The PioCreat G12 is a large-format, industrial-grade 3D printer using Fused Granulate Fabrication (FGF) to process thermoplastic pellets instead of filaments, offering 60% lower material costs. With a massive 1200×1000×1000mm build volume and high-flow screw extrusion delivering 3kg/hour at ±0.5mm accuracy, it enables full-scale, single-piece production across sectors like automotive and aerospace. Compatible with over 15 thermoplastics — including shredded recycled plastic and composite materials — it features a 450°C nozzle, open-source material flexibility, touchscreen controls, Wi-Fi/USB connectivity, predictive failure prevention, and robust industrial design. Weighing 750kg with dual Z-axis servo control, it comes with 25kg of starter material, upgrade options, and structured maintenance support from Piocreat 3D.

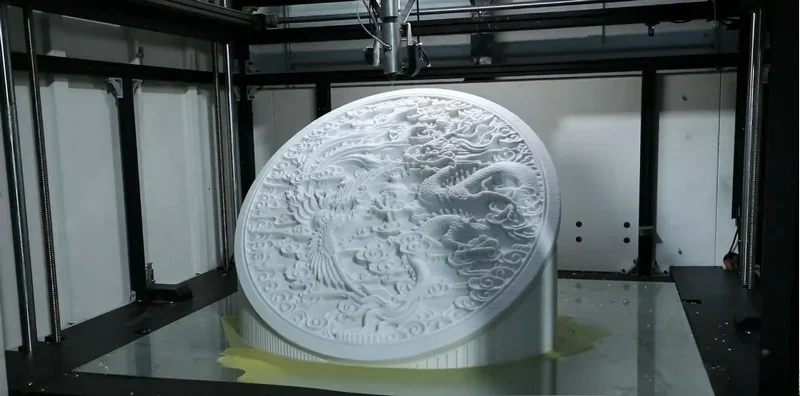

The PioCreat G12 delivers high-precision, industrial-grade 3D printing using FGF technology, achieving ±0.5mm accuracy and up to 10X cost savings over filament systems. With layer thicknesses from 0.2mm to 2.0mm and nozzle sizes from 0.6mm to 4.0mm, it supports both detailed and high-volume prints. Its high-throughput extrusion system delivers up to 3kg/hour — over 60X the output of standard FDM printers — while supporting recycled pellets to cut material costs by more than 60%. A standout example includes a complex 750×750×50mm dragon carving printed in 65 hours.

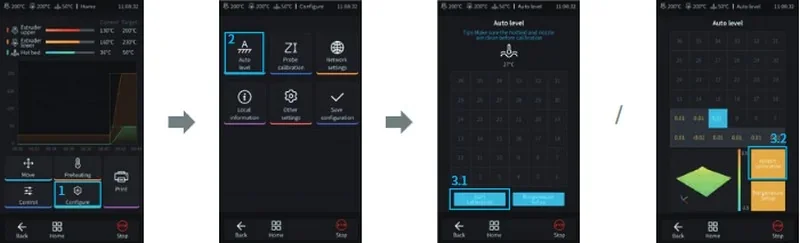

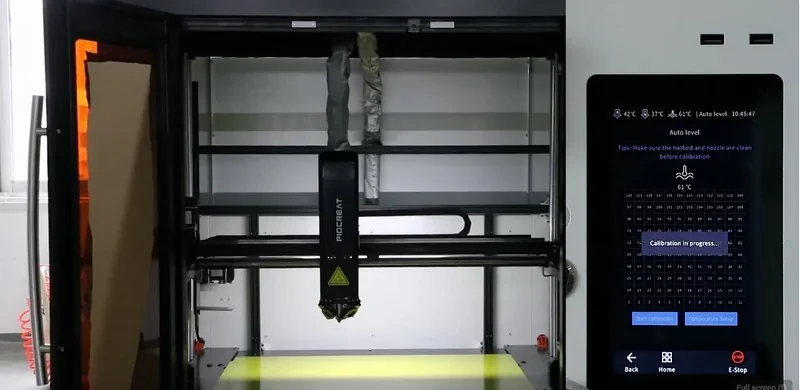

Mechanical features like a 120-point laser leveling system, dual Z-axis servo motors, hot bed zoning, and a quick-release platform enhance accuracy, stability, and ease of use across large-format prints.

