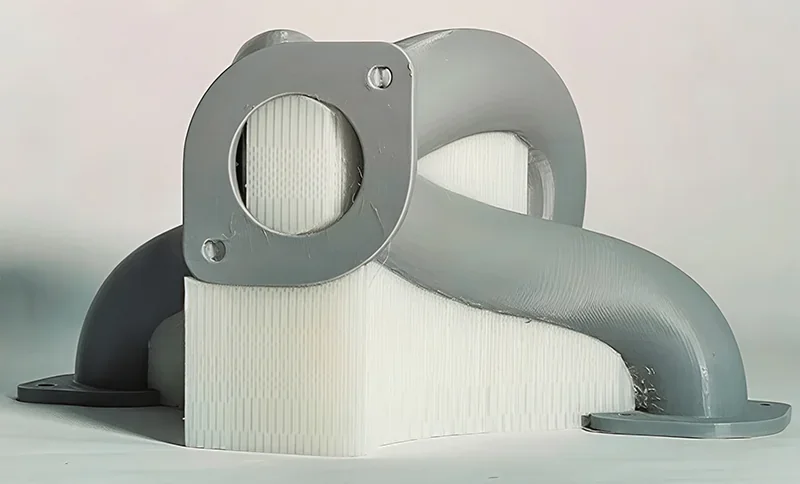

3D Print Sample: Printing with soluble support filament

PETG 3D Print Sample:

Image Credit: Glen Waldner

PETG 3D Print Sample:

Image Credit: Glen Waldner

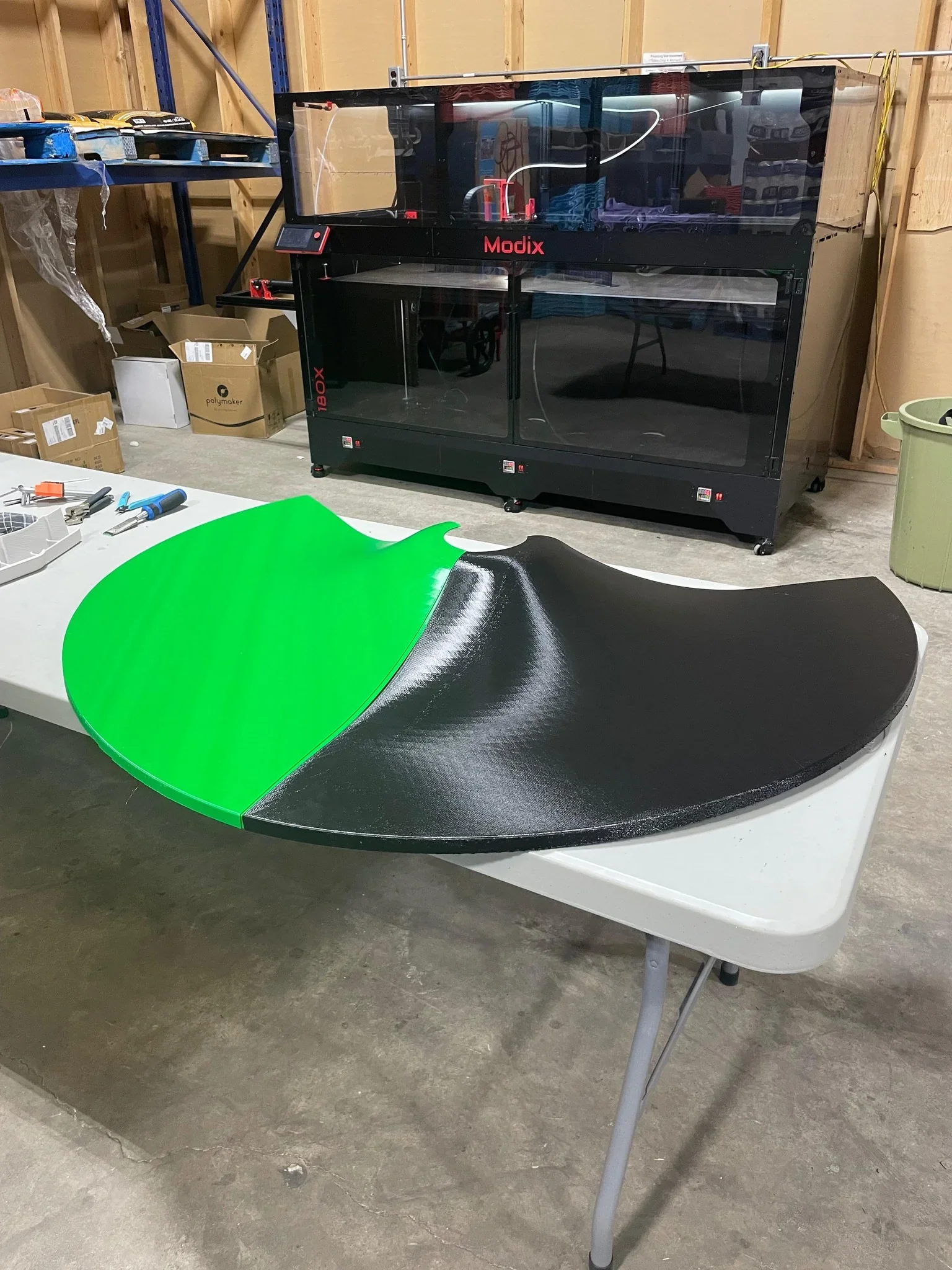

Case Study: Wyve Surf — French startup revolutionizing surfboard manufacturing with sustainable, customizable boards that won the 2020 Greentech Innovation Award for their Hexa surfboard. Their fleet of BIG-180X printers uses recycled materials including PET bottles and fishing nets, printing boards as single pieces for superior strength while eliminating up to 100 pounds of pollutants per board compared to conventional manufacturing.

Case Study: Illumaesthetic — Custom automotive parts manufacturer evolved from a college project to a global force operating five Modix printers ranging from BIG-60 to BIG-180X. They create race car bumpers, custom car body parts, and collaborated with Donut YouTube channel on a record-breaking minibike project utilizing 25 total print days distributed across three different printers.

