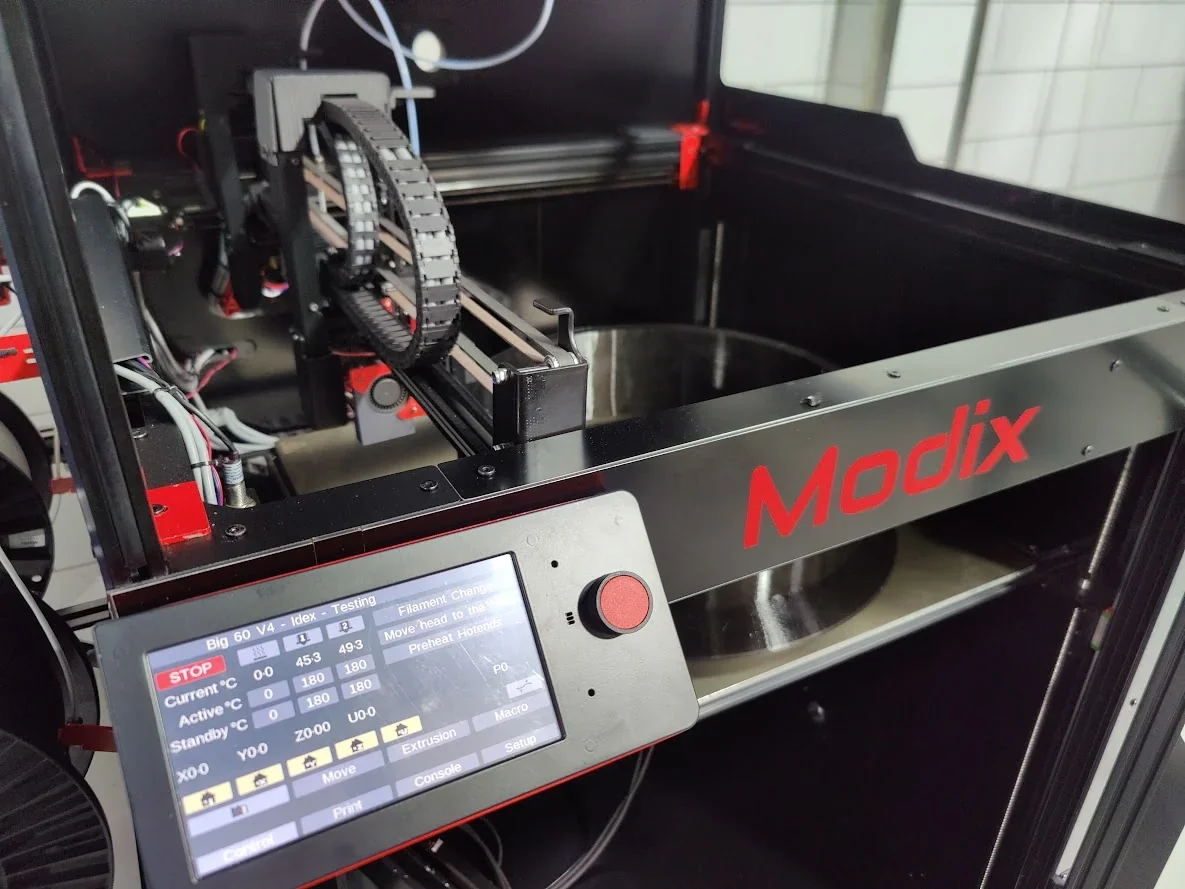

The Modix BIG-60 V4 is a large-format, modular 3D printer with a 600 x 600 x 660 mm build volume, capable of 350 mm/s print speeds and precise, industrial-grade output thanks to components like HIWIN linear rails and the high-performance Griffin print head. Supporting materials such as PLA, ABS, nylon, and carbon-fiber composites, this Modix Generation 4 flagship 3D printer model offers automated calibration, optional IDEX for soluble supports, and open-source slicer compatibility. Designed for professionals and advanced hobbyists, it includes a 7-inch touchscreen, Wi-Fi, and comes as a self-assembly kit, providing scalable, cost-effective printing with long-term upgrade support.

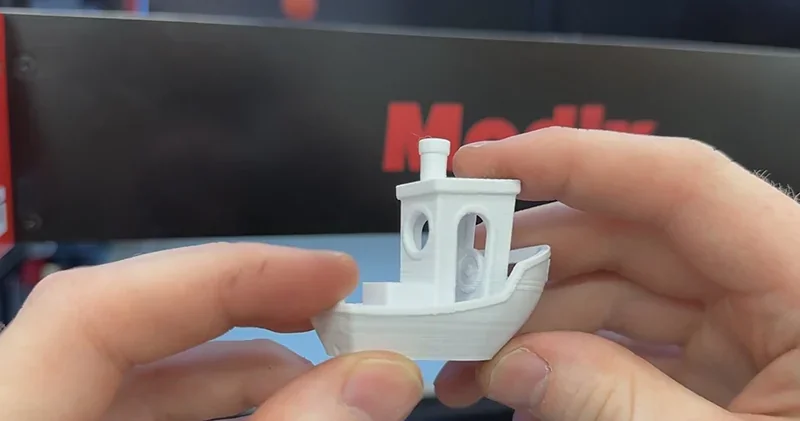

The Modix BIG-60 V4 delivers high print quality with a precision motion system and advanced mechanics, achieving 0.5-micron Z-axis and 10-micron X/Y resolution across its 600 × 600 × 660 mm build volume. For example,

For example, user testing demonstrates the Modix Big 60 achieves exceptional print quality with 0.4mm nozzles at 0.2mm layer heights while maintaining reliable operation during 70+ hour print cycles at 60 mm/s speeds across PETG, ABS, and PLA materials.

The productivity of the Modix 3D printer depends on the extruder, with Griffin variants ranging from ~46.9 g/h (High-Resolution) to over 500 g/h (Ultra), driven by differences in hotend length, melt path design, and heater power.

| Feature / Spec | Griffin (Standard) | Griffin High-Resolution | Griffin High-Flow | Griffin Ultra |

|---|---|---|---|---|

| Use Case | All-purpose printing | Ultra-fine detail | High-speed, large prints | Maximum throughput, industrial use |

| Design | Standard hotend | 50% shorter for precision | Double-length for more melt volume | Extended dual-zone melt path (4× standard) |

| Flow Rate | ~30 mm³/s | ~15 mm³/s | ~45–60 mm³/s | ~160 mm³/s |

| Extrusion Rate | ~93.8 g/h | ~46.9 g/h | ~140.6–187.5 g/h | >500 g/h |

| Nozzles | Volcano-compatible; 0.4, 0.6, 0.8mm | Volcano-compatible; 0.4mm | Volcano-compatible; 1.0mm | Volcano-compatible; 1.6mm |

| Heater | 50W standard | 50W standard | 80W upgraded | Dual heaters (>80W) |

| Cooling | Standard fan | Standard fan | Standard fan | Dual XXL blowers |

| Max Temp | Tested to 340°C, supports up to 500°C | Tested to 340°C, supports up to 500°C | Tested to 340°C, supports up to 500°C | Tested to 340°C, supports up to 500°C |

| Build Volume Impact | None | None | None | Reduces X by 50mm; Y by 50mm (IDEX mode) |

The optional Griffin High-Resolution Extruder supports tight tolerances. For example, this video shows 50-micron layer height printing on the Modix BIG-60, producing two detailed 11.5mm bolt parts in 27 minutes. Printed in Glitter Gray PLA using a 0.4mm nozzle at 185°C, 55°C bed, 2.5mm retraction, 100% fan, 2 outer walls, and 7 top solid layers.

The optional Griffin Ultra hotend halves production time — a 1-meter statue printed in 21 hours vs. 47 with the standard Griffin Extruder.

