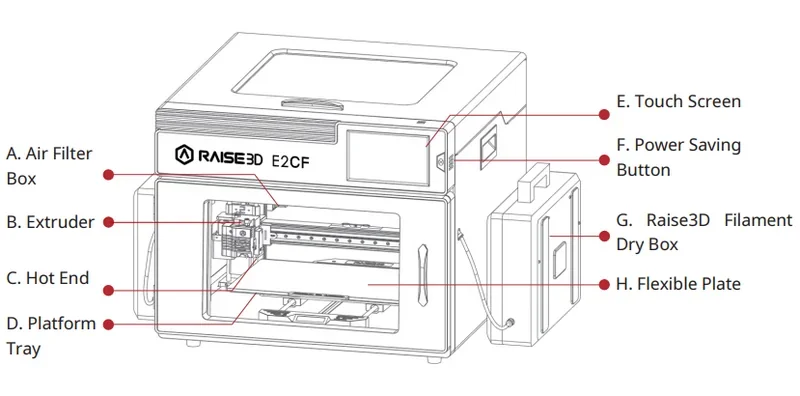

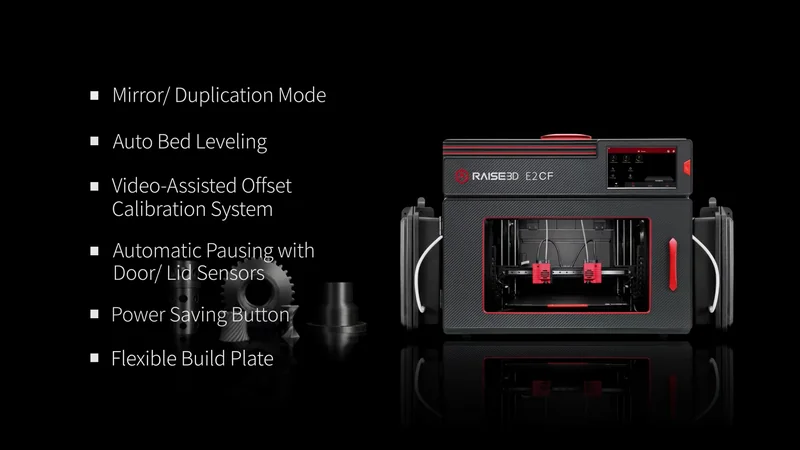

The Raise3D E2CF is a compact, professional IDEX 3D printer optimized for 3D printing carbon fiber and composite materials, offering a 330 × 240 × 240 mm enclosed build volume, corrosion-resistant silicon carbide nozzles (up to 330°C), reinforced gears, and dual filament dry boxes for consistent quality. Its IDEX system enables support material use or faster output via mirror and duplication modes. Targeted at engineers, small manufacturers, and design studios, it delivers strong, lightweight parts with features like a HEPA filter, quiet sub-50dB operation, and certified filaments such as PA12 CF and PPA GF for reliable, around-the-clock production. This desktop 3D printer is excellent for manufacturing and prototyping.

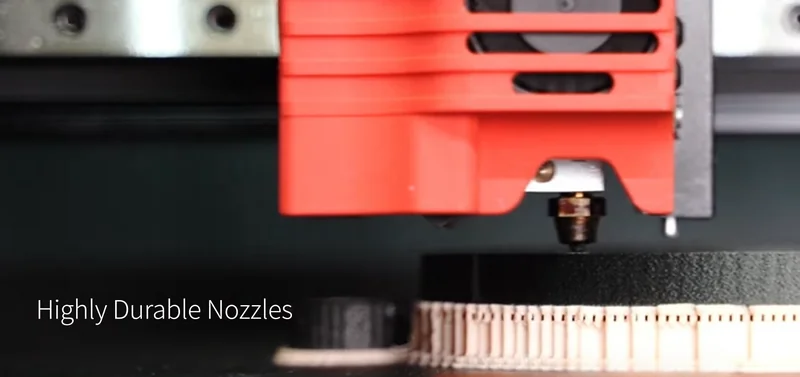

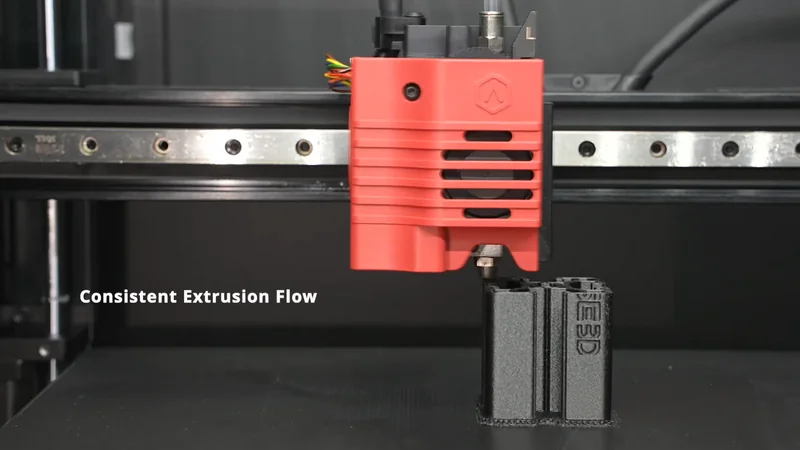

The Raise3D E2CF delivers high-quality composite 3D prints with smooth surfaces and strong layer adhesion, reliably operating at speeds of 15–150 mm/s and temperatures up to 330°C using abrasion-resistant silicon carbide nozzles.

Case Study: The Raise3D E2CF showed excellent print quality and durability with carbon fiber composites, maintaining consistent performance after 1,000 hours thanks to its abrasion-resistant silicon carbide nozzles.

PA12 CF Print Sample: Printed at 0.2 mm layer height, it shows excellent flatness, smoothness, and dimensional stability after annealing for reliable parts with consistent surface quality.

PA12 CF Print Sample: Printed on the E2CF at 0.2mm, the parts show smooth surfaces, consistent quality, and no ghosting or ringing, proving the printer’s precision and the material’s suitability for composite additive manufacturing.

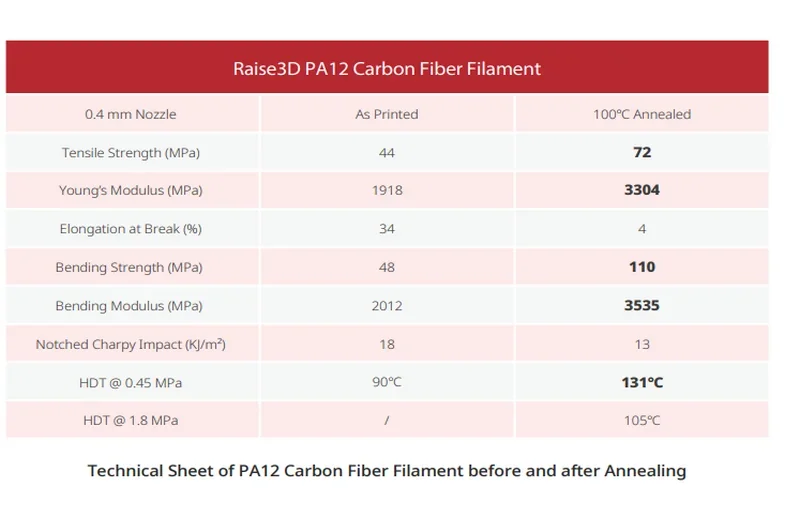

Anneal parts for best performance. Small parts (< 50 mm) require 6-8 hours at 80°C, larger parts (> 50 mm) require 100°C annealing for at least 12 hours. PA-12 Carbon Fiber Parts produced on the Raise3D E2 reached 72 MPa tensile strength after annealing. The system showed low water absorption, an outstanding strength-to-weight ratio, and excellent rigidity and strength typical of high-performance carbon composites. In fact, PA12 CF achieves 11% higher strength-to-weight ratio than A36 steel while being 7.4 times lighter, making it ideal for lightweight structural applications.

