The D200-E is a debinding device from Raise3D. It serves as a part of the new MetalFuse solution offered by the company that also includes the large-format metal 3D printer Forge1 and S200-C vacuum sinter. The system is aimed at high performance, better repeatability, smooth post-processing, and environmental safety.

With a working chamber of 7.87 x 7.87 x 7.87 inches (200 x 200 x 200 mm), the D200-E provides high productivity and outstanding quality of debinding. The machine can achieve the speed of 1.55 mm/h. It is equipped with various smart functions, such as the safety interlocks, front-mounted E-stop, and activated carbon adsorption facilities. In addition, the device boasts mobility and user-friendly design.

Credit: raise3d.com

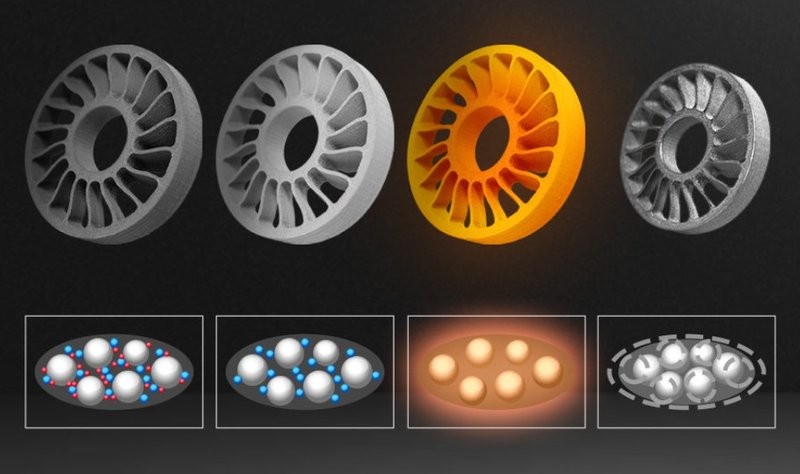

For better results, it is recommended to use the Raise3D D200-E as a part of the MetalFuse system, along with the Forge1 3D printer and S200-C. Thus, the polymer will be removed from the model during the catalytic debinding process, which will result in a pure metal with residual binder. The sintering process will further remove the binder due to the temperatures below the melting point of the metal. That way, the product achieves its final hardness and strength properties.

Credit: raise3d.com

The D200-E uses the catalytic debinding process based on oxalic acid. It is safe, environmentally friendly, easier than nitric acid treatment, and faster than solvent and thermal debinding. It can even be used for titanium and copper.

With this method, the debinding cycle takes much less time (4–12 hours instead of 12–72 hours). Moreover, there are no limitations considering the layer height, and the residual rate of the polymer is lower. By applying a catalyst, one can reduce the time cost by 60% and still obtain parts with a density up to 97% of wrought iron’s level, which is 52% more compared to products obtained by debinding with solvents.