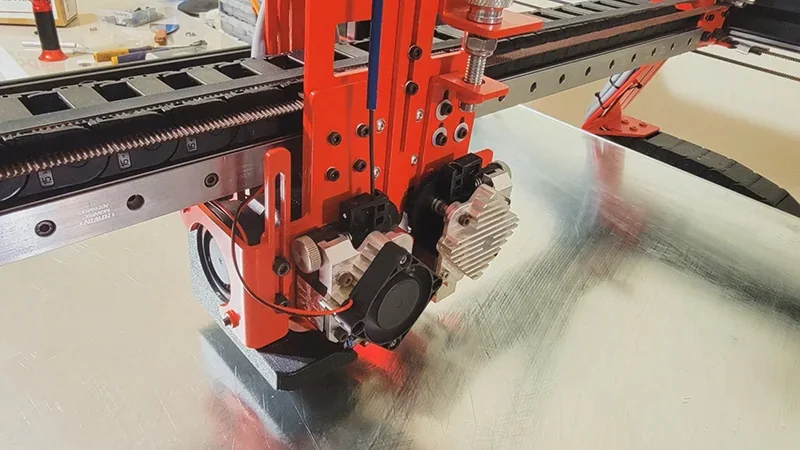

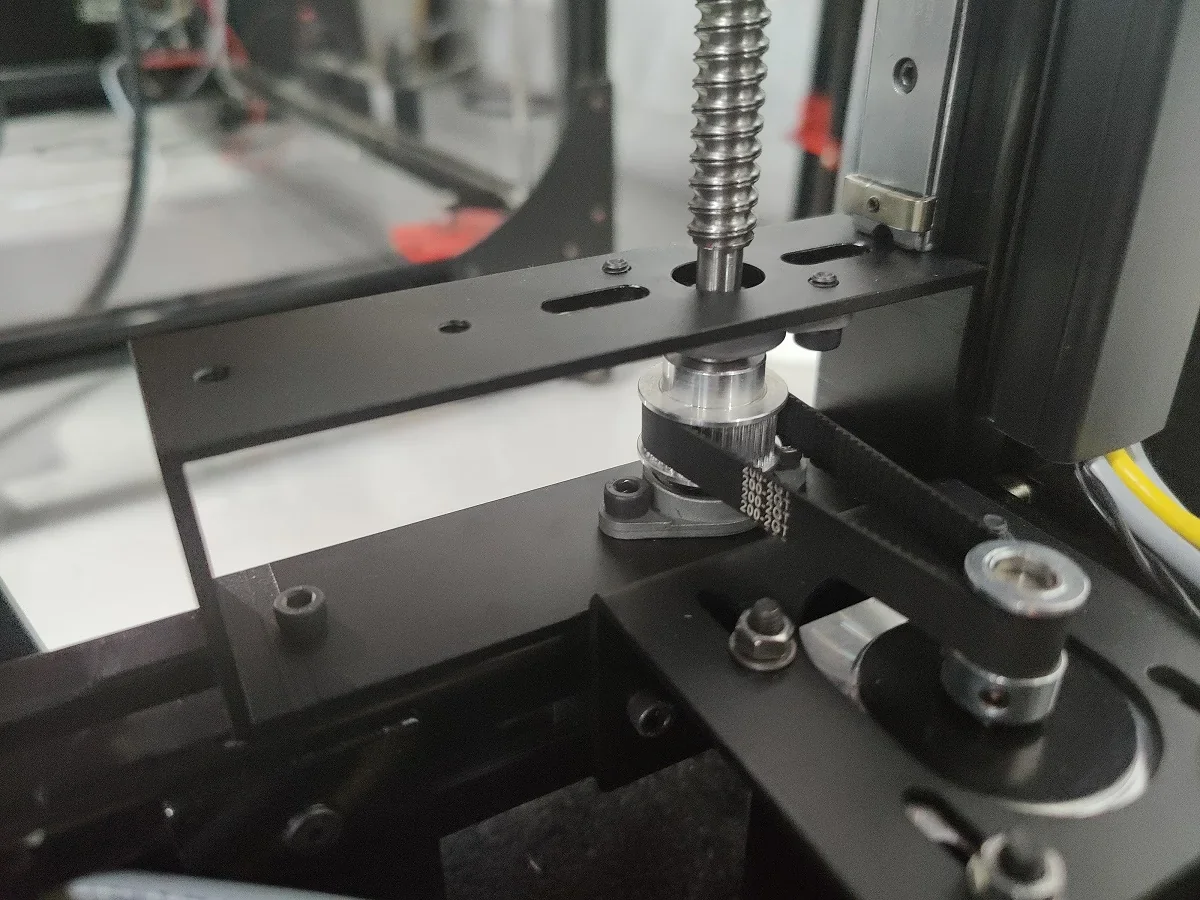

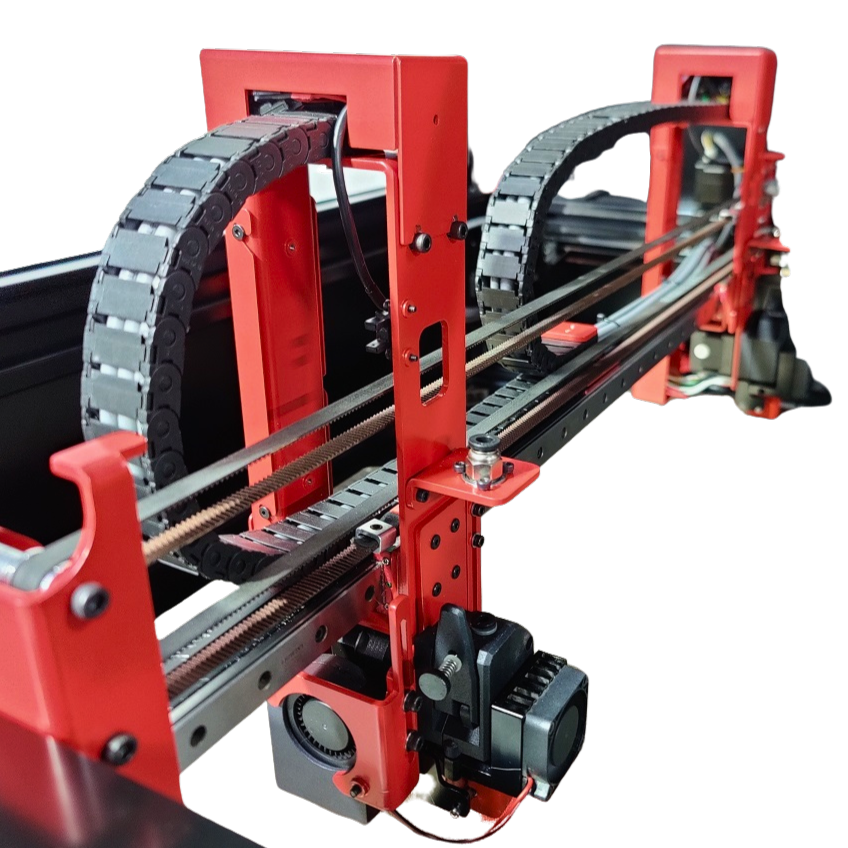

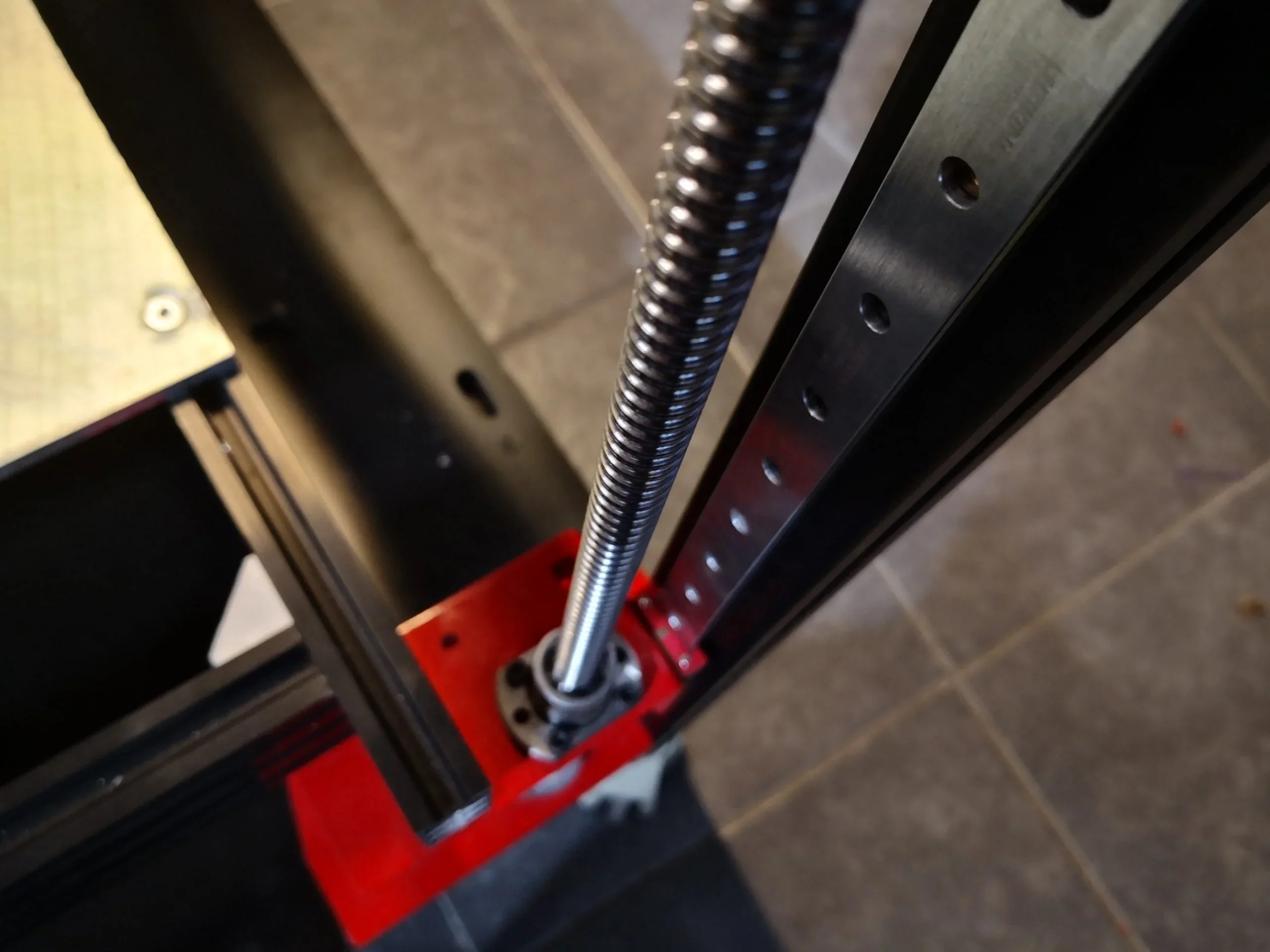

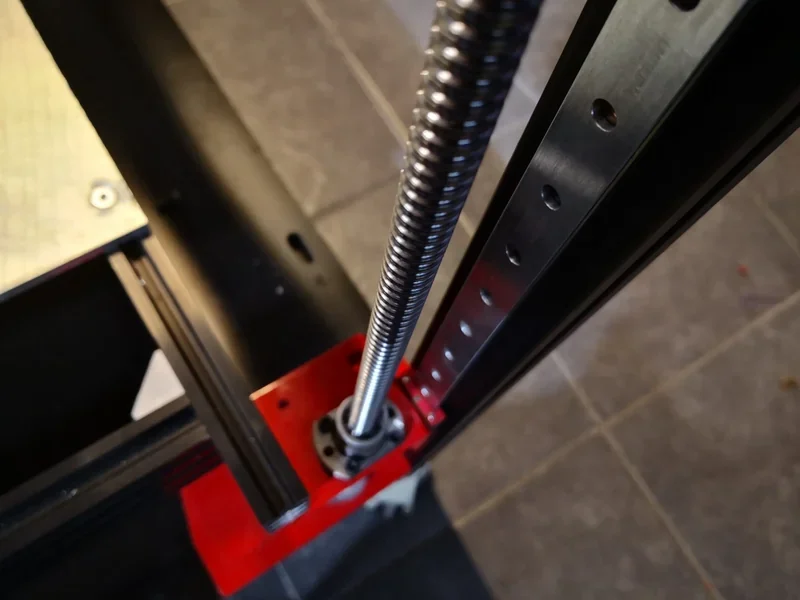

The Modix BIG 60's print quality relies on a robust motion system with HIWIN MGW9 linear rails on the X and Y axes and four 12mm ball screws for the Z-axis. Powered by NEMA-23 motors on X and Z, and NEMA-17 on Y, the upgraded Z-axis with CNC brackets improves bed stability and accuracy. Reinforced 9mm Gates GT2 belts and Trinamic TMC2660 drivers ensure quiet, precise operation during long prints.