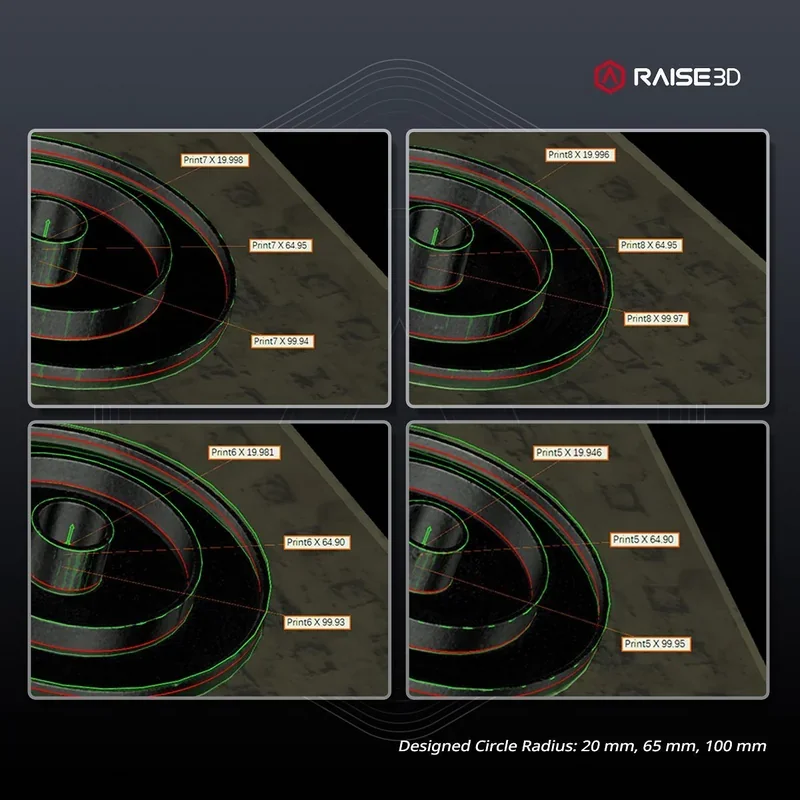

Raise3D E2CF Print Sample: The Raise3D E2CF kept deviations under ±0.1 mm across 20–100 mm circles (19.946–19.998 mm, 64.90–64.95 mm, 99.93–99.97 mm), showing precision beyond typical ±0.5 mm desktop FDM tolerances and nearing industrial-grade standards.

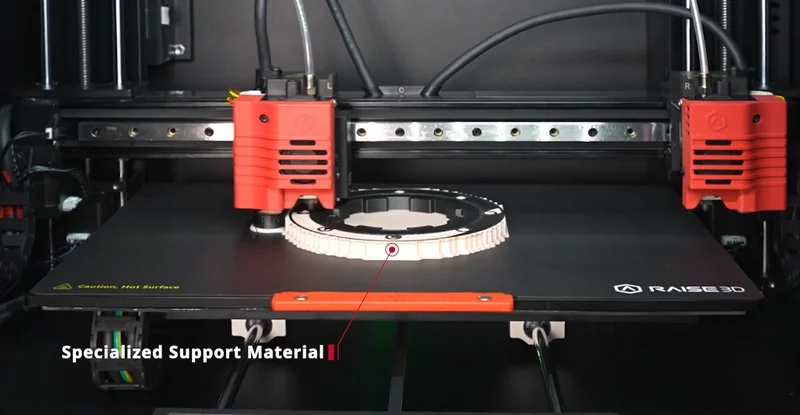

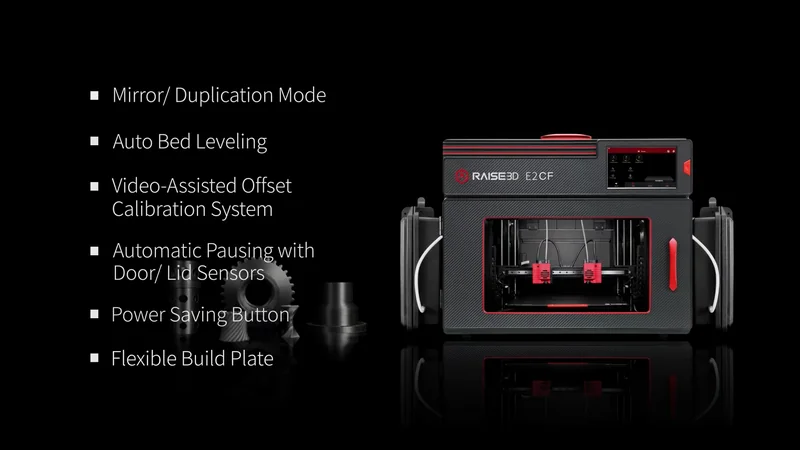

The Raise3D E2CF is an IDEX 3D printer whose IDEX system supports dedicated supports or faster production with mirror/duplication modes. A mesh-leveling system ensures strong first-layer adhesion, while the 110°C heated bed and flexible steel plate make part removal easy. For example, the E2CF print achieved clean overhangs, excellent surface finish – the breakaway supports were instantly removed with no damage to the print surface.

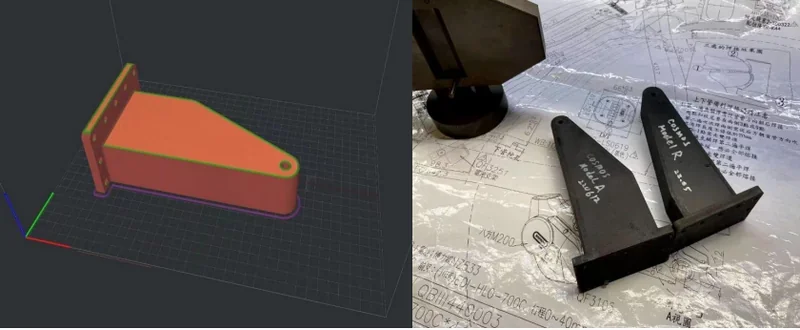

Case Study: Escudero Auto produces brackets, gaskets, hinges, and functional products for the automotive and mechanical manufacturing industry. They replaced metal parts with carbon-fiber parts, reducing cost of production by up to 50%.

