For limited US stock, please contact our sales team at sales@top3dshop.com or +1 (888) 871-17-51.

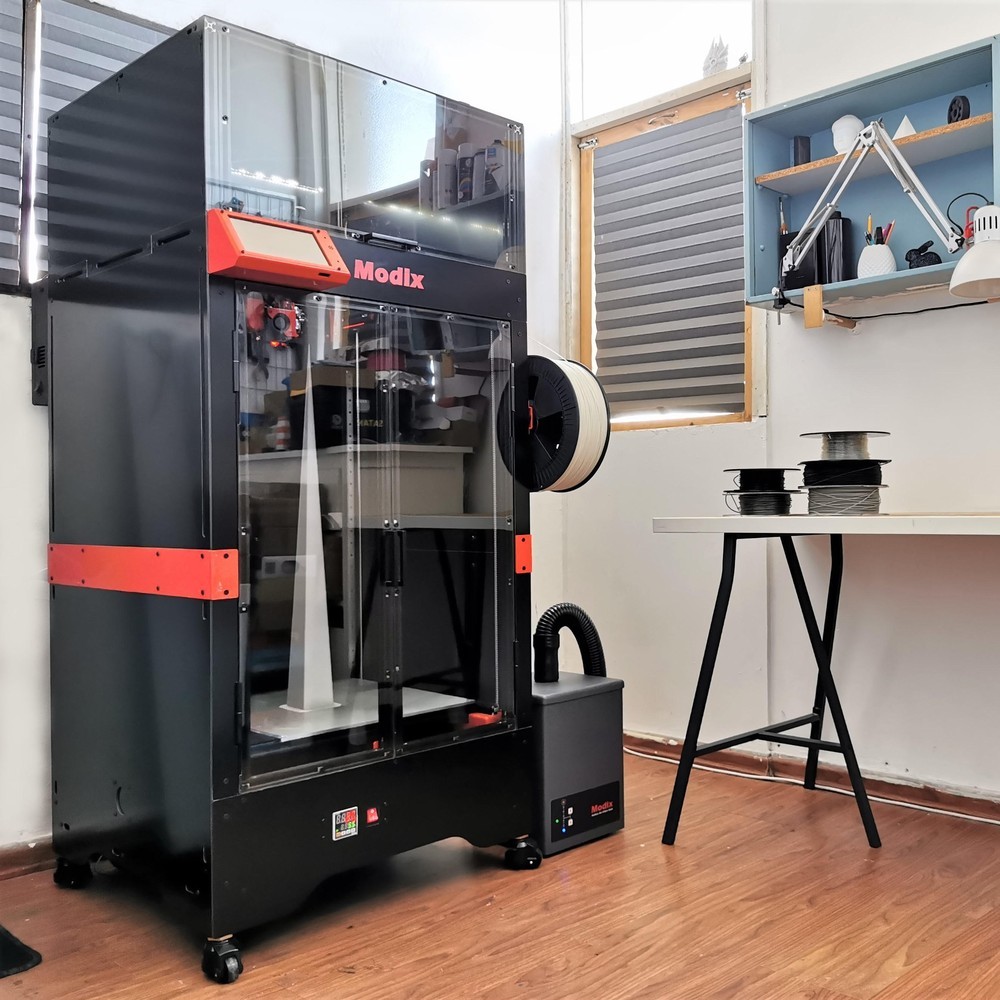

Modix BIG-40 is a professional industrial-grade self-assembly FDM 3D printer kit produced by Modix — an Israeli-based company renowned for the production of high-quality large-format machines. The BIG-40 is one of the latest additions to the company’s lineup and is the most compact and budget-friendly one. Aside from an outstanding build volume of 400 x 400 x 800 mm, the printer offers a handful of other useful features. For instance, it has an automatic bed leveling system, filament run-out sensor, and can be equipped with a secondary print head.

The Modix BIG-40 is designed to provide the utmost degree of reliability and precision. It is equipped with a robust frame made of T-slot aluminum profiles, employing powder-coated aluminum-based brackets and joints. Its axes feature Hiwin MGW motion rails that ensure swift and unparalleled movement smoothness. In addition, the Z-axis motion system features four ball screws for improved stability. Moreover, the printer employs high-grade low-noise Trinamic TMC2660 stepper motor drivers. The device’s heated bed is represented by a cast aluminum plate made of MIC-6 Aluminum Mold Alloy with dual heating zones. The BIG-40 is powered by an easily-configurable RepRap Firmware. The machine can also be upgraded with an active air filter, high-temperature sensor, or the E3D Super Vulcano hotend.

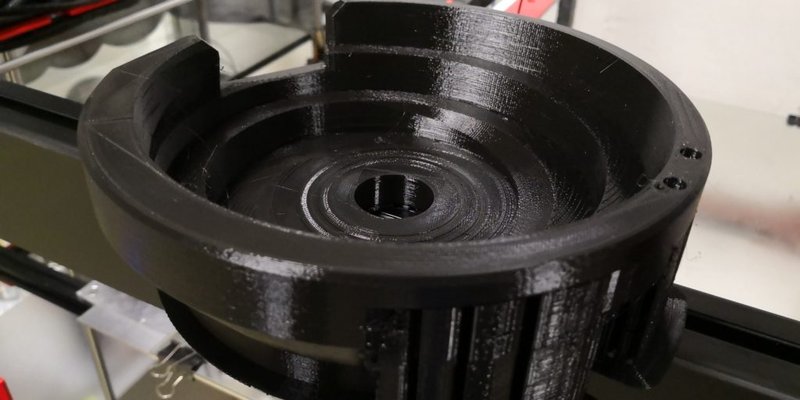

The BIG-40 is made for industrial applications and is expected to be used by experienced makers. It is perfect for prototyping and batch production of tall and narrow parts, such as prosthetic legs.