The BIG-60 V4 ensures consistent prints with an automated calibration system that probes 100 bed points to adjust for surface variations. It offers a full set of automated calibration routines, including bed tilt calibration, bed leveling, gantry alignment, and Z offset calibration.

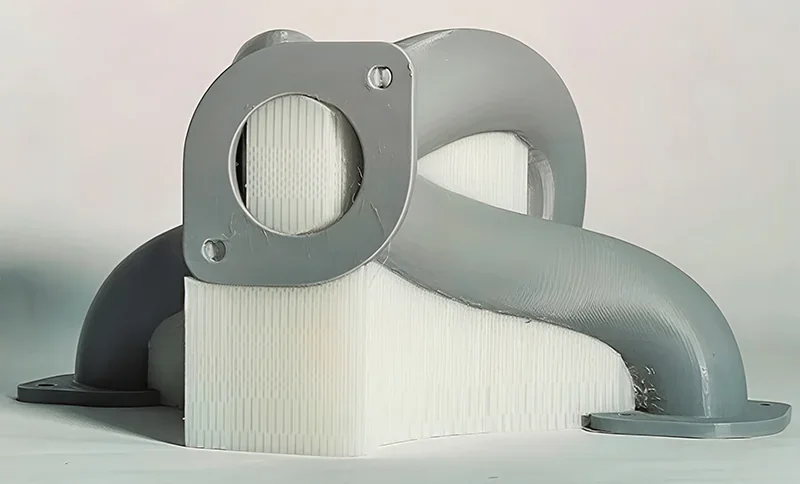

Example: the video shows the Modix Big-60 printing 12 fittings in one batch across its large build area of 660 x 600 mm.

The T-slot aluminum frame with coated brackets ensures stable, high-quality prints, while upgraded optical end-stops boost accuracy and enable reliable recovery after power loss or filament swaps.

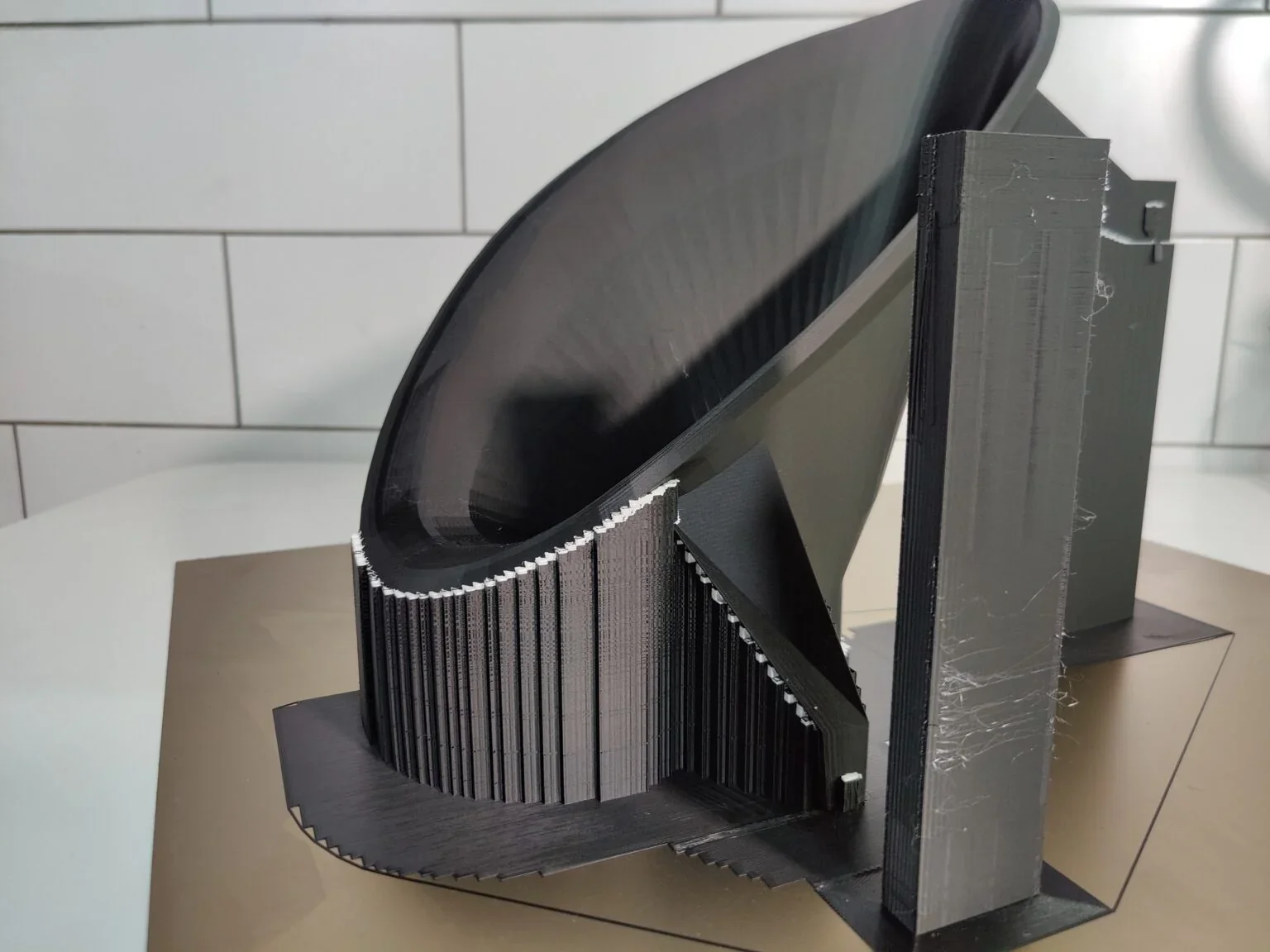

An optional enclosure controls temperature and prevents warping. A Nylon Carbon Fiber bike intake was successfully printed in 42 hours.