Case Study: Comosworks Ltd. used Raise3D E2CF to cut e-bike development time and costs, producing up to 20 durable, precise parts weekly with minimal tooling investment.

The Raise3D E2CF supports 11+ materials, including carbon fiber reinforced filament such as Industrial PA12 CF and other composites like PPA CF/GF, PET CF/GF, PETG ESD, plus supports such as PA12 CF Support and PVA+. The Raise3D Open Filament Program (Raise3D OFP) offers 100+ tested profiles for filaments from such manufacturers as eSUN, Polymaker, Extrudr, Fiberology, BASF, Kimya, etc.

PET CF Print Sample: external rotor with carbon fiber reinforcement, circular geometry, mounting slots, and embossed text.

PET CF 3D Print Sample: Rectangular jig with alignment slots, stepped surfaces, and embossed branding for stable assembly positioning.

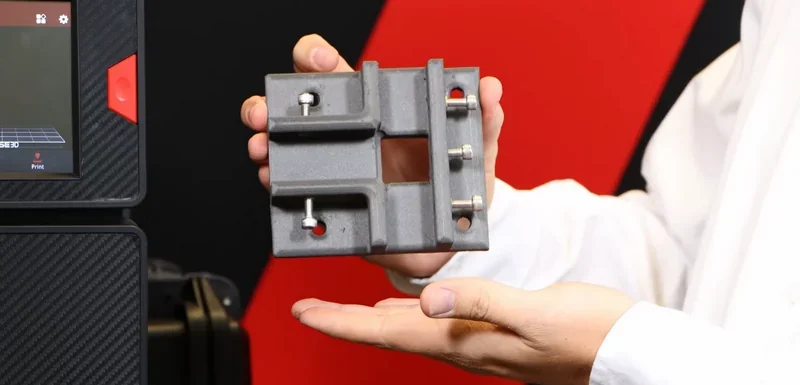

PPA CF Print Sample: a welding jig with reinforced geometry, bolt mounts, and recessed cavities for precise metal alignment.

PA12 CF Print Sample: a carbon fiber–reinforced nylon mouse shell printed on the Raise3D E2CF with composite support, demonstrating strong layer adhesion, complex geometry, and a durable finish.

PA12 CF Print Sample: a red composite fixture with numbered alignment holes and mounting features, printed on the Raise3D E2CF for accuracy, consistent fit, and reliable industrial performance.

PA12 CF Print Sample: A cylindrical part with smooth surfaces, precise holes, and strong dimensional accuracy, showing the high-performance capability of carbon fiber-reinforced polyamide.

Print Sample: A complex circular part with intricate overhangs printed using specialized supports, showing stable printing and high precision in challenging geometries.

PA12 CF Print Sample: black carbon fiber–reinforced nylon parts, showcasing high strength, dimensional accuracy, and smooth finish for industrial use.

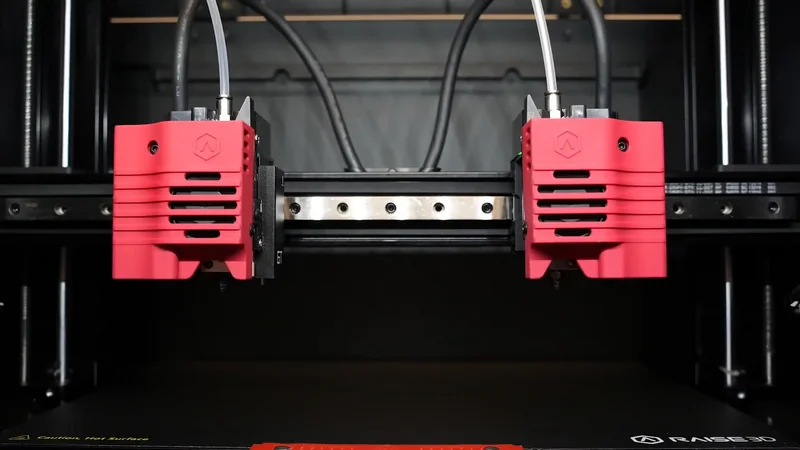

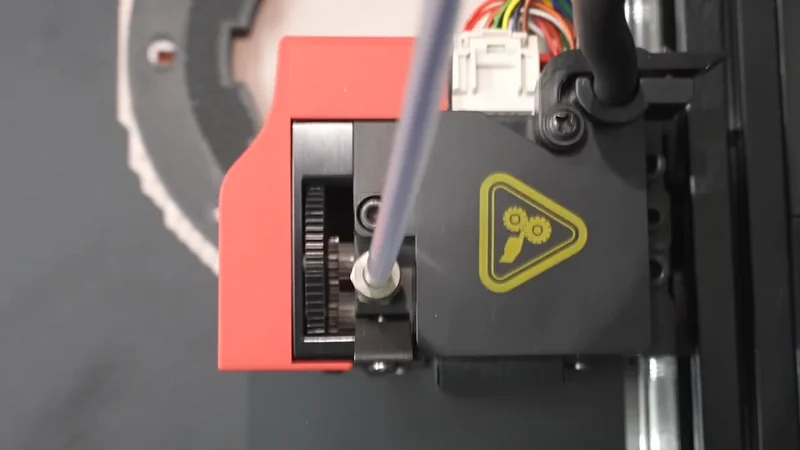

The Raise3D E2CF is built for carbon fiber printing with silicon carbide nozzles, dual direct drive steel gears that resist abrasive wear, and side-mounted dry boxes to prevent humidity damage, ensuring consistent material quality. When closed, they can effectively prevent dust and moisture from affecting the material, for a period of up to 30 days.

The Raise3D Industrial PA12 CF Support Filament from the Raise3D Industrial series is a break-away support material engineered for carbon fiber-reinforced composites like PA12 CF that creates a stable support structure and ensures proper adhesion to printed surfaces.

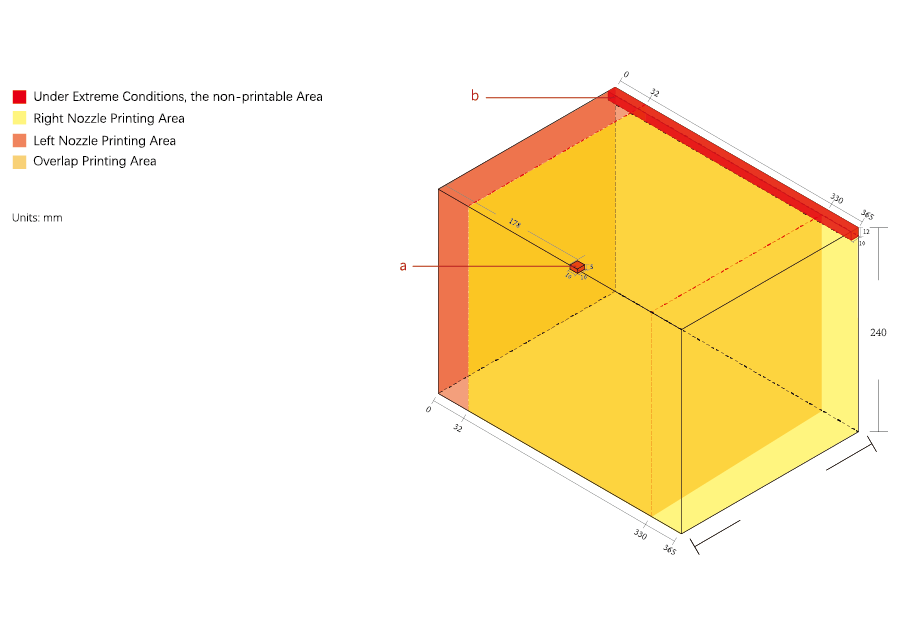

The Raise3D E2CF offers a 330 × 240 × 240 mm build volume with one extruder, reduced to 295 × 240 × 240 mm in dual mode to account for nozzle offset and prevent collisions.

