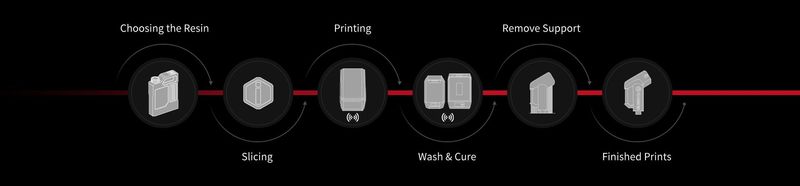

The Raise3D DF2 Solution is a professional DLP 3D printing system that is aimed at an accurate, fast, clean, reliable, and simplified Digital Light Printing experience. The Complete Package consists of the Raise3D DF2 3D printer as well as the dedicated DF Wash and DF Cure machines. All these devices are linked into a single mechanism with the help of RFID integrated into the build platform, which guarantees an exceptionally efficient workflow and completely redefines the possibilities of 3D printing with high-performance resins.

Representing a next-gen digital light printing (DLP) solution, the Raise3D DF2 utilizes RFID technology to seamlessly unite the capabilities of hardware, software, and printing materials, offering users an open resin progtam and streamlined workflow without the need for manual entry of process settings. Paired with a logical interface, this not only saves operational time, but also ensures consistent, high-quality outputs, which is critical for production of any level.

In addition, the Raise3D DF2 Complete Package provides a number of quality-of-life features for even more comfortable use. The 3D printer comes with an easily mounted and dismantled build platform that does not require screws, intelligent material management system for better production rate and product quality, the unique Magic Layout function that delivers competent placement of future printouts, automatic pre-print inspection, chamber heating of up to 40 ℃ for smooth work with engineering materials, and reliable air filtration eliminating unpleasant resin odors.

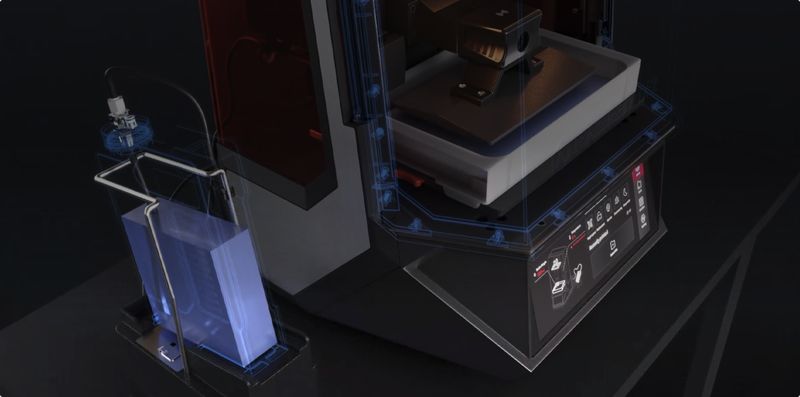

The Raise3D DF2 Complete Package includes all the auxiliary equipment necessary for post-processing. As the names suggest, the DF Wash and DF Cure included in the kit are post-processing devices. The former is an automatic cleaning solution offering easy maintenance, capacious washing tank, and smart functionality comprising twin-turbo washing, hand washing simulation, and double-fan drying. The latter is a powerful curing station with multiple customizable UV curing and heating profiles. Both devices can be configured automatically through RFID in accordance to previous print settings or manually. Thus, the Raise3D DF2 Complete Package represents a full-fledged solution for comfortable, streamlined, and efficient production with printing, washing, and curing without the need for extra tedious manual operations.

Considering all the benefits mentioned, the Raise3D DF2 Complete Package is ideal for a variety of professional-grade applications, such as engineering prototyping, manufacturing aids, and low-volume production with a wide variety of high-performance resins. Due to its optimized performance, high repeatability, and remarkable usability, the solution adapts effortlessly to the scale of production and maintains consistent quality throughout the whole process.