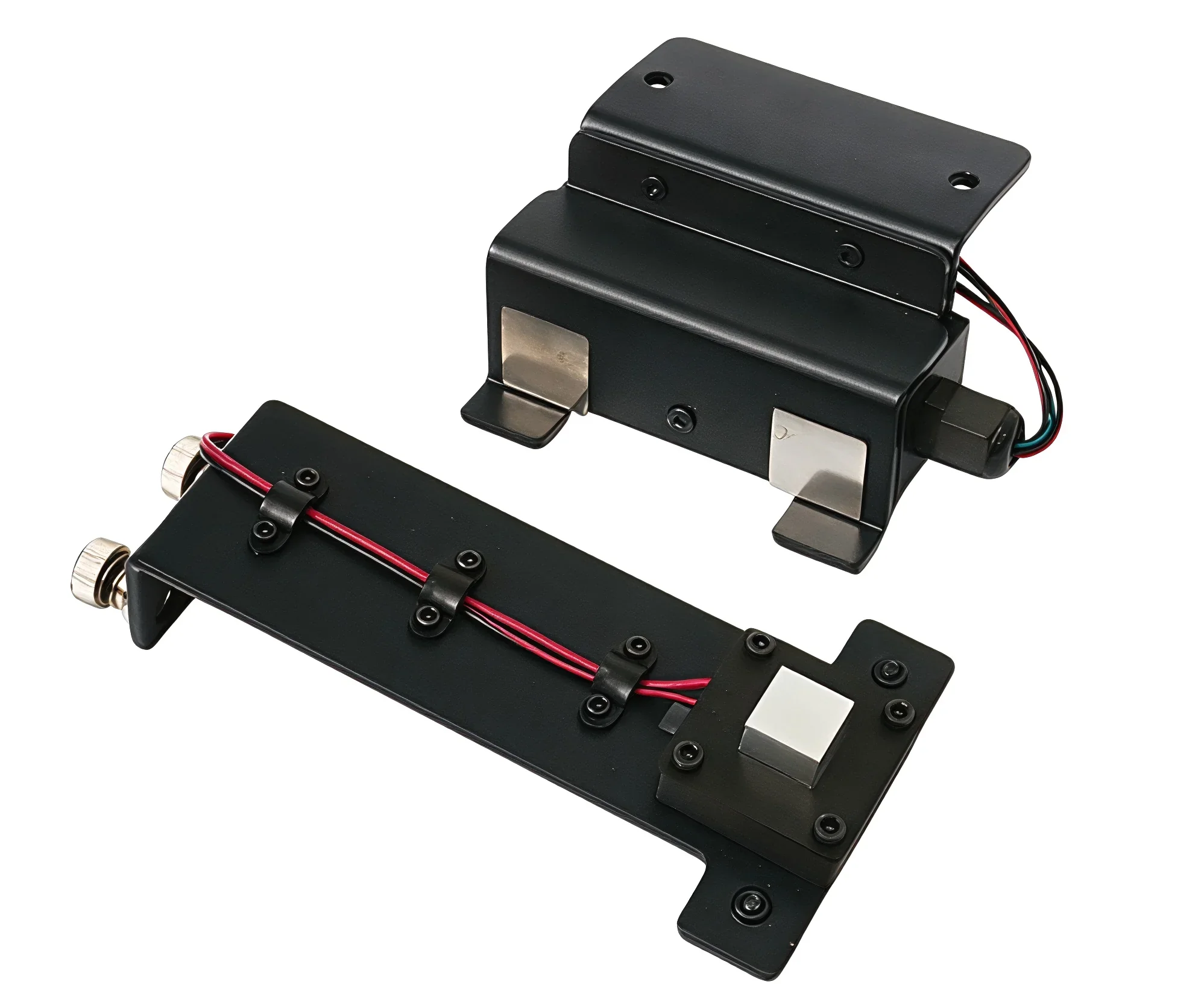

The Clog Detector improves printer reliability by using a sensitive encoder to detect issues like hot-end clogs, filament knots, run-out, and under-extrusion, pausing the print to prevent failed jobs.

The Clog Detector improves printer reliability by using a sensitive encoder to detect issues like hot-end clogs, filament knots, run-out, and under-extrusion, pausing the print to prevent failed jobs.

Case Study: TTICI, German technology consulting specialist provides rapid prototyping solutions for robotics and machinery clients.

Case Study: Sim Automation, a German special-machine builder, uses the Modix Big-60 to prototype and develop custom components for automation equipment.

The Modix BIG-60 V4 supports 15+ filament types, including high-temp and abrasive materials, thanks to its Griffin print head and 500°C nickel-coated copper heat block. Optional hardened steel nozzles handle composites like carbon fiber and wood without wear. It supports open materials, allowing any filament brand. An adjustable gear tensioner improves TPU control, while the Bondtech dual-drive extruder ensures consistent feeding.

Optional air filtration handles fumes from materials like ABS, and an enclosure add-on stabilizes temperatures to reduce warping and improve adhesion.

Example: The video showcases Engineering Garage's use of the Modix BIG-60 for printing a utensil organizer, coffee cart stand, nesting block, growler carrier, and casting sample..

Example: Printing with breakaway support filament

Example: Printing with soluble support filament

PLA 3D Print Sample:

PLA 3D Print Sample: the following video demonstrates the Modix Big-60 3D printer producing a mold model using PLA filament from Rigid-ink at the I-D-E-E factory, showcasing industrial mold-making applications.

PLA 3D Print Sample: Patrick Laroche, a renowned French sculptor, creates custom art and furniture from miniatures to large installations.

PLA 3D Print Sample: TCB Composite, an aerospace manufacturer, produces aircraft spinners and bulkheads for military and commercial use, including Piper, Cessna, and American Grumman. They print large PLA molds for composites in 60-hour cycles at 80 mm/s, creating fixtures weighing 2.5 lbs solid or 1.5 lbs with integrated holes.

PETG 3D Print Sample: Printing a full scale robot with the Modix Big-60 3D printer.

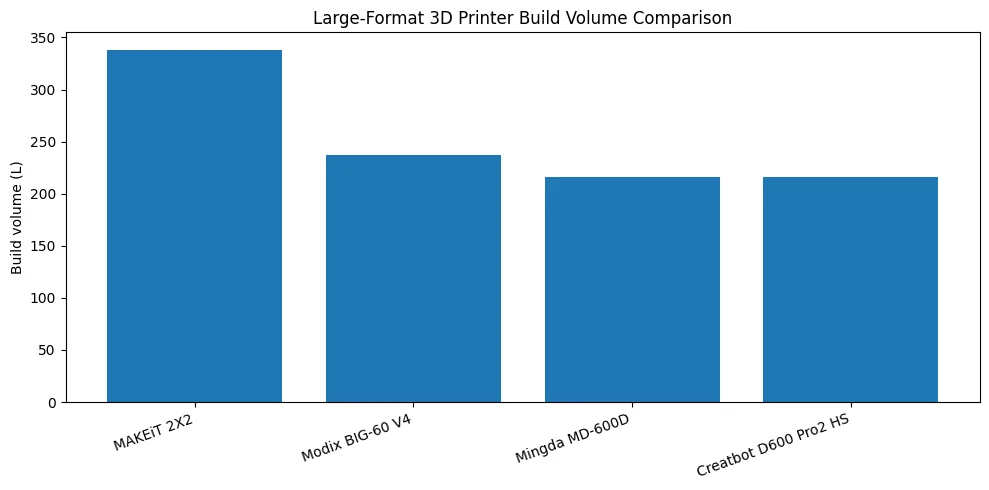

The Modix BIG-60 V4 offers a 600 x 600 x 660 mm build volume (237.6 liters). For larger build needs, there are other Modix large format 3D printers, including the BIG-120X, 120Z, 180X, BIG-Meter, and BIG-2Meter Everest, with volumes up to 2,000 mm in height. For industrial-scale projects, the MAMA-XL3000 delivers a massive 3,000 x 1,000 x 1,000 mm build volume.

The Modix BIG-60 V4 offers the best value in large-format 3D printing at $8,000+, with the tallest build (600×600×660 mm), optional IDEX, and scalable throughput—30 mm³/s (Standard), up to 160 mm³/s (Ultra). It has a 110 °C bed, components rated to 500 °C (tested to 340 °C), and ships as a self-assembly kit (assembly services available). No active heated chamber.