Raise3D E2CF — IDEX benchtop optimized for carbon-fiber and glass-fiber filaments with a 330 °C V4P hot end, 110 °C bed, HEPA + activated-carbon filtration, and build areas of 330×240×240 mm (single) or 295×240×240 mm (dual); tuned for 0.1–0.3 mm layers on a 0.4 mm nozzle with validated CF/GF profiles (PA12 CF/CF+, PPA CF/GF, PET CF/GF).

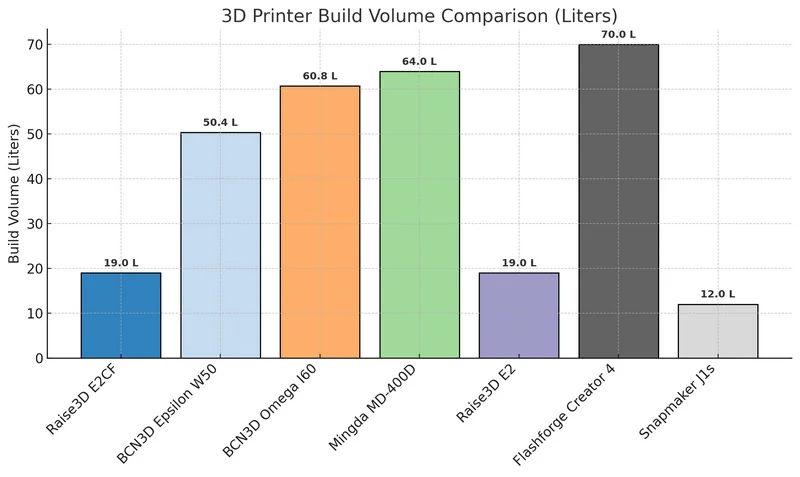

In contrast:

| Specification | Raise3D E2CF | CreatBot F430 NX | BCN3D Epsilon W50 | BCN3D Omega I60 | Mingda MD-400D | Raise3D E2 | Flashforge Creator 4 | Snapmaker J1s |

|---|---|---|---|---|---|---|---|---|

| Build volume (mm) | 330×240×240 (single); 295×240×240 (dual) | 400×300×300 | 420×300×400 | 450×300×450 | 400×400×400 | 330×240×240 | 400×350×500 | 300×300×200 |

| Extruder system | IDEX | IDEX | IDEX | IDEX | IDEX | IDEX | IDEX | IDEX |

| Max nozzle temp (°C) | 330 | 420 | 300 | 300 | ≤350 | 300 | 360 | 300 |

| Heated bed max (°C) | 110 | 140 | 120 | 120 | ≤110 | 110 | 130 | 100 |

| Active chamber heating | N/A (passive enclosure) | Max 70 °C | Max 60 °C | Max 70 °C | N/A | N/A | Max 65 °C | N/A |

| Min layer height (mm) | 0.10 | 0.05 | 0.05 | 0.05 | 0.05 | 0.10 | 0.10 | 0.10 |

| Price (USD) | $4,000+ | $6,500+ | $9,400+ | $27,000+ | $4,300+ | $3,000+ | $11,000+ | $1,150+ |

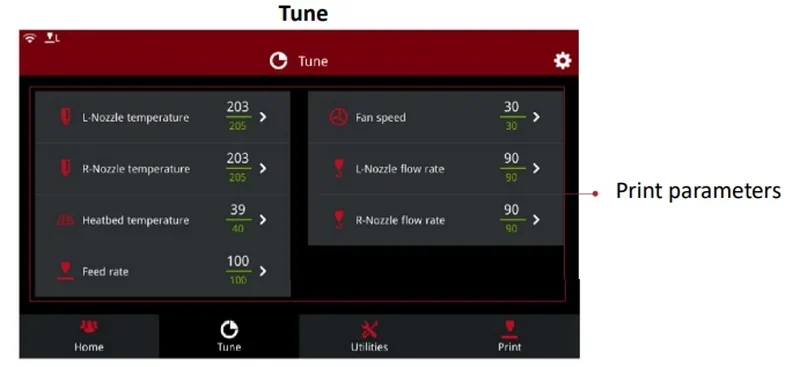

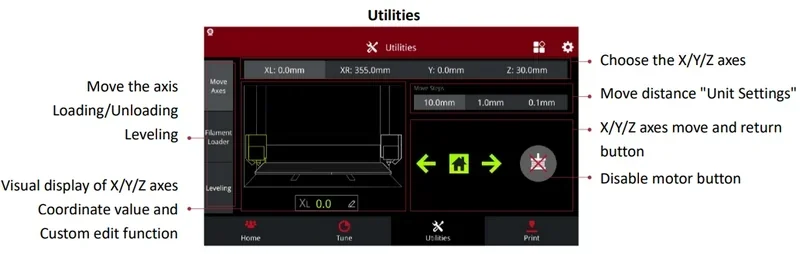

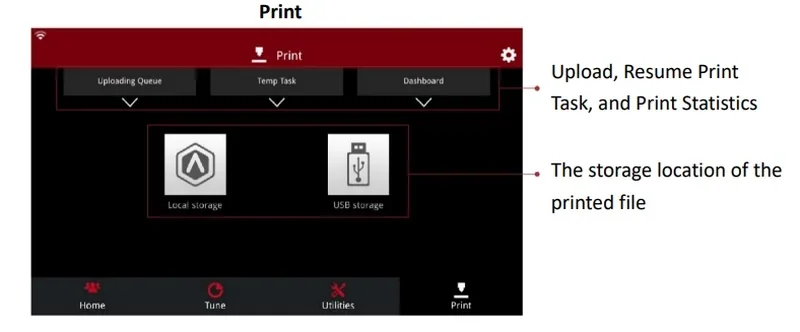

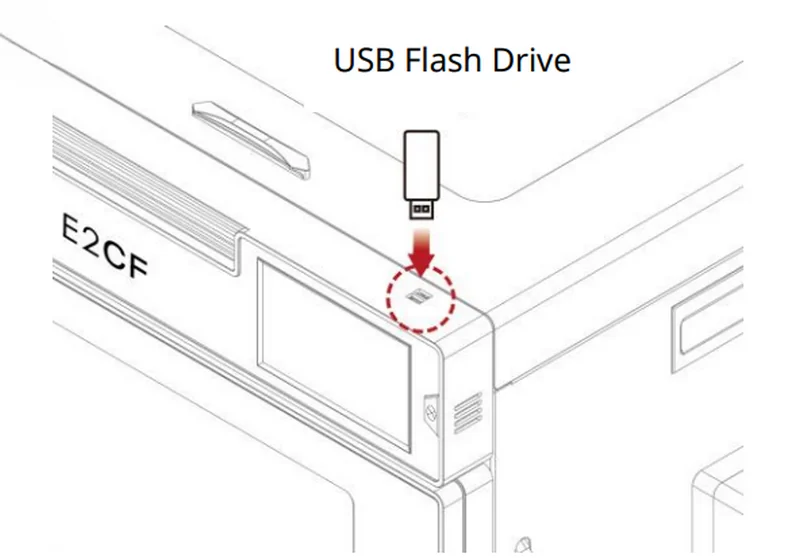

The Raise3D E2CF offers full control with real-time monitoring, adjustable nozzle/bed temps, feed rate and fan tuning, manual axis movement, 9-point auto leveling, filament loading/unloading, and file management via local or USB.

