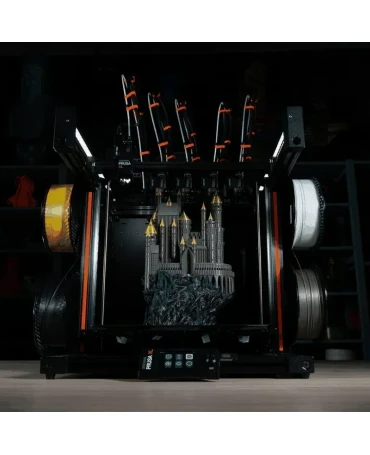

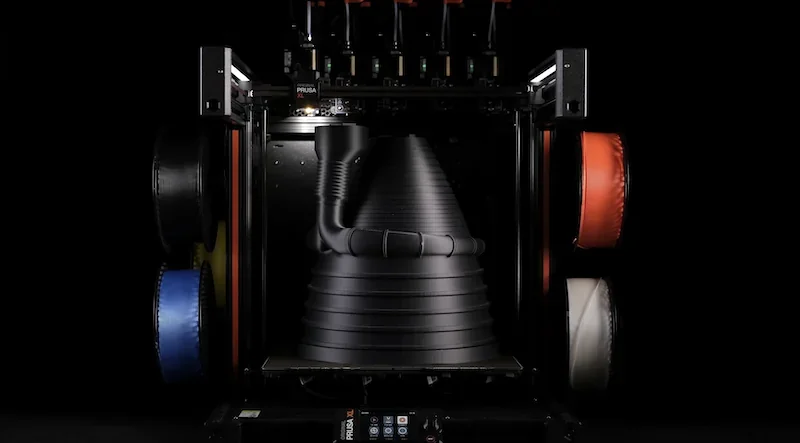

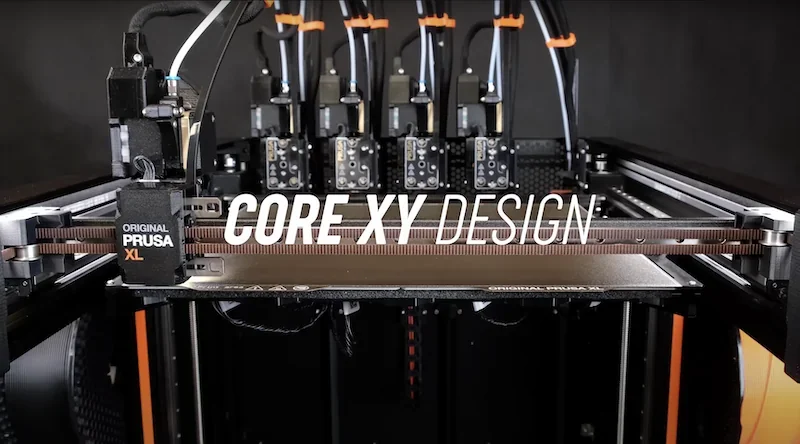

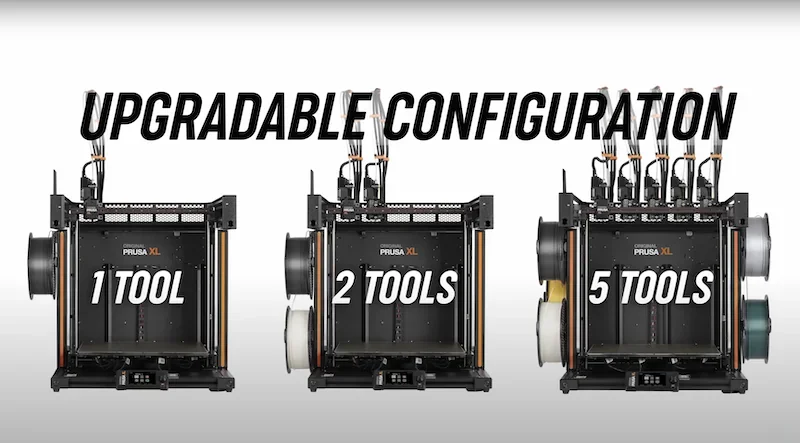

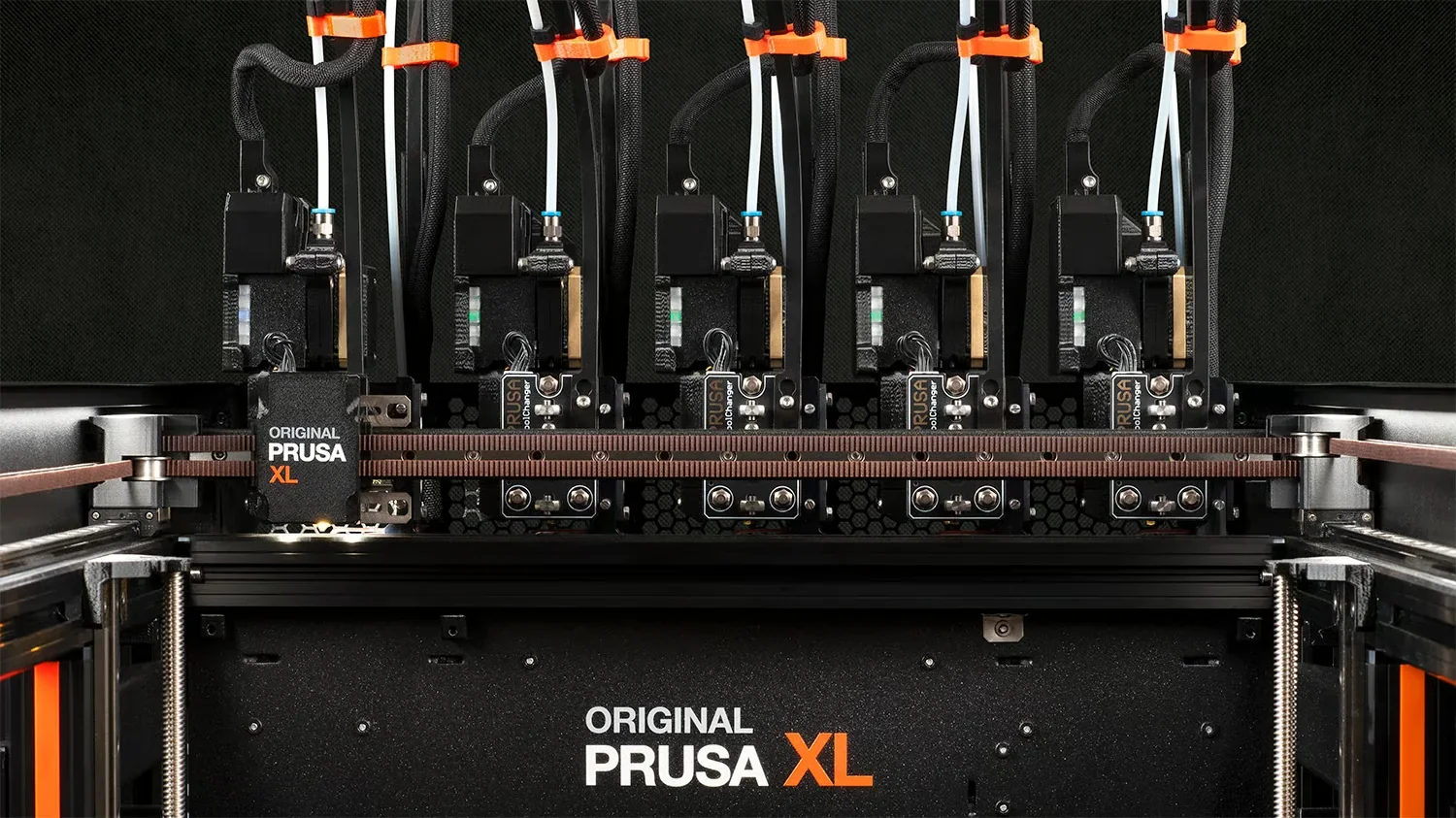

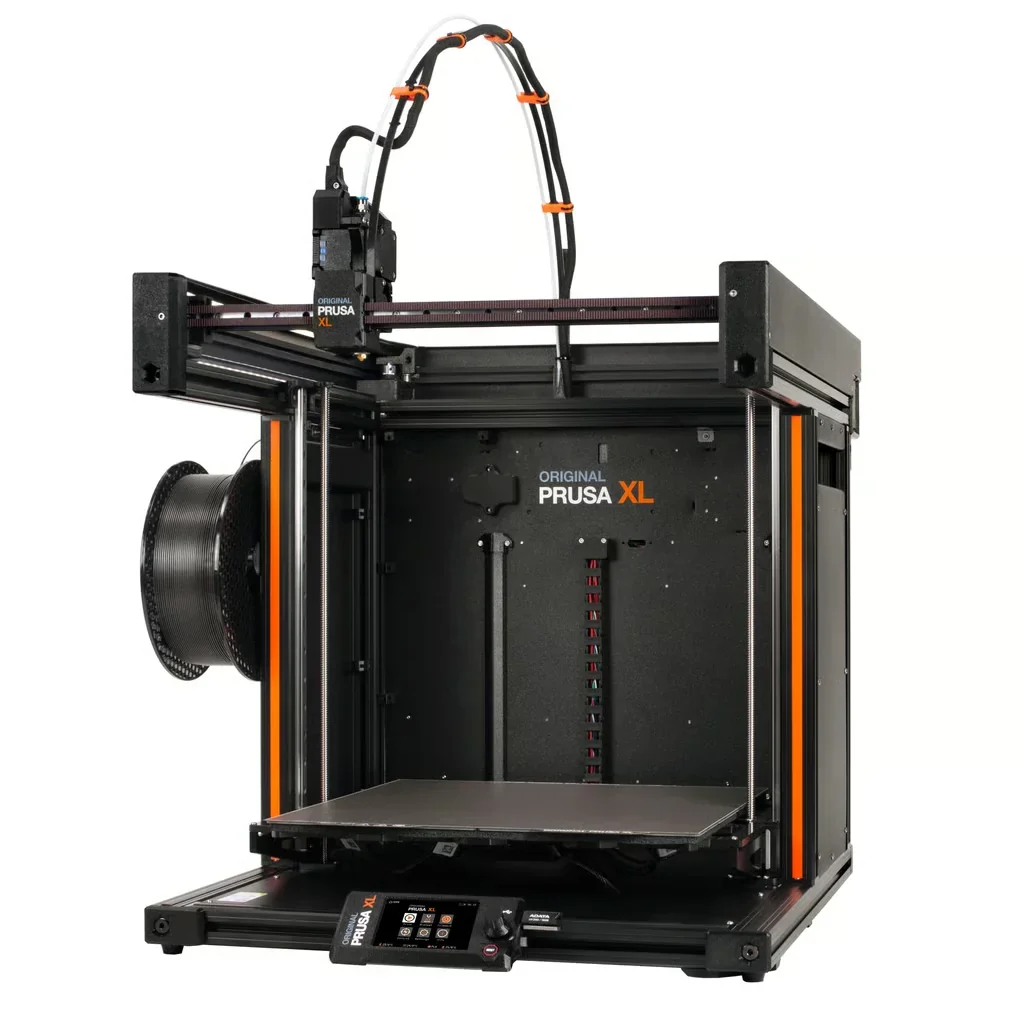

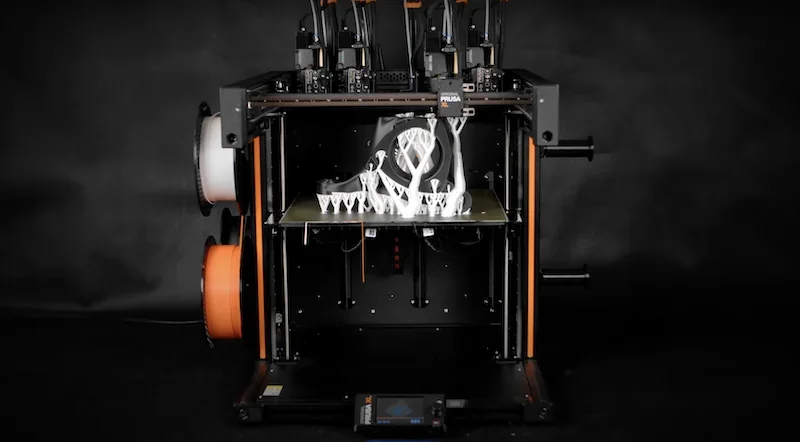

The Original Prusa XL is a large-scale CoreXY 3D printer with a 360×360×360 mm build volume and up to five independent toolheads. Its fast tool-changing system reduces waste in multi-material printing by avoiding nozzle purging. Praised for accuracy and speed, it's been called the best large-format 3D printer of 2025 by All3DP.