In contrast:

| Specification | Modix BIG-60 V4 | Mingda MD-600D | Creatbot D600 Pro2 HS | MAKEiT 2X2 |

|---|---|---|---|---|

| Price (USD) | $8,000+ | $16,999+ | $16,999+ | $25,000+ |

| Build volume (mm) | 600 × 600 × 660 | 600 × 600 × 600 | 600 × 600 × 600 | 650 × 650 × 800 |

| Enclosure / chamber | Enclosed; No active heated chamber. | Enclosed; No active heated chamber. | Enclosed, Active Heated chamber: 60 °C | Optional, no heated chamber |

| Extruders / IDEX | Single; IDEX optional | Dual extruders, not IDEX | Dual, not IDEX | Single |

| Max nozzle temp (°C) | Components rated 500 (tested to 340) | ≤ 350 (rec ≤ 320) | 420 | 450 |

| Max bed temp (°C) | 110 | 110 | 100 | 110 |

| Volumetric flow (mm³/s) | Std ~30; High-Flow 45–60; Ultra 160 | 40 | 90 | n/s |

| Rated output (g/h) | Std ~93.8; Ultra >500 | n/s | n/s | n/s |

| Assembly | Self-assembly kit (assembly services available in the US/EU) | Assembled | Assembled | Assembled |

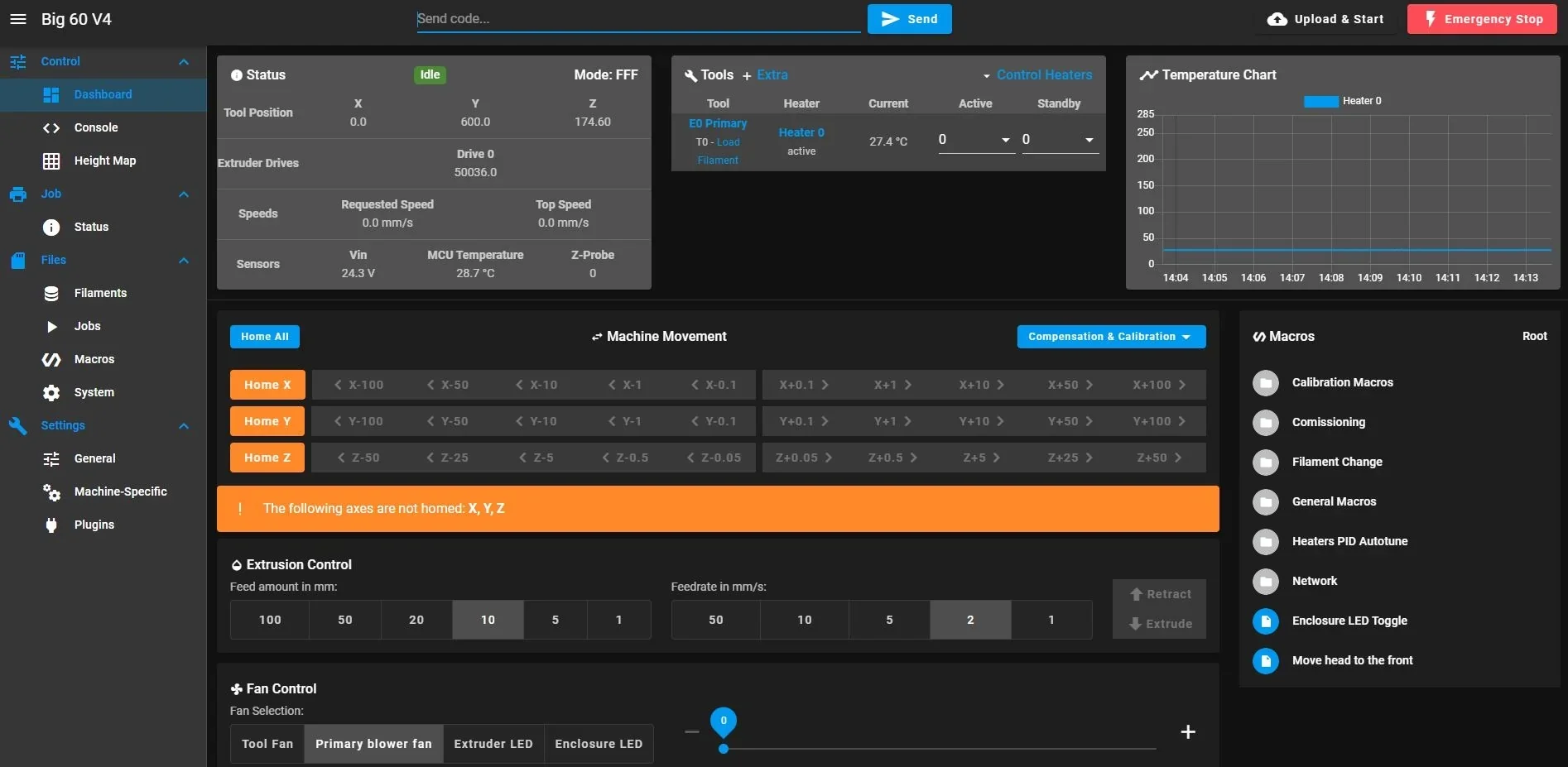

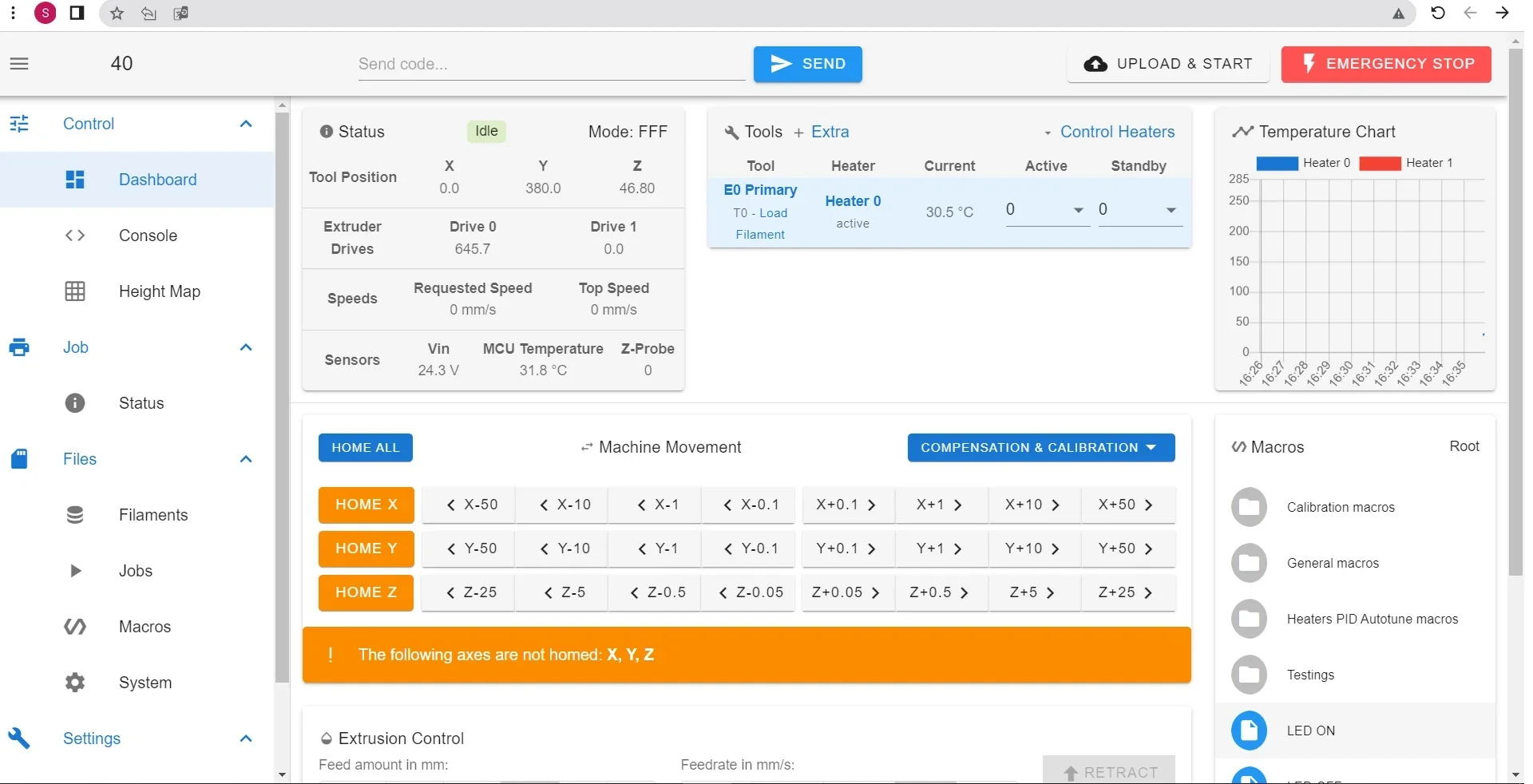

The Modix BIG-60 V4 3D printer features 5 distinct printer control interfaces: touchscreen, remote web-access interface, emergency stop button (optional add-on with electronic controller reset), SD card interface, and USB cable connection.

1. 7-inch Touchscreen Interface

The machine features a 7-inch, 800 x 480 color touchscreen (PanelDue by Duet3D) integrated with the Duet2 3D printer electronic controller for direct physical control.

2. Remote Web Interface (Wi-Fi)

The Duet 2 WiFi controller allows full printer control via a web interface on PC, tablet, or smartphone. Users can upload G-code and monitor prints remotely.