Home

Tune

Utilities

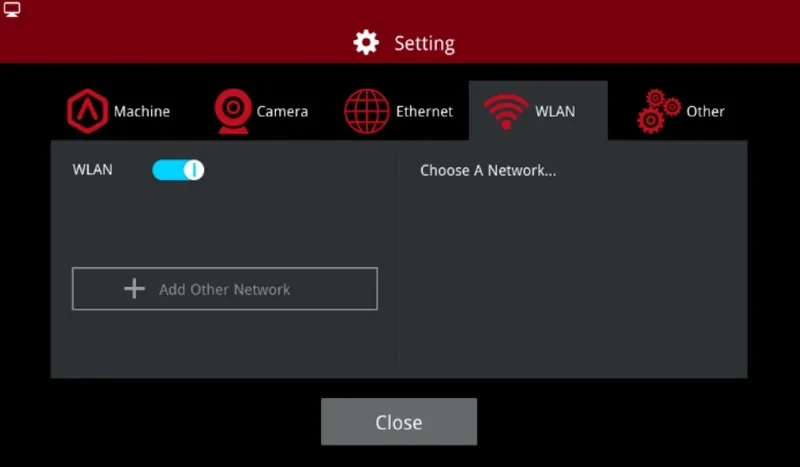

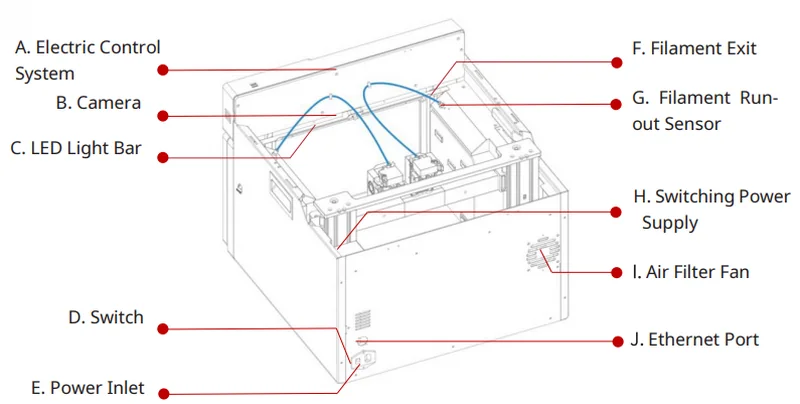

The Raise3D E2CF features 3 connectivity options: USB, Ethernet, or Wi-Fi (2.4/5GHz) and has 8GB onboard storage for standalone file management. Network setup is done through the touchscreen. It works with ideaMaker software on Windows, macOS, and Linux.

The Raise3D E2CF comes with ideaMaker 3D slicing program for Windows, macOS, and Linux, supporting STL, OBJ, 3MF, and OLTP files. It provides easy print setup, support generation, Wi-Fi file transfer, and 3D previews on both the software and printer. Integration also allows full remote printer control.

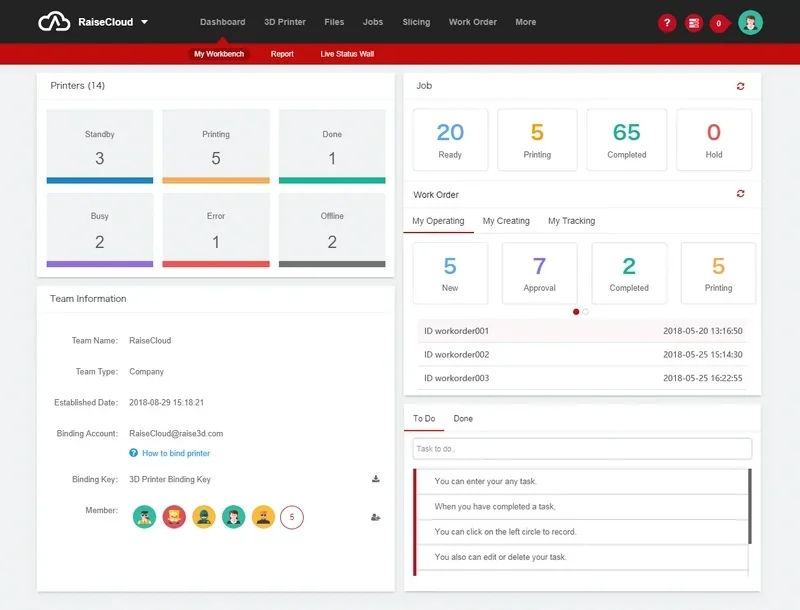

The Raise3D E2CF works with RaiseCloud, a cloud-based 3D printing management platform, for remote monitoring and job control. Its 800×600, 10fps camera enables live views and time-lapse videos. RepRapFirmware adds power loss recovery, filament run-out detection, and wireless updates via touchscreen.

The Raise3D E2CF is a compact enclosed printer with front door access, measuring 607 × 596 × 465 mm and weighing 36.6 kg, with an enclosure that stabilizes printing and contains composite material fumes.

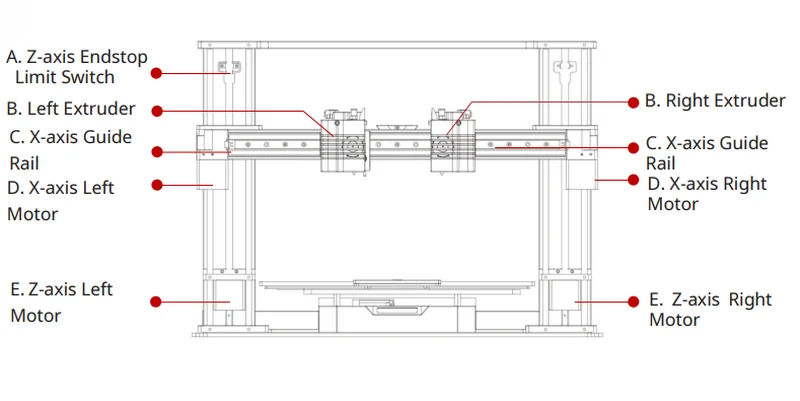

The Raise3D E2CF uses an IDEX system where extruders operate independently of one another along the same axis, featuring X-axis linear rails and independent stepper motors for each extruder.