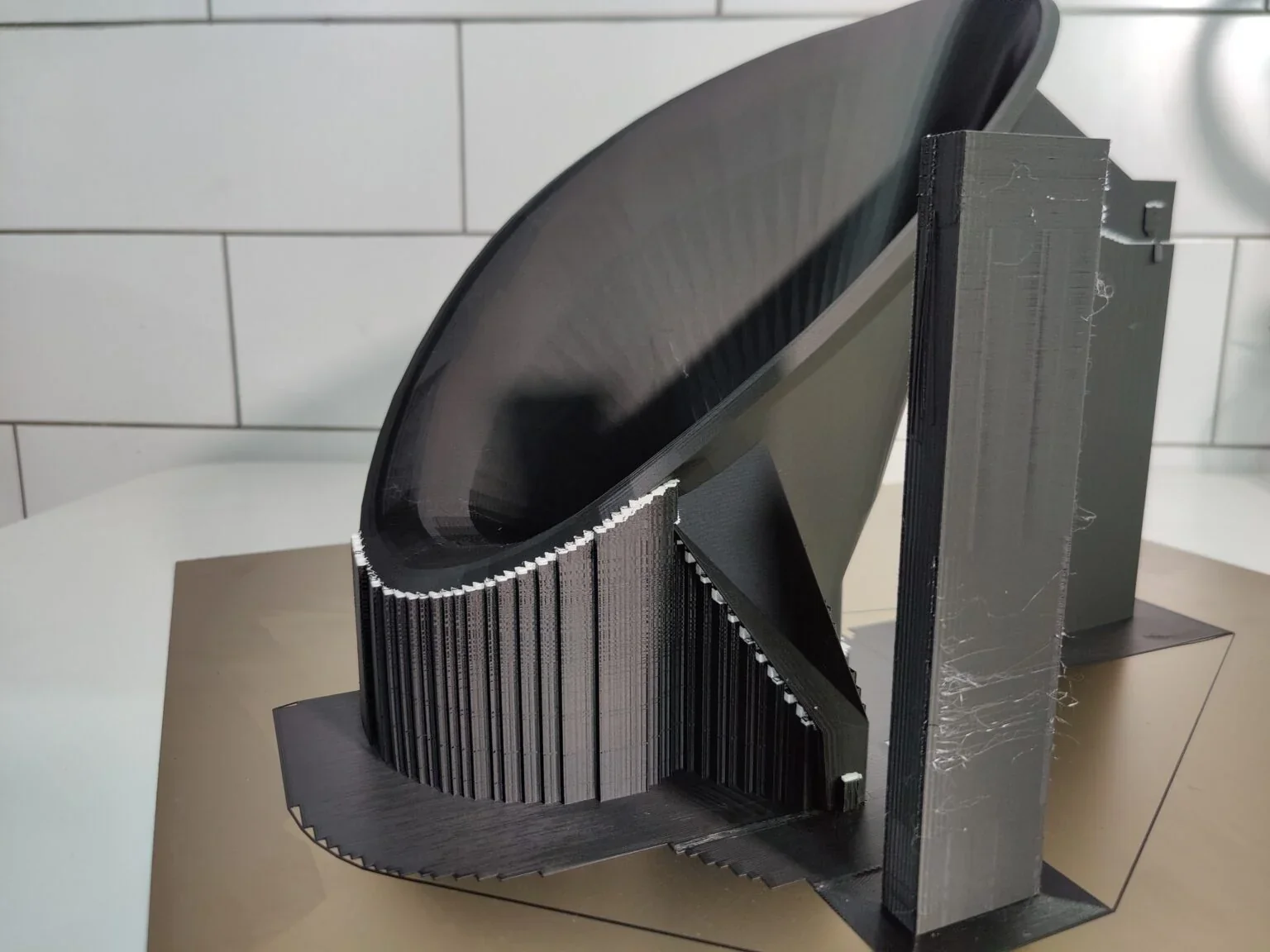

ASA 3D Print Sample: This video shows Illumaesthetic using a Modix printer to prototype a custom Subaru STI front bumper in ASA. Due to size limits, the bumper was printed in five parts, which were used as master patterns for fiberglass mold and final part production at Big Dog Club.

PETG 3D Print Sample: In collaboration with Donut Media, Illumaesthetic used multiple Modix printers, including the BIG-180X, to 3D print PETG aerodynamic fairings over 25 days across three machines. The resulting cowling system reduced drag by 4% — from 431 to 413 Newtons — on Donut’s 100 mph record-breaking minibike.

PETG Print Sample

With a massive 1800 × 600 × 600 mm (648 L) build volume, the Modix BIG-180X V4 is among the largest FDM/FFF printers available. Designed for automotive professionals, it enables single large-part prints or batch printing of multiple mid-sized models without compromising quality or reliability.

The BIG-180X V4’s extended build length is ideal for automotive, aerospace, and product development, enabling large, single-piece prints that improve structural integrity and reduce post-processing.

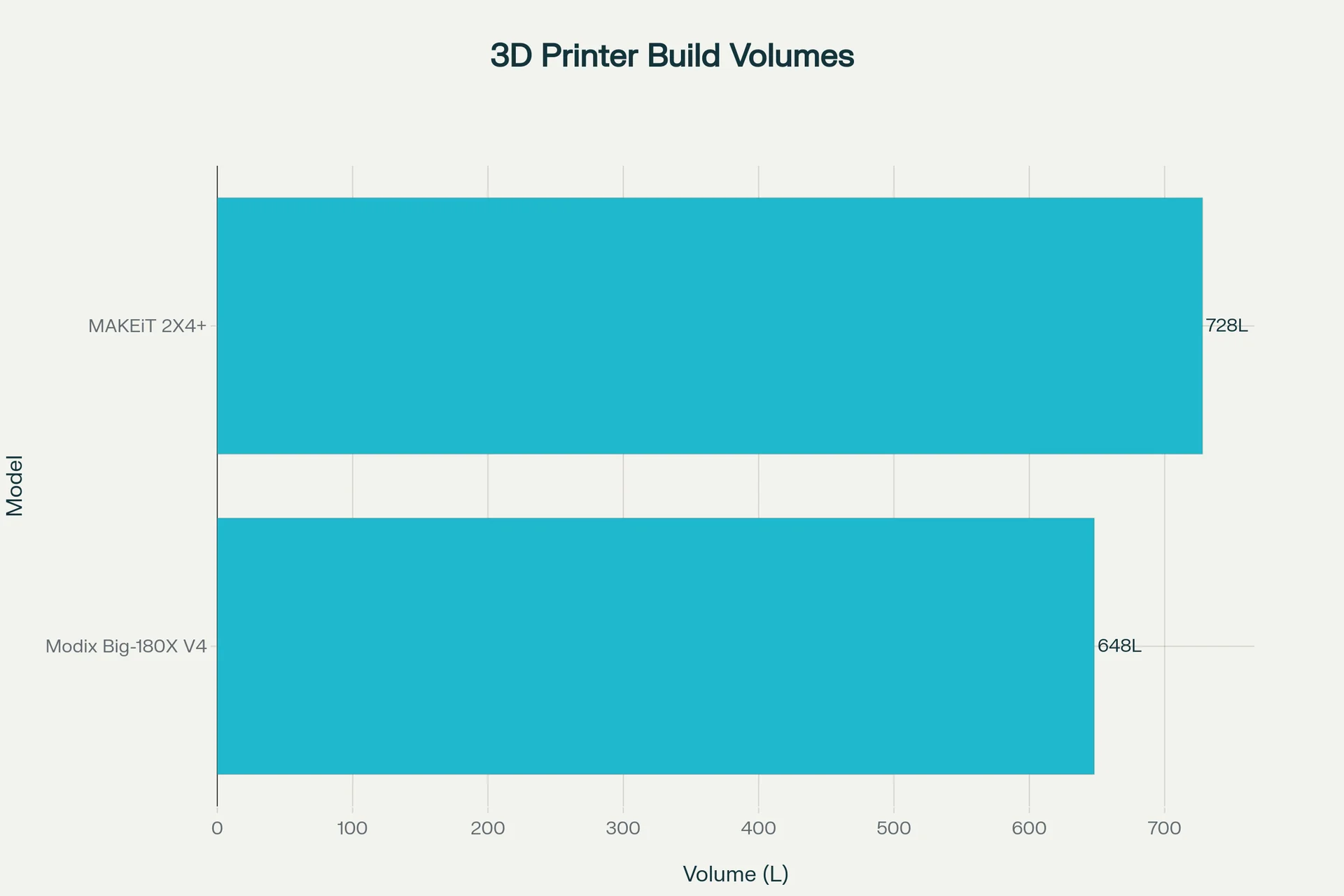

The Modix BIG-180X V4 offers strong value in large-format FDM printing by focusing on X-axis width (1800 mm), a precision 300-point bed leveling system, and a lower $25,000+ price — compared to the MAKEiT 2X4+’s 728 L capacity, heated chamber, and $32,000–$45,000+ price range. While the MAKEiT excels in turnkey operation and thermal control, the BIG-180X V4 appeals to budget-conscious professionals with its self-assembly design, optional IDEX, and 500°C hotend, surpassing MAKEiT’s 450°C. It’s ideal for wide-format, high-temp, cost-sensitive applications; the MAKEiT suits users needing fully assembled, industrial-grade performance.