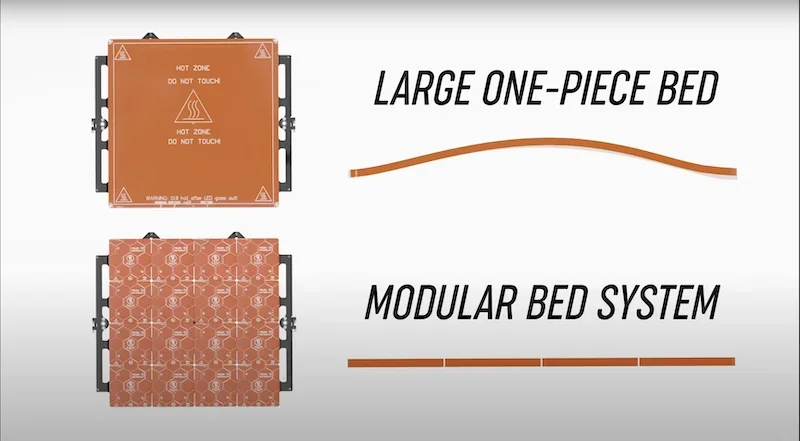

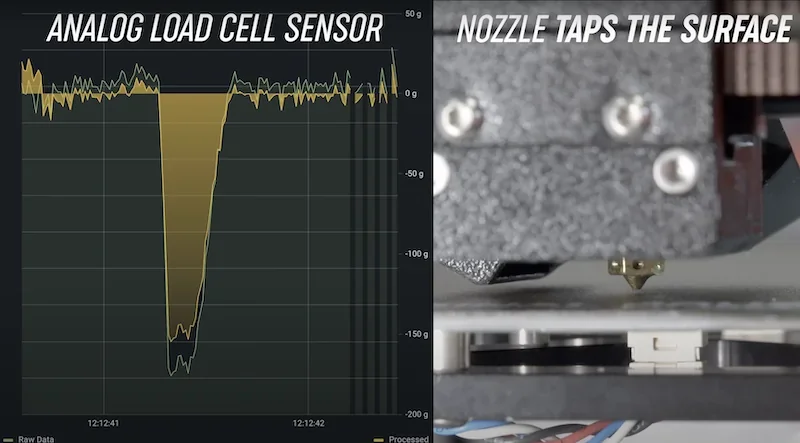

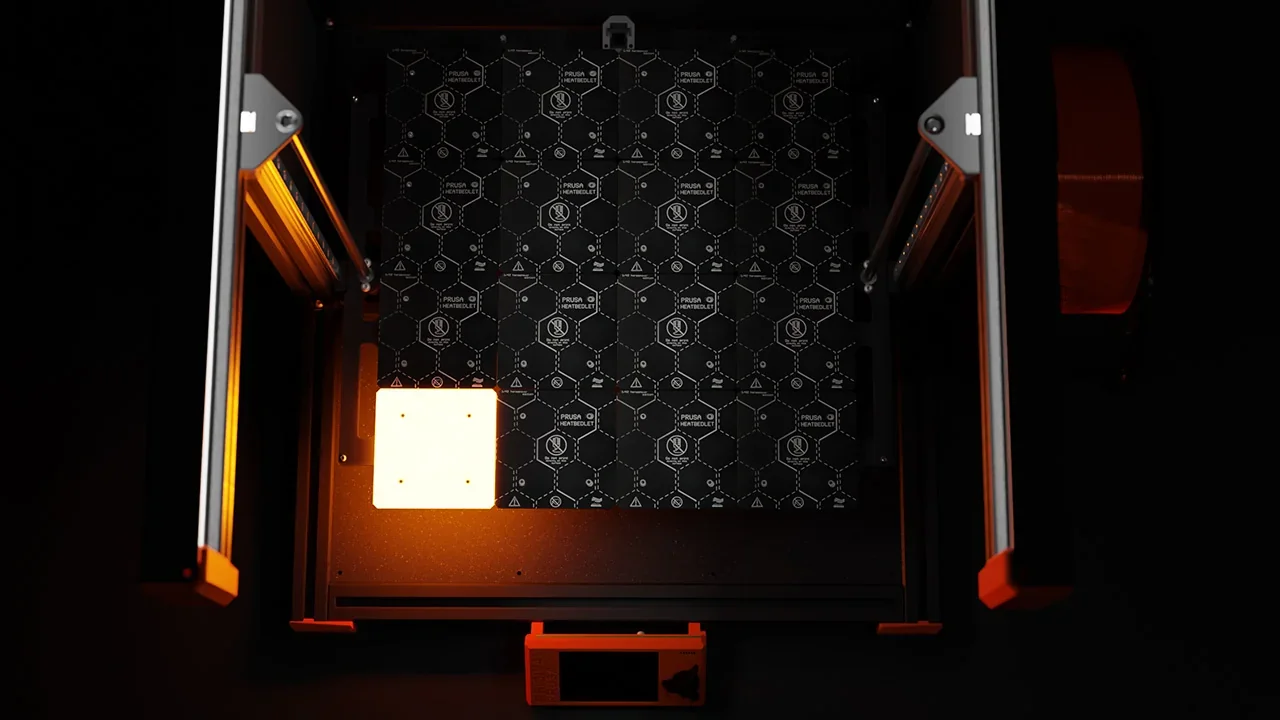

The Original Prusa XL has a segmented heatbed with 16 individually controlled tiles, reducing energy use and heat deformation by activating only needed areas. XL's loadcell sensor auto-calibrates for a perfect first layer. Technologies like Input Shaper, Pressure Advance, and Phase Stepping improve print quality, print speed, and reduce noise.

