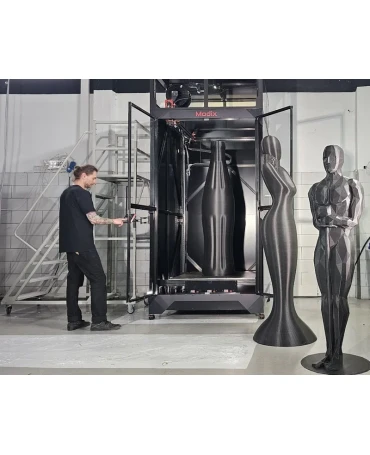

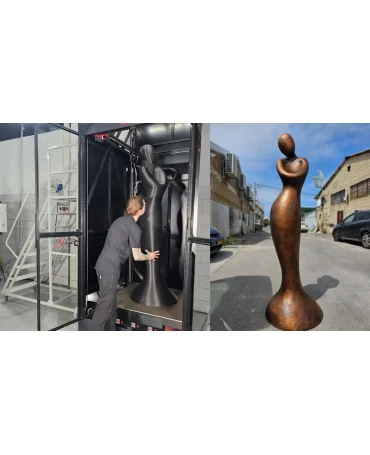

The Modix Everest 3D printer enables single-print objects up to two meters tall, eliminating the need for assembly. Its Griffin Ultra hotend prints over 500 grams per hour with thick layers, reducing post-processing and producing stronger, seamless results. The Everest is based on the Modix BIG-Meter platform, featuring a reinforced frame with 4080 mm profiles — twice the size of its predecessor. This Modix 3D printer comes equipped with an enclosure, Griffin and Griffin Ultra print heads, internal spool mount, casters, tilt screen, Z HiWin rails, and clog/crush detectors. The Griffin Ultra hotend's 1.6 mm nozzle prints 1.2 mm layers, cutting print time significantly. The Everest supports a wide range of materials — PLA, PETG, ABS, ASA, PVA, PC, Nylon, TPU, carbon fiber composites, and more — making it suitable for automotive, aerospace, and commercial design applications. Optional add-ons like the IDEX dual print head and magnetic bed enhance functionality, while its core strength remains large, seamless, extreme-height printing.

The Modix Everest offers high print quality and performance with its Griffin Ultra hotend, capable of 1.2 mm layer height at 250 mm/s.

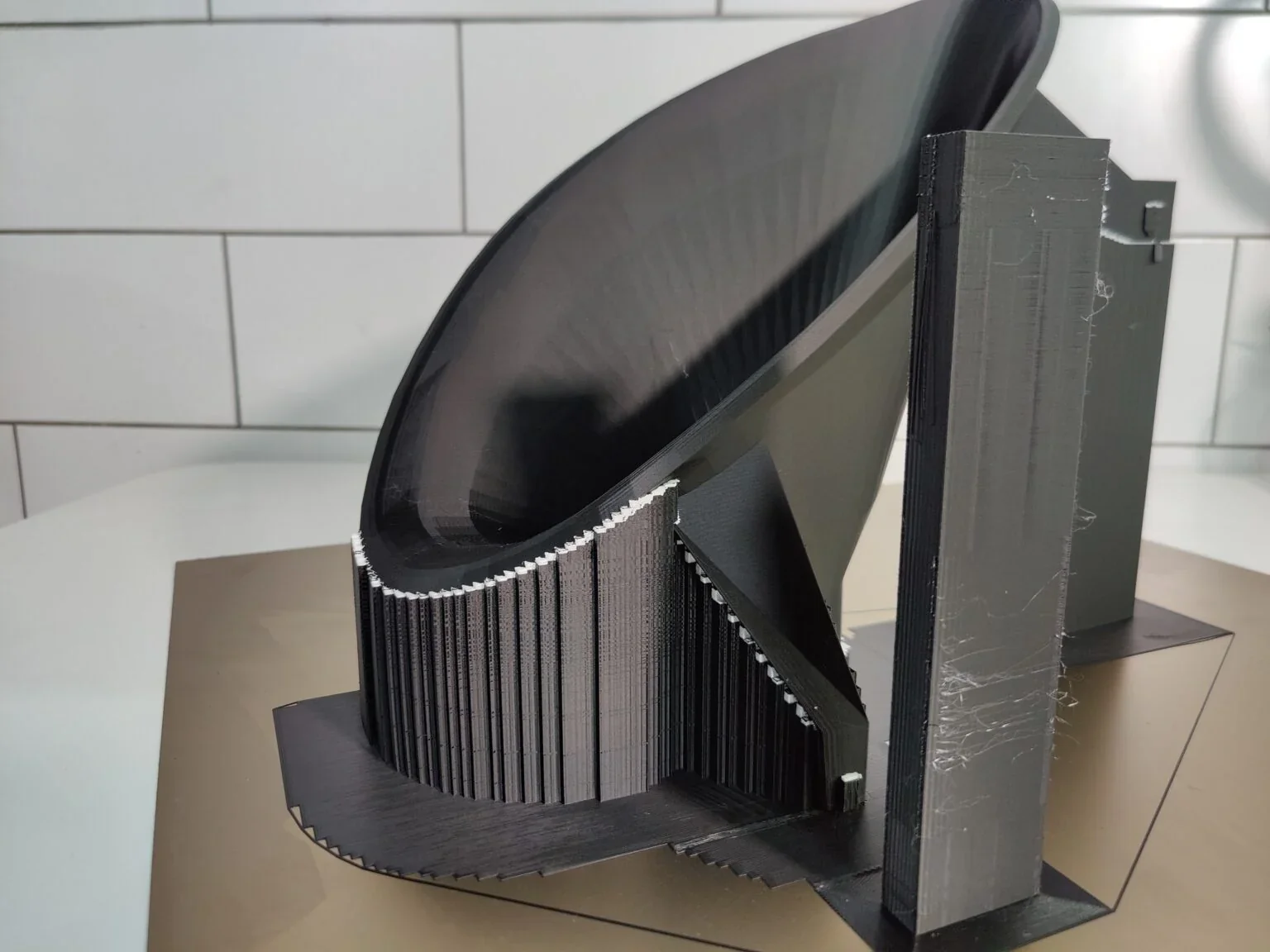

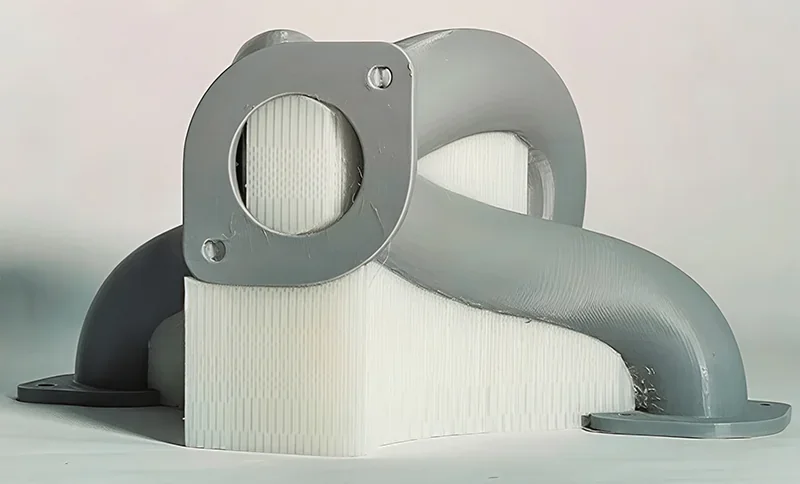

With an extrusion rate over 500 g/h, the Everest significantly cuts production time while maintaining surface quality. Real-world prints include:

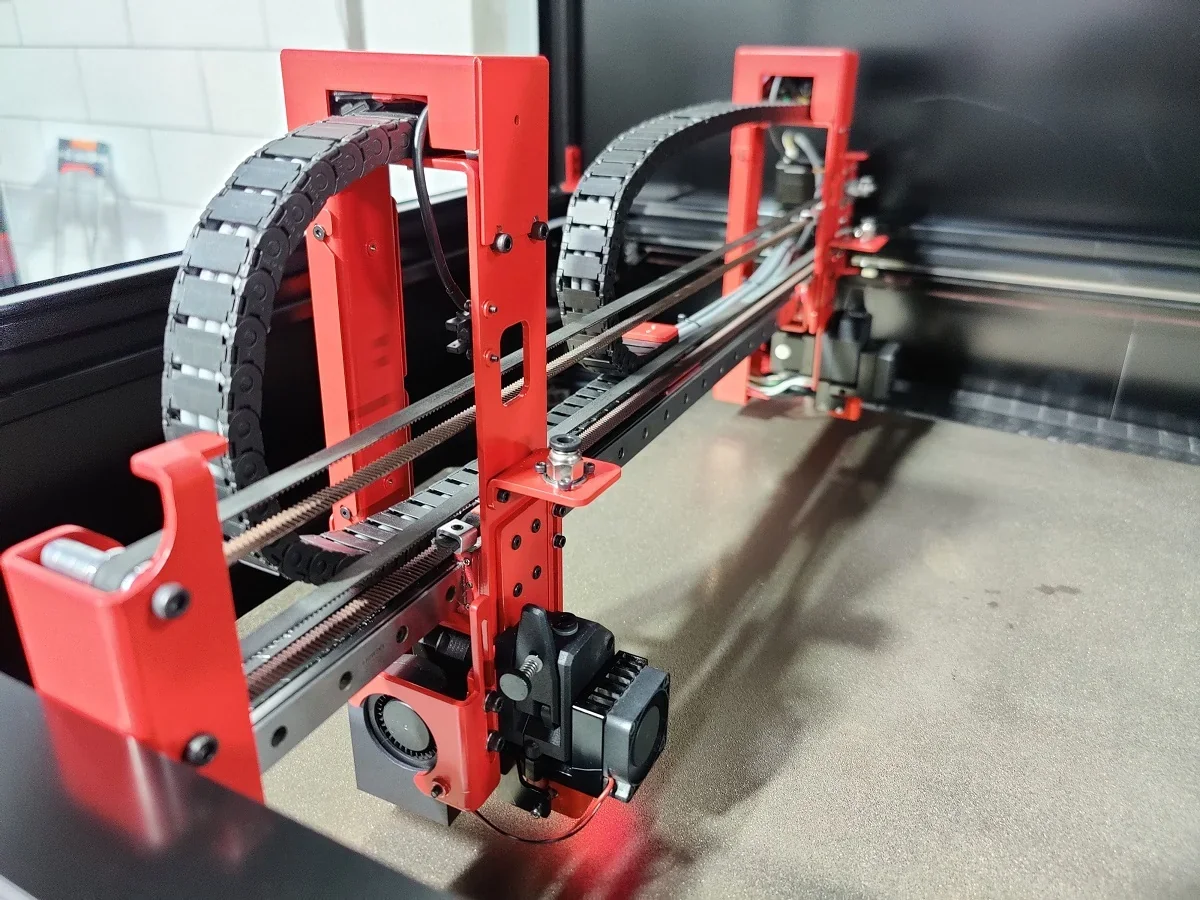

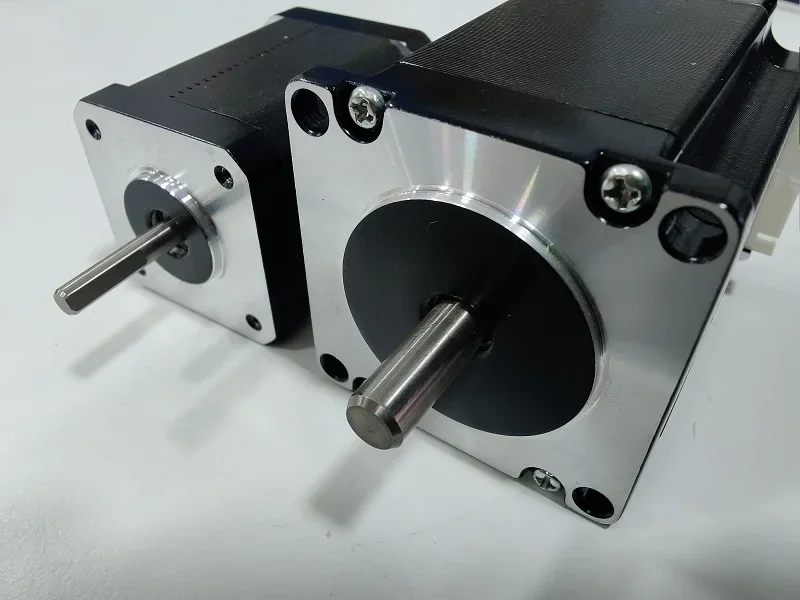

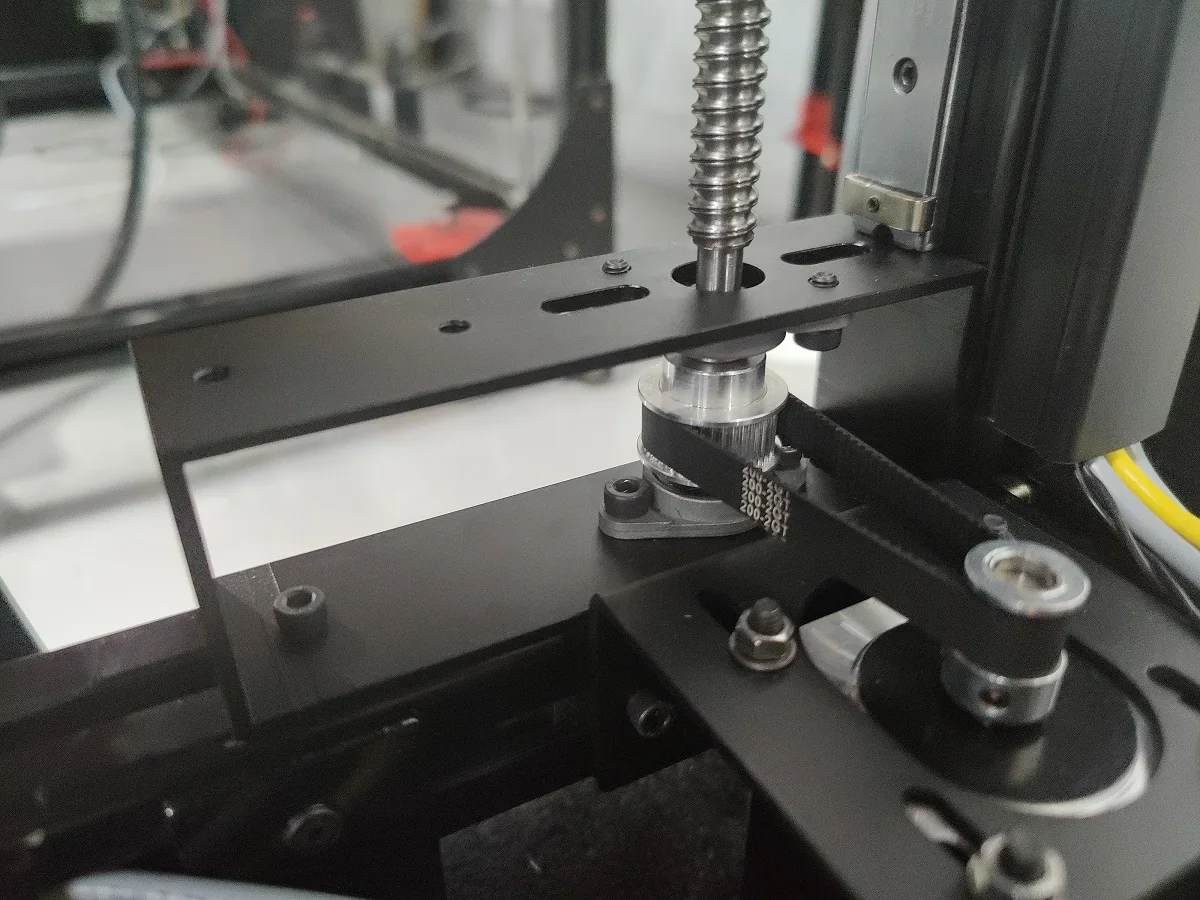

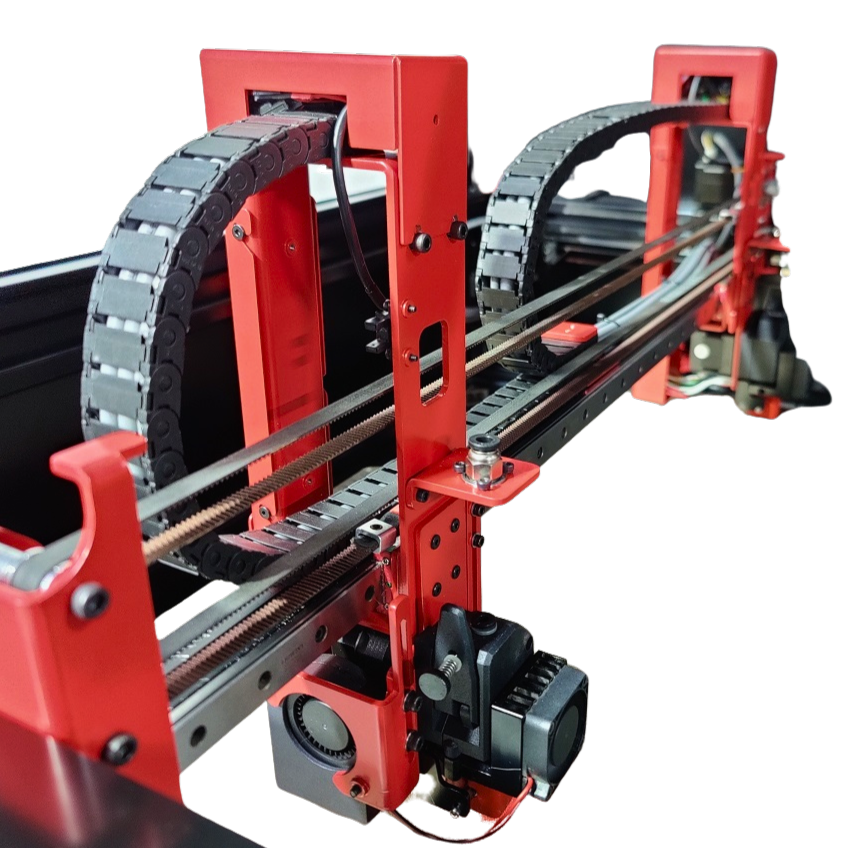

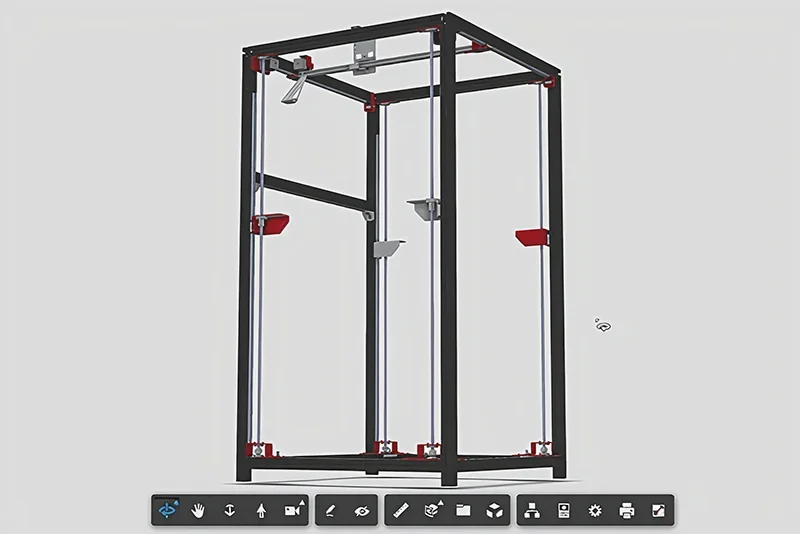

The Everest’s reinforced 4080 mm frame and HIWIN rails ensure stability during tall prints. The bed moves down smoothly on Z-profile