The Raise3D Pro3 Plus HS is a large-format professional 3D printer with a 300×300×605 mm build volume (255×300×605 mm with dual extrusion) and speeds up to 300 mm/s using Hyper FFF® Technology for fast, high-quality, and reliable printing. Designed for manufacturing, education, and engineering, it features a dual-head system with electronic lifting, quick-swap hot ends (0.2–1.0 mm), and supports advanced materials up to 320°C. Automatic bed leveling, filament run-out sensing, and an enclosed chamber with HEPA and charcoal filters ensure consistent output. Connectivity options include Wi-Fi, LAN, and USB, with real-time HD monitoring and the EVE Smart Assistant for an efficient, versatile workflow.

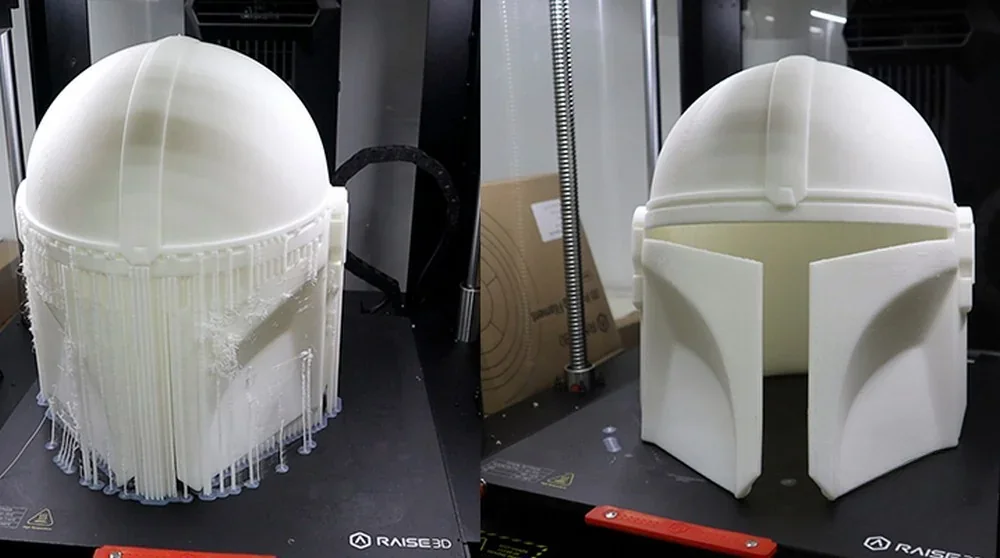

The Raise3D Pro3 Plus HS offers layer heights from 0.05–0.6 mm with ±0.05 mm flatness accuracy over 100 mm and ±0.02 mm wall consistency. Hyper FFF® Technology enables speeds up to 300 mm/s with 10,000 mm/s² acceleration, printing a calibration cube in 17 minutes and a 30 cm Mandalorian helmet in 48 hours — 65% faster than standard methods.

Example: ABS test samples with a 0.2 mm layer height show the Pro3 Plus HS delivers high dimensional accuracy and surface quality. Flatness is maintained within ±0.05 mm over 100 mm, with stable extrusion and no waviness or delamination. The 0.2 mm layer height balances surface detail and productivity for prototypes and production parts.

Double-cone tests confirm the motion system maintains sub-millimeter accuracy on complex surfaces, including 45° overhangs and 2–3 mm curvatures. PLA calibration prints show wall thickness consistency within ±0.02 mm, proving resistance to backlash and servo lag. No ghosting, corner overshoot, or Z-bandings appear, demonstrating structural stiffness and dimensional accuracy across all geometries.

Polycarbonate (PC) overhang tests at 0.2 mm layer height show effective thermal management, producing defect-free unsupported geometries. The cylindrical sample displays clean transitions without sagging or surface flaws typical of poor cooling in high-temperature plastics.

Powered by Hyper FFF® Technology, the printer uses active vibration cancellation to maintain stability and precision at speeds up to 300 mm/s and accelerations of 10,000 mm/s², ensuring consistent accuracy and surface quality.