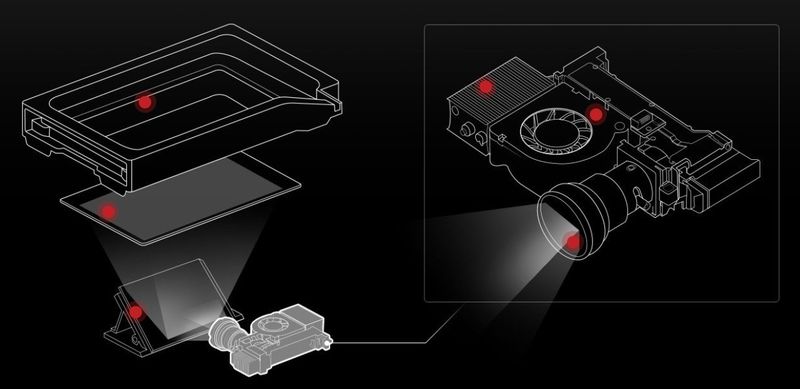

The Raise3D DF2 is capable of printing objects with a layer height of 50–100 microns, which lets you make fairly complex parts with smooth exterior surfaces and clear edges, from intricate model designs to complicated engineering prototypes. Built with top-performing optical components, the printer captures every detail with the utmost accuracy, while the maximum print speed of the device is 25 mm/h (0.1 mm per layer).

The industrial-grade optical components mentioned above are used throughout the entire optical path projection system to reduce loss, eliminate dispersion, and ensure high-precision image quality in reproduction of sharp layers.

Due to a remarkable load capacity for Z-axis, the Raise3D DF2 features no staggered layers and high movement accuracy, ensuring the stability of printing large parts and extended service life.

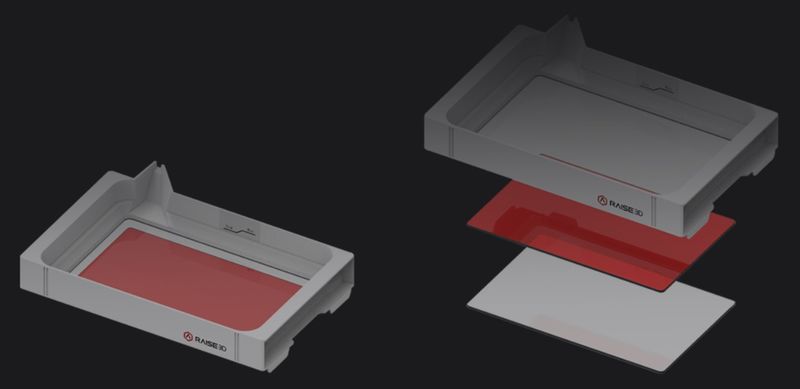

A thoughtful air peel design between the resin vat bottom and the highly clear glass reduces the force from 50 to 10 kg, effectively peeling each layer and ensuring successful printing with consistent output.

For efficient material management, the printer is supplied with an ultrasonic liquid level detection module that defines a lack of resin and a dosing device that automatically replenishes the container. This makes for a smooth, uninterrupted workflow that maintains the overall quality of print results.

The Raise3D DF2 3D printer supports a variety of Raise3D resins that meet demands for customized small batch production of precise prototypes and industrial engineering parts. Apart from standard resins, the machine successfully works with high-resolution, clear, durable, and heat-resistant materials from both the manufacturer and third parties, making for the open resin program.

Furthermore, under the Open Resin Program (ORP), Raise3D has partnered with BASF and Henkel to develop special co-branding resins, including high-performance LOCTITE 3D IND405™, LOCTITE 3D PRO476™, Ultracur3D® RG 3280, and Ultracur3D® RG 1100 B. This collaborative effort provides users with a wider range of options to get the desired results.

The Raise3D DF2 3D printer offers a build size of 7.87 x 4.41 x 11.8 in (200 x 112 x 300 mm). In combination with the maximum workload of 10 kg, this lets one produce fairly large objects as a whole or smaller items in batches. The DF2 model can effectively print almost anything, from large-scale prototypes to intricate artistic models.

Another bright feature of the Raise3D DF2 3D printer is its smart build plate with RFID — a tag device that automatically stores and reads the relevant parameters of an entire workflow for printing, washing, and curing procedures. With this information transferred between all three machines, usually time-consuming and messy resin 3D printing becomes faster, cleaner, and more straightforward. Apart from this, the platform is easy to mount and unmount, reducing the need for tedious manual operations.

As for the additional devices included in the Raise3D DF2 Complete Package, the washing system is engineered with the 14L washing tank volume, while the curing station possesses a working area of φ9 x 11.8 in (φ230 x 300 mm), making for a sufficient amount of post-processed items in a single session.