The Raise3D E2CF operates at under 50 dB(A) during printing.

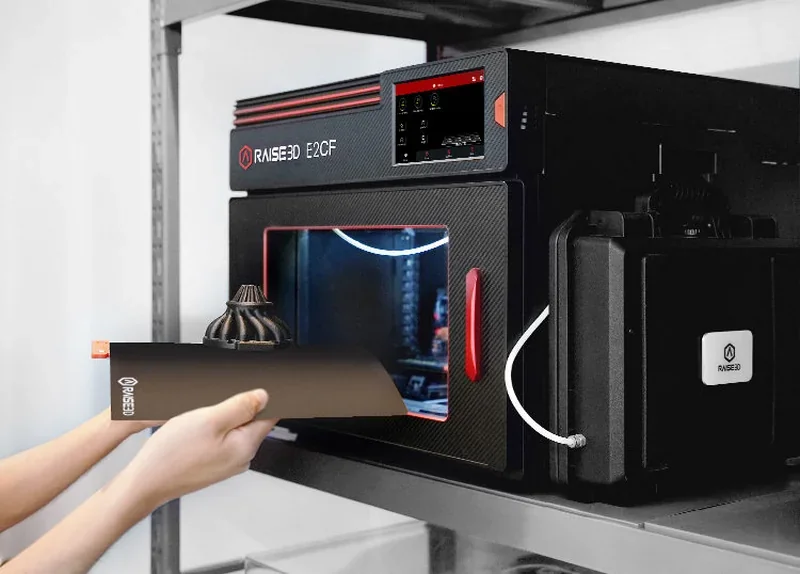

The Raise3D E2CF has a BuildTak-coated flexible steel plate for easy part removal, a dual-extrusion build volume of 295 × 240 × 240 mm, a heated bed up to 110°C, and mesh leveling with flatness detection for precise calibration.

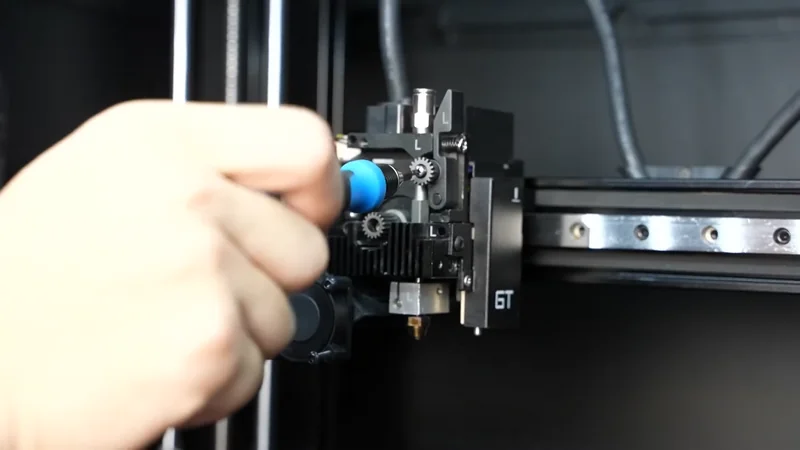

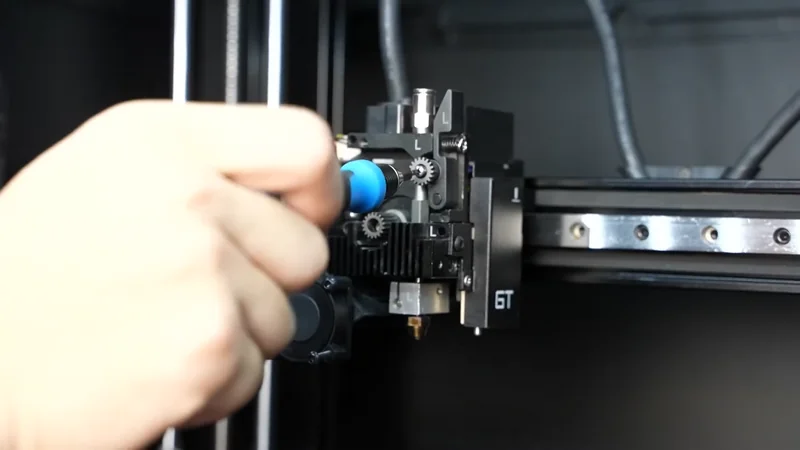

The Raise3D E2CF uses a V4P hot end reaching 330°C with a double-gear direct drive that incorporates a custom gear tooth profile for abrasive composites. It comes with a 0.4 mm nozzle, with 0.6 mm and 0.8 mm options, ensuring reliable feeding and durability.

The Raise3D E2CF includes sealed removable dry boxes with silica gel to keep filament dry and mitigate risks from static electricity. Each holds one roll, feeds smoothly through a side connector, and attaches conveniently to the printer’s sides.

The Raise3D E2CF runs on embedded Linux with a 1 GHz ARM Cortex-A9 quad-core controller and an ARM Cortex-M4 motion processor. It has Wi-Fi, LAN, USB, a camera interface, 1 GB RAM, and 8 GB flash storage.

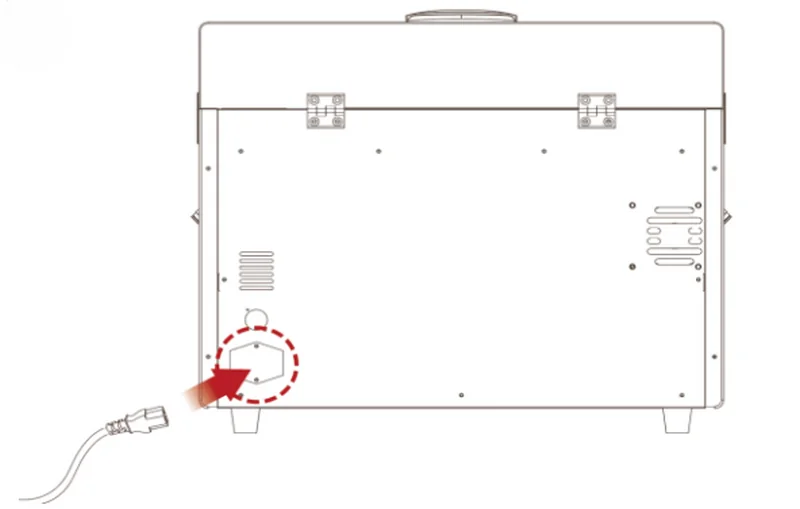

The Raise3D E2CF uses a 100–240 V AC, 50/60 Hz input with 24 V DC, 350 W output. It requires proper grounding and should only be used with the approved power cord, not extensions or adapters.