rails, keeping the frame steady. Its motion system, with NEMA-23 motors on X and Z axes, delivers 10-micron accuracy on X/Y and 0.5 microns on Z.

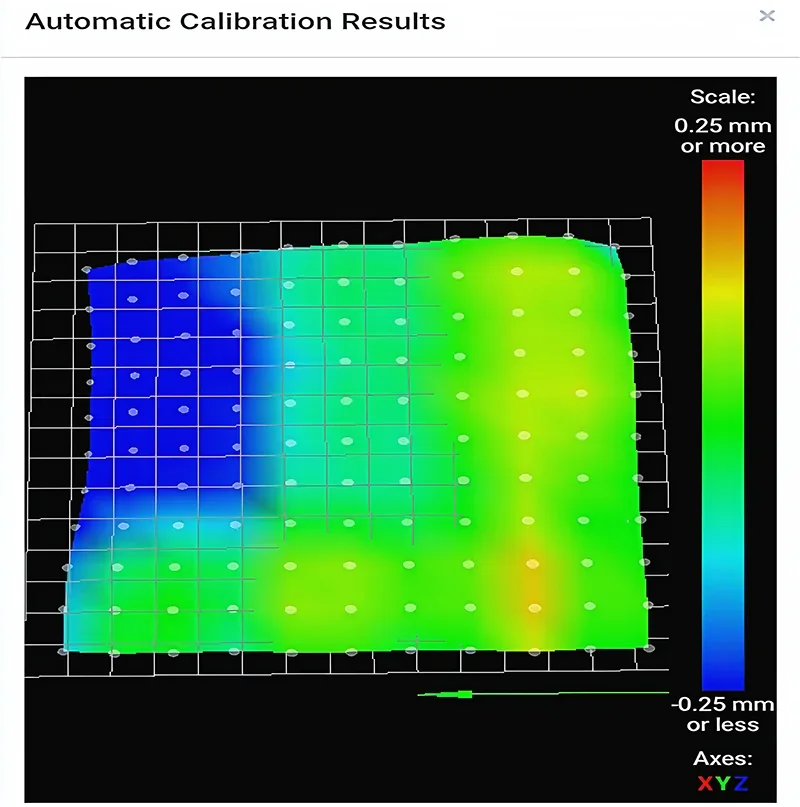

The Everest features automatic calibration with 100 probing points and bed tilt adjustment, ensuring consistent first-layer adhesion across the build area.