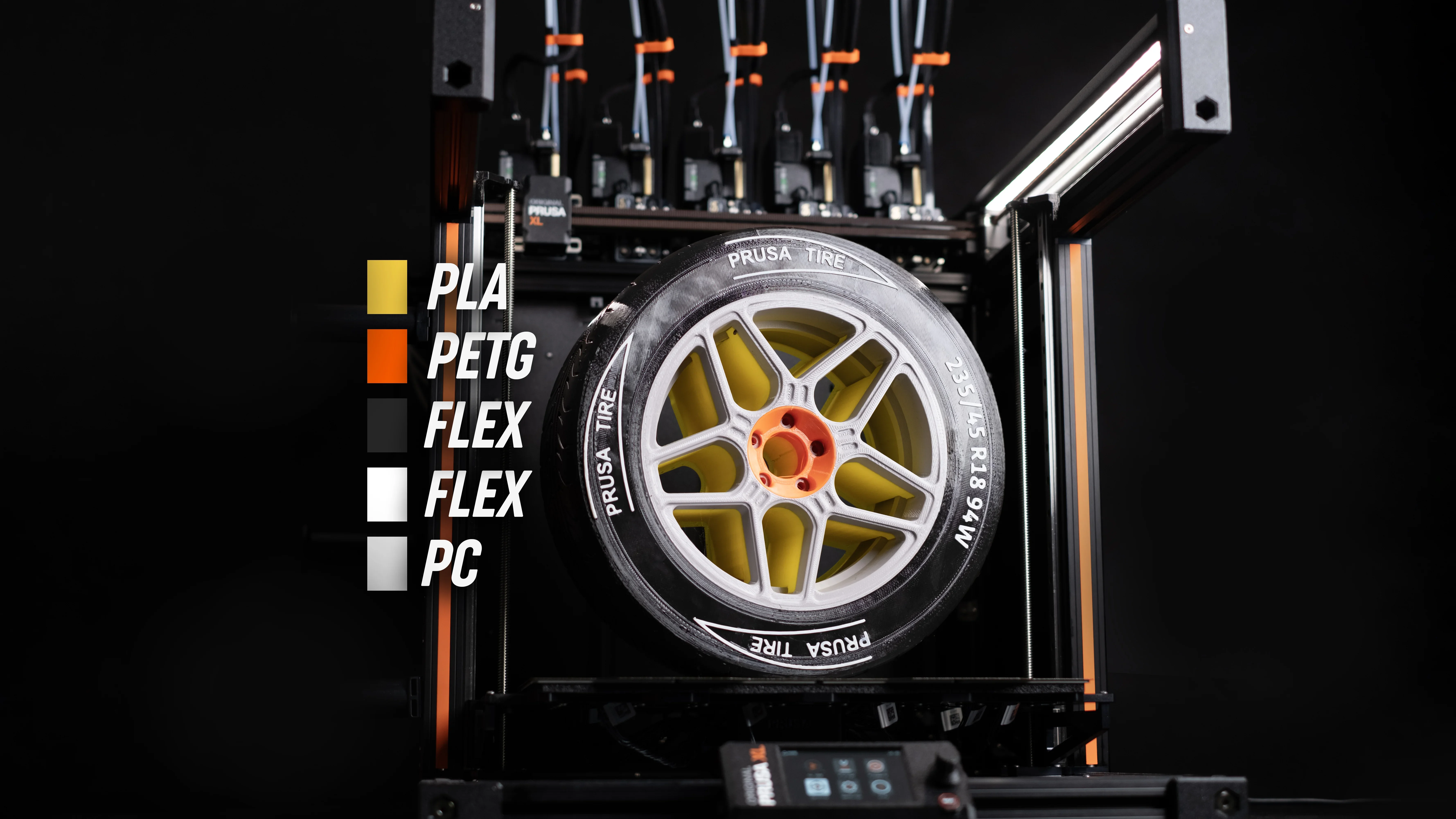

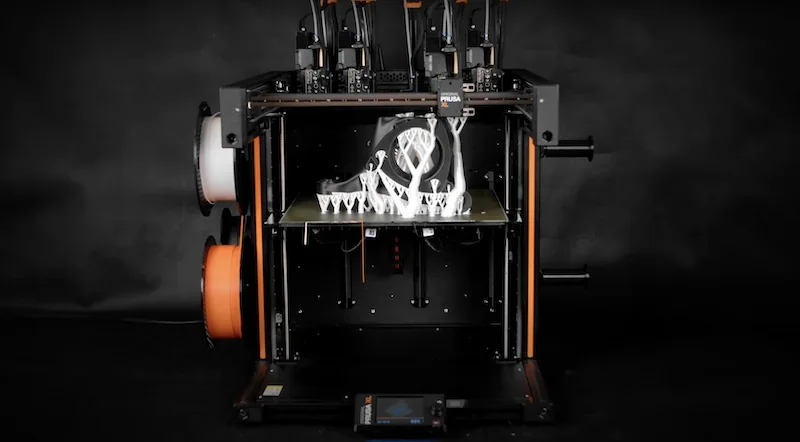

The Original Prusa XL supports multi-material printing—combining rigid and flexible filaments, costly filaments with cheap support materials (eg. CF-Nylon and ABS), or multiple colors—making it ideal for engineering, design, and manufacturing.

The Original Prusa XL offers high print quality with 0.05–0.30 mm layer heights and dimensional accuracy within 0.2 mm across its 360 mm³ print volume. Tests show strong repeatability: 0.0836 mm for squares, 0.0378 mm for hexagons, and 0.0599 mm for tubes. Circular accuracy is enhanced by PrusaSlicer’s Arc Fitting tool, with X/Y deviations under 0.0211 mm.

The Original Prusa XL uses CoreXY kinematics, Input Shaper, and Pressure Advance to balance speed and quality. This high-speed printing machine prints up to 400 mm/s, with standard speeds of 170 mm/s for walls and 200 mm/s for infill. Acceleration is set at 5000 mm/s² for travel and 4000 mm/s² for infill. In tests, the XL completed a print in 19:05, slightly slower than the BambuLab X1-Carbon (16:25) and Prusa MK4 (16:44) due to longer preheating, though overall speed is comparable.

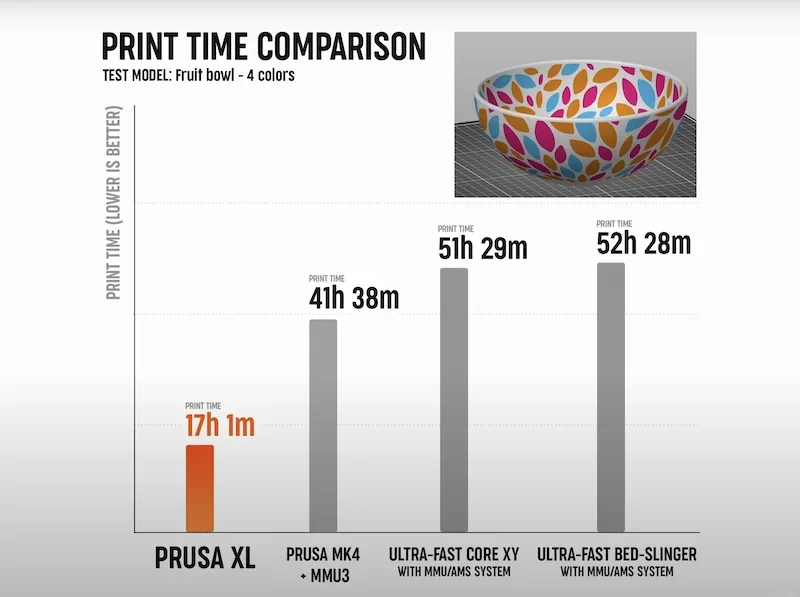

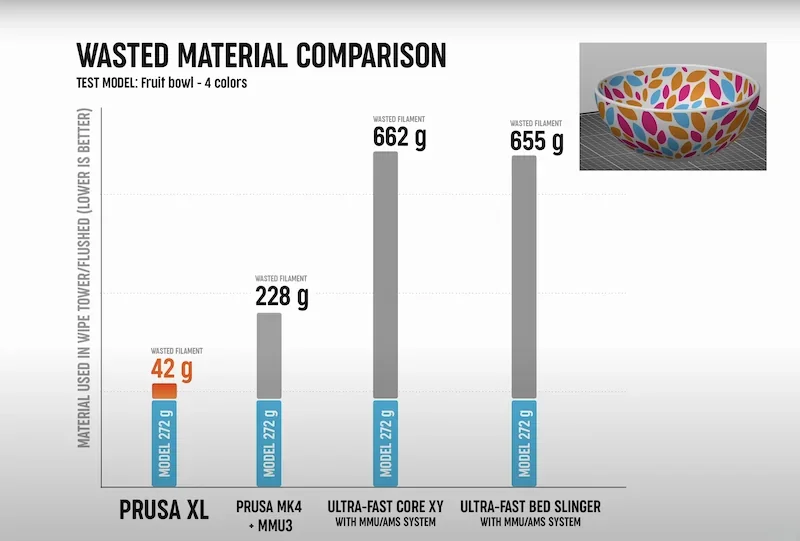

Multi-color tests show that Prusa XL is the fastest desktop printer on the market. A four-color dragon printed in 13h 51m—8 hours faster than on a Bambu Lab P1P. In the fruit bowl test, the XL finished in 17h 1m, far ahead of single-nozzle systems: Prusa MK4 + MMU3 (41h 38m), Bambu X1 Carbon (51h 29m), and Bambu A1 with AMS (52h 28m), thanks to its multi-toolhead design that eliminates filament swap delays.

The Prusa XL wasted only 42g of filament, almost zero-waste printing, thanks to the 5 tool system avoiding purges. In contrast, single-nozzle systems wasted significantly more: Prusa MK4 + MMU3 (228g), Bambu X1 Carbon (662g), and Bambu A1 with AMS (655g).

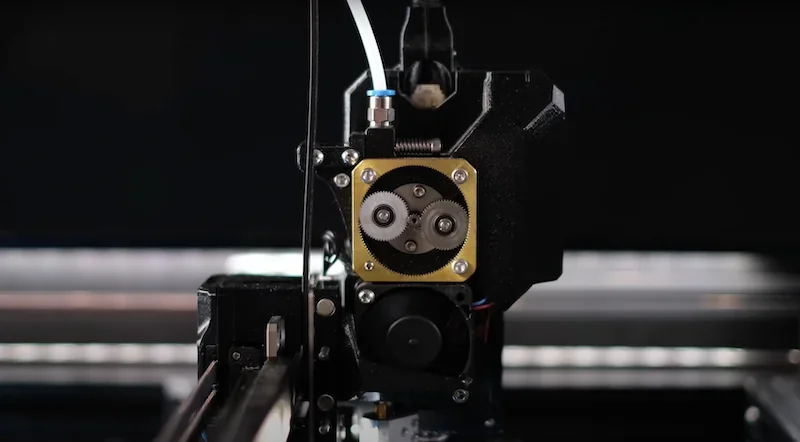

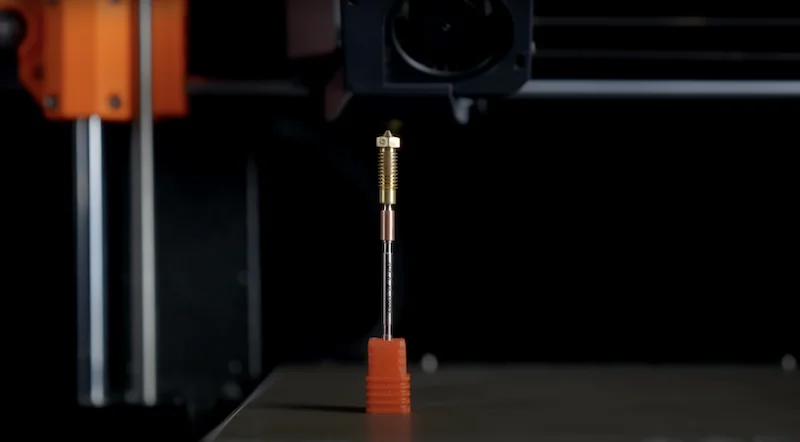

The Nextruder handles overhangs up to 75°—far above the 50° industry average—and cleanly prints 1.0 mm thread pitches (M6).

A multi-material anatomical heart model was printed in 33 hours with minimal defects and no color bleed.

A functional skeleton arm using PLA, PETG, and FLEX was printed with strong layer adhesion and no defects.

The Original Prusa XL’s 16-segment heatbed prevents heat deformation and maintains consistent print surface temperature.

The Loadcell sensor enables accurate first layers using physical detection instead of optical sensing. Each toolhead has an accelerometer for Input Shaper calibration, and fan RPM monitoring detects failures early.

The segmented heatbed and Phase Stepping technology create a stable print environment, earning the XL an 82.47 score on the 3D Printing Industry benchmark—above average for large-format printers.

Input Shaper reduces vibrations and ringing from fast direction changes, while Pressure Advance compensates for nozzle pressure buildup during acceleration/deceleration. Together, they enable high-quality prints at up to 400 mm/s.