The Modix BIG-40 is an FDM 3D printer that can print layers at a minimum layer height of 40 μm. This way, you can produce parts with smooth exterior surfaces.

The Modix BIG-40 comes stock with a 0.4 mm nozzle, giving you the best balance between speed and detail. The printer is compatible with nozzles of different sizes, allowing you to choose the best option for a particular application. It can also be equipped with an additional nozzle for multi-material printing.

The print head runs on Hiwin MGW9W motion rails, which makes printing reliable, fast and precise. The motion rails, along with the upgraded stepper motor drivers, make for very quiet operation and higher accuracy.

The Modix BIG-40 offers a variety of filament types to choose from. It is compatible with PLA, ABS, composites such as Carbon fiber, Wood, Copper, Brass, Magnetic, PHA, PVA, Hips, Nylon, TPE & TPU (flexible) Co-Polyester, and PETG.

Each of the BIG-40’s extruders is equipped with a fan, allowing printing with PLA-type materials. Additional cooling also reduces warping, stringing, and other issues associated with FDM printing.

Modix BIG-40 offers an extra-tall build volume of 400 x 400 x 800 mm (16 x 16 x 32 in.) that lets you print just about anything. Such a build area lets you produce tall and narrow parts in one piece, just like these prosthetic leg covers.

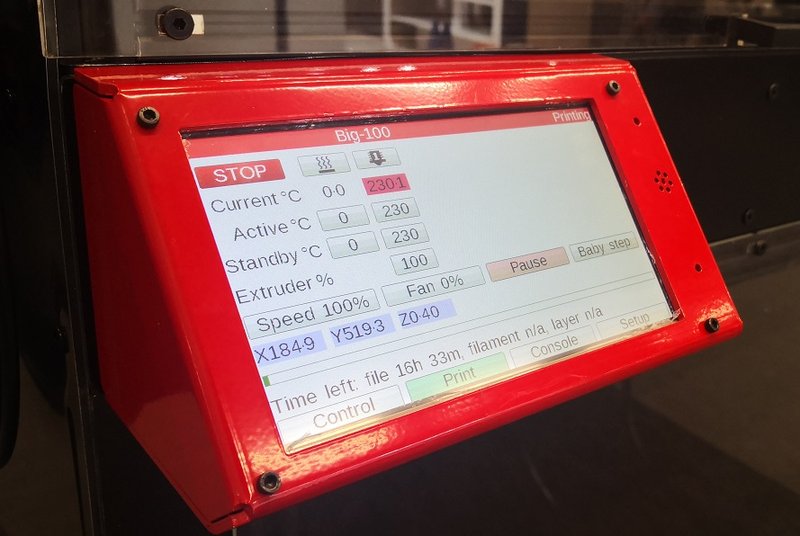

The Modix BIG-40 can be controlled via PC, smartphone, or its built-in 7″ LCD display.

The BIG-40 features Wi-Fi, USB, and SD card connectivity, making it a highly accessible machine.

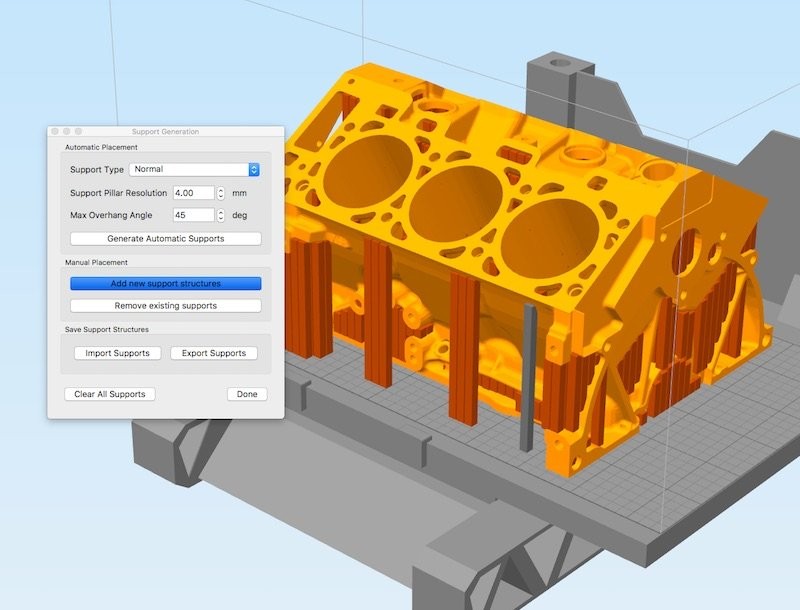

The machine can interact with a 3D model of almost any format and is compatible with a number of slicing software solutions, such as Simplify3D, Slic3r, Cura, Printerface, and many others.

For some items, package content may change. In case of any questions, please get in touch.

Modix BIG-40 is available in black with red trimmings. Its stylish appearance, premium-grade components, and smart design make it ideal for a number of professional and industrial applications.

The price of the Modix BIG-40 is $4,500.00, which is reasonable considering its functionality, build area, and upgrade potential.

Update your browser to view this website correctly. Update my browser now