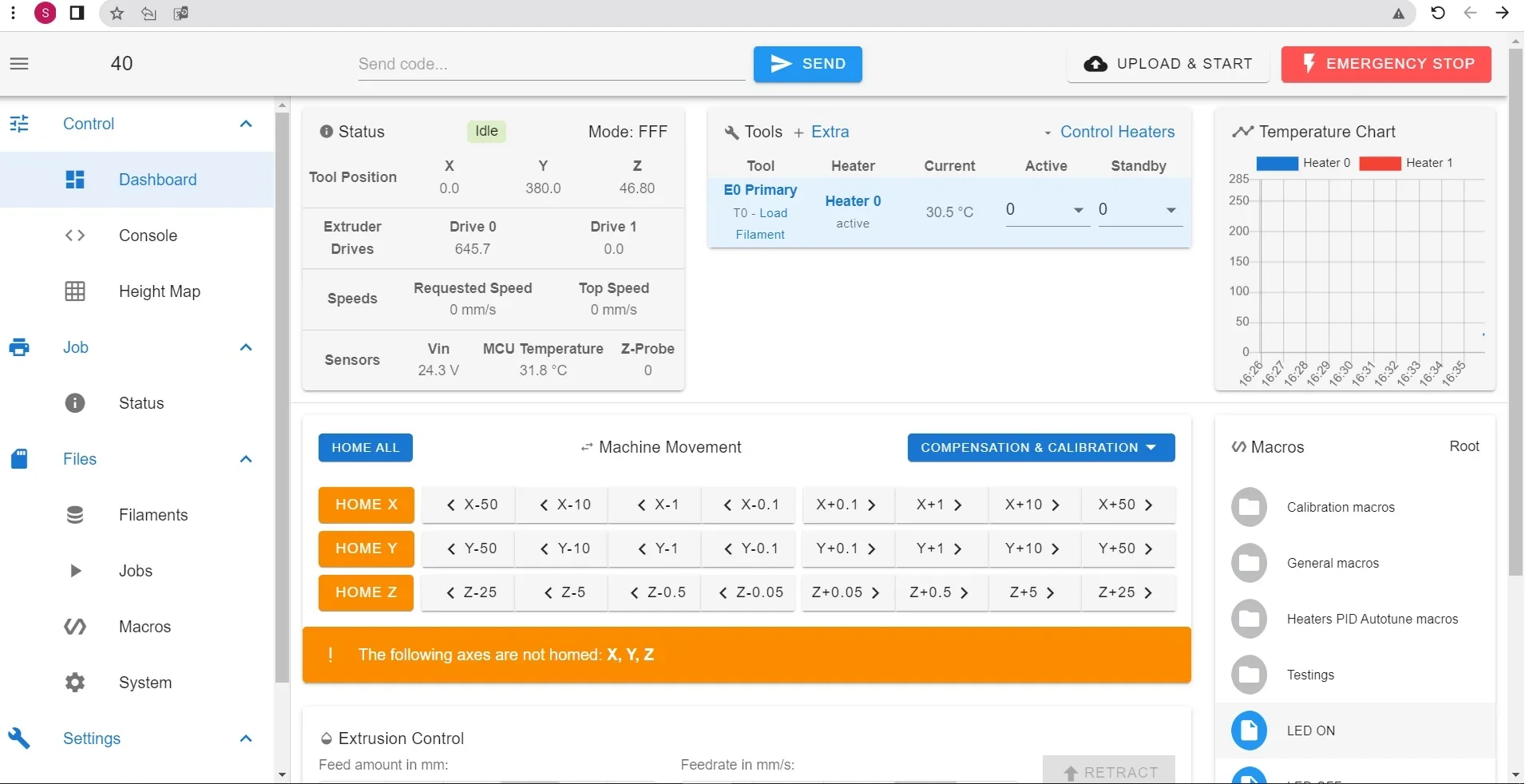

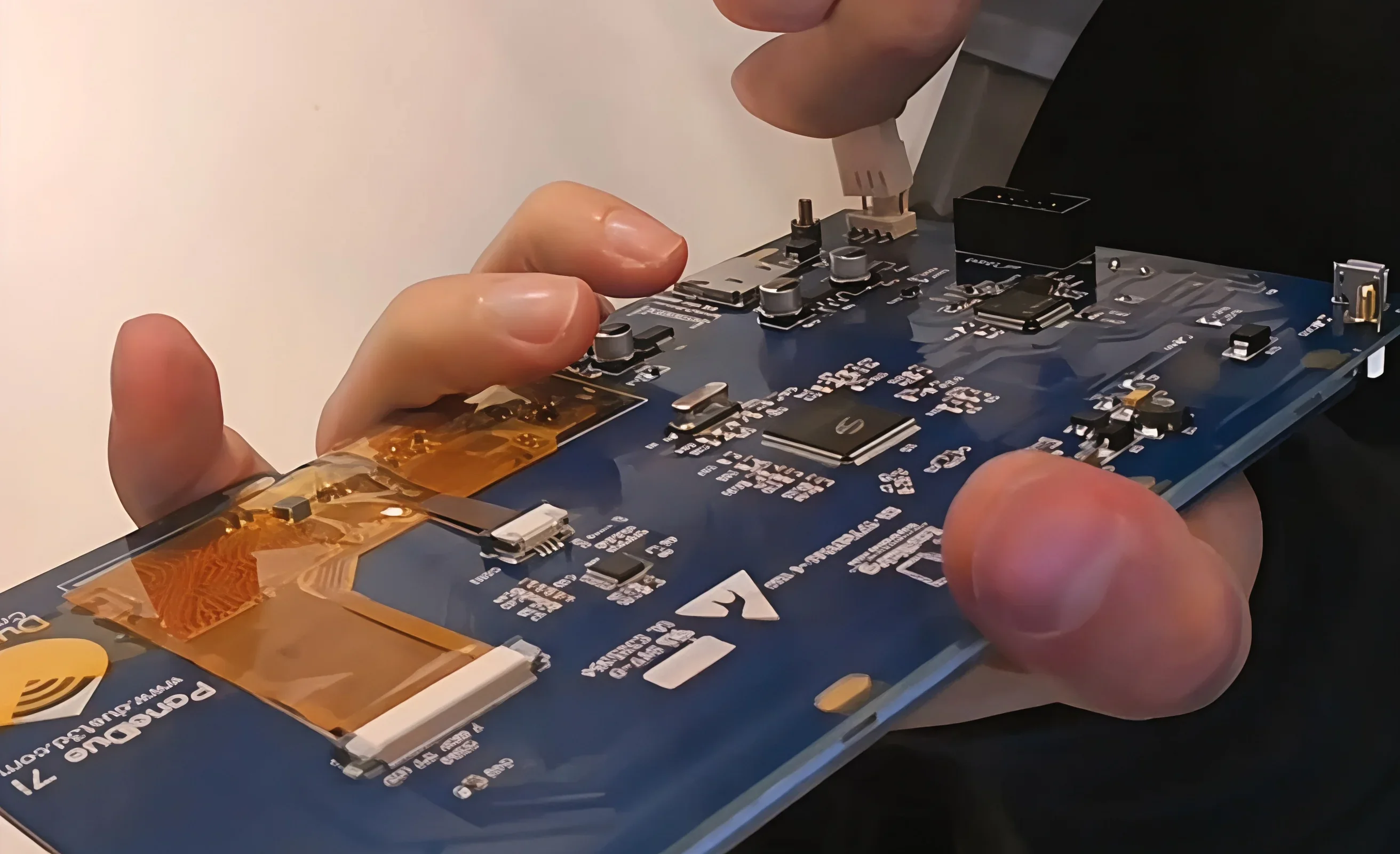

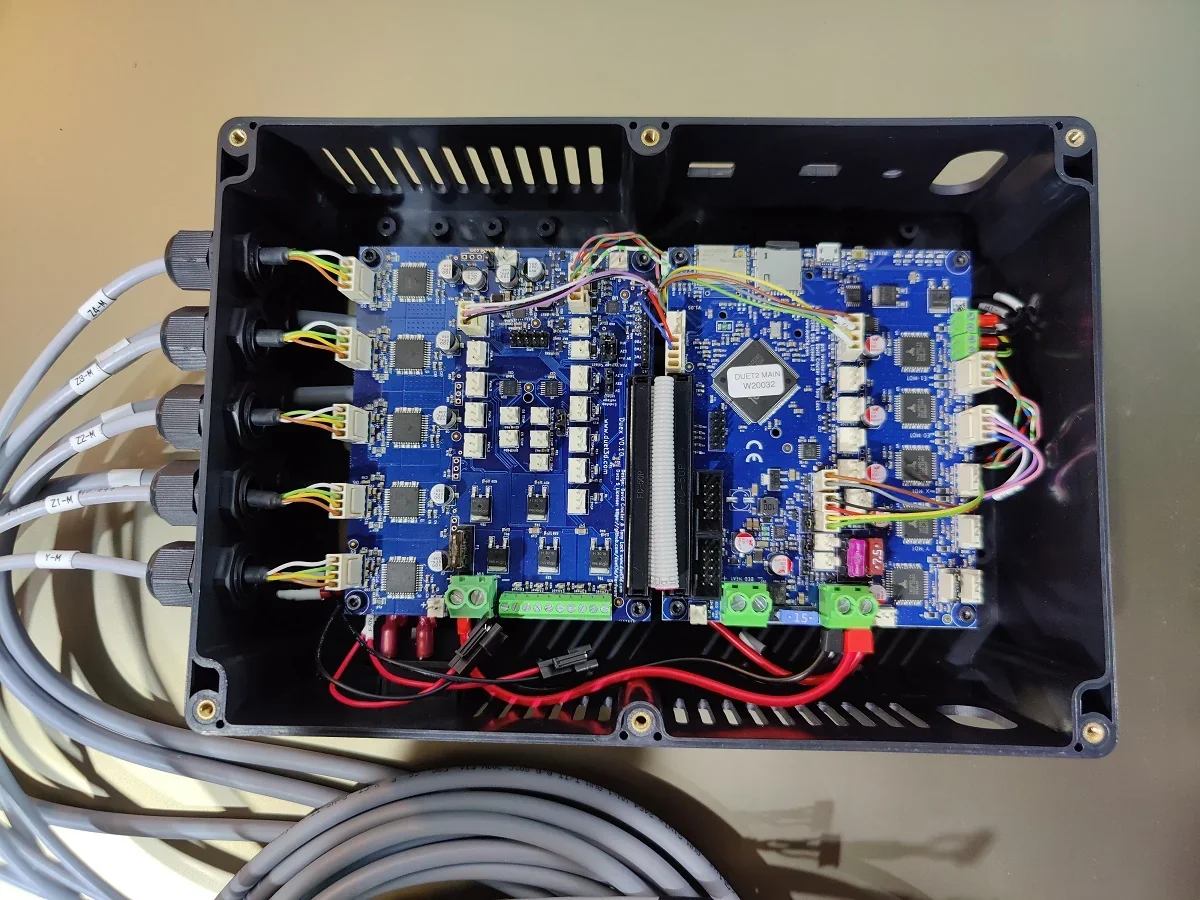

The Duet3D Wi-Fi controller with Duex5 expansion provides dedicated drivers for each Z and X motor, enabling automated calibration routines — bed tilt, leveling, gantry alignment, and Z offset — for precise printing, even at extreme heights.