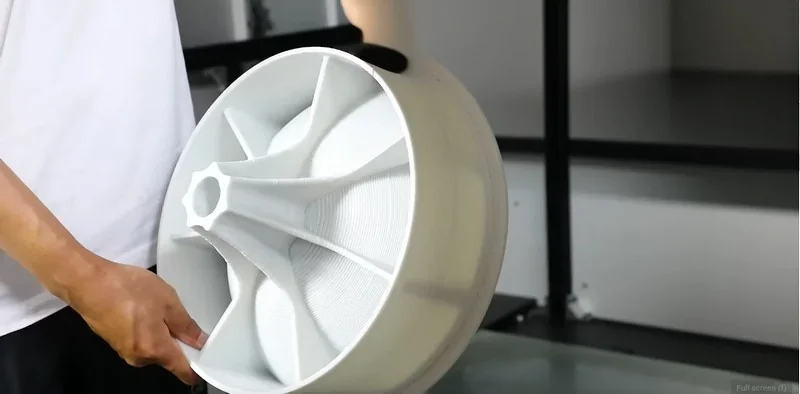

3D Print Sample:

3D Print Sample:

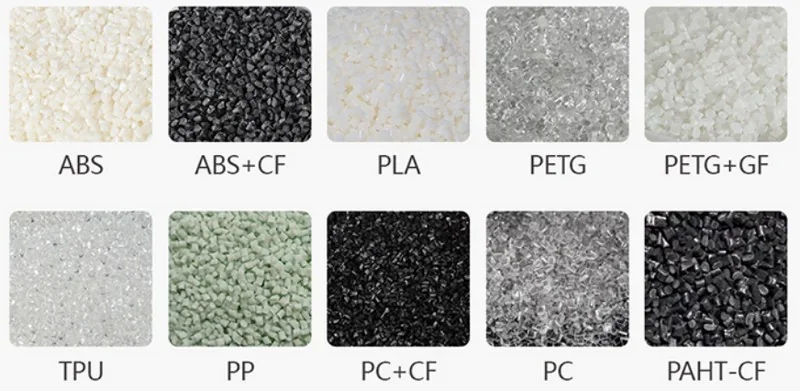

The PioCreat G12 FDM 3D printer supports over 15 plastic pellets, including PLA, ABS, PETG, Nylon, TPU, and reinforced composites like carbon and glass fiber variants. The direct pellet feeding system removes the need for filament and allows on-the-fly pellet changes for adjusting properties or colors. Its open-source design accepts third-party virgin or recycled pellets (2–5mm), eliminating the need for proprietary materials. Key hardware features — such as a 450°C high-temp nozzle, screw extrusion system, and a 130°C heated bed —ensure consistent performance and adhesion.

PETG 3D Print Sample: Chair

PETG + 10% Glass Fiber 3D Print Sample: Prototype 321 x 321 x 183 mm tyre sample printed in 12 hours.

PETG 3D Print Sample: A decorative vase with a 0.2mm layer thickness, external contour printing speed of 20mm/s, and bottom solid filling of 30mm/s.

PETG 3D Print Sample: A 750x750x50mm sculpture printed in 65 hours.

PETG and Glass 3D Fiber 3D Print Sample: a 2200 mm reconstruction of Michelangelo's David Sculpture.