The Original Prusa XL supports over 8 filament types using its direct drive Nextruder and all-metal hotend reaching 290°C. Compatible materials include PLA, PETG, TPU, PVA, PC, PP, CPE, and PVB. Its 10:1 geared extruder handles flexible filaments well, proven with Fiberlogy Fiberflex and Matterhackers TPU. The printer excels in multi-material prints, such as the Prusa Tire model, which used five materials: Black and White TPU FLEX, Orange PETG, Yellow PLA, and Gray PC.

The multi-material system reduces waste compared to single-nozzle setups, lowering material costs and expanding project possibilities.

Prusa offers a dedicated enclosure for advanced filaments like ASA, ABS, and HIPS. It stabilizes the environment, blocks drafts, reduces odors, and filters ultra-fine particles.

Even without an enclosure, the Original Prusa XL performs well with carbon-filled materials like PCCF (Polycarbonate Carbon Fiber).

Testing shows ASA can be printed on the open-frame XL without an enclosure, though some prints may warp.

The Original Prusa XL supports Prusament and third-party filaments without vendor lock-in. It detects loaded filament and prompts material selection for optimal settings. This open system allows cost-effective material use—e.g., PCCF for exteriors, PETG for infill—and strategic pairings like PLA supports with PETG parts for easy removal.

|

|

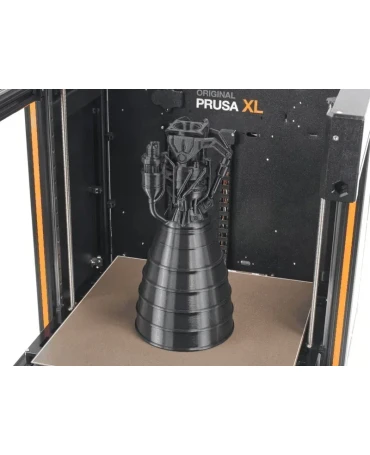

The Original Prusa XL offers a large 360 × 360 × 360 mm build volume, making it one of the largest multi-material desktop 3D printers. It can produce full-size models in a single print with smooth surfaces and consistent layers, thanks to its rigid frame and CoreXY vibration compensation.

| 3D Printer Model | Build Volume | Price |

|---|---|---|

| Original Prusa XL (single-head) | 360 x 360 x 360 mm | $2000+ |

| Prusa CORE One (single-head) | 250 x 220 x 270 mm | $1200+ |

| Bambu Lab X1C (single head) | 256 x 256 x 256 mm | $1000+ |

| Original Prusa XL (dual-head) | 360 x 360 x 360 mm | $3500+ |

| Flashforge Guider 3 Ultra (dual-head) | 330 x 330 x 600mm | $3500+ |

| Raise3D Pro3 Plus (dual-head) | 300 x 300 x 605mm | $5500+ |

| Original Prusa XL (5 toolheads) | 360 x 360 x 360 mm | $4100+ |

| Bambu Lab X1C (w/ AMS, 4 colors) | 256 x 256 x 256 mm | $1200+ |

| Prusa CORE One (w/ MMU3, 4 colors) | 250 x 220 x 270 mm | $1600+ |

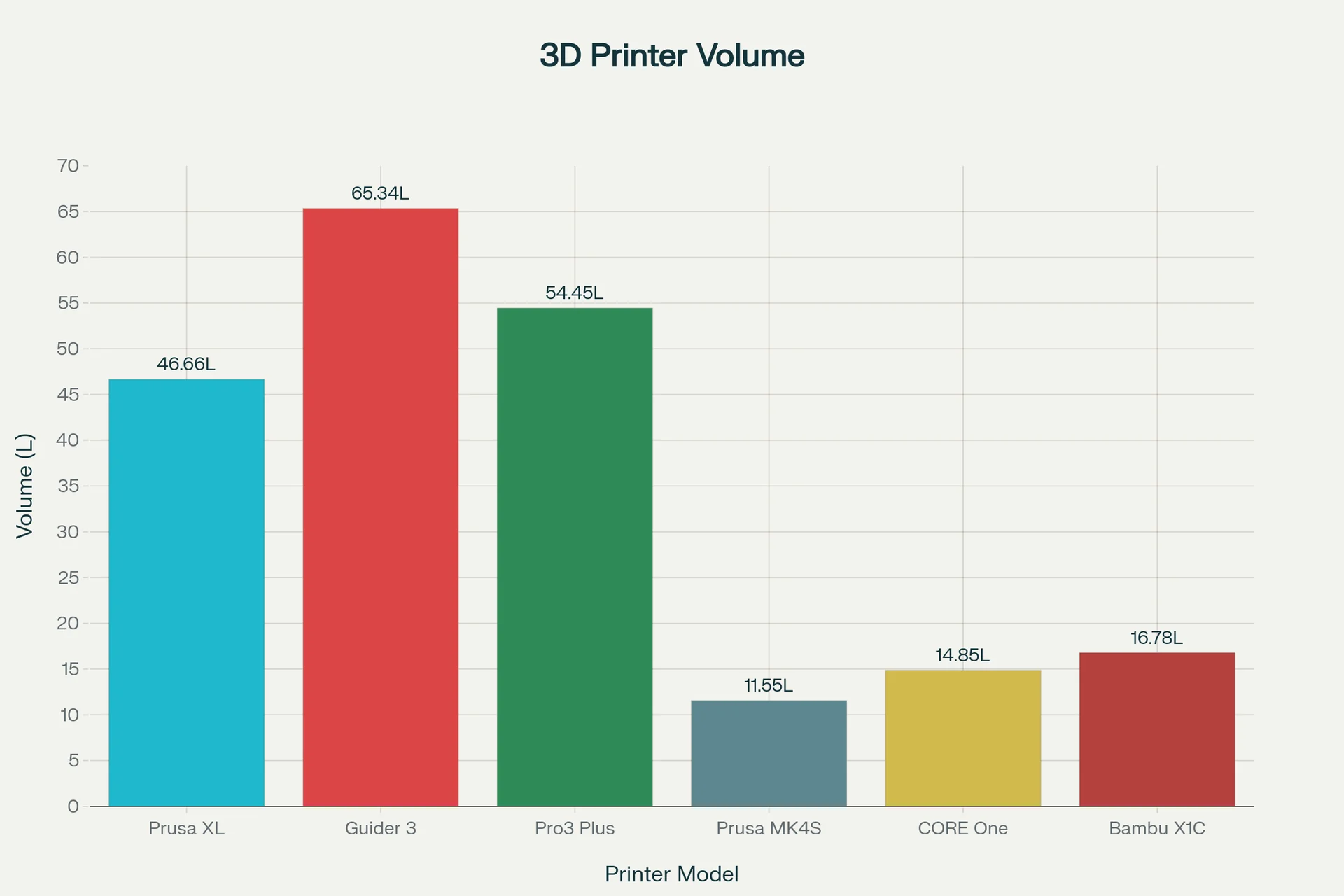

The Original Prusa XL offers top value among CoreXY printers, especially in the single-head category with a 46.66L build volume at $42.87/L—beating the Prusa CORE One ($80.81/L) and Bambu Lab X1C ($59.59/L). In the dual-head segment, it trades a higher $75.02/L for a cubic build area and waste-free tool-changing, compared to the larger height-focused Flashforge Guider 3 Ultra ($53.57/L) and the pricier Raise3D Pro3 Plus ($101.01/L). In multi-material use, the XL’s 5-toolhead setup at $87.87/L offers far less waste than purge-based systems like the Bambu X1C with AMS ($71.53/L) and Prusa CORE One with MMU3 ($107.74/L).

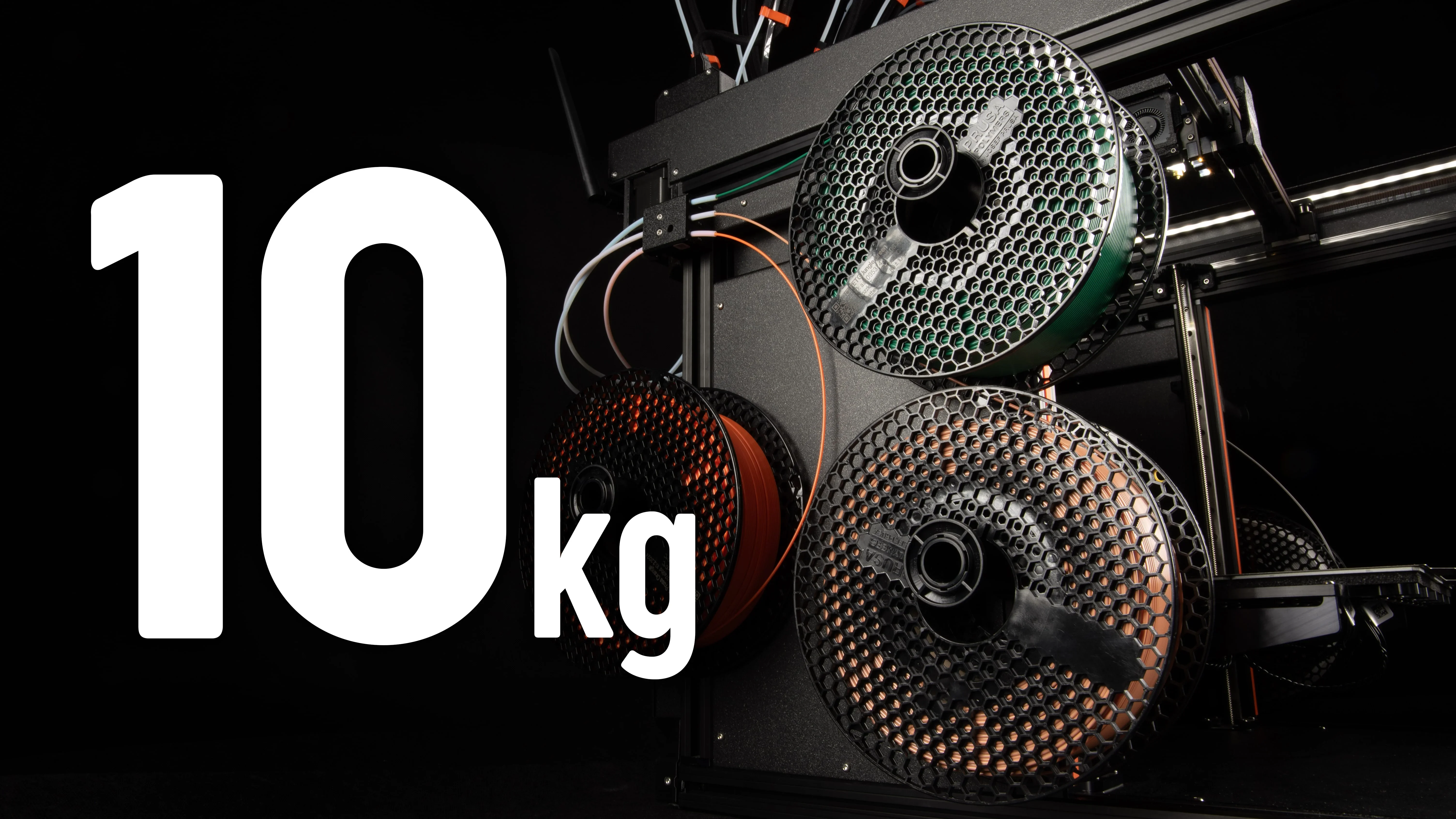

The Original Prusa XL delivers precise large-format printing across the entire print surface of its 360 × 360 mm platform, confirmed by perimeter tests showing flawless surface quality and first/last layers. With five toolheads, it supports up to five 2kg spools and can print 10kg objects uninterrupted using the Spool Join feature for automatic spool switching.