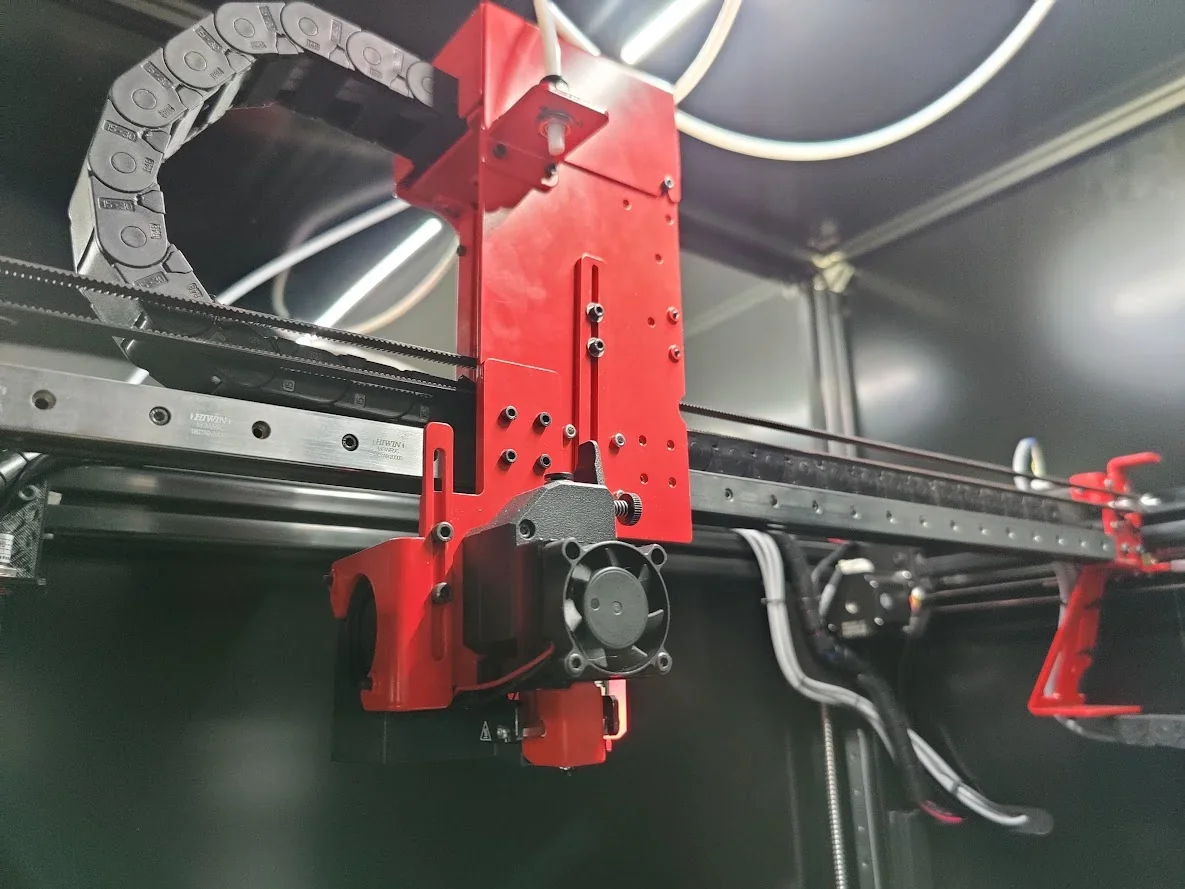

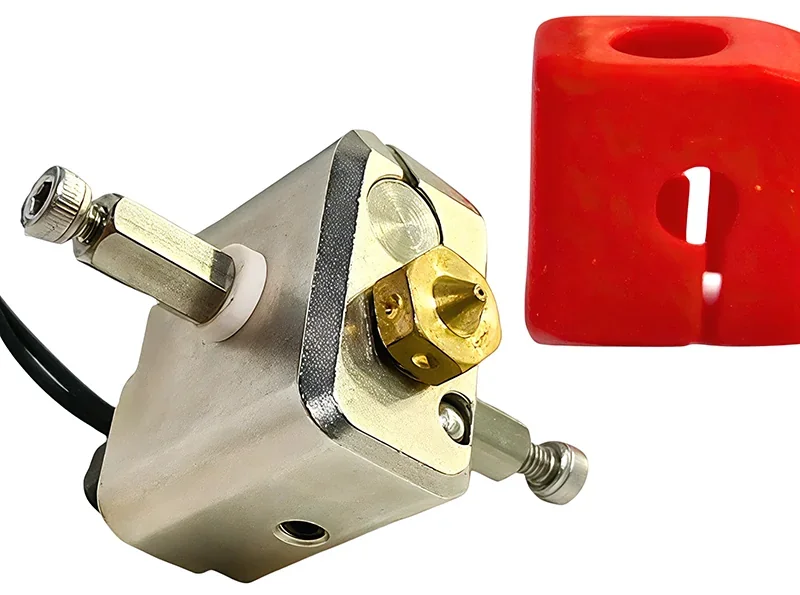

The standard Everest setup includes both Griffin and Griffin Ultra print heads, plus clog and crush detectors to monitor filament run-out, under-extrusion, and clogs — preventing failures and ensuring consistent quality during long prints.

The Modix Everest supports 15+ filament types, offering versatility for large-format printing. Its Griffin Ultra hotend reaches 500°C, handling standard materials like PLA, PETG, PVA, ABS, and high-performance filaments such as ASA, PC, and Nylon, as well as flexible TPU/TPE for elastomeric applications.

3D Print Samples:

For specialized use, this Modix FDM professional 3D printer handles composite filaments like carbon, glass, and wood-filled materials. The optional Nozzle-X pack includes hardened, nickel-plated, non-stick nozzles that resist wear and maintain consistent extrusion with abrasive filaments. The Everest uses an open material system, allowing filaments from any manufacturer to suit specific project needs.

The optional IDEX dual print head allows use of soluble support materials for complex geometries. Paired with Modix soluble filament, this independent dual extruder setup enables intricate models with internal features, reducing post-processing while preserving model integrity.

Printing with breakaway support filament

Printing with soluble support filament (PVA)

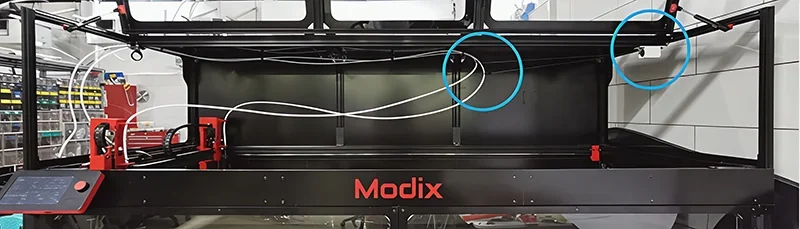

The Modix Everest offers a massive build volume of 970 x 1030 x 2000 mm (1998.2 liters), making it one of the tallest large-format 3D printing machines available. It can print objects up to two meters tall in one piece, eliminating the need for sectioning or assembly.

The Everest’s large build volume enables life-size prints in a single run avoiding assembly of smaller parts. The printer's enclosed chamber maintains stable internal ambient temperature, and HIWIN Z-rails ensure bed stability during downward movement.

The Modix Everest model stands out with three key advantages: a Griffin Ultra print head delivering 5× faster print speed than competitors, a Duet3D 32-bit controller with 100-point auto bed leveling, and a reinforced 4080 mm frame that maximizes usable build volume.