3. Emergency Stop Button

A dedicated emergency stop button allows immediate print termination for safety (optional add-on).

4. SD Card Interface

The printer supports direct printing via high-speed SD card slots built into the touchscreen.

5. USB Cable Connection

Direct USB connectivity enables file transfer and printer control.

Additional Control Features:

The Modix BIG-60 V4 offers 3 connectivity options including Wi-Fi, USB, and SD card. Its Duet 2 Wi-Fi 3D printer controller, with an external antenna, enables wireless access and control from any device on the local network. Users can upload G-code and manage prints via a web interface — no extra software needed. For regulated environments where Wi-Fi connectivity is prohibited, the Duet3D Ethernet board can be ordered and installed as an alternative networking solution.

The Modix BIG-60 V4 includes a high-speed microSD slot in the touchscreen and supports a second external SD card. A USB port provides wired file transfer from a computer.

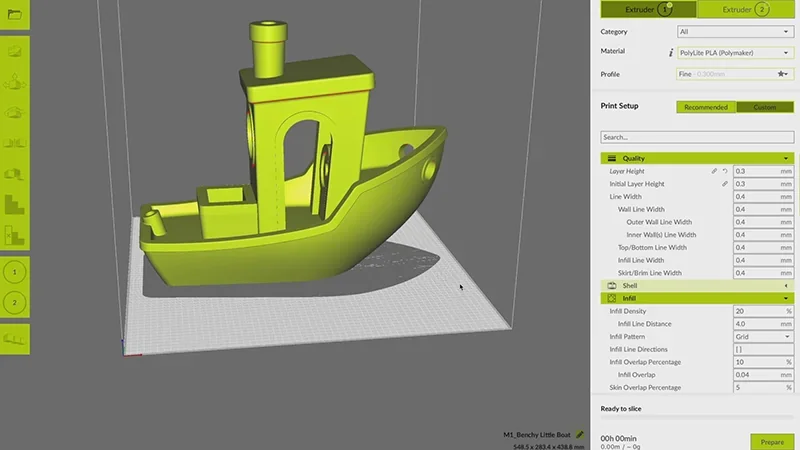

The Modix BIG-60 V4 runs on open-source Duet RepRap firmware, giving users flexibility in slicing software choice. Instead of proprietary slicers, the Modix Large 3D printers provide optimized profiles for Simplify3D, Cura, and PrusaSlicer.

The firmware includes a powerful macro system for custom print configurations. Maintained by Duet3D, it receives regular updates and follows a stable development path.

Users can control the printer via the 7-inch touchscreen or remotely through a web interface on any device connected to the same network. A dedicated mobile app also supports remote monitoring and control.

The Modix BIG-60 V4 has a sturdy industrial design with a 40×40 T-slot aluminum frame and powder-coated brackets. With the optional enclosure, it measures 906 × 1,060 × 1,506 mm (35.6 × 41.7 × 59.3 inches) and weighs 120 kg when shipped. Articulated leveling feet are standard, and casters are available for mobility.

The Modix BIG-60 has an open-frame design, with an optional enclosure made of 3mm black aluminum composite panels and a polycarbonate door with transparent viewing panels.

The motion system uses HIWIN MGW9 linear guides on the X and Y axes. The Z axis uses standard smooth rods, upgradeable to HIWIN rails.

Motion System Specifications:

The build platform uses a 6.35mm Alcoa Mic-6 milled aluminum plate for exceptional flatness across the 600 × 600 mm surface. The bed heater delivers 1,370W at 230V (1,200W at 110V) with a max temperature of 120°C. An Autronics TCN4 PID controller ensures precise temperature control.