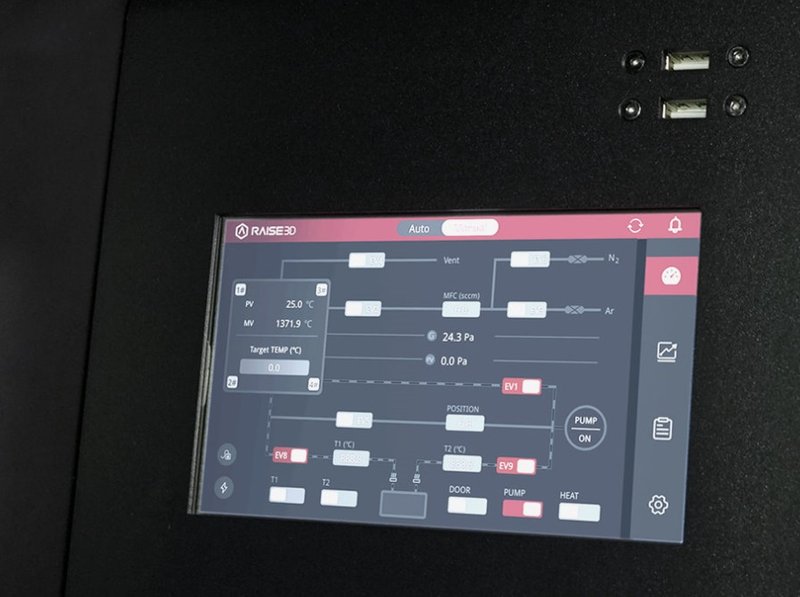

The Raise3D D200-E is equipped with a 7" touchscreen display for comfortable control. Its intuitive interface allows users to easily manage the process.

Credit: raise3d.com

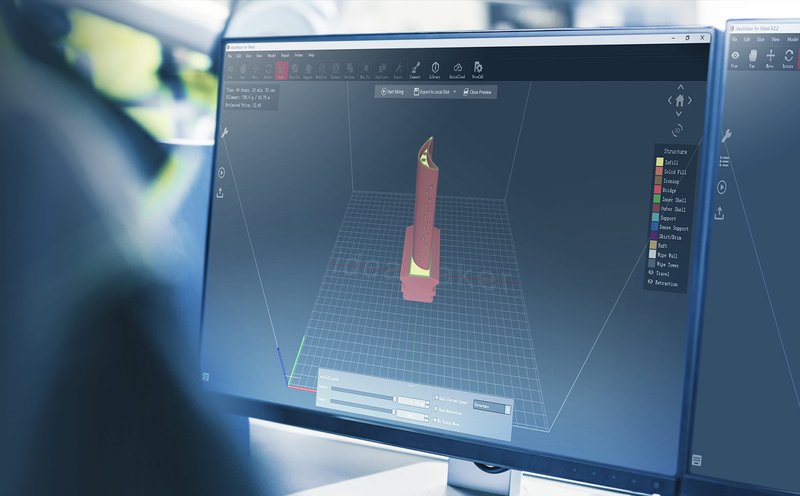

The device is fully compatible with a special edition of the ideaMaker software that offers templates optimized for smooth debinding.

Credit: raise3d.com

Credit: raise3d.com

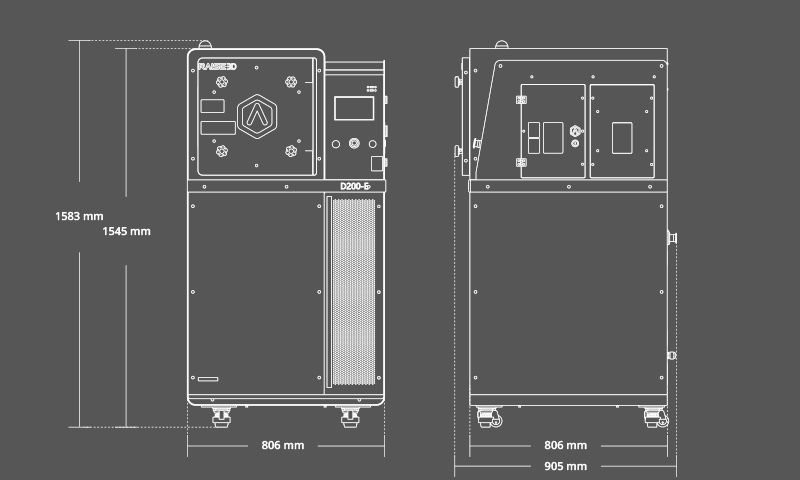

The Raise3D D200-E is available in black with white and red trimmings. Its stylish look makes it ideal for any workshop or maker lab. For convenience’s sake, the machine is equipped with wheels so you can easily move it.

The outer dimensions of the device are 31.73 x 35.63 x 62.32 inches (806 x 905 x 1583 mm). It weighs 640 lb (290 kg).

To learn the current price of the Raise3D D200-E, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now