Compared to rivals:

With true 2-meter capacity, high-speed extrusion, and precise motion control, the Everest justifies its higher price by delivering superior large-format print performance.

| Specification | Modix Everest | Tronxy VEHO 1000-20 | Dowell DM-2000 Plus | Builder Extreme 2000 PRO |

|---|---|---|---|---|

| Build Volume (mm) | 970 x 1,030 x 2,000 | 1000 x 1000 x 2000 | 1000 x 1000 x 1600 (up to 2000 mm custom) |

700 x 700 x 1700 |

| Price (USD) | $40,000+ | $8,000+ | $8,450–$12,000+ | $40,000+ |

| Max. Nozzle Temp (°C) | 350–420 | 320 | 420 | 260 |

| Max. Bed Temp (°C) | 110 | 110 | 100–150 | 70 |

| Enclosed | Yes | Optional | Optional | Yes |

| Weight (kg) | 236 | 240 | ~200 | ~350 |

| Assembly | Self-assembly kit or assembled by Top3DShop | Self-assembly kit | Self-assembly kit | Factory assembled |

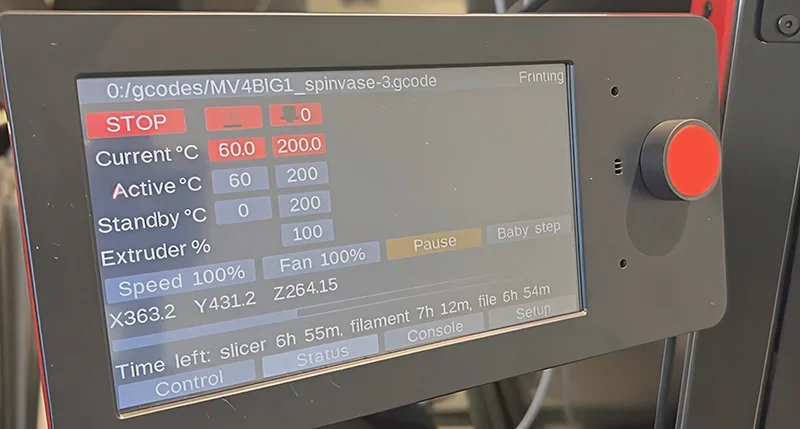

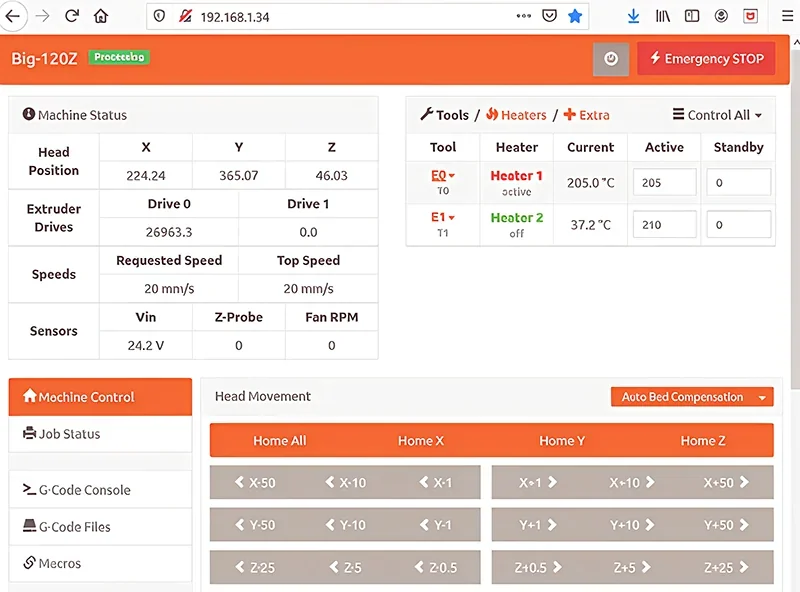

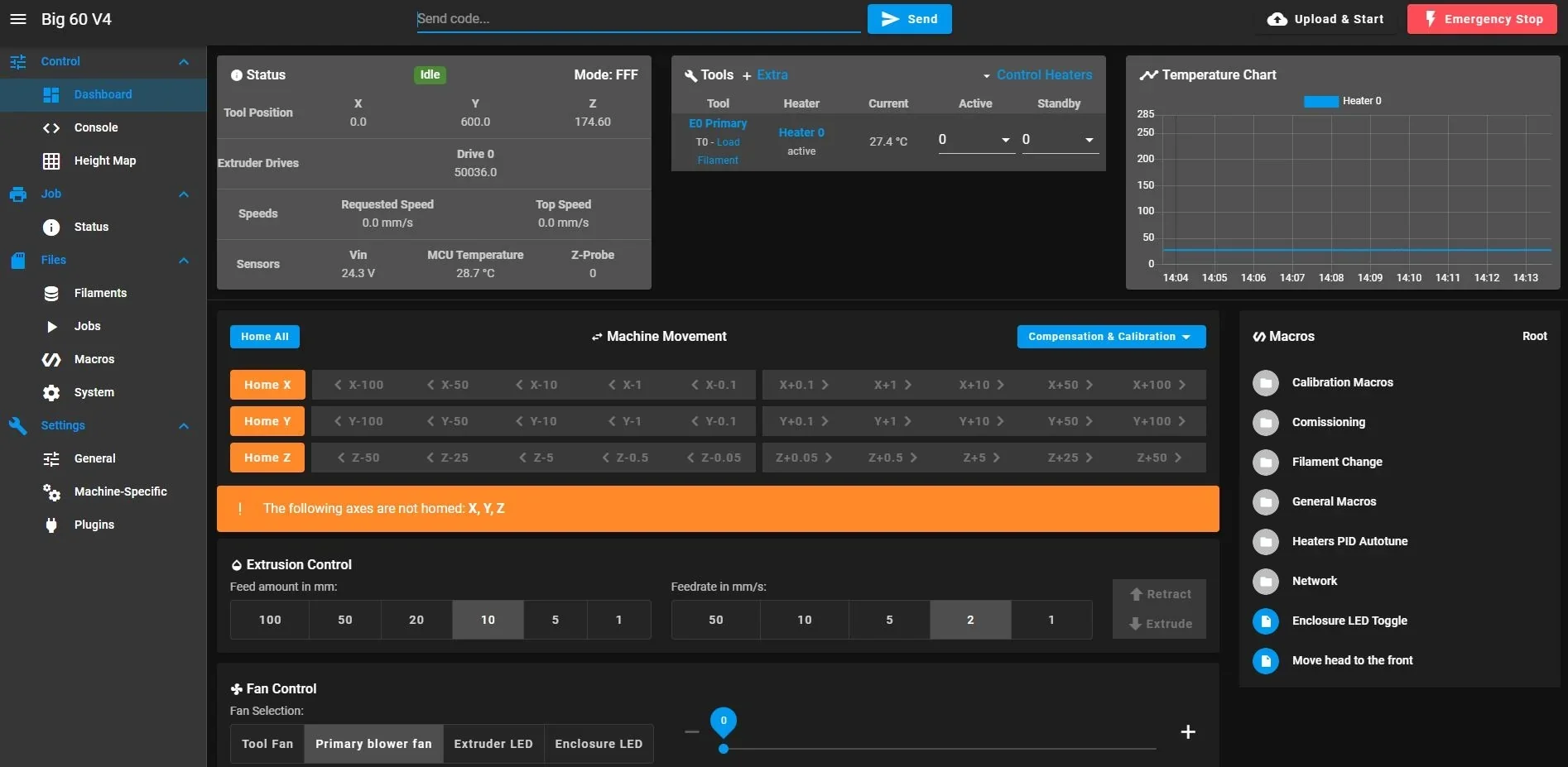

The Modix Everest provides 3 distinct printer control methods: Duet3D web interface, SD card transfer, and USB file transfer.

1. Duet3D Web Interface (Wi-Fi)

The Everest's Duet3D Wi-Fi 32-bit controller with Duex5 expansion enables remote operation via web browser. Users can upload G-code, monitor prints, run calibrations, and update the system from any networked device. The interface also supports macros and 100-point bed leveling.

2. SD Card File Transfer

The Everest supports standalone printing via direct SD card use. Users can run G-code, macros, and calibration routines without network connectivity.

3. USB File Transfer and Direct Connection

The Everest supports USB file transfers and direct connection to a host computer, enabling real-time control via slicing software or command-line tools for users needing wired access.

The Duet3D controller with Duex5 automates filament sensors, bed leveling, and thermal management, ensuring consistent performance across all control methods.

The Modix Everest offers 3 connection methods — USB, SD card, and Wi-Fi connectivity — via its Duet3D controller and Duex5 expansion. USB and SD slots support direct file transfers from external storage.