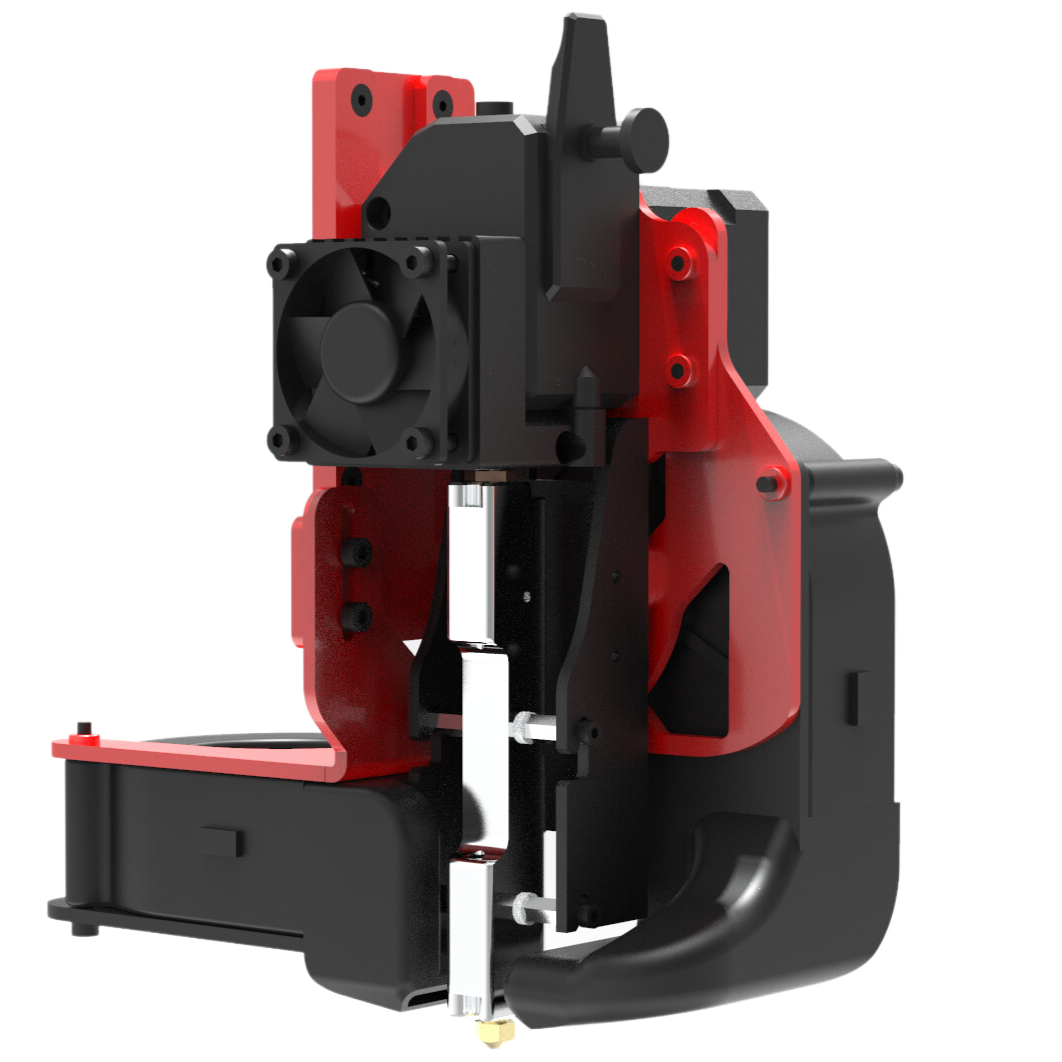

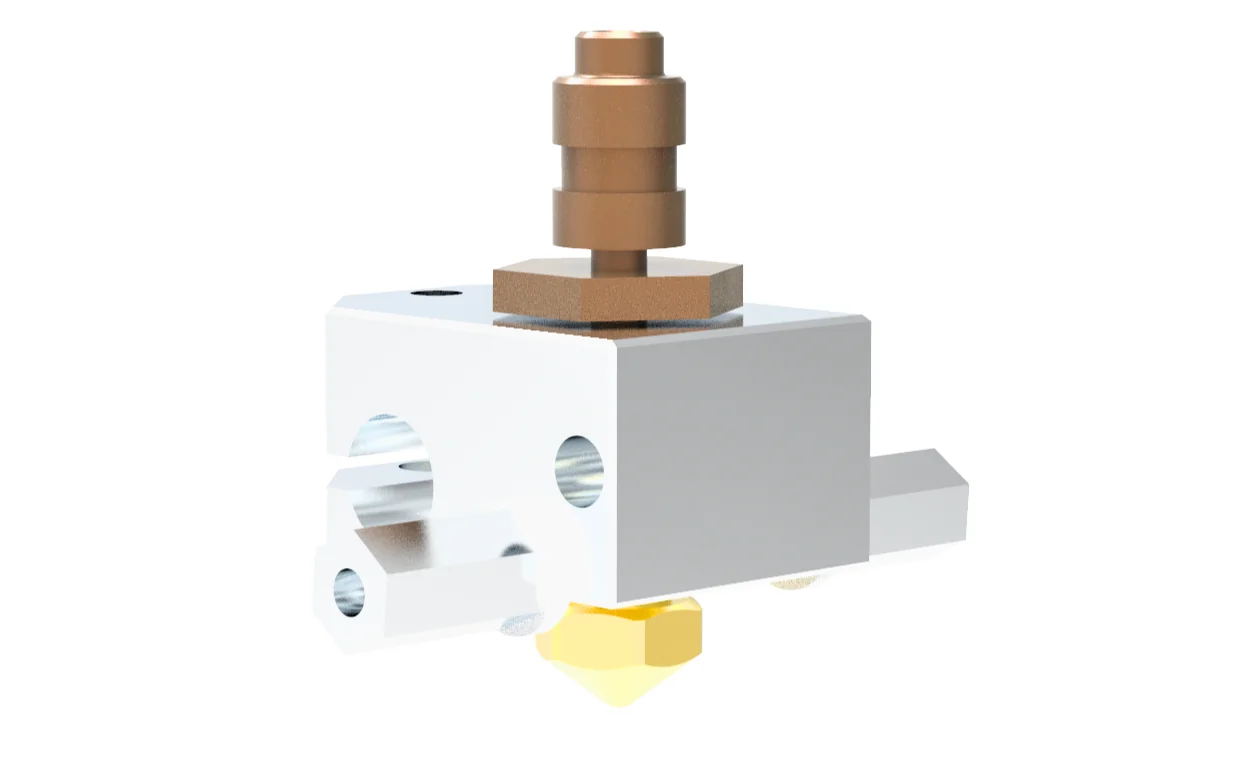

The BIG-60 V4 features the Modix Griffin High Flow hotend with a nickel-coated copper heat block for efficient heat transfer, supporting up to 500°C (tested to 340°C) via a PT-1000 thermistor. It’s compatible with E3D Volcano nozzles and offers easier swapping and higher temps than the V3. The Bondtech BMG direct-drive extruder uses a 3:1 gear ratio and Motech MT-1703HS168A motor for reliable feeding, with clog detection, filament runout, and under-extrusion monitoring. Optional hotends include the E3D V6 for fine detail and Super-Volcano for high-flow printing up to 300 g/hr.

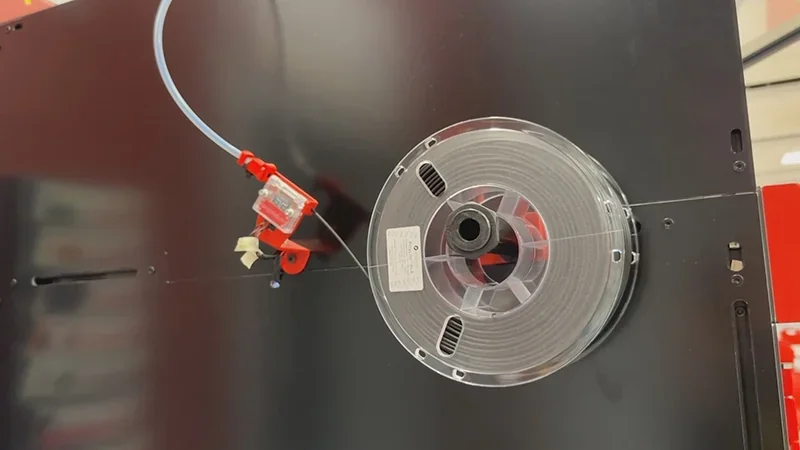

The BIG-60 V4 features an external spool mount for standard 1.75mm filament as part of its filament handling system, with the default mounting configuration supporting spools up to 3kg. The Spool Shelf optional upgrade extends capacity to 8kg, utilizing bearing rollers to reduce friction and facilitate smooth filament feeding to the extruders.

The filament path uses PTFE tubing with a retractable reel and roller guides to minimize friction by keeping the tube relaxed during printing (shown: the Spool Shelf add-on, not included in standard configuration).

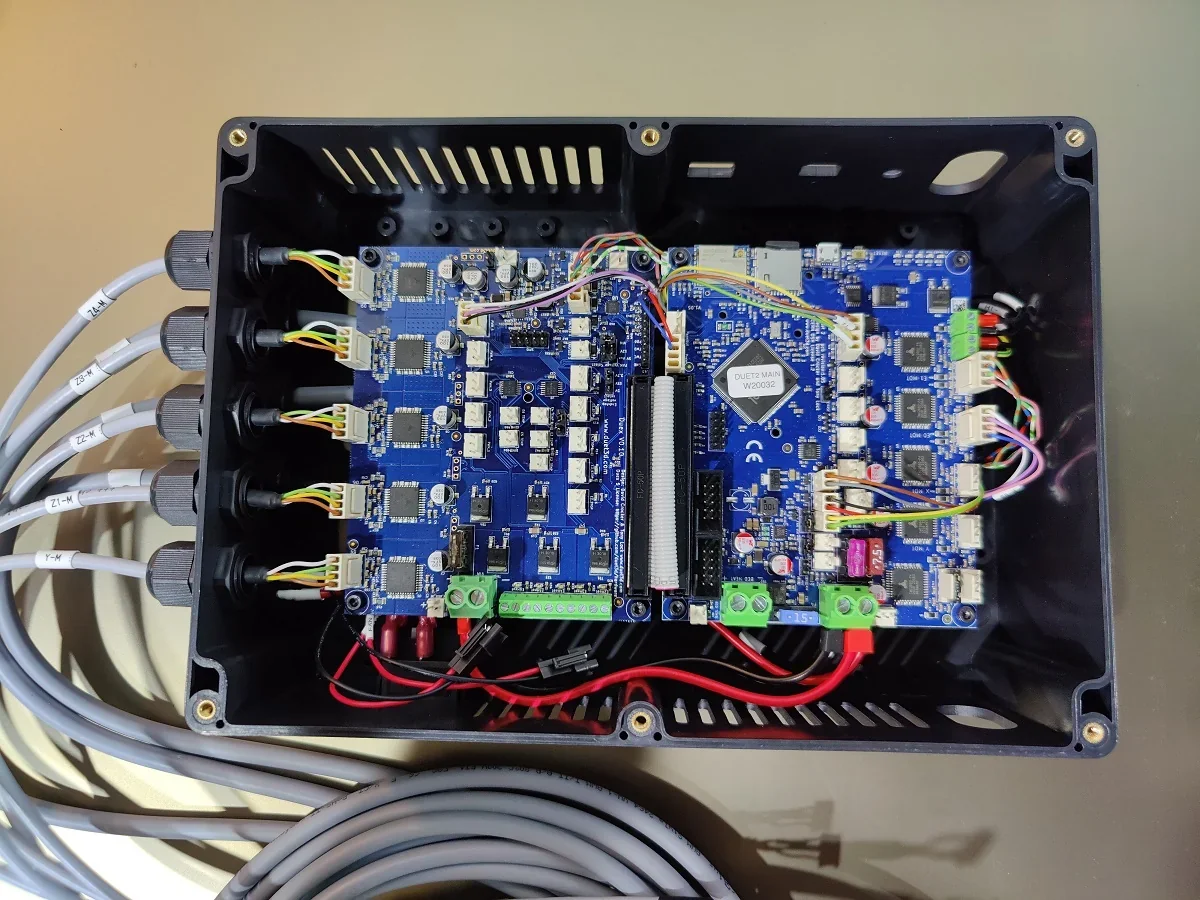

The UK-made Duet2 Wi-Fi controller uses a 32-bit processor, external-antenna Wi-Fi module, quiet TMC2660 drivers (up to 256 micro-steps), and supports high-speed microSD cards with an optional second slot. Paired with the DUEX expansion board, it supports dual extruders and five extra stepper drivers, each handling up to 2.8A (software-limited to 2.4A). Full control is available via web interface on PC, tablet, or smartphone.

Optional

The electrical system supports 110V or 230V at 50/60 Hz, using a Meanwell 24V/280W power supply for electronics and motion. It includes protections against short circuit, overload, overvoltage, and overheating. Idle power draw is under 0.5W, with LED power indication. The bed heater runs on AC power, drawing 1,370W at 230V or 1,200W at 110V, with 230V setups requiring a dedicated 15A outlet. Aviation-grade switches and connectors ensure safety, and power cords match local standards.