| Specification | Modix Big-180X V4 | MAKEiT 2X4+ |

|---|---|---|

| Build Volume (X×Y×Z mm) | 1800 × 600 × 600 | 1400 × 650 × 800 |

| Total Volume (Liters) | 648 | 728 |

| Price Range (USD) | $25,000+ | $33,000-45,000+ |

| Assembly Method | Self-assembly kit | Fully assembled + tested |

| Max. Hotend Temperature | 500°C | 450°C |

| Bed Leveling | 300 probing points, automatic | 100% automatic |

| Dual Extruder Option | IDEX optional kit | N/A |

| Heated Chamber | Enclosed (not heated) | Built-in heated chamber |

| Frame Construction | 40mm T-slot aluminum | Steel frame structure |

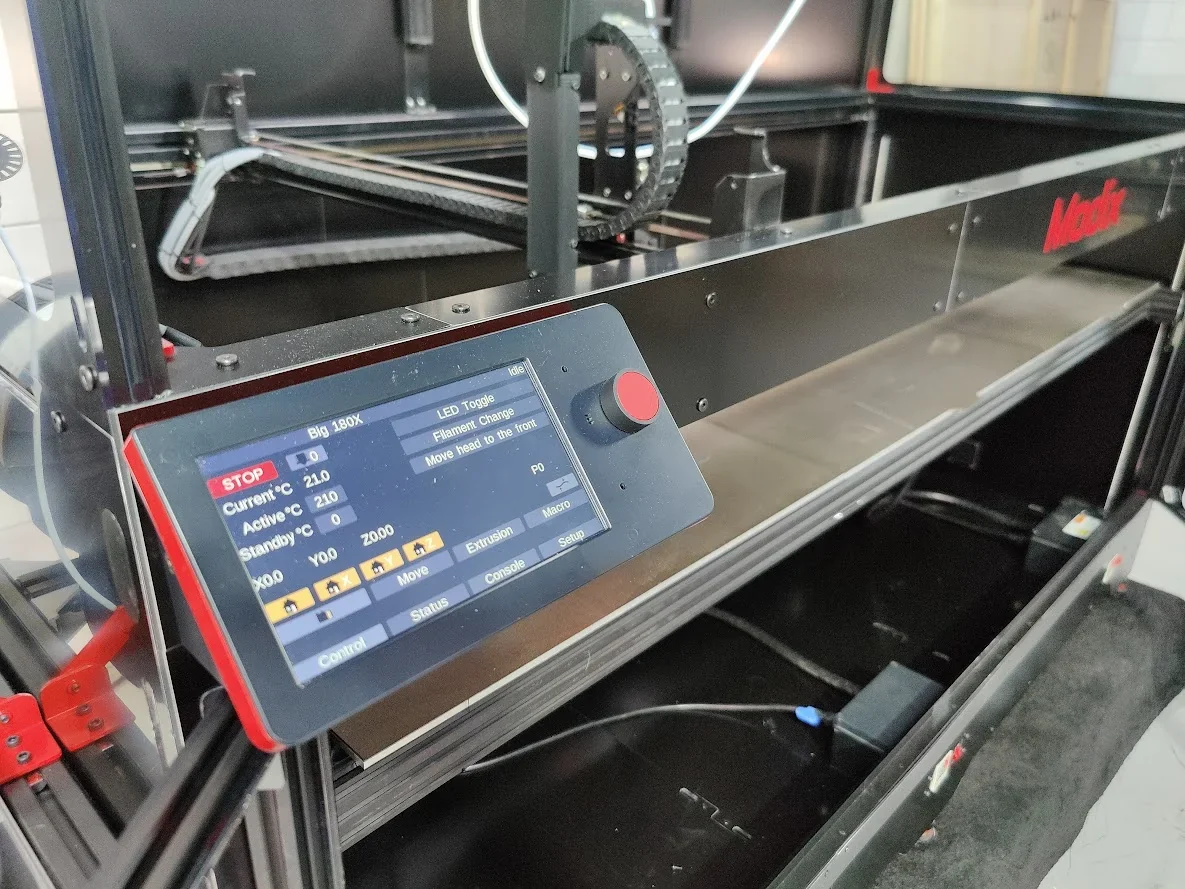

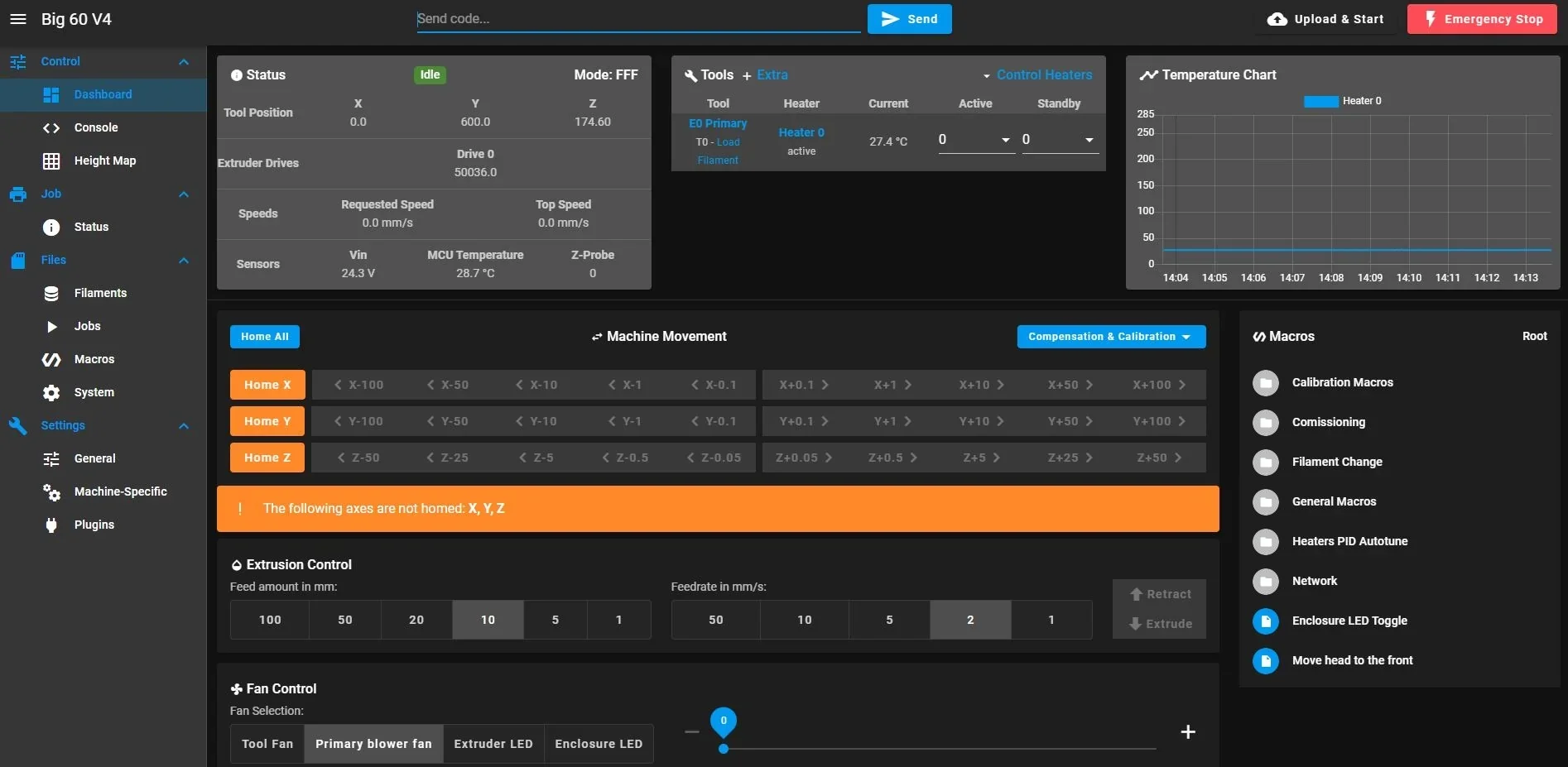

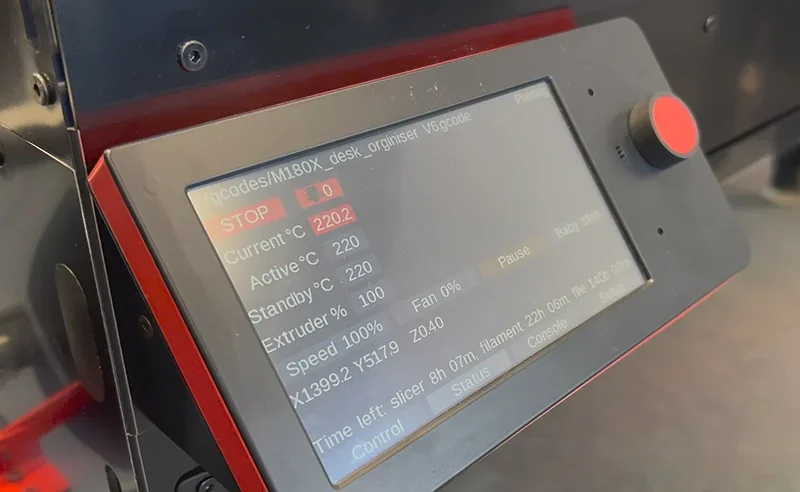

The Modix Big-180X V4 offers 4 distinct control methods, such as PanelDue touchscreen, Duet Web Control, Local File Input, and optional Ethernet, giving operators complete control over all printer functions.

1. PanelDue Touchscreen

A 7-inch touchscreen (PanelDue) mounted on the gantry gives direct access to print settings, axis controls, and live temperature data. Users can start, pause, cancel prints, and adjust settings in real time — no separate computer needed.