The integrated Wi-Fi module allows remote monitoring and control via web interface from any PC or mobile device on the same network. Wi-Fi is especially useful for the Everest’s height, removing the need to access the control panel. Users can upload files, monitor progress, and make adjustments remotely.

The Modix Everest supports Cura, Simplify3D, PrusaSlicer, and OrcaSlicer, and includes dedicated print profiles for each to ensure optimal performance.

The Everest runs on RepRapFirmware, offering flexible, configurable control. It powers automatic bed tilt calibration and 100-point leveling. Files can be sent via the Duet Web Control interface from any networked device. The system supports multiple 3D model formats, avoiding reliance on proprietary software.

The Modix Everest stands at 53.4 x 56.9 x 120.8 inches (1356 x 1445 x 3068 mm) and weighs 520.3 lbs (236 kg). Its reinforced frame uses 4080 mm T-slot aluminum profiles for the structural rigidity needed to support its 2-meter print height.

The Modix Everest includes a full enclosure with elastic seals, reinforced hinges, and a pneumatic top cover to maintain internal temperature. An internal holder for filament spools enhances safety but requires ladder access for filament changes and high-point maintenance.

The Modix Everest uses a precision motion system with upgraded NEMA-23 stepper motors and dedicated drivers for each Z and X axis via the Duex5 expansion board.

The motion system uses HIWIN rails on the Z-axis for bed stability, along with Gates timing belts for smooth, precise movement.

The Modix Everest reaches travel speeds of 350 mm/s and print speeds up to 250 mm/s, using optical end-stop switches for improved accuracy and repeatability over mechanical ones.

The Modix Everest uses NEMA-23 motors and Gates belts, producing typical noise levels for large-format FDM kits. It lacks active soundproofing; the enclosure offers only basic noise containment.

The Modix Everest features a heated build platform measuring 970 x 1030 x 2000 mm (1,994 liters), mounted on HIWIN linear rails along the Z-axis for stable vertical movement.

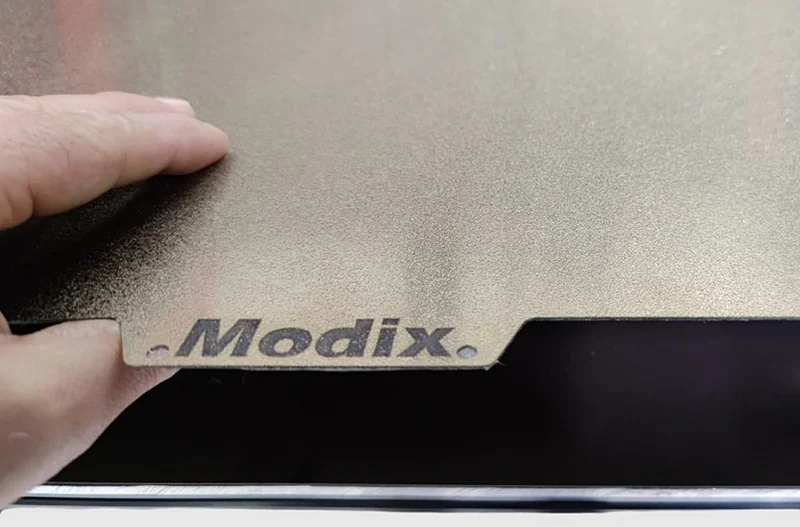

The Modix Everest supports optional magnetic flex beds for easy part removal, avoiding the need to reach into the back of the 2-meter chamber during extraction or maintenance.

The Modix Everest’s Griffin Ultra hotend processes over 500 g/hour using custom Bondtech extruders and E3D Super Volcano hotends. It includes 0.4, 0.6, and 0.8 mm Volcano brass nozzles, with 1.0 and 1.2 mm options available.

The Modix Everest stores filament inside the enclosed chamber, with internal spool holders for improved safety and temperature stability.

The system includes filament sensors that detect run-out, under-extrusion, and clogs for automated monitoring.

The Modix Everest's fourth-generation design improves PTFE tube and wire management, offering smoother maintenance access and better filament routing than previous versions.

The Modix Everest uses a Duet3D Wi-Fi 32-bit controller with a Duex5 expansion, providing dedicated drivers for each axis. It supports automated calibration routines — bed tilt, leveling, gantry alignment, and Z-offset — as well as Wi-Fi, USB, and SD card connectivity for remote or standalone operation.

The Modix Everest uses a dual-voltage power system (110V/230V). Motion electronics run on a 24V 280W Meanwell PSU with built-in protections and <0.5W no-load draw. The heated bed uses a separate 1370W (or 1200W at 110V) AC heater, managed by an Autonic PID controller and requiring a dedicated 15A AC line. Aviation-grade switches and connectors ensure reliability, with an optional Power Distribution Unit (PDU) for consolidating AC cables and improving safety.

The Modix Everest ships with:

• All parts required to assemble the Modix Everest 3D printer

• Powder-coated aluminum components

• Aluminum print bed with PEI surface

• Hex and screwdriver sets

• Cable and wire sets

• Power cords

• Power supply

• Power Distribution Unit (PDU)

• Enclosure components

• Casters (4x)

• 7-inch tilting LCD touchscreen

• Modix Griffin standard printhead

• Griffin Ultra high-flow printhead

• Internal spool mounting hardware

• SD card with software and documentation

The Modix Everest ships as a self-assembly kit, making it easy to transport through narrow spaces and install in rooms with standard ceilings despite its 3-meter assembled height. The kit includes detailed instructions via a customer portal, along with print profiles, firmware, and technical docs. A 12-month warranty and lifetime support are included.

Please Note: Package contents are determined by the manufacturer and may change without notice. To confirm the current items included with this product, please contact a Top3DShop sales representative before placing your order.

The Modix large 3D printers support 10+ upgrades.

| Accessory | Function | Target User | Price (USD) |

|---|---|---|---|

| IDEX Dual Printhead | Independent dual extrusion for multi-material/color printing and support structures | Professional users requiring complex geometries or dissolvable supports | $1,100 |

| IDEX Calibration Tool | Precision calibration and alignment tool for dual extruder setup | IDEX system users needing accurate dual nozzle positioning | $250 |

| Removable Magnetic Bed | Quick part removal and easy bed surface replacement | High-volume production users and frequent material switchers | $1,700 |

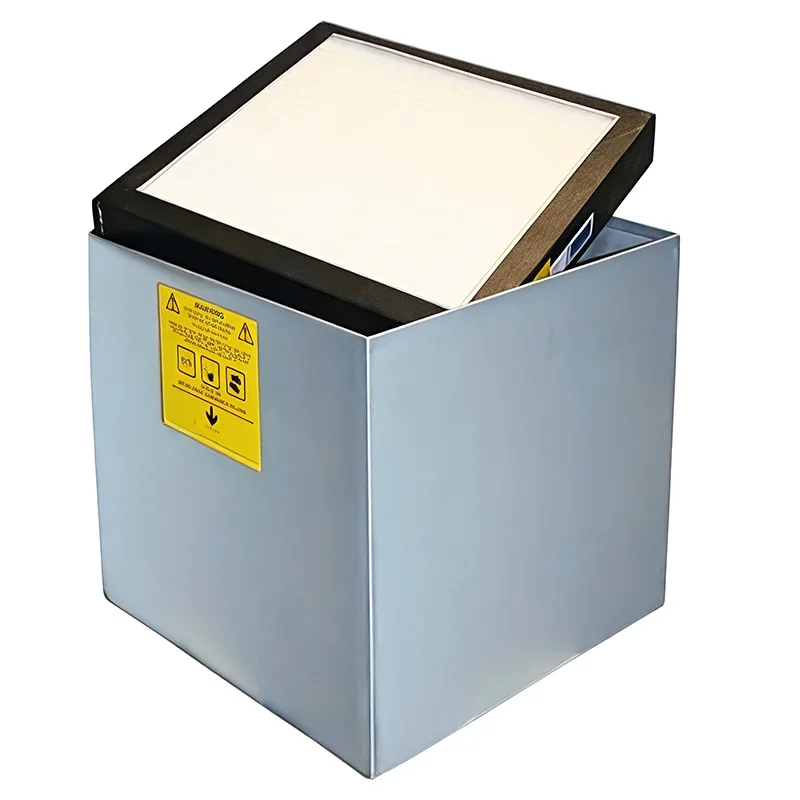

| Active Air Filter | HEPA filtration system for toxic fume removal during printing | Industrial users printing ABS, ASA, or engineering materials | $1,350 |

| Filter Spares Set | Replacement HEPA and carbon filters for air filtration system | Active air filter owners requiring periodic maintenance | $300 |

| Griffin High-Flow Hotend | Ultra-high throughput print head for rapid large part production | Production users prioritizing speed over fine detail | $350 |

| Spare Griffin Hotend | Backup hotend assembly for minimal downtime during maintenance | Production facilities requiring continuous operation | $180 |

| Volcano Brass Nozzles | Large orifice nozzles for high-flow printing with standard materials | Users printing large, less detailed parts with PLA/PETG | $60 |

| Nozzle-X Pack | Hardened steel nozzles for abrasive materials (carbon fiber, glass fill) | Engineering users printing composite and filled materials | $170 |

| Basic Maintenance Kit | Essential consumables: nozzles, thermistors, heating cartridges | General users performing routine maintenance | $300 |

| Advanced Maintenance Kit | Complete spare parts set including motors, belts, electronics | Professional users managing multiple machines or critical applications | $1,400 |