The Original Prusa XL offers 4 main controls:

Physical Controls:

Display Interface:

An LCD screen paired with the rotary knob provides access to:

During printing, the Tune menu allows real-time adjustments to speed and other parameters. The LCD shows all operational data, including temperatures and status.

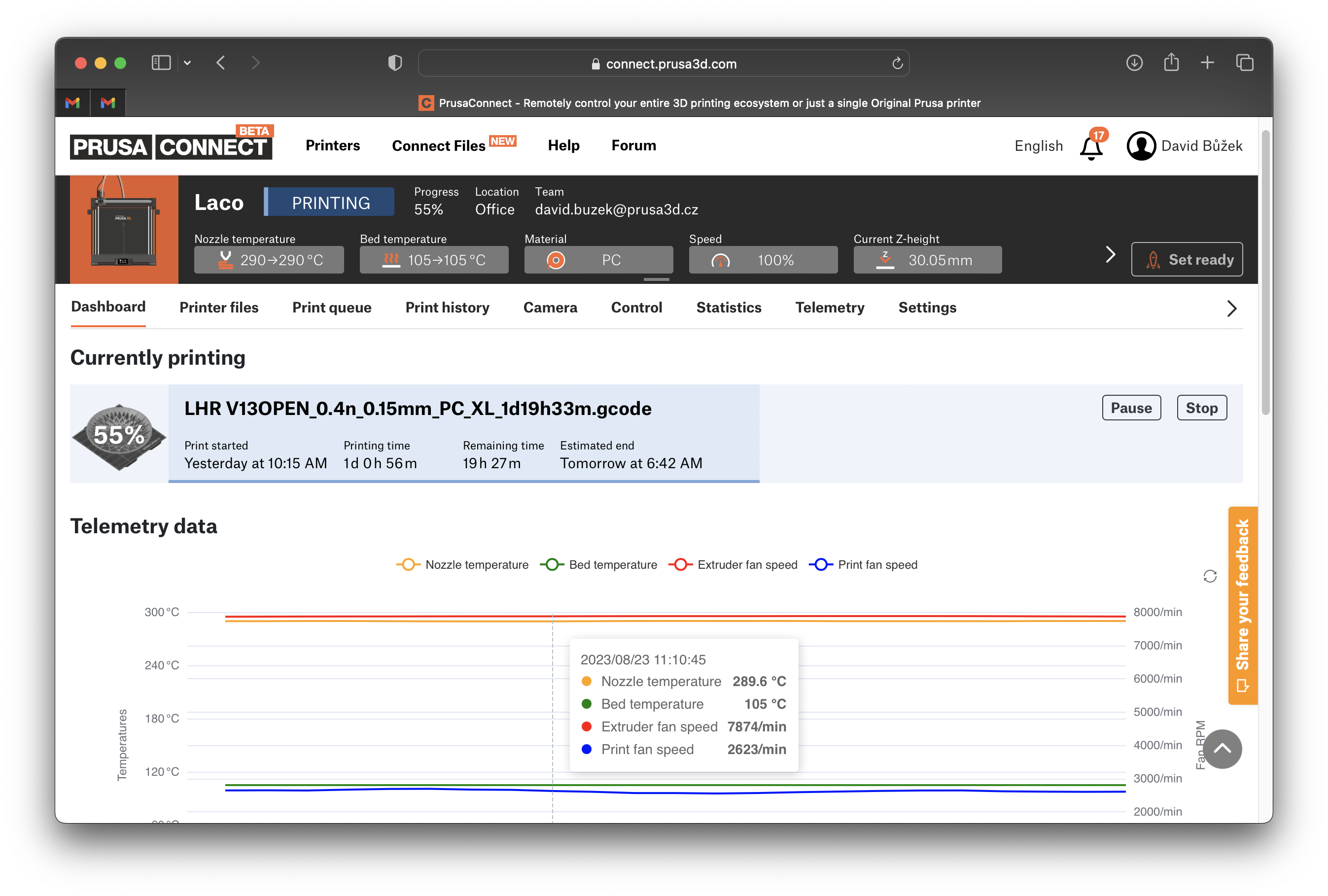

The Original Prusa XL supports USB, Ethernet, and Wi-Fi connectivity. It works with Prusa Link (local) and Prusa Connect (cloud), while also allowing full offline use. An NFC receiver enables instant connection with the device.

Through Prusa Connect, users can upload G-code, schedule their prints, monitor prints remotely, and control jobs via browser. Webcam integration allows visual monitoring with still image capture. Files can be transferred via USB or network, and firmware updates are available through USB, Prusa Connect, or the Prusa Mobile App—no physical access required.

The Original Prusa XL is optimized for PrusaSlicer, an open-source slicer for Windows, Mac, and Linux. It offers tiered settings—green (beginner), orange (normal), and red (expert)—to match user experience. Features include multi-color painting, paint-on supports, and fine-tuned print profiles. PrusaSlicer connects to the printer via Prusa Link for one-click printing and instant file transfers.

The Prusa ecosystem includes Prusa Link for local control and Prusa Connect for full remote management with 2GB of cloud storage, printer telemetry, and webcam support. The Prusa Mobile App adds mobile access. Firmware updates are delivered via USB or Prusa Connect, regularly adding new features. Input Shaper and Pressure Advance are built into the firmware, enhancing print quality and speed without third-party mods.

The Original Prusa XL has a sturdy C-shaped frame made of steel, aluminum, and PETG parts. Its open-front design allows easy access to the build plate and camera placement. Built-in top LED lighting improves print visibility. Despite its large build volume, this multi-material printer remains desktop-friendly, measuring 700 × 900 × 720 mm and weighing 25.3–33.7 kg depending on toolhead count.

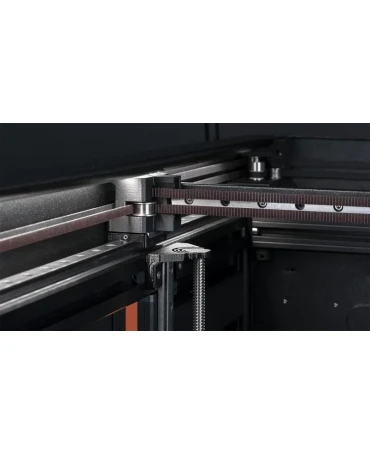

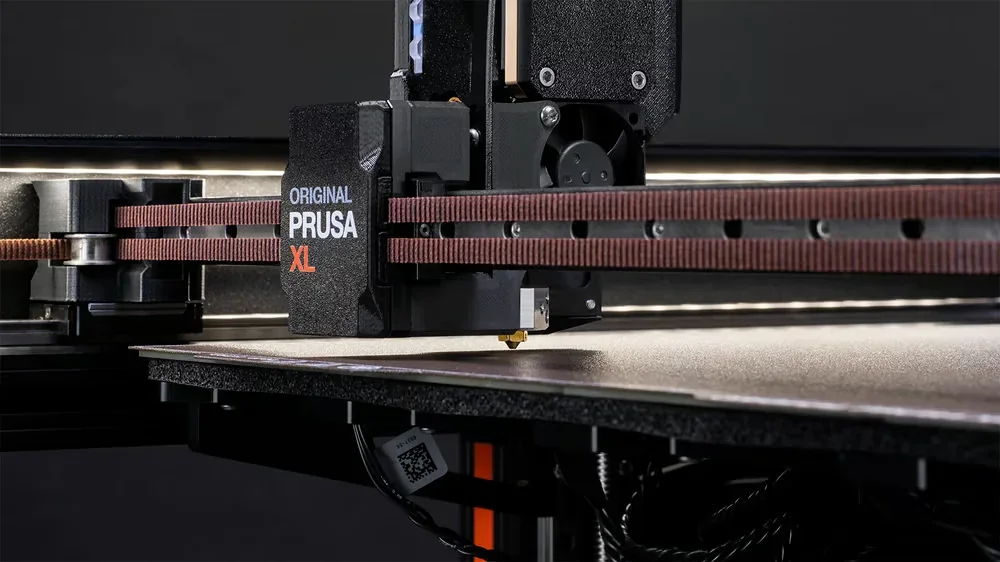

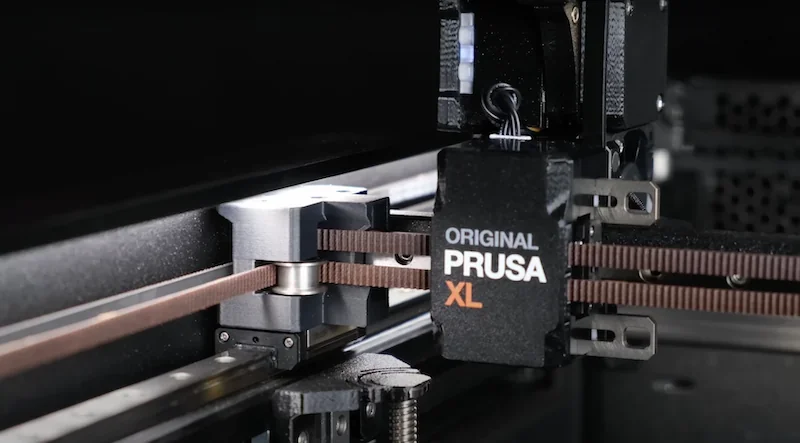

The Prusa XL uses a precision CoreXY system with high-grade linear rails and timing belts. The X-axis runs on a 12mm MGN-12H rail, supporting up to 780N dynamic and 1,100N static loads, with a flatness tolerance of ±0.01mm for accurate motion control.