PETG 3D Transparent Parts for House Decoration:

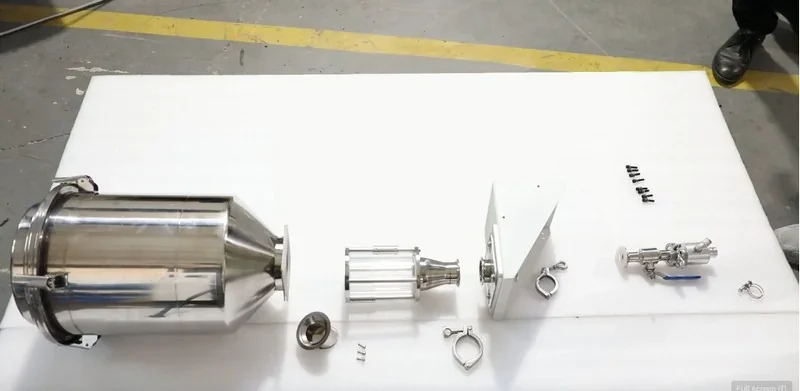

3D Print Sample: 3D Printed Tube.

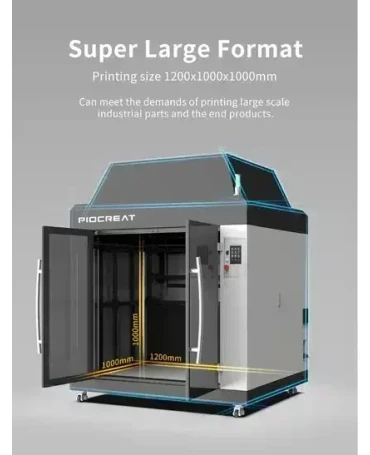

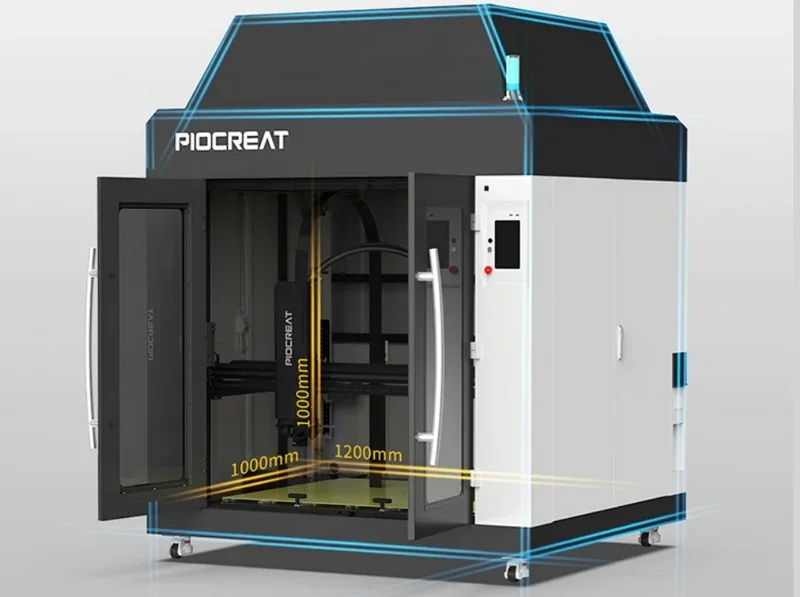

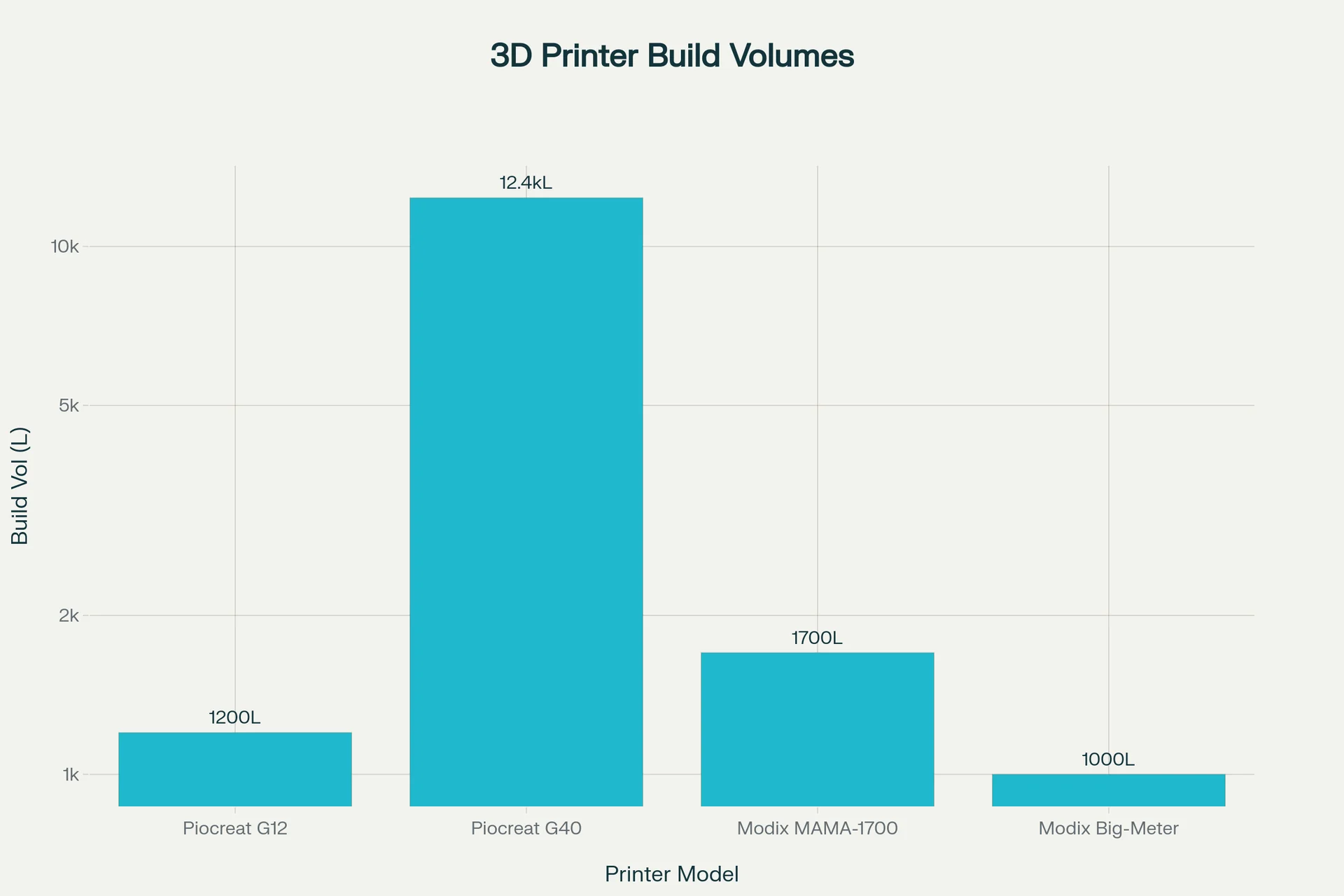

The large-format Piocreat G12 offers a 1200 x 1000 x 1000 mm build volume — 1,200 liters — enabling single-print production of large parts, prototypes, and furniture. It ranks among the largest enclosed FGF 3D printers for industrial use.

| Feature | Piocreat G12 | Piocreat G40 | Modix MAMA-1700 | Modix Big-Meter |

|---|---|---|---|---|

| Manufacturing tech | FGF (pellet) | FGF (pellet) | FGF (pellet) + FFF (filament) | FFF (filament) |

| Build volume (mm) | 1200 × 1000 × 1000 | 3725 × 2500 × 1330 | 1700 × 1000 × 1000 | 1000 × 1000 × 1000 |

| Max flow rate | 3 kg/h | 25 kg/h | Pellet: ≈3 kg/h; Filament: ≈0.5 kg/h | Filament: ≥0.5 kg/h (Griffin Ultra) |