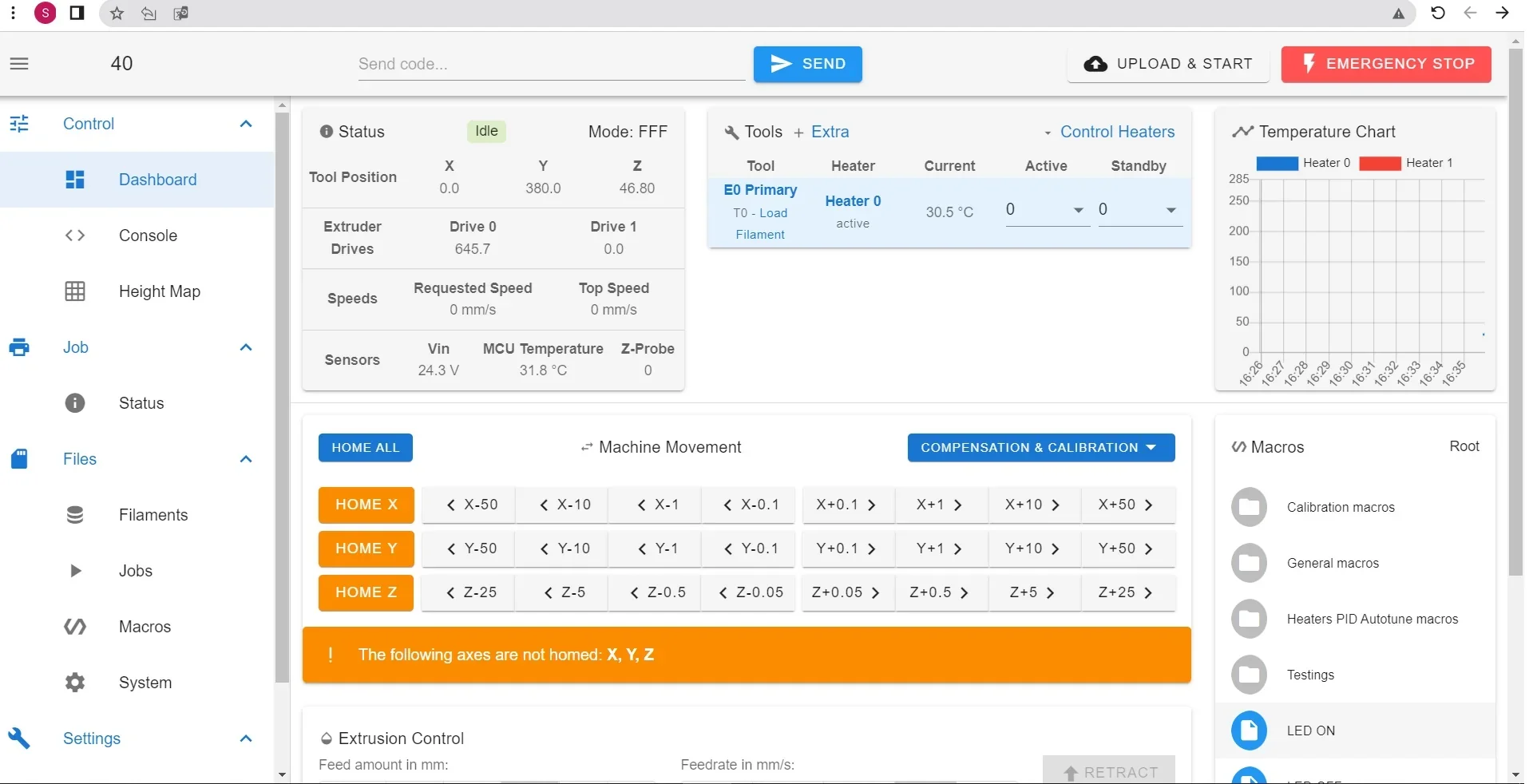

2. Duet Web Control (Wi-Fi Interface)

Powered by the Duet 2 mainboard, the BIG-180X V4 features Duet Web Control — a browser-based interface accessible via Wi-Fi or local network. It lets users upload G-code, monitor prints, queue jobs, and adjust settings remotely from any web-enabled device.

3. Local File Input (SD Card & USB)

For offline use, the BIG-180X V4 supports G-code via SD card or USB-A. Jobs can be launched from the PanelDue screen, allowing autonomous printing without network access or tying up a workstation.

4. Ethernet Connectivity (Optional)

The optional Duet Ethernet board provides a stable, wired RJ-45 connection to Duet Web Control — ideal for industrial environments prone to Wi-Fi issues. It also enables advanced features like node-red remote monitoring and syslog diagnostics.

These four control options — touchscreen, web interface, offline media, and Ethernet — give users precise, flexible control whether operating the printer locally or managing it remotely.