The motion system uses 2GT belts (2246mm length, 6mm width, 2mm pitch). X and Y motors operate together, with the left motor driving X-axis movement and the right controlling Y-axis. Each belt has its own tensioning mechanism for independent adjustment.

The Prusa XL uses Trinamic TMC2130 drivers for quiet, precise motor control. Its 1.8° stepper motors provide 400 steps per revolution for smooth, artifact-free prints. The linear rails are low-maintenance, needing only occasional dry cleaning.

The Prusa XL’s heatbed has 16 individually controlled segments, each running at 24V with a 40W output.

Each 120mm heatbed tile functions as an independent heating zone. The system can heat all zones up to 120°C or selectively heat the print area to save energy.

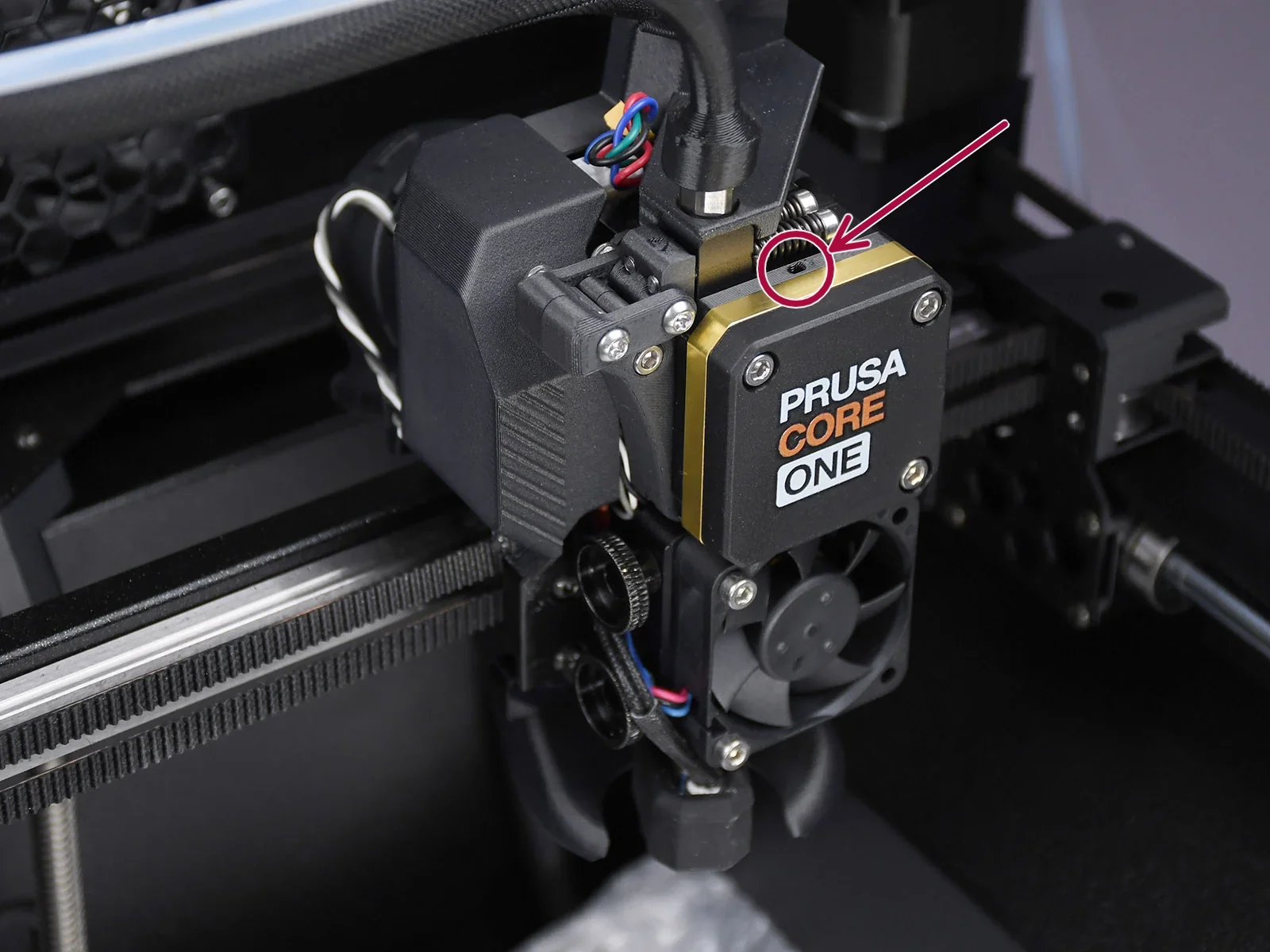

The Nextruder is a redesigned extruder with a 10:1 planetary gearbox for increased torque and control. It uses a central drive gear linked to the stepper motor, driving two satellite gears inside an outer ring.

The extruder includes two filament sensors—one at the PTFE inlet and one inside the extruder—for accurate detection and automatic retraction when filament runs out.

The all-metal hotend features an aluminum heatsink and reaches up to 290°C. Dual thermistors—one in the hotend and one in the heatbreak—enable precise temperature monitoring and heat creep detection.

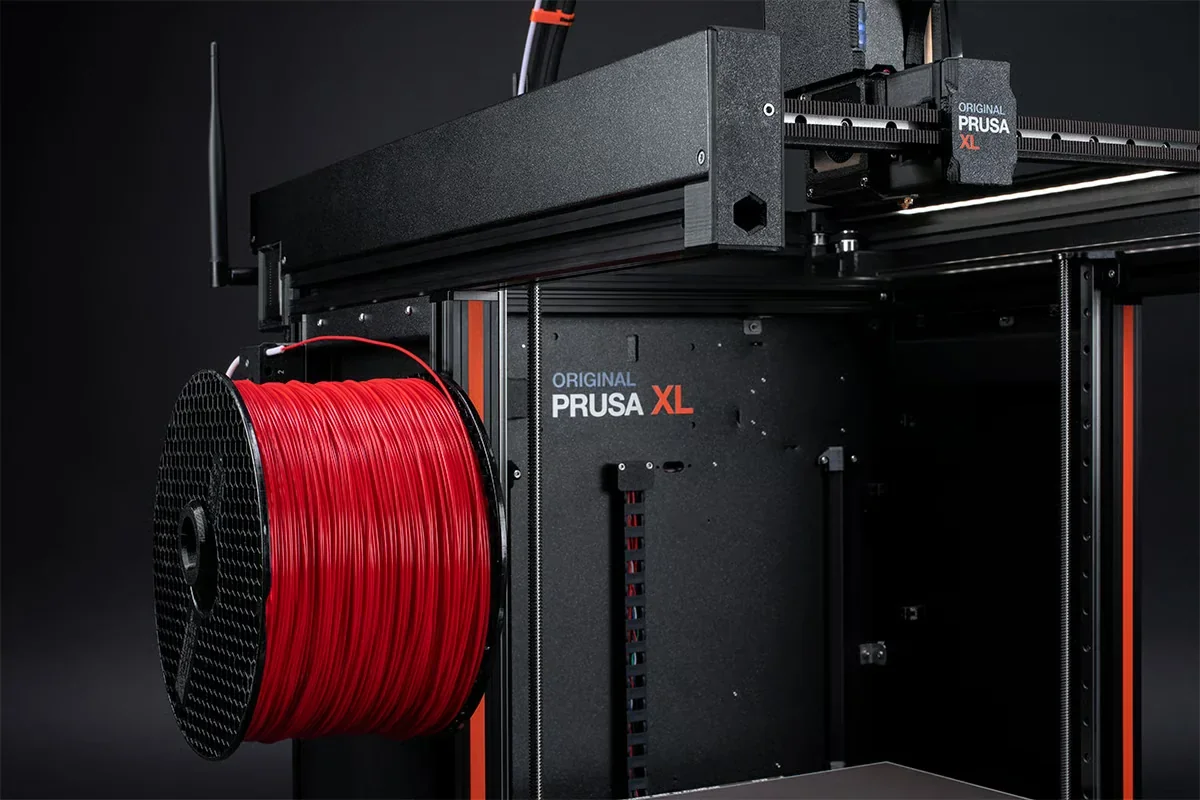

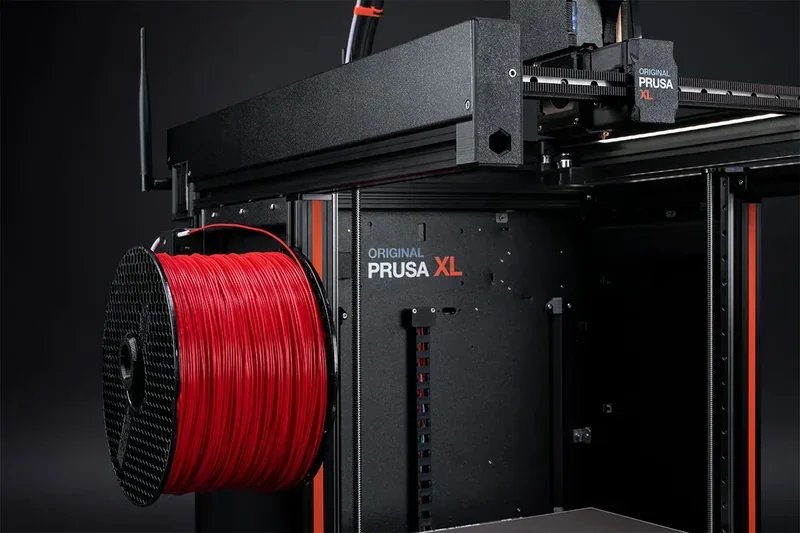

The XL holds up to five 2kg spools using built-in holders—three on the left, two on the right. Each toolhead feeds filament through clear PTFE tubing for easy visual monitoring.

The XL uses Prusa’s custom 32-bit xBuddy mainboard with STM32 ARM processors, replacing the older EINSY RAMBo. It includes safety features like dual voltage sensing, heater current monitoring, and auto power cutoff if limits are exceeded.

The xBuddy board offers full connectivity, including an ESP-01 Wi-Fi module, Ethernet, USB-C service port, I2C connections, and dedicated Nextruder ports.

Safety features include auto heater cutoff at 2.8A and full power shutdown above 15A. Hardware-based power-loss recovery stores print position for seamless resume. Four Semitec thermistors ensure precise temperature monitoring.