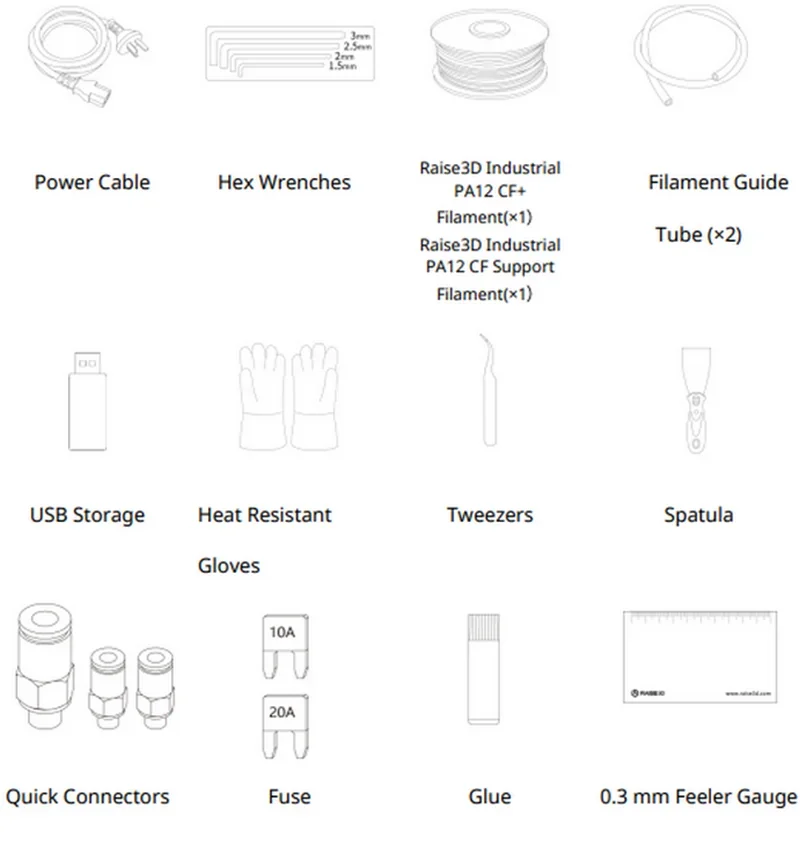

The Raise3D E2CF comes fully assembled, needing only removal of shipping locks before use. It includes dry boxes for filament protection, a flexible steel plate for easy part removal, and accessories like gloves and Magigoo. A USB with ideaMaker software for Windows, macOS, and Linux enables immediate file preparation.

Note: Package contents may change without notice. Contact a Top3DShop sales representative to confirm current inclusions before ordering.

The Raise3D E2 offers over 30 upgrades, accessories and spare parts.

| Accessory | Function | Price (USD) | Image |

|---|---|---|---|

| Build Plate and Print Surface Accessories | |||

| PEI Build Plate (E Series) | Replacement PEI build plate for E Series printers; provides a consistent print surface for first-layer adhesion and part release. | $44.99 |  |

| Flexible Steel Build Plate (E Series) | Flexible steel build plate for E Series printers; enables easier part removal by flexing the plate. | $34.99 |  |

| Flexible Plate with BuildTak (E Series) | Flexible build plate with BuildTak surface for E Series printers; combines flexible removal with a BuildTak adhesion surface. | $89.99 |  |

| BuildTak Build Surface (E Series) | Replacement BuildTak print surface for E Series printers; restores a high-adhesion build surface when the original is worn. | $49.99 |  |

| Air Filtration Parts | |||

| Air Filter | Replacement air filter for the printer’s filtration module; helps reduce airborne particles and odors inside the printer enclosure. | $39.99 |  |

| Air Filter Fan | Replacement fan for the air filtration module; moves air through the air filter during printing. | $19.99 |  |

| Nozzles, Hot End and Print Head Spare Parts | |||

| Silicon Carbide Nozzle 0.4mm | Replacement Silicon Carbide Nozzle | $99.99 |  |

| Silicon Carbide Nozzle 0.6mm | Replacement Silicon Carbide Nozzle | $99.99 |  |

| Left Print Head with Auto-leveling System Assembly | Replacement print head | $409.99 |  |

| Left Print Head | Replacement print head | $389.99 |  |

| Right Print Head | Replacement print head | $389.99 |  |

| Left Hot End Assembly | Replacement hotend | $199.99 |  |

| Right Hot End Assembly | Replacement hotend | $199.99 |  |

| 0566 Extruder Driven Gear | Replacement extruder driven gear | $39.90 |  |

| Flexible Filament Guide Tube | Replacement filament guide tube | $24.99 |  |

| Heating Rod | Replacement heating rod for the hot end; heats the hot end to the target printing temperature. | $45.99 |  |

| Thermocouple | Replacement hot end temperature sensor (thermocouple); measures hot end temperature for accurate temperature control. | $14.99 |  |

| Print Head Cooling Fans and Air Ducts | |||

| Left Extruder Front Cooling Fan | Replacement front cooling fan for the left extruder area; supports stable print head cooling. | $14.99 |  |

| Right Extruder Front Cooling Fan | Replacement front cooling fan for the right extruder area; supports stable print head cooling. | $14.99 |  |

| Left Extruder Model Cooling Fan | Replacement model cooling (part cooling) fan on the left side; cools the printed part during printing. | $14.99 |  |

| Right Extruder Model Cooling Fan | Replacement model cooling (part cooling) fan on the right side; cools the printed part during printing. | $14.99 |  |

| Model Cooling Fan Duct | Replacement air duct for the model cooling fan; directs cooling airflow to the printed part. | $14.99 |  |

| Sensors, Auto-Leveling and Endstop Switches | |||

| Auto-leveling System Assembly | Replacement auto-leveling system assembly; supports automatic build plate leveling calibration. | $59.99 |  |

| X Endstop | Replacement X-axis endstop switch; detects the X-axis home/limit position. | $14.99 |  |

| Y/Z Endstop | Replacement Y/Z endstop switch; detects the Y-axis and Z-axis home/limit positions. | $14.99 |  |

| Electronics Boards and Cables | |||

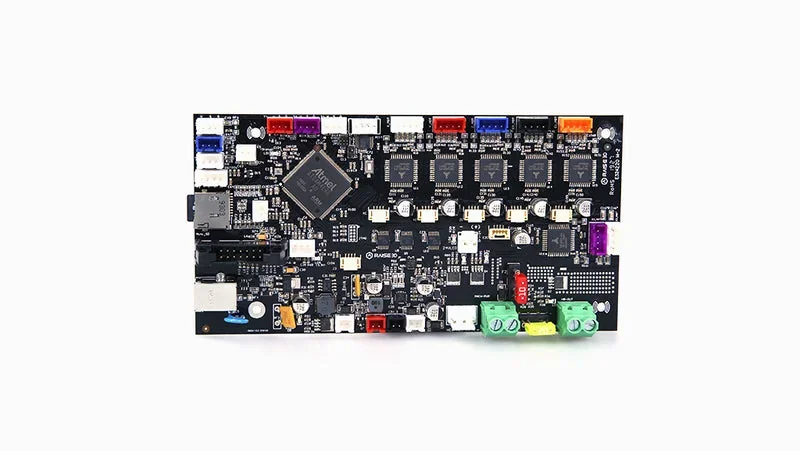

| Motion Controller Board | Replacement motion controller board; controls motors and core motion functions of the printer. | $249.99 |  |