The Modix BIG-180X V4 offers 3 connectivity options: Wi-Fi, USB, and SD card. Its Duet3D Wi-Fi controller allows remote access via PC, tablet, or smartphone on the same network to upload files, monitor progress, and adjust settings in real time.

The system includes a high-speed microSD slot and supports a second external SD card, offering flexible file transfer without needing network access.

For regulated environments where Wi-Fi connectivity is prohibited, the Duet3D Ethernet board can be ordered and installed as an alternative networking solution.

The Modix BIG-180X V4 is fully compatible with Cura, PrusaSlicer, and Simplify3D.

Customers gain access to a secure support zone with pre-configured slicing profiles and printer settings, streamlining setup and eliminating manual configuration.

The Modix BIG-180X V4 runs on open-source Duet RepRap firmware by Duet3D, offering a flexible, customizable environment. Users can create multiple configurations and automate tasks using its powerful macro system.

The Modix BIG-180X V4 uses an industrial open-frame design with 40×40 mm T-slot aluminum profiles for rigidity and modularity. Powder-coated, laser-cut brackets ensure precise assembly and a professional finish.

Physical Specifications:

The BIG-180X includes a full enclosure with 3 mm aluminum composite panels for heat retention and noise reduction. Polycarbonate doors and a pneumatic top lid offer easy access while preserving temperature. Casters and leveling feet ensure mobility and accurate setup.

The BIG-180X V4 uses HIWIN MGW9H linear rails on all axes, offering high precision and load capacity with their stainless steel build and Gothic arch contact design.

The motion system uses Gates GT2 fiberglass-reinforced belts for reliable, low-stretch power transmission, with temperature tolerance from -30°C to +100°C.

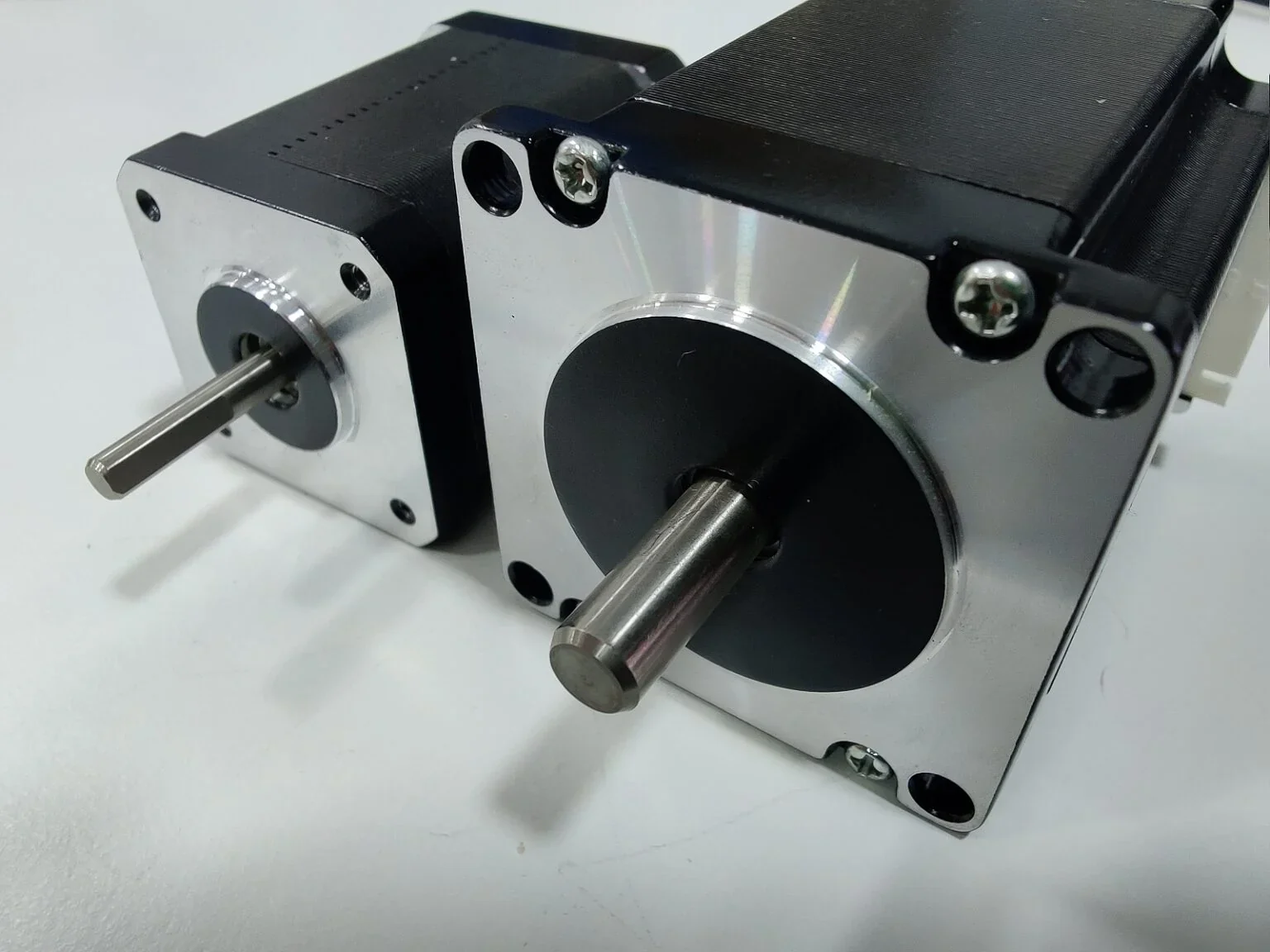

The BIG-180X V4 uses NEMA-23 stepper motors for higher torque, with four independently driven Z-axis motors enabling automatic bed tilt calibration and synchronized lifting. SFU1204 ball screws with 2:5 belt reduction ensure precise vertical positioning.

Gates GT2 belts feature nylon tooth covers for reduced noise and resistance to tooth jump. Their fiberglass cords and neoprene construction ensure long life and consistent performance under high-acceleration printing.

The BIG-180X V4 uses a 6.35 mm Alcoa Mic-6 cast aluminum build plate for excellent flatness and thermal stability across its 1800 × 600 mm surface. Three AC heaters deliver 1,370 W in a triple-zone setup for even heat distribution.

The BIG-180X V4 uses an Autonics TCN4 PID controller for ±0.5% temperature accuracy with a 100 ms sampling rate. A 300-point bed leveling system and four independent Z-axis motors ensure precise calibration and automatic tilt correction.

The BIG-180X V4 uses an Autonics TCN4 PID controller for ±0.5% temperature accuracy with a 100 ms sampling rate. A 300-point bed leveling system and four independent Z-axis motors ensure precise calibration and automatic tilt correction.

The BIG-180X V4 features the Griffin print head, Modix’s fourth-gen extruder system, combining Bondtech BMG direct drive extruders with 3:1 gearing for high-torque control. It uses Motech MT-1703HS168A stepper motors optimized for direct drive performance.

The BIG-180X V4 includes an integrated 8 kg spool shelf for industrial spools, eliminating the need for external supports. Its dual spool system supports two large spools simultaneously, ideal for IDEX printing.

The filament management system includes clog detection, runout sensing, and under-extrusion monitoring for reliable, uninterrupted printing.