As the main unit in the Raise3D DF2 Complete Package, the 3D printer is equipped with a responsive touch screen with a resolution of 1920 x 720 that makes for a convenient user experience. Due to a carefully designed logical interface, the machine provides easy control allowing users to seamlessly manage the production process with just a few clicks.

One of the main features of the product is its innovative Magic Layout function that allows to easily adjust the print layout and duplicate prints. This can be performed right through the touch screen before the printing session, which greatly accelerates and simplifies the preparation process.

After everything is set for printing, the automatic pre-print inspection will verify all working conditions, including resin type, build platform and feeding station installation, resin margin, etc. to ensure smooth and hassle-free building of your models.

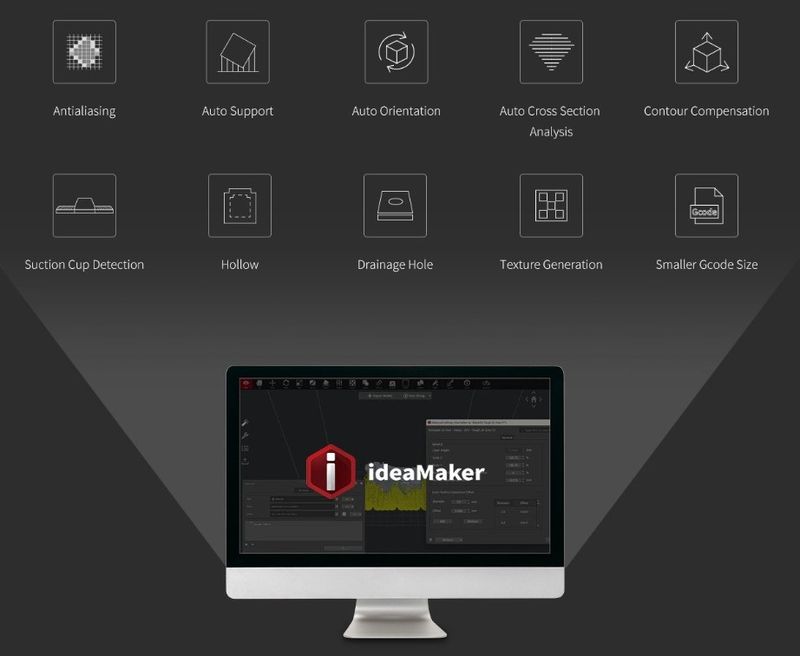

In terms of software, the DF2 digital light printing system is powered by the manufacturer's self-developed ideaMaker slicing software that helps to prepare models for digital light printing in a smart and user-friendly way. The program offers a wide range of useful functions, such as texture creation, support customization, automatic optimization, flexible parameter adjustment, and more. As for the latest version, the ideaMaker has added multiple new features that are compatible with the Raise3D DF2 printer, reducing learning curves and improving the success rate of DLP printing.

The Raise3D DF2 Complete Package boasts slick yet attractive design. The 3D printer features a black base with a transparent red cover. Both post-processing machines are available in black with white trimmings. The overall stylish look of the set makes it ideal for any workshop or maker lab.

The DF2 3D printer dimensions are 17.7 x 15.7 x 28.7 in (450 x 400 x 730 mm), and it weighs 88.2 lb (40 kg). The washing system dimensions are 15.7 x 16.1 x 25.4 in (400 x 410 x 646 mm), it weighs 61.1 lb (27.7 kg). The dimensions of the curing station are 19.3 x 15.7 x 24.0 in (490 x 400 x 610 mm), with a weight of 72.3 lb (32.8 kg).

DF Wash parameters:

Compatible solvent: IPA, Water, TPM

Max. washing size: 200 x 112 x 300 mm

Operating ambient temperature: 10–35 ℃

Outer dimensions: 400 x 410 x 646 mm

Power supply input: 100–240 V AC, 50/60 Hz, 96W

Wash profile: RFID auto set or manual entering

Washing tank volume: 14 L

Weight: 27.7 kg

DF Cure parameters:

Cure profile: RFID auto set or manual entering

Curing source: LED (365nm, 385nm, 405nm mixed)

Max. air heating temperature: Up to 120 ℃

Max. curing size: φ 230 x 300 mm

Operating ambient temperature: 10–35 ℃

Outer dimensions: 490 x 400 x 610 mm

Power supply input: 100–240 V AC, 50/60 Hz, 500W

Weight: 32.8 kg

To learn the current price of the Raise3D DF2 Complete Package as well as delivery options, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now