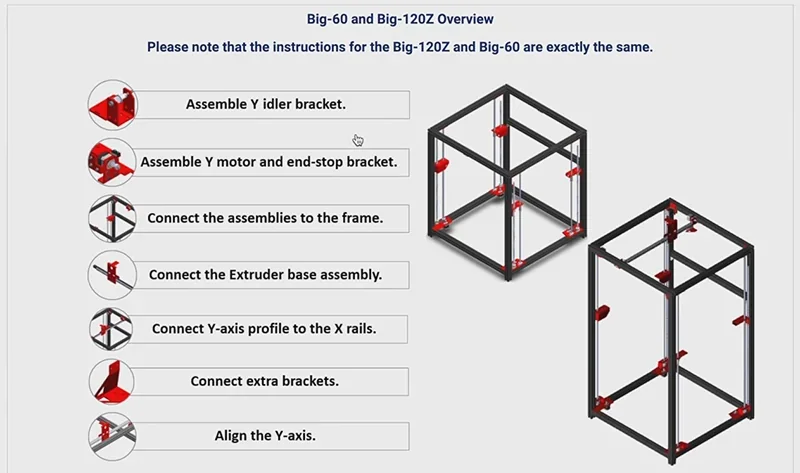

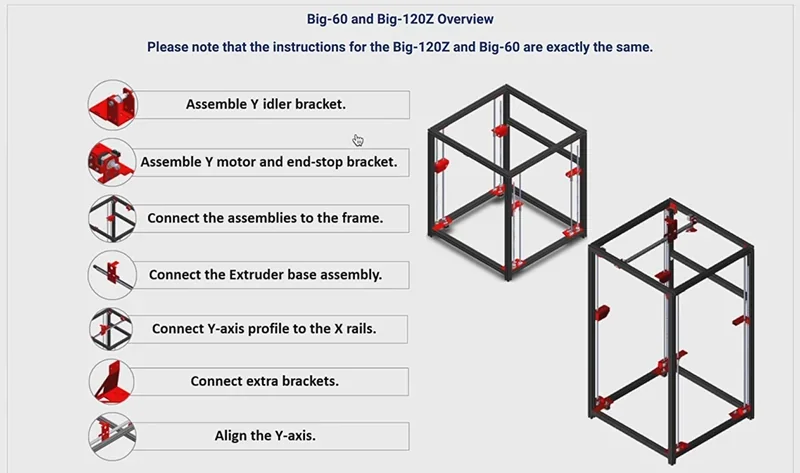

The Modix BIG-60 V4 ships as a self-assembly kit with all required components, clearly labeled and boxed for easy assembly. The online user manual includes step-by-step instructions, videos, and interactive 3D models.

Please Note: Package contents are determined by the manufacturer and may change without notice. To confirm the current items included with this product, please contact a Top3DShop sales representative before placing your order.

The fourth-generation Modix BIG-60 features a modular design, supporting over 19 upgrades.

| Accessory | Function | MSRP (USD) | Image |

|---|---|---|---|

| Printer Add-ons | |||

| Enclosure Add-on | Enclosure to improve printer stability and print quality; helps retain bed-heater heat to reduce warping and cracking caused by uneven cooling. | $1,680.00 |  |

| Casters | Caster wheel set to move the printer easily; includes adjustable leveling feet to balance the printer and reduce vibrations. | $168.00 |  |

| Printhead & Hotend Upgrades | |||

| Griffin Ultra | High-flow hotend upgrade for very high extrusion rates (up to 500 g/hr). | $1,232.00 |  |

| Griffin High-Flow | High-flow hotend upgrade for faster large-object printing (includes HF heat-block, 80W heater, PT-1000 thermistor, and 1.0 mm nozzle). | $392.00 |  |

| Griffin High Resolution Hotend | High-resolution hotend upgrade for fine layer heights (down to 50 microns) and tight tolerances (includes heat block, heatbreak, PT1000, 40W heater, silicon sock, and 0.4 mm nozzle). | $145.60 |  |

| Dual Print-Head & Calibration | |||

| IDEX Dual Print-head | Dual print-head upgrade for printing with dedicated support material; can also be used as an automatic filament changer. | $1,232.00 |  |

| IDEX Calibration Tool | Hands-free calibration tool to ensure optimal nozzle alignment. | $280.00 |  |

| User Interface & Safety Controls | |||

| Tilt Screen | Tilt screen upgrade with large emergency stop button and front power switch. | $280.00 |  |

| Support Materials & Dissolution Supplies | |||

| Soluble solution – 1000g | Dissolution solution used with water to dissolve prints made with soluble filament; 1000g. | $39.20 |  |

| Soluble filament – 500g | Soluble filament for printing supports/intricate designs; dissolves using water + soluble solution (solution purchased separately); 500g. | $112.00 |  |

| Filament Drying & Spool Handling | |||

| Filament Dryer | Large-capacity filament dryer for moisture control; fits two 5 kg spools or one 8 kg spool, with added storage. | $1,792.00 |  |

| 8KG Spool Shelf | Heavy-duty spool shelf upgrade to support spools up to 8 kg; uses bearing rollers to help extruders pull filament smoothly (default mounting supports up to 3 kg spools). | $448.00 |  |

| Nozzles | |||

| Griffin Brass Nozzles | Brass nozzle pack (0.4 / 0.6 / 0.8 / 1.0 / 1.2 mm) for high-flow, fast printing; note: 0.4 / 0.6 / 0.8 mm already come with the printer by default. | $67.20 |  |

| Griffin Hardened Steel Nozzles Pack | Hardened steel nozzle pack (0.4 / 0.6 / 0.8 mm) for abrasive materials (carbon fiber-filled, glass fiber-filled, wood, glitter); rated up to 450°C. | $190.40 |  |

| Build Plate & Surface Parts | |||

| Magnetic Bed | Magnetic build surface for easier part removal and easier bed maintenance; dual-sided surface (rough PEI powder side + glossy PEI sheet side). | $672.00 |  |

| Extra PEI Sheet | Spare PEI sheet (660 × 660 mm) covering the entire bed plate; not required if you purchase the Magnetic Bed. | $168.00 |  |

| Air Filtration Parts | |||

| Active Air Filter | Three-stage air filtration device: pre-filter (dust), HEPA (sub-micron particles), and active carbon filter (fumes). | $1,512.00 |  |

| Filter Spares Set | Replacement filter set (5× pre-filter, 1× HEPA/carbon combo). | $336.00 |  |

| Electronics & Power Management | |||

| Power Distribution | Power Distribution Unit (PDU) to integrate and organize high-power AC cabling into the machine (bed heater, electronics box, noise reduction). | $1,008.00 |  |

| Motion System Upgrades | |||

| Z Axis Hiwin Rails | Z-axis upgrade replacing smooth rods with high-precision HIWIN linear rails for smoother surface finish on tall models. | $1,008.00 |  |

| Maintenance & Spare Parts Kits | |||

| Basic Maintenance Kit | Essential spare components for the print head and motion system to keep the printer running smoothly. | $336.00 |  |

| Advanced Maintenance Kit | Expanded spare parts kit (belts, pulleys, screws, bearings, motors, printhead parts, fasteners) designed to fit Modix printers V4. | $1,568.00 |  |

The Modix BIG-60 V4 requires 8+ maintenance procedures to maintain print quality, mechanical precision, and long-term reliability.

Daily Maintenance

Weekly Maintenance

Monthly Maintenance

Quarterly Maintenance (Every 3–6 Months)

The Modix BIG-60 V4 includes a 12 month warranty covering non-consumable parts, excluding items like the PEI sheet and nozzles. Optional extensions of up to two years cover manufacturer defects, including electronics, offering added protection for production use.

Modix offers lifetime technical support via email Sunday–Thursday, 09:00–18:00 GMT+3, with video sessions available on request. Customers also get access to a dedicated support zone with manuals, print profiles, firmware, and interactive 3D assembly guides.

The Modix BIG-60 V4 includes video-guided assembly instructions with interactive 3D models for visual clarity. For those who prefer not to self-assemble, professional assembly by Top3DShop is available as a paid service.

Full warranty terms: https://www.modix3d.com/terms

| Service Package | Description | Price (USD) |

|---|---|---|

| 3-Hour Call with Modix 3D Technicians | Remote optimization support for design, slicing settings, and material selection; includes 3 hours of video calls with Modix technicians. | 500 |

| 1-Year Warranty Extension | Extends Modix manufacturer warranty by 12 months beyond the standard warranty period. | 450 |

| 2-Year Warranty Extension | Extends Modix manufacturer warranty by 24 months beyond the standard warranty period. | 900 |

| Assembly Services by Top3DShop (Off-Site) | Off-site assembly of the Modix kit per official manual + calibration (bed compensation ≤2 mm corner-to-corner), IDEX XY calibration (if applicable), test prints (cube/mesh), photo/weekly progress reporting, and delivery of assembled unit (per agreement terms). | 9000 |

| Assembly Services by Top3DShop (On-Site) | On-site assembly and commissioning at customer facility; includes the same assembly/calibration/test-print scope plus on-site handover/training and verification as described in the agreement. | 14000 |

The Modix BIG-60 V4 base model is priced at $6,048.00 and includes the self-assembly kit, Griffin print head, Duet Wi-Fi controller with expansion board, and 7-inch touchscreen. The IDEX upgrade adds ~20%, the enclosure kit adds ~28%, and the Griffin Ultra high-flow head adds ~20% with double the extrusion capacity. For custom builds with add-ons like HIWIN Z-axis rails, air filter, or professional assembly, contact sales for a personalized quote including shipping.

Update your browser to view this website correctly. Update my browser now