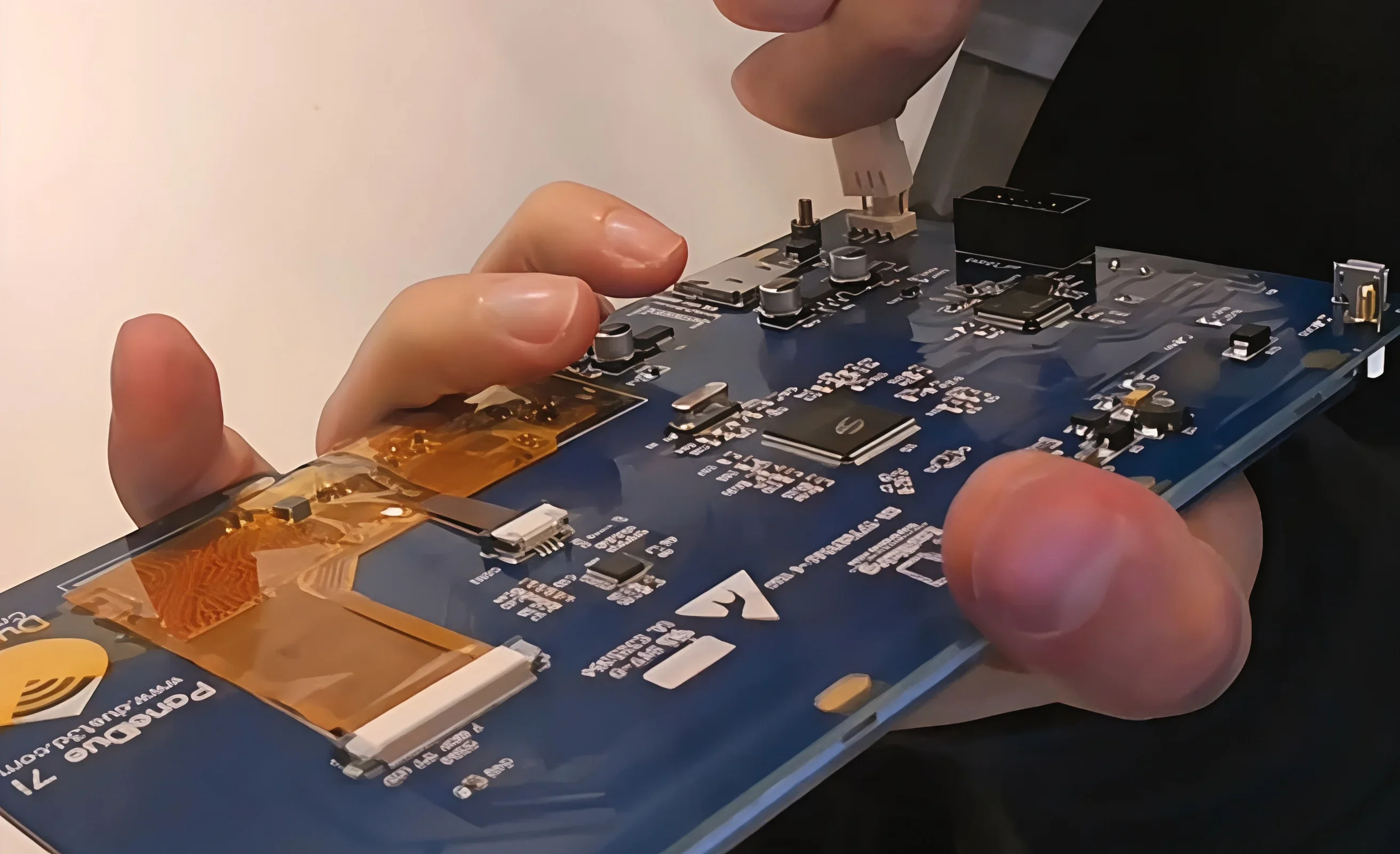

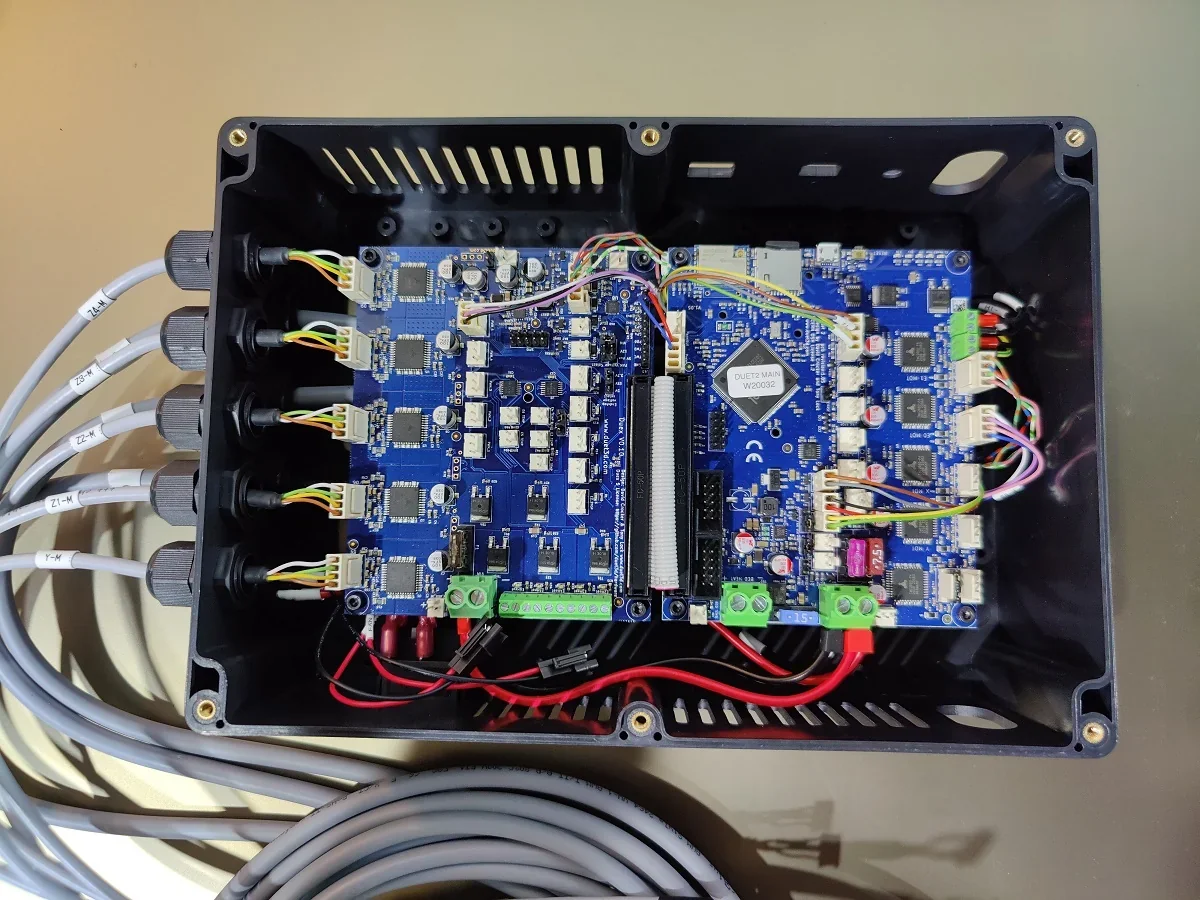

The BIG-180X V4 features a Duet3D Wi-Fi 32-bit controller with a Duex5 expansion board for advanced motion control and I/O. The dedicated Wi-Fi module with external antenna ensures stable remote access, while the Duex5 adds support for IDEX, auto calibration, and multi-zone heating with extra drivers, heater outputs, fan outputs, and thermistor inputs. Users can operate the printer remotely via a web interface or locally using the 7-inch touchscreen.