| Max nozzle temp | ≤ 450 °C | ≤ 450 °C | Up to 500 °C | Up to 500 °C |

| Bed / workbench heat | ≤ 130 °C | ≤ 120 °C | ≤ 110 °C | ≤ 110 °C |

| Nozzle diameter (mm) | 0.6–4 | 3–8 | Pellet: 3 & 5 (1 add-on); Filament: 1.6 (smaller add-ons) | 0.4–1.6 (w/ packs up to 1.6; hardened options) |

| Layer height (mm) | 0.2–1.5 | 0.2–1.0 | Pellet: up to multi-mm (e.g., 1.5–3.0); Filament: high-res w/ small nozzles | Up to ~1.2 |

| Price (USD) | from $44,999 | from $450,000 | from $47,000 | from $17,850 |

| Assembly | Assembled & factory-tested | Assembled & factory-tested | Self-assembly kit (flat-pack) | Self-assembly kit |

| Enclosure | Enclosed | Enclosed | Included | Included |

Physical Controls (4 categories):

The Piocreat G12 supports USB, Ethernet, and WiFi for remote control via IP, enabling easy monitoring in industrial settings. It includes a USB port and SD card slot for direct file transfer.

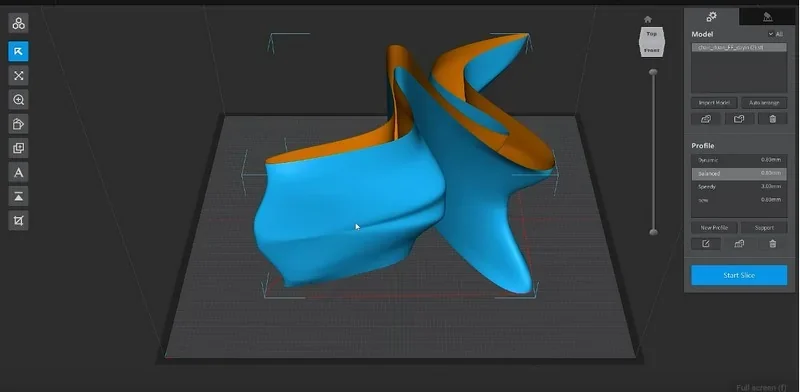

The PioCreat G12 features the proprietary PioCreat Slicer optimized for FGF printing, with dedicated pellet material profiles, G-code previews, and layer simulations, while also supporting Cura and Simplify3D for workflow flexibility. As of 2025, new G12 purchases include Dragon by Helio Additive — a physics-based simulation and slicing software that improves print quality by predicting cooling, bonding, and stress. It automates parameter adjustments, often boosts speeds by 20–30%, and optimizes G-code for high-quality, hands-off pellet printing.

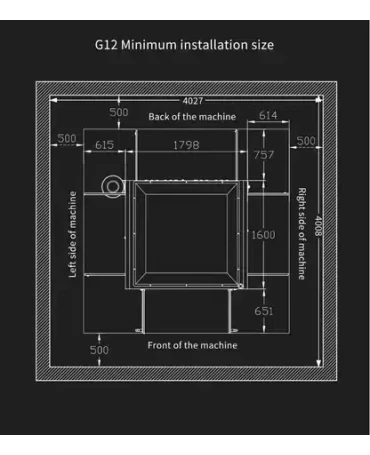

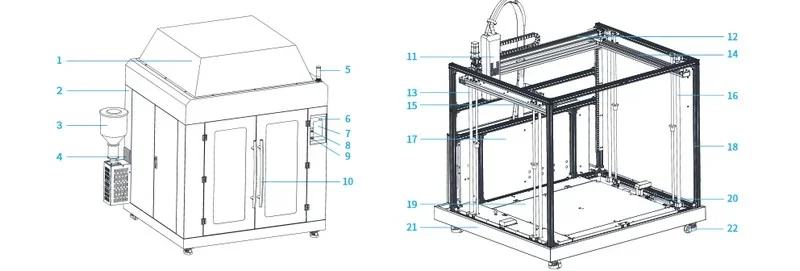

The PioCreat G12 features a heavy-duty industrial enclosure measuring 2135×1775×2305mm and weighing 750kg, designed for professional manufacturing use. Its fully enclosed chamber includes front-access doors, viewing windows, a sheet metal shield, and an integrated top-mounted storage hopper. Safety features include a three-color warning light, internal lighting controls, and an emergency stop button.