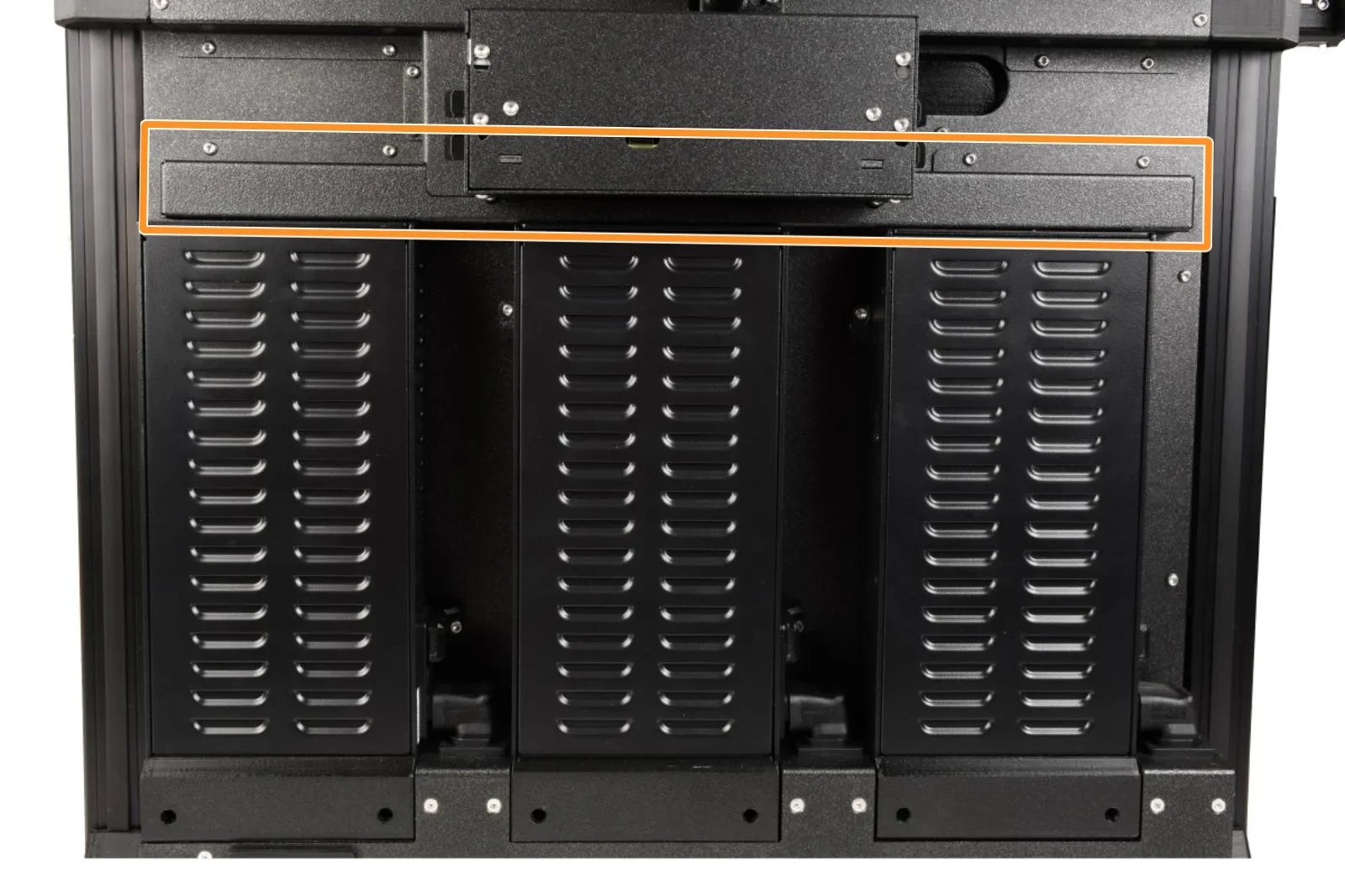

The Prusa XL uses Delta-made 240W, 24V power supplies rated at 10A each. Five-toolhead setups use three units (720W total), while single and dual-toolhead versions use two. Power supplies include F8AH250V fuses and custom Power Panic hardware for instant power-loss detection. Typical power use: 80W standby, 550W heating, 235W printing. Max draw can reach 600W with all toolheads and heatbed active. The modular setup enables load distribution, redundancy, and includes built-in safety and thermal protection.

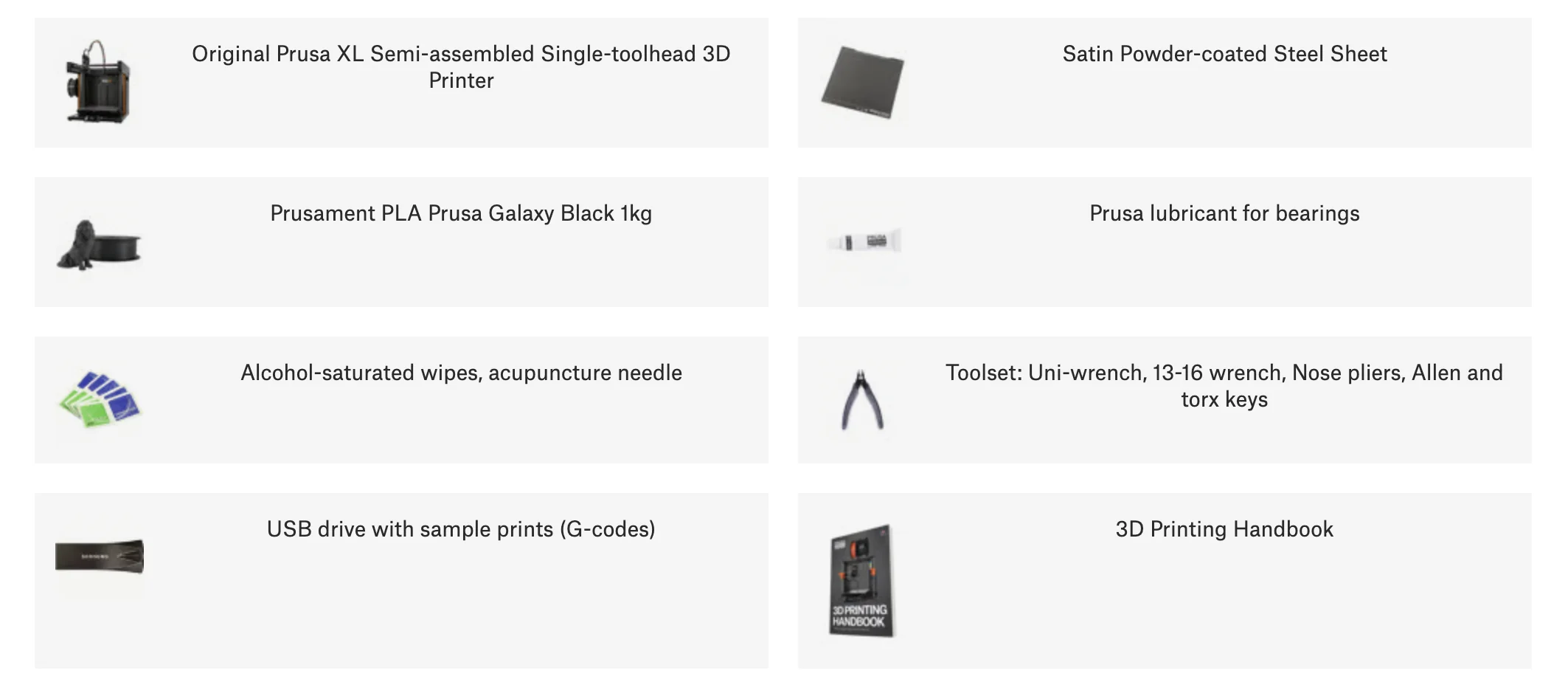

The Original Prusa XL comes in semi-assembled state or fully assembled version designed to print out of the box. The semi-assembled model requires toolhead and display installation; the fully assembled needs minimal setup. Each unit is factory-tested, ships with a checklist and sample print, and includes Prusament PLA Galaxy Black, making it ready to print immediately.

Please Note: Package contents are determined by the manufacturer and may change without notice. To confirm the current items included with this product, please contact a Top3DShop sales representative before placing your order.

| Accessory | Function | Price (USD) | |

|---|---|---|---|

| Multi-Tool Upgrades for the Original Prusa XL | |||

| Original Prusa XL Single-Tool to Dual-Head Upgrade | Upgrade that adds a second toolhead to an Original Prusa XL Single-Tool configuration, enabling two-toolhead (two-material) printing on the same printer. | $759 |  |

| Original Prusa XL Single-Tool to Five-Head Upgrade | Upgrade that adds four additional toolheads to an Original Prusa XL Single-Tool configuration, expanding the printer to five toolheads for five-material printing. | $2,119 |  |

| Original Prusa XL Dual-Head to Five-Head Upgrade | Upgrade that adds three additional toolheads to an Original Prusa XL Dual-Head configuration, expanding the printer from two toolheads to five toolheads for multi-material printing. | $1,529 |  |

| Enclosure and Monitoring Tools | |||

| Original Prusa XL Enclosure | Enclosure that creates a controlled printing environment for advanced/technical materials by reducing exposure to ambient drafts and stabilizing the area around the printer. | $1015 |  |

| Buddy3D Cam | Remote print monitoring camera for observing prints while the printer is operating. | $70 |  |