The BIG-180X V4 uses a 24V 280W Meanwell power supply with universal input (85–264VAC), built-in protections, active PFC, and Energy Efficiency Level VI compliance, consuming under 0.5W in standby. Its 1,370 W triple-zone bed heater runs on single-phase 208–240 V at 32 A, using NEMA L6-30P outlets in North America and IEC 309 32A Blue in EU/AU/UK. The system delivers fast, even heating with a silent, fanless design and features durable aviation-grade switches and connectors for industrial reliability.

The Modix BIG-180X V4 ships as a self-assembly kit with all components securely packaged, essential tools included, and full documentation in the customer support portal.

Please Note: Package contents are determined by the manufacturer and may change without notice. To confirm the current items included with this product, please contact a Top3DShop sales representative before placing your order.

The Modix BIG-180X supports over 15 upgrades.

| Accessory | Function | MSRP (USD) | Image |

|---|---|---|---|

| Printhead & Hotend Upgrades | |||

| Griffin Ultra | High-flow hotend upgrade for very high extrusion rates (up to 500 g/hr). | $1,232.00 |  |

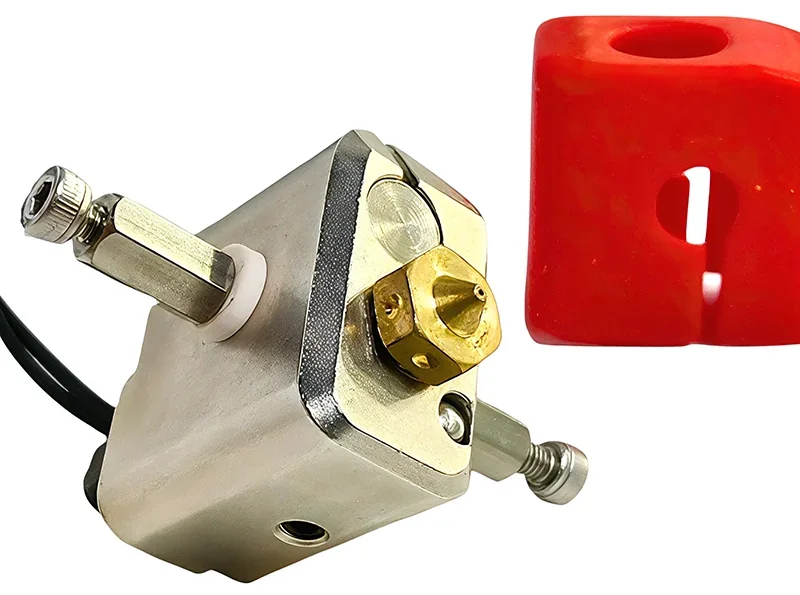

| Griffin High-Flow | High-flow hotend upgrade for faster large-object printing (includes heat-block, 80W heater, PT-1000 thermistor, and 1.0 mm nozzle). | $392.00 |  |

| Spare Griffin Hotend | Spare Griffin hotend set for replacement (includes bi-metal heatbreak, Griffin heat block, 0.4 mm nozzle, 50W heater, PT-1000 thermistor, and silicon sock). | $201.60 |  |

| Dual Print-Head & Calibration Parts | |||

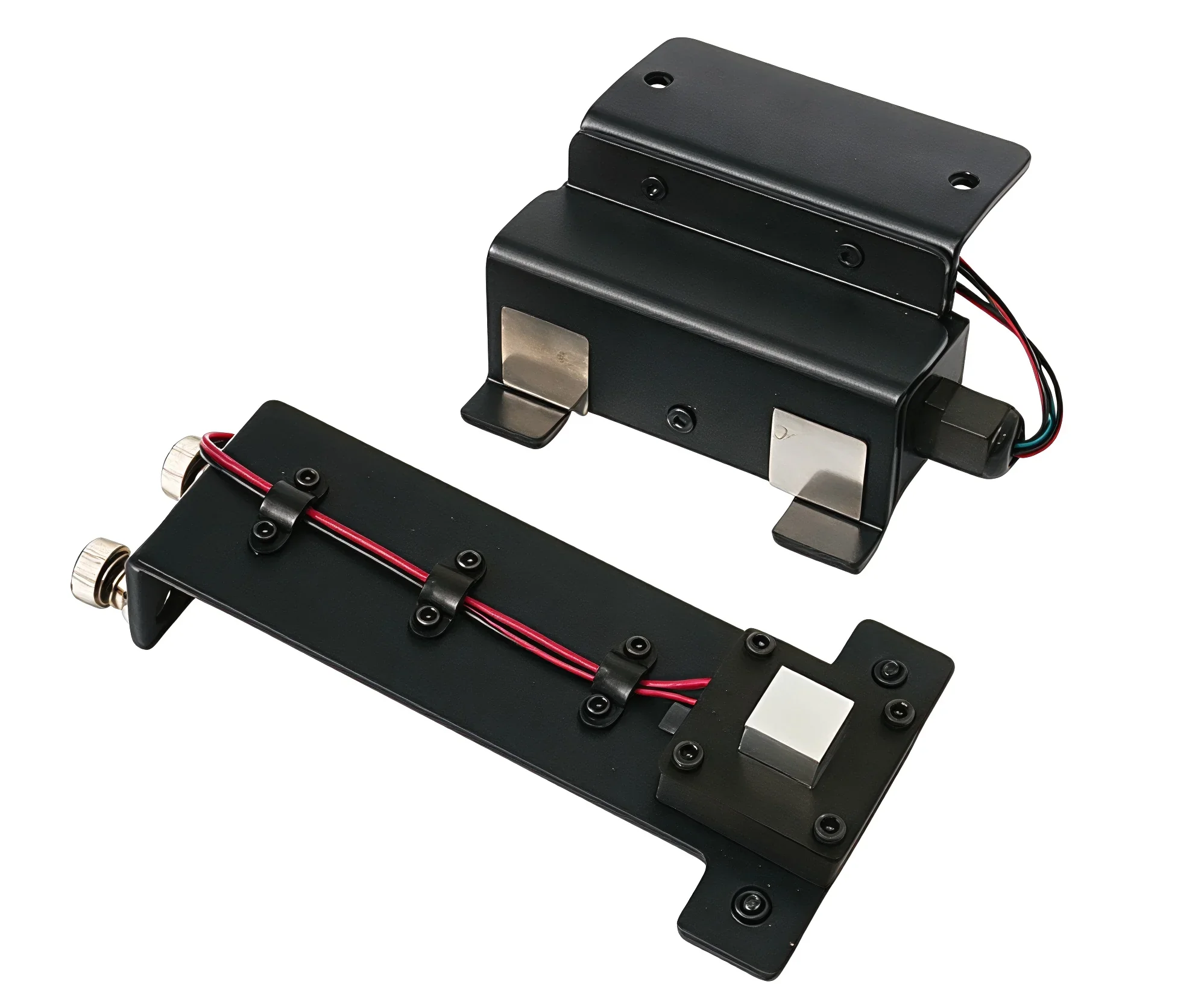

| IDEX Dual Print-head | Dual print-head upgrade for printing with dedicated support material; can also be used as an automatic filament changer. | $1,232.00 |  |

| IDEX Calibration Tool | Hands-free calibration tool to ensure optimal nozzle alignment. | $280.00 |  |

| User Interface & Safety Controls | |||

| Tilt Screen | Tilt screen upgrade with large emergency stop button and front power switch (compatible with V4 printers). | $280.00 |  |