The PioCreat G12’s motion system features dual Z-axis lifting modules with powerful, custom servo motors for stable, precise movement across its large 1200×1000×1000mm build area. A high-precision guide belt module and coordinated X/Y-axis systems ensure consistent positioning and motion control under high-load conditions.

The G12 FGF offers a 1200 x 1000 x 1000 mm build volume with a heated fiberglass platform reaching up to 130°C. The platform is secured with M6x10+15x15 screws, which must be removed before printing to avoid nozzle collisions. It includes automatic bed leveling via a CR-TOUCH probe.

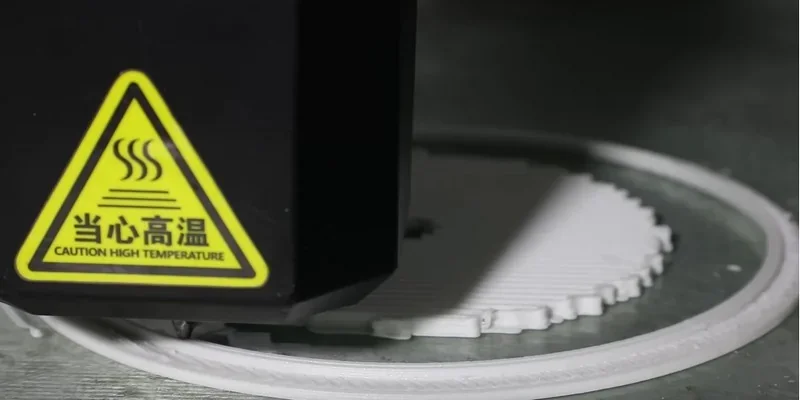

The G12 utilizes a single-nozzle screw rod pellet extrusion system for granular materials, with interchangeable nozzles from 0.6 mm to 4.0 mm. The hotend reaches up to 450°C and features dual heating zones — the lower zone near the nozzle is set 10°C higher than the upper zone for uniform material deposition.

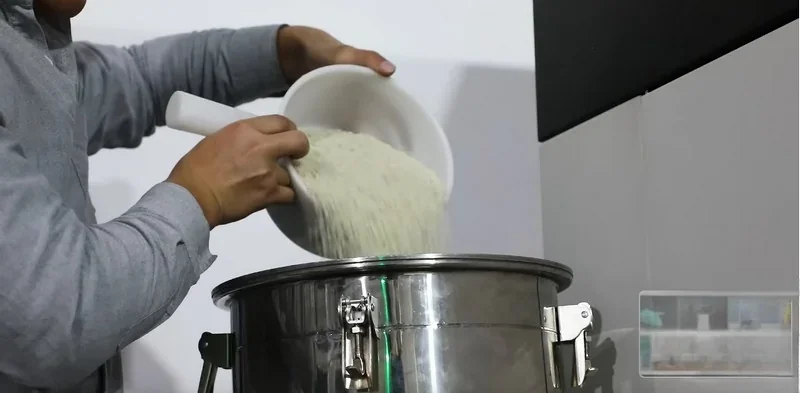

The G12 FGF is built for 2.0–5.0 mm granular materials, not filament. A top-mounted hopper feeds pellets through a pneumatic conveyer to the screw extruder. A photoelectric sensor monitors material levels to prevent printing with an empty hopper.

