The Nexa3D QLS 820 is an industrial SLS 3D printer aimed at unprecedented production speed, throughput, and flexibility. The noted QLS (Quantum Laser Sintering) technology applies four lasers at once, which takes thermoplastic 3D printing to a whole new level. With full Industry 4.0 capabilities, the machine is designed for consistent and highly economical production compared to traditional tooling costs.

The QLS 820 model is equipped with a spacious build volume, which in combination with a removable build unit and capacity for automation enables smooth 24/7 operation. Due to high temperature support, the machine is able to process a vast variety of materials covering all user’s needs, from general purpose prototyping to industry-specific manufacturing at scale.

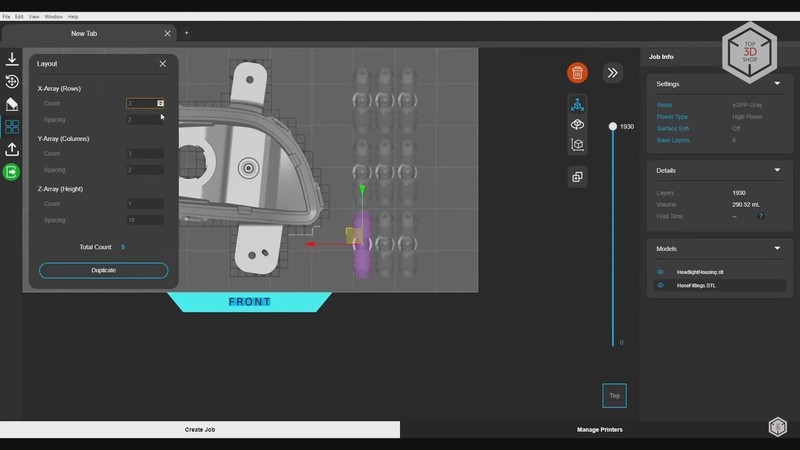

The in-house NexaX software encompasses not only smart build preparation functions, but also real-time data monitoring and flexible machine control. In addition, historical data analytics provides enough data to easily keep track of your printer’s performance.

The machine introduces a modular material processing station (MMPS) covering all manufacturing stages, from powder containment and blending to breakout, powder reclamation and sieving, in a completely safe, clean, and efficient way. With an automation-ready structure, scalable system, and advanced fleet management software, the QLS 820 is clearly aimed at massive production.

Considering the above mentioned features, the Nexa3D QLS 820 3D printer is ideal for professional use in manifold spheres, including automotive, aerospace and defense, industrial manufacturing, medical, consumer goods, etc. It is great for functional prototyping, production of high-temperature components as well as durable end-use parts, and as an effective alternative to injection molding.

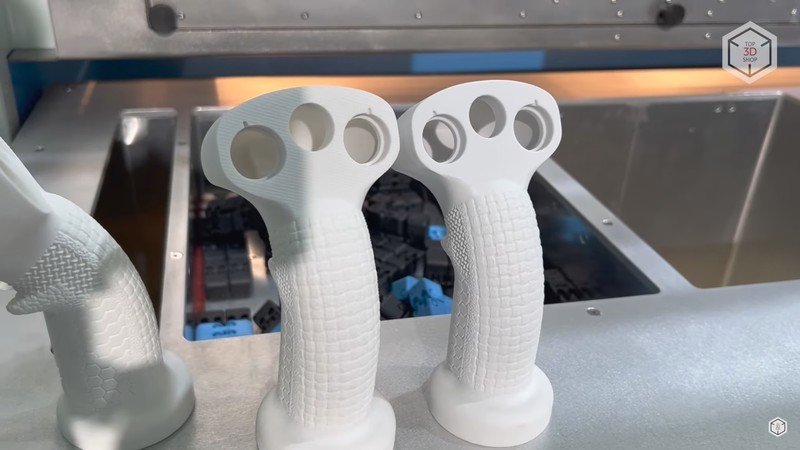

The Nexa3D QLS 820 can print layers with a minimum thickness of 50 microns. It lets you produce solid parts with smooth exterior surfaces, complex geometry, and detailed composition.

The machine is equipped with four 100W CO2 lasers making for more power and throughput compared to competitor models. Overall, the QLS 820 can print up to 8 liters per hour.

The Nexa3D QLS 820 3D printer boasts a broad material compatibility due to its wide-use temperature range, inert processing atmosphere, and an open source platform. The machine supports a decent variety of powders with repeatable and reliable properties, including PA12, PA11, PBT, Polypropylene, as well as aluminum, glass, and fiber-filled options. It can also work with PA6 at processing temperatures of up to 240 °C.

The Nexa3D QLS 820 is equipped with an industrial-scale build area of 13.8 x 13.8 x 15.8 inches (350 x 350 x 400 mm), which lets you print large parts as a whole as well as batches of medium-to-small items in one session, ensuring the highest throughput in the class.

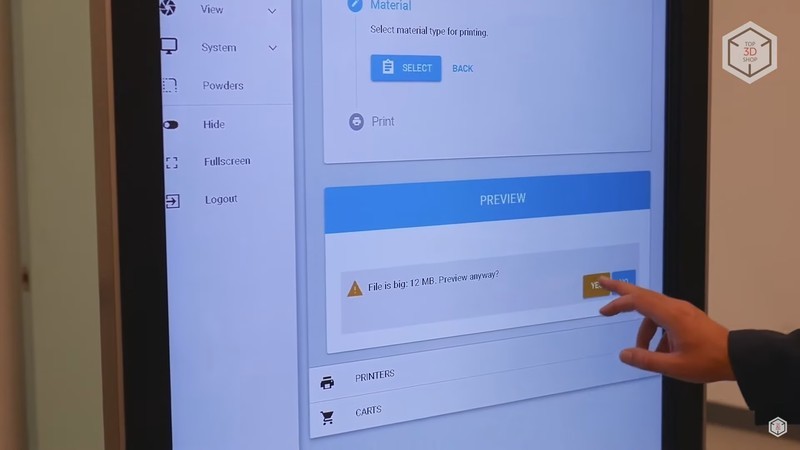

The Nexa3D QLS 820 3D printer can be managed via the hub monitor, computer, or mobile device. An intuitive web dashboard interface gives the user access to complete control over their whole QLS fleet.

The solution is supplied with the dedicated NexaX 2.0 software, which ensures simple build processing and convenient remote control. Along with the handy model editing features, such as automatic orientation and nesting, support generation, and mesh repair wizard, the program empowers submission and queues functionality, statistical reports, etc.

The Nexa3D QLS 820 is available in gray. Its stylish look will decorate any factory, workshop, or lab.

The printer outer dimensions in a closed form are 78.7 x 55.1 x 78.7 in (2000 x 1400 x 2000 mm). The machine weighs 1653.5 lb (750 kg).

To learn the current price of the Nexa3D QLS 820 3D printer, click the "request a quote" button and fill in the form. We will contact you as soon as possible and send you all the details

Update your browser to view this website correctly. Update my browser now