| Support Materials & Dissolution Supplies | |||

| Soluble solution – 1000g | Dissolution solution used with water to dissolve prints made with soluble filament. | $39.20 |  |

| Soluble filament – 500g | Soluble filament for printing supports/intricate designs; dissolves using water + soluble solution (solution purchased separately). | $112.00 |  |

| Filament Drying & Storage | |||

| Filament Dryer | Large-capacity filament dryer for moisture control; fits two 5 kg spools or one 8 kg spool, with added storage. | $1,792.00 |  |

| Nozzles | |||

| Griffin Brass Nozzles | Brass nozzle pack (0.4 / 0.6 / 0.8 / 1.0 / 1.2 mm) for high-flow, fast printing; note: 0.4 / 0.6 / 0.8 mm already come with the printer by default. | $67.20 |  |

| Griffin Hardened Steel Nozzles Pack | Hardened steel nozzle pack (0.4 / 0.6 / 0.8 mm) for abrasive materials (carbon fiber-filled, glass fiber-filled, wood, glitter); rated up to 450°C. | $190.40 |  |

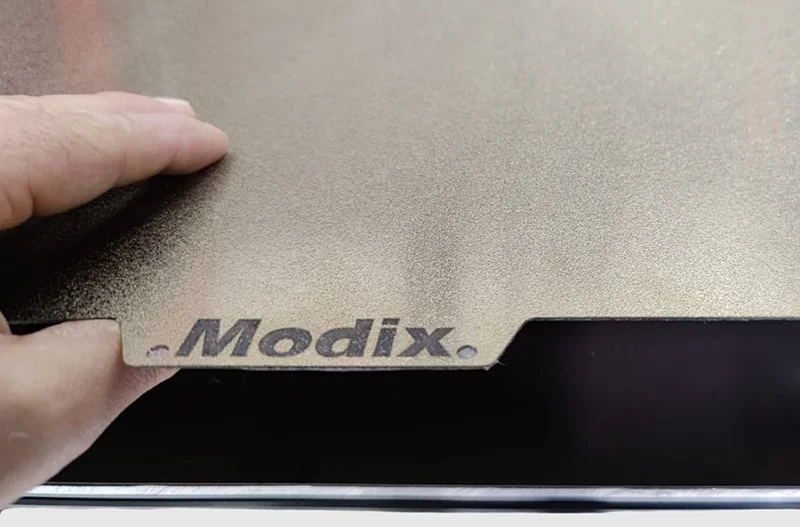

| Build Plate & Surface Parts | |||

| Magnetic Bed | Magnetic build surface system for easier part removal; dual-sided PEI surfaces (one rough PEI-coated side and one side with a PEI sheet for a glossy bottom surface). BIG-180X requires 3 pieces to cover (cart shows 3× $600 each). | $2,016.00 |  |

| Extra PEI Sheet | Spare PEI sheet (660 × 660 mm). BIG-180X requires 3 sheets to cover. Not required if you purchase the Magnetic Bed. | $168.00 |  |

| Air Filtration Parts | |||

| Active Air Filter | Three-stage air filtration device: pre-filter (dust), HEPA (sub-micron particles), and active carbon filter (fumes). | $1,512.00 |  |

| Filter Spares Set | Replacement filter set (5× pre-filter, 1× HEPA/carbon combo). | $336.00 |  |

| Maintenance & Spare Parts Kits | |||

| Basic Maintenance Kit | Essential spare components for the print head and motion system to keep the printer running smoothly. | $336.00 |  |

| Advanced Maintenance Kit | Expanded spare parts kit (belts, pulleys, screws, bearings, motors, printhead parts, fasteners) designed to fit Modix printers V4. | $1,568.00 |  |

The Modix Big-180X V4 requires 10+ maintenance procedures to maintain consistent dimensional accuracy and surface quality.

Daily maintenance

Weekly maintenance

Monthly maintenance

Quarterly maintenance

Due to its large scale, the printer requires ongoing calibration of the motion system, bed leveling, and temperature controls to maintain consistent print quality across the large build volume.

The Modix BIG-180X V4 includes a 12 month warranty covering non-consumable parts, excluding items like the PEI sheet and nozzles. Optional extensions of up to two years cover manufacturer defects, including electronics, offering added protection for production use.

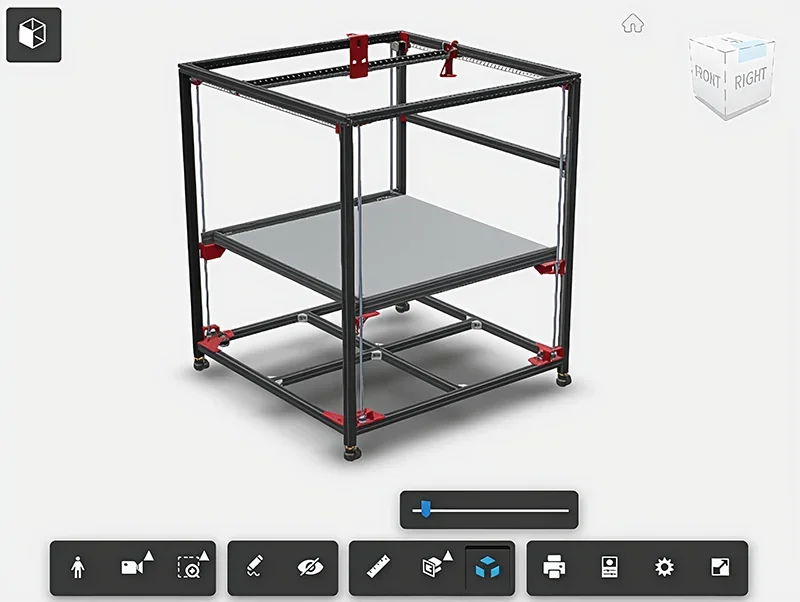

Modix offers lifetime technical support via email Sunday–Thursday, 09:00–18:00 GMT+3, with video sessions available on request. Customers also get access to a dedicated support zone with manuals, print profiles, firmware, and interactive 3D assembly guides.

The Modix BIG-180X V4 includes video-guided assembly instructions with interactive 3D models for visual clarity. For those who prefer not to self-assemble, professional assembly by Top3DShop is available as a paid service.

Full warranty terms: https://www.modix3d.com/terms

| Service Package | Description | Price (USD) |

|---|---|---|

| 3-Hour Call with Modix 3D Technicians | Remote optimization support for design, slicing settings, and material selection; includes 3 hours of video calls with Modix technicians. | 500 |

| 1-Year Warranty Extension | Extends Modix manufacturer warranty by 12 months beyond the standard warranty period. | 1000 |

| 2-Year Warranty Extension | Extends Modix manufacturer warranty by 24 months beyond the standard warranty period. | 2000 |

| Assembly Services by Top3DShop (Off-Site) | Off-site assembly of the Modix kit per official manual + calibration (bed compensation ≤2 mm corner-to-corner), IDEX XY calibration (if applicable), test prints (cube/mesh), photo/weekly progress reporting, and delivery of assembled unit (per agreement terms). | 14,000 |

| Assembly Services by Top3DShop (On-Site) | On-site assembly and commissioning at customer facility; includes the same assembly/calibration/test-print scope plus on-site handover/training and verification as described in the agreement. | 19,000 |

The Modix BIG-180X V4 is priced at $19,040.00, offering strong value for a large-format industrial 3D printer.

Update your browser to view this website correctly. Update my browser now