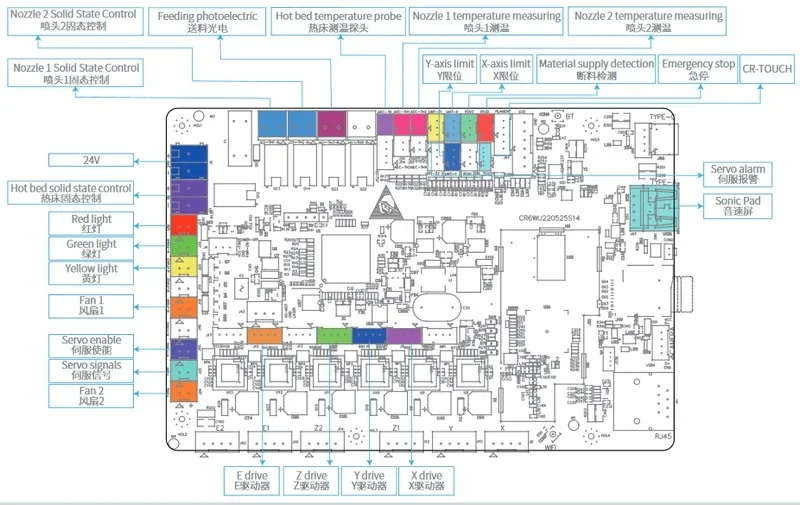

The mainboard of the Piocreat G12 is the CR6WU220525S14, a feature-rich controller supporting dual extruders, servo motors, auto-leveling, and multiple industrial connectivity options.

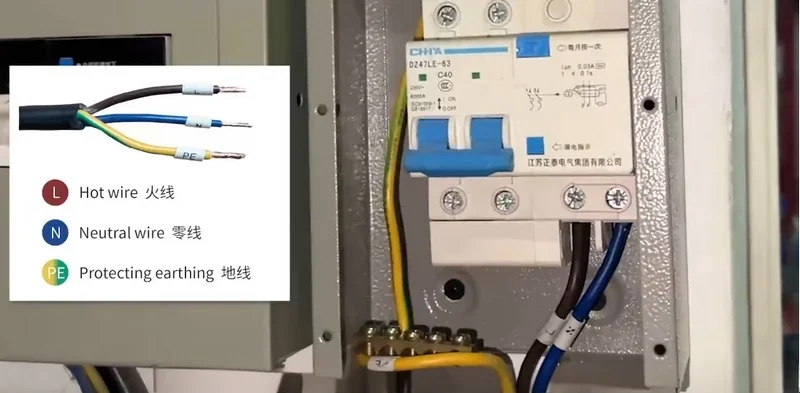

The G12 FGF runs on 220V AC with a rated power of 7000W. It requires a 3-core, 4 mm² power cable connected to a circuit breaker in the machine’s cabinet and plugged into a grounded outlet rated for at least 30A.

The Piocreat G12 package includes:

Fully Assembled Printer:

Tools & Setup Accessories:

Essential Printing Components:

Starter Materials:

Platform Management Hardware:

The Piocreat G12 ships fully assembled, needing minimal setup. It includes a toolbox with required hardware, a USB drive with setup guides and videos, a starter pellet pack for immediate testing, and a funnel for easy loading. All components are built for industrial reliability and durability.

Note: Package contents may vary. Contact a Top3DShop sales representative to confirm included items before ordering.

The PioCreat G12 requires over 12 maintenance tasks across daily, weekly, and periodic intervals to ensure print quality and extend lifespan.

Daily:

Weekly:

Periodic:

Additional:

The PioCreat G12 comes with a 1-year limited warranty covering material defects and workmanship for genuine products purchased with valid proof. It excludes consumables and damage from misuse, modifications, or environmental factors.

User-caused damage or out-of-warranty repairs require customer-paid service, including parts, packaging, and shipping. Support is available via email at after@piocreat3d.com and phone at +86 0755-2103-9743, with service based in Shenzhen, China. Link to the support guide: https://www.piocreat3d.com/3d-printer-user-guide/

The PioCreat G12 is priced at $44,999.00 and targets industrial-scale manufacturing with a 1200×1000×1000mm build volume, 3kg/hour extrusion rate, and support for over 15 engineering-grade materials — cutting material costs by up to 60% compared to filament systems. It is an industrial additive manufacturing system.

Update your browser to view this website correctly. Update my browser now