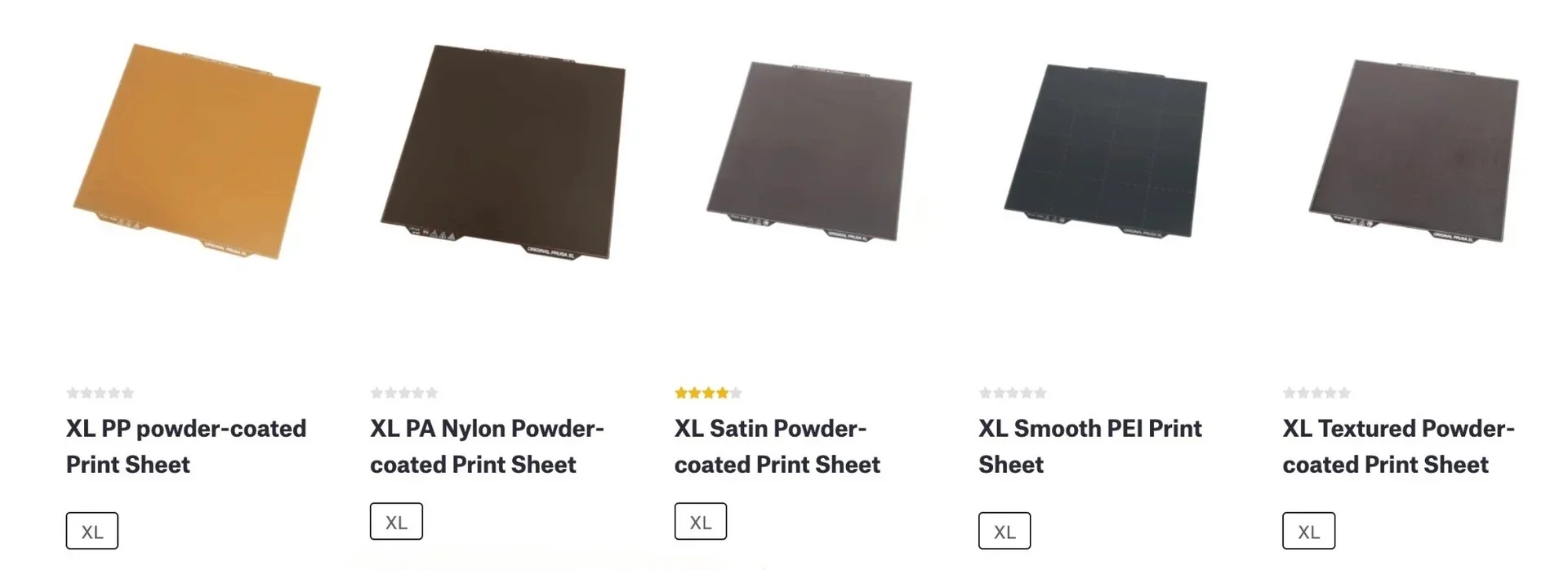

| Print Sheets and Build Surfaces for the Original Prusa XL | |||

| XL PP powder-coated Print Sheet |

Removable spring-steel, powder-coated print sheet for polypropylene-based filaments, especially Prusament PP Carbon Fiber Black. PP typically adheres poorly to textured or satin sheets, so this sheet uses a special finish to boost adhesion and is intended to be ideal for Prusament PP. It has a lightly textured surface similar to a satin sheet. Care: never clean with acetone, which can damage the coating and reduce adhesion. |

$169 |  |

| XL Satin Powder-coated Print Sheet |

Powder-coated spring-steel sheet with a lightly textured matte (satin) finish, positioned between smooth and textured sheets in printing behavior. Offers balanced, reliable adhesion—especially for PLA and PETG. Compatible with a wide range of filaments (including ABS, ASA, FlexFill 98A, and Polycarbonate), and most can be printed without a separation layer like glue. For Polycarbonate, use a glue-stick layer to prevent possible damage to the sheet. |

$130 |  |

| XL Textured Powder-coated Print Sheet |

Textured, powder-coated spring-steel sheet that gives prints a distinct textured bottom surface. Durable and hard to damage: the powder coating is on metal, which can dissipate heat during a nozzle crash. The texture also hides most tool marks—scratches usually only affect the tops of the bumps and typically won’t show on the print. Care: never clean with acetone, which can cause microfractures and degrade the surface. |

$122 |  |

| Material and Print Sheet Bundles | |||

| Prusa XL - Prusament PP-GF (NFC) + XL PP Print Sheet BUNDLE |

Bundle includes Prusament PP Glass Fiber Natural (850g, NFC) and the XL PP powder-coated Print Sheet. The PP filament is lightweight with excellent heat and chemical resistance; added glass fibers improve dimensional stability (little to no warping) and strength, but they’re highly abrasive—use a hardened nozzle. It prints with a rough matte finish, can be colored from its translucent white base, and isn’t ideal for very fine details. The included PP sheet is made to boost adhesion for polypropylene-based filaments compared with satin or textured sheets. |

$240 |  |

| Nozzles, Hotends, and Adapters | |||

| Prusa Nozzle brass CHT |

Brass CHT nozzle for a Prusa-compatible nozzle system. Sold as a replaceable wear part to restore nozzle performance or to switch nozzle size/configuration. Available in 0.4 / 0.6 mm sizes. |

$44 |  |

| Prusa Nozzle brass |

Brass nozzle for a Prusa-compatible nozzle system. A replaceable wear part used to maintain extrusion quality or to change nozzle size/configuration. Available in 0.25 / 0.3 / 0.4 / 0.5 / 0.6 / 0.8 mm sizes. |

$28 |  |

| Prusa Nozzle ObXidian | ObXidian nozzle for a Prusa-compatible nozzle system. Used as a replaceable nozzle option. Available in 0.4 / 0.5 / 0.6 mm sizes. | $75 |  |

| E3D Prusa Nozzle: DiamondBack |

Premium nozzle co-developed with E3D for extreme abrasion resistance and broad compatibility with fibre-, metal-, and ceramic-filled filaments. It uses a polycrystalline diamond (PCD) tip: many diamond crystals bonded in a binder matrix, keeping diamond-level hardness while being less brittle than single-crystal diamond. The diamond is a solid insert—not a coating—for higher precision and long service life. Available in 0.4 / 0.6 / 0.6 mm sizes. |

$189 |  |

| E3D Prusa Nozzle: High Flow Brass |

E3D High Flow brass nozzle (available in 0.4 and 0.6 mm). Replaceable nozzle option for a high-flow setup, with size variants selectable on the product page. |

$50 |  |

| E3D Prusa Nozzle: High Flow ObXidian™ |

E3D High Flow ObXidian™ nozzle (available in 0.4, 0.5, and 0.6 mm). Replaceable nozzle option for a high-flow setup. |

$91 |  |

| Standard Nozzle Kit |

Kit of standard brass nozzles for a Prusa-compatible nozzle system, meant for easy replacement and for switching nozzle sizes. Includes 0.25, 0.4, 0.6, and 0.8 mm brass nozzles, plus a brass nozzle brush and CNC Kitchen nozzle cleaning wires. |

$138 |  |

| Nextruder Hotend brass |

Replacement Nextruder hotend assembly used to restore extrusion performance or switch hotend size/configuration. Available in 0.4, 0.6, and 0.8 mm variants. Includes one brass nozzle (selected size), Nextruder heaterblock, 40 W heater (120 mm set), and an NTC 100k thermistor (115 mm). |

$72 |  |

| Nextruder Hotend brass High Flow |

Replacement Nextruder hotend assembly in a brass High Flow configuration. Used to swap in a complete hotend for high-flow printing. Includes a Prusa brass CHT nozzle (selected size), Nextruder heaterblock, 40 W heater (120 mm set), and an NTC 100k thermistor (115 mm). Available in 0.4 and 0.6 mm variants. |

$83 |  |

| Nextruder V6 Nozzle Adapter |

Adapter that lets you use V6-style nozzles with the Prusa Nextruder nozzle system. Install your V6 nozzle together with this adapter to convert between the nozzle standards. Includes one Nextruder V6 Nozzle Adapter; V6 nozzle not included. |

$28 |  |

| Prusa Nextruder Silicone sock - set | Set of silicone socks for the Prusa Nextruder hotend area, designed to fit around the hotend/heater-block region. Install only when the nozzle and heaterblock are clean, and never while the printer is hot or running (burn risk). Includes 3 Nextruder socks. | $8 |  |

| Toolhead Parking Components | |||

| Parking plate set |

Replacement set of parking plates for the Original Prusa XL toolhead parking/docking system, used at the toolhead parking positions. Includes 5 nozzle seals and 5 parking plates. |

$40 |  |

| Maintenance, Filtration, and Spare Parts | |||

| Spare Parts Bundle (XL Single Tool) |

Includes:

|

$259 |  |

| Spare Parts Bundle (XL Multi-Tool) |

Includes:

|

$429 |  |

| HEPA filter |

Replacement HEPA filter element for compatible air-filtration setups. Estimated lifespan is at least 600 hours of runtime. Includes 1× HEPA filter. |

$41 |  |

| Lubrication set |

Includes a dosing needle (SSS15 2), a cartridge with manual piston (2/2.5 mm), Microlube GL 261 lubricant (20 g), and two nitrile gloves. |

$35 |  |

The Original Prusa XL is engineered for long-term reliability, with a process capability score of 3.84 — well above the optimal threshold of 2.0 — based on 150 consecutive test prints, confirming its consistency for high-volume use.

As Needed

Every 50–100 Hours

Every 100–200 Hours

Every 200–300 Hours

The Original Prusa XL includes full warranty coverage and support from Prusa Research.

Warranty terms:

Assembled units are covered for both parts and assembly. Coverage excludes consumables and damage from misuse or unauthorized modifications.

Prusa offers 24/7 live chat support in seven languages, even outside warranty periods or for third-party purchases. Their knowledge base features detailed guides and videos. Firmware updates continue for years post-release—previous Original Prusa 3D printers received six years of updates.

Top3DShop provides additional pre- and post-sales support, including setup and troubleshooting assistance. For warranty claims, Top3D coordinates directly with Prusa. Optional 1- or 2-year extended warranties can be added at purchase.

Full warranty terms: https://help.prusa3d.com/article/warranty_2288

| Service package | What it is | Price |

|---|---|---|

| 3D Printing and Modeling for Beginners (XL) | Intro course for absolute beginners on the Original Prusa XL: downloading models, PrusaSlicer basics, basic 3D modeling, and some maintenance (useful for many printers). | Free |

| +1 Year of Extended International Warranty (1 pc) | Extends standard warranty + 24/7 support with free repairs and replacement parts for 1 additional year. | $379 |

| +2 Years of Extended International Warranty (1 pc) | Extends standard warranty + 24/7 support with free repairs and replacement parts for 2 additional years. | $629 |

| 3D Modeling in Autodesk Fusion | Beginner Fusion course focused on 3D-printing-relevant tools, includes 4 sample projects with tips/tricks. | $24.99 |

| PrusaSlicer Masterclass – Beginner to Advanced | PrusaSlicer course from workflow basics to advanced features; includes 4 sample projects and quizzes. | $24.99 |

The Original Prusa XL base model's price is $2,720.00, including a 360 × 360 × 360 mm build volume, Input Shaper, and automatic mesh bed leveling. The dual-tool version costs 15–20% more, enabling dual-material printing with two independent Nextruder toolheads. The five-tool configuration, priced 35–40% higher, allows automatic switching between five materials or colors in a single print using advanced tool parking and positioning.

All versions share the same steel frame, 32-bit electronics with Wi-Fi, and full warranty. Price differences reflect added toolheads, expanded electronics, and firmware for multi-tool operation.

Update your browser to view this website correctly. Update my browser now