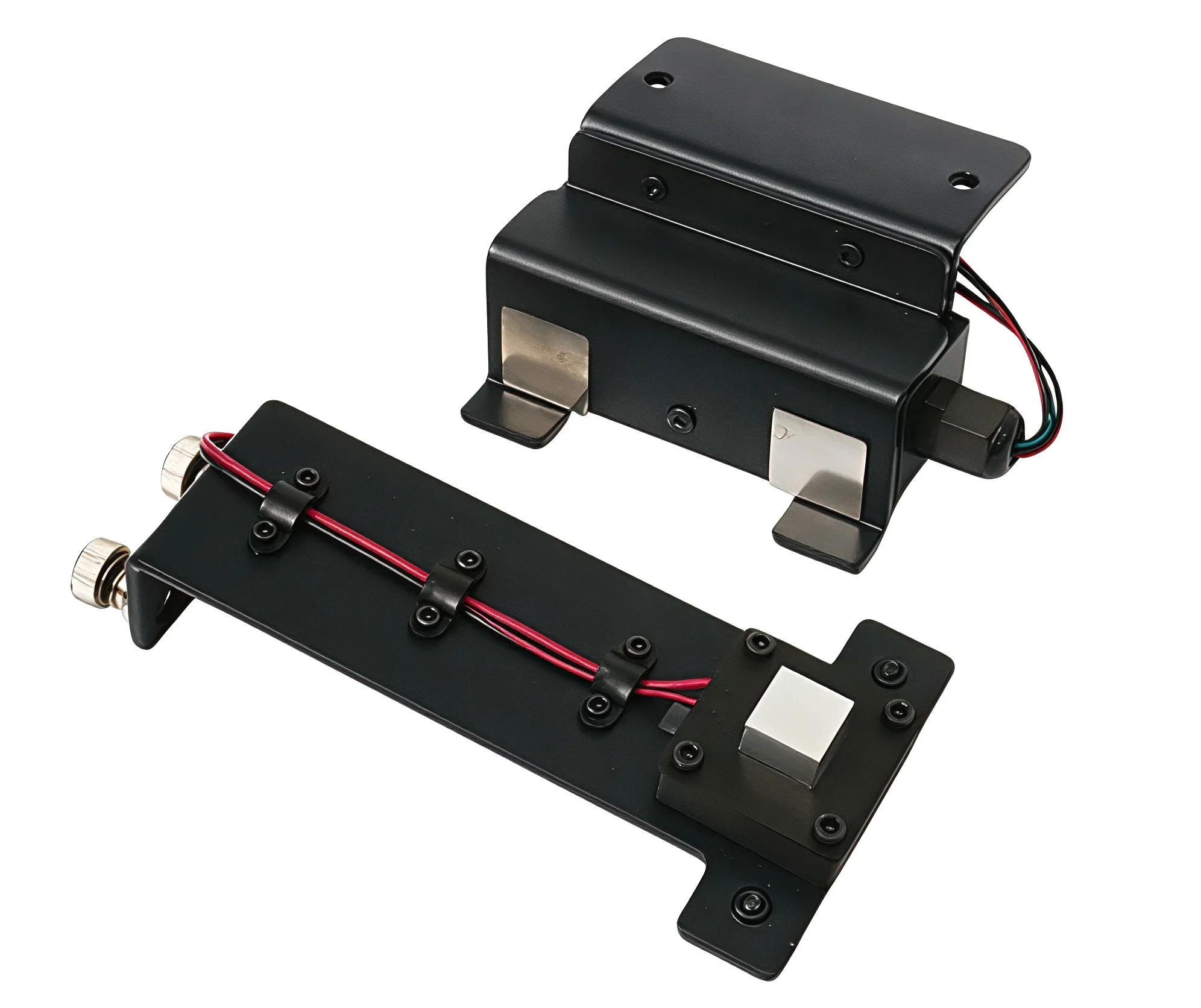

The IDEX system for Modix V4 printers uses two independent X-axis print heads, enabling multi-material or color printing without cross-contamination. It supports water-soluble supports like PVA or HIPS, eliminates purge tower waste, and offers mirror and duplicate modes to boost productivity.

The IDEX Calibration Tool for Modix printers ensures precise alignment between the two extruders, providing X, Y, and Z reference points to prevent layer misalignment and ensure proper dual-material adhesion.

The magnetic build surface uses a coated flexible steel sheet held by neodymium magnets. Parts are easily removed by flexing the sheet, reducing surface damage and allowing quick material changeovers without scraping tools.

The HEPA-grade Active Air Filter captures ultrafine particles and VOCs from high-temp printing. Its multi-stage system — pre-filters, HEPA, and activated carbon — removes particles down to 0.3 microns and neutralizes emissions from ABS, ASA, PC, and PETG.

The Filter Spares Set includes replacement HEPA elements, carbon layers, and pre-filters to maintain air quality. Regular replacement based on print hours and material use ensures consistent filtration performance in enclosed environments.

The Griffin High-Flow hotend melts filament at over 500 g/hour with an enlarged melt zone and enhanced heaters. It supports 1.2–1.8 mm nozzles and prints thick layers up to 1.2 mm for fast, large-scale printing.

The Spare Griffin Hotend includes a heating block, thermistor, cartridge, and thermal barrier tube for quick replacement. It minimizes downtime during maintenance, supporting continuous production.

Volcano Brass Nozzles are large-format nozzles with extended heating zones for high-flow printing of standard thermoplastics. Available in 0.6–1.4 mm sizes, they maintain consistent temperature during high-volume extrusion with PLA, PETG, and TPU.

The Nozzle-X Pack includes hardened steel nozzles built for abrasive filaments like carbon fiber, glass fiber, and metal-filled materials. Their wear-resistant design maintains accuracy and surface quality, unlike standard brass nozzles.

The Basic Maintenance Kit includes essential consumables like brass nozzles, thermistors, heating cartridges, and PTFE tubing. It provides replacements for routine wear items to support continuous operation with standard thermoplastics.

The Advanced Maintenance Kit includes spare stepper motors, belts, bearings, electronics, and tools for full system upkeep. It supports on-site repairs, reducing service calls and ensuring uptime in production environments.

The Modix Everest requires 15+ scheduled maintenance tasks to maintain motion stability, accurate 2-meter calibration, and reliable extrusion.

Daily maintenance

Weekly maintenance

Monthly maintenance

Quarterly maintenance

Semi-annual maintenance

The Everest’s 2-meter height requires frequent automated calibration and motion checks to maintain consistent print quality over long runs.

The Modix Everest includes 12 months of warranty covering all non-consumable parts, excluding items like PEI sheets and nozzles. Modix offers lifetime technical support for Everest owners, available via email Sunday–Thursday, 09:00–18:00 GMT+2, with video sessions on request. Buyers gain access to a customer portal with interactive 3D manuals, print profiles, firmware, and essential technical documentation.

Full warranty terms: https://www.modix3d.com/terms

The Modix Everest is a premium large-format 3D printer priced at $30,240.00, offering a 970 x 1,030 x 2,000 mm build volume for printing objects up to 2 meters tall. It features the high-throughput Griffin Ultra print head (>500 g/h), a Duet3D Wi-Fi controller with Duex5, 100-point auto bed leveling, and a reinforced 4080 mm aluminum frame.

Update your browser to view this website correctly. Update my browser now