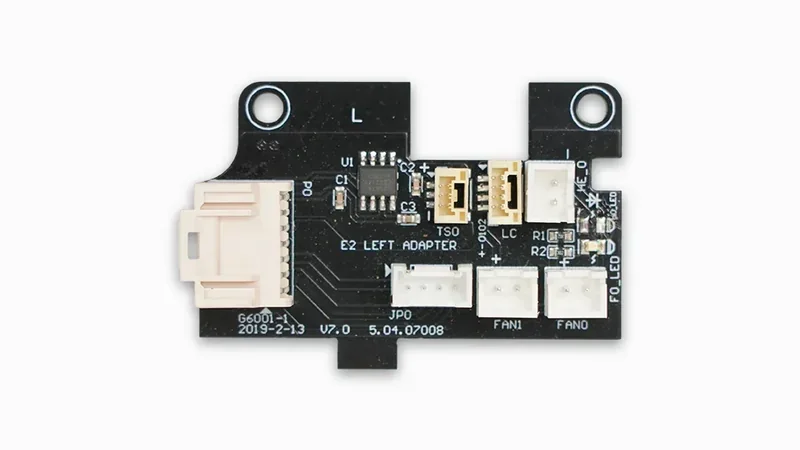

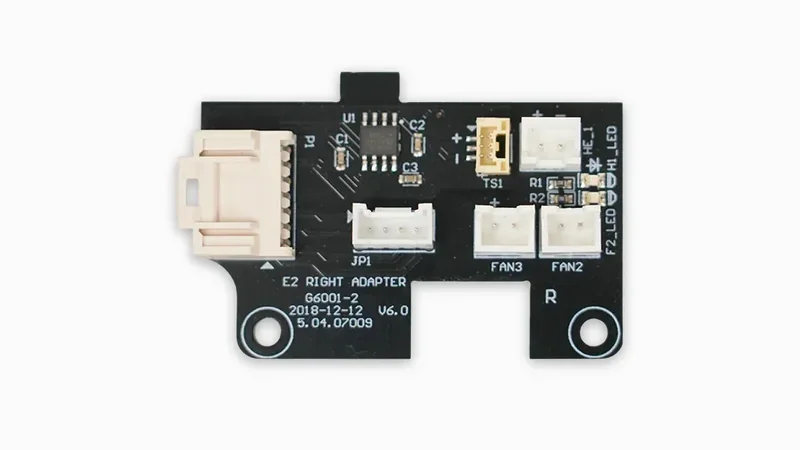

| Left Extruder Connection Board | Replacement left extruder connection board; provides the electrical interface for left-side toolhead connections. | $29.99 |  |

| Right Extruder Connection Board | Replacement right extruder connection board; provides the electrical interface for right-side toolhead connections. | $29.99 |  |

| Extruder Connection Cable | Replacement extruder connection cable; connects extruder/toolhead electronics to the printer. | $19.99 |  |

| E2 USB Cable | USB cable for Raise3D E2; enables a wired connection between the printer and a computer. | $14.99 |  |

| Filament Handling and Storage Accessories | |||

| Raise3D Filament Dry Box | Passive filament dry-storage box that uses silica-gel desiccant to reduce moisture in the enclosed air; designed for carbon-fiber composite filaments, nylon filaments, and other hygroscopic filaments. Supports one 1 kg spool and maintains humidity ≤25% (within one month) when used as specified; includes desiccant sachets and filament guiding hardware (guide tube / quick connector). Replace or regenerate desiccant regularly (recommended monthly). Alternatively, put the desiccant into the microwave oven for 3-5 minutes to restore its drying ability. | $99.99 |  |

| Raise3D Dry Box Shelf (E2CF Cart Add-on) | Cart mounting kit (pair of mounts) designed for holding Raise3D E2CF Filament Dry Boxes on a Raise3D Printer Cart (Pro3/Pro2/E2/E2CF). Does not dry filament by itself; it is a mechanical support accessory. | $199.99 |  |

| Raise3D 2.5 kg Filament Box | Large-capacity filament storage box with real-time humidity and temperature display and sealed enclosure. Compatible with one 2.5 kg spool or two 1 kg spools. | $79.00 |  |

| Printer Stand and Safety Hardware | |||

| Raise3D Cabinet for Standard Size Printer | Printer cabinet/stand for a standard-size printer; provides a stable base and convenient storage space. | $899.00 |  |

| Security Clip Assembly | Replacement security clip assembly; secures components in place to help prevent unintended loosening or movement. | $19.90 |

Before Each Print:

Filament Care:

After Printing:

General:

The Raise3D E2CF includes a 12-month limited warranty.

| Warranty Plan | What’s Included | Price |

|---|---|---|

| Standard Limited Warranty (12 months) | Coverage for the printer and its parts against defects in materials/workmanship under normal use; excludes consumables such as Hotend(s), Hotend(s) Assembly(ies), Nozzle(s), Fan Cover(s), Build Surface, Build Plate(s), Top Acrylic Lid, Filter, Extruder Front Model Cooling Fan, P Thermocouple, Screw Buckle, Raise3D 2.5KG Filament Box, PC Cable Support, Short Tube, Filament Detection Assembly (Filament Run-out Sensor Assembly), 2.5kg Filament Support Shaft Sleeve, Top Cover(s), USB flash drive, SD card, E3 Desiccant Storage Box(es), or other items that are expended in the normal operation of the product, nor does it cover external devices, accessories or parts added to the PRODUCTS after the system is shipped from RAISE3D. | Included (with printer purchase) |

| 1-Year RaiseShield Warranty Plan | Full warranty coverage of electrical and mechanical components of Raise3D E2 3D printers for 1 year, consumables and cosmetic imperfection not included. | $500 |

| 2-Year RaiseShield Warranty Plan |

Full warranty coverage of electrical and mechanical components of Raise3D E2 3D printers for 2 year, consumables and cosmetic imperfection not included. |

$750 |

Raise3D provides digital resources for E2CF owners, including firmware, software, and documentation downloads, a Support Center with troubleshooting and maintenance guides, and Raise3D Academy for training. The Resources section offers applications and STL files, while the OFP page lists approved third-party filaments.

Top3DShop, an authorized Raise3D E2CF retailer, provides setup help and basic troubleshooting as the first support contact. For advanced issues, we coordinate with Raise3D to resolve them efficiently. Contact our sales team before ordering for current warranty terms and coverage details.

Full warranty terms: https://www.raise3d.com/download/raise3d-limited-warranty-all-versions/

To open a support ticket, visit support.raise3d.com.

The Raise3D E2CF, available at $2,754.05, offers pro-grade composite 3d printing printing at a competitive cost. Built for carbon and glass fiber filaments, it features durable silicon carbide nozzles, reinforced gears, and independent dual extruders for mirror/duplication modes. The package includes two filament dry boxes, a HEPA filter with charcoal, a flexible steel plate, and network connectivity with a camera. Ideal for engineers and manufacturers, it delivers reliable small-batch composite production with features usually found in pricier industrial systems.

Update your browser to view this website correctly. Update my browser now