This technology enables consistent high-speed printing, boosting productivity by shortening prototyping and production cycles. With Hyper FFF® Technology, it maintains speed with Hyper Core materials, cutting print time by up to 70% without quality loss.

The Raise3D Pro3 Plus HS achieves 0.1 mm precision when printing complex cavity and core structures with Raise3D Premium PLA and standard templates. Parts fit seamlessly, confirming dimensional accuracy in intricate geometries. Its advanced motion control and thermal regulation ensure detailed, high-speed prints ideal for prototyping and small-batch production.

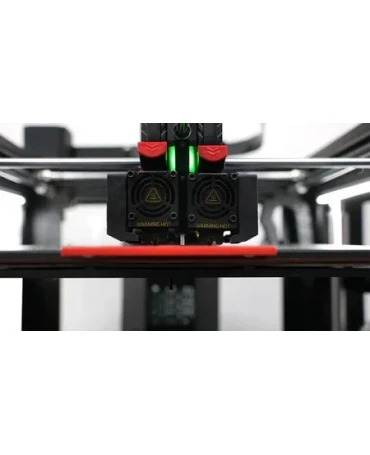

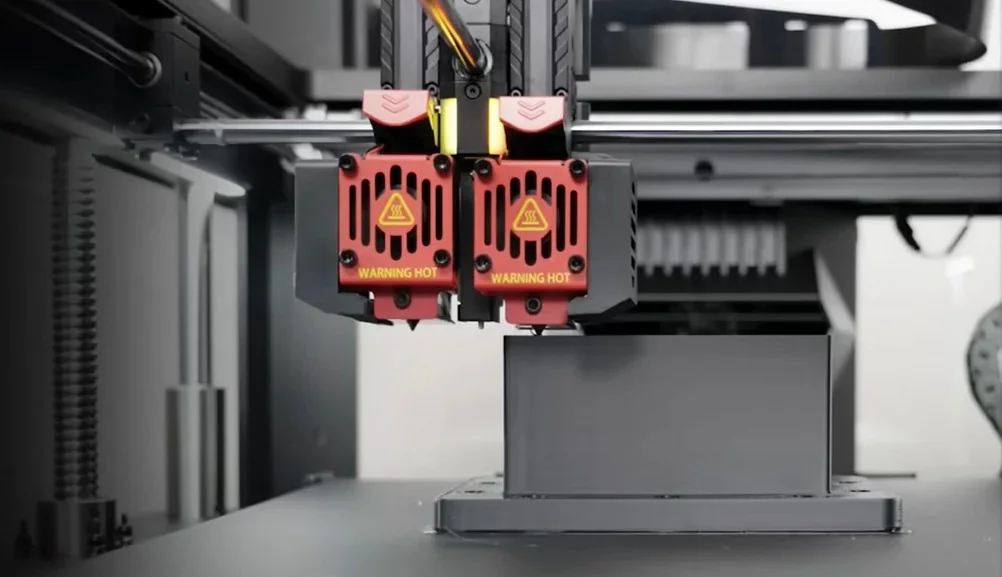

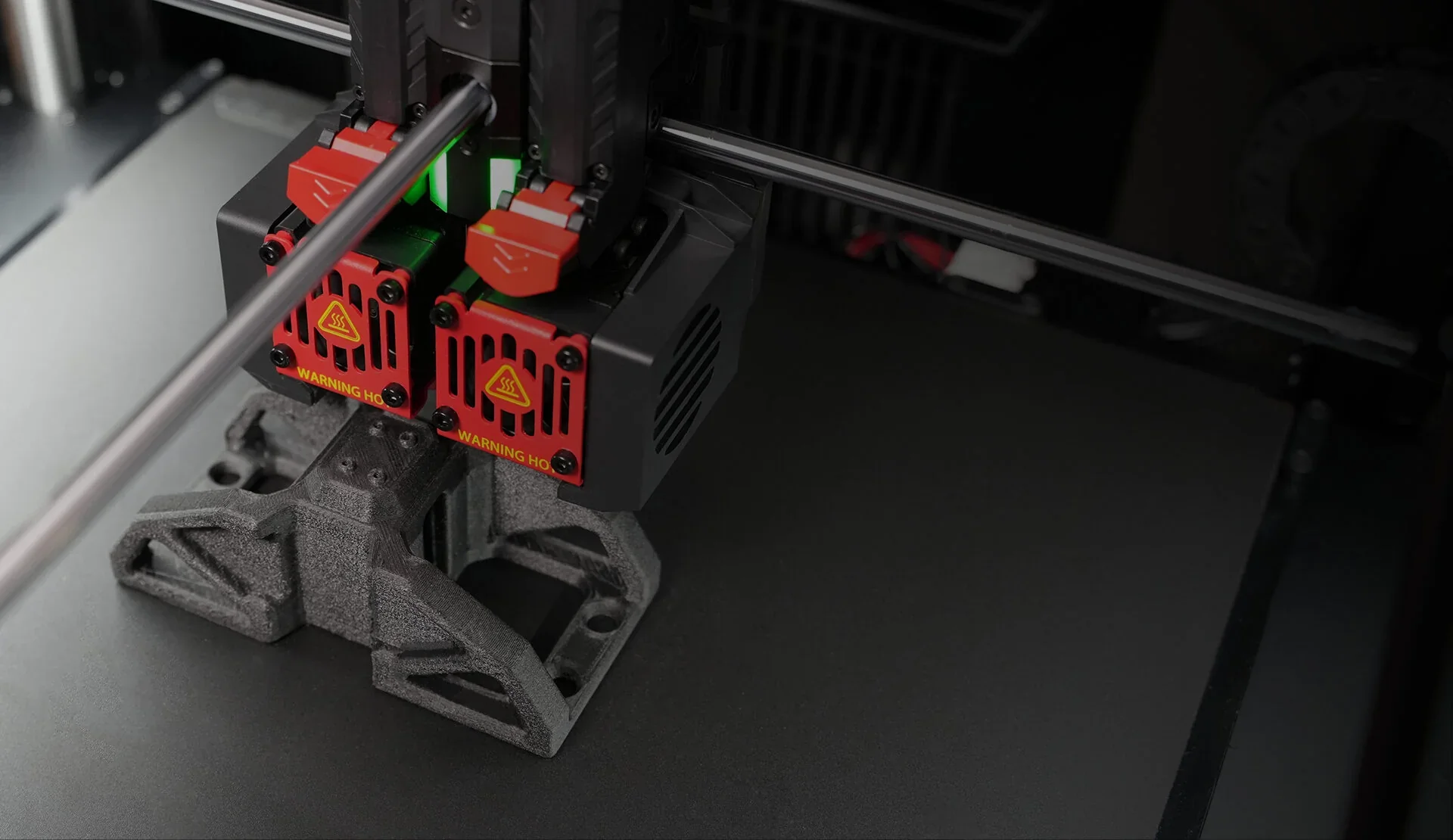

The Pro3 Plus HS enhances print reliability through a mesh-leveling system with flatness detection for consistent first-layer adhesion. Its dual-head IDEX system with electronic lifting prevents inactive nozzles from touching prints, ensuring smooth single-extruder operation.

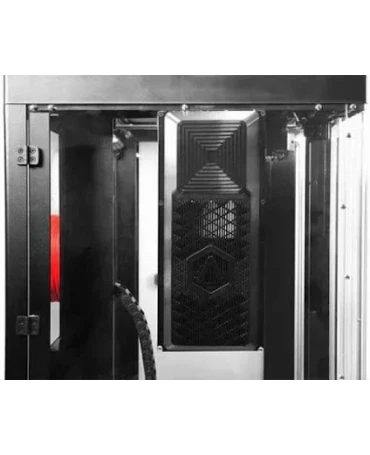

The enclosed chamber features a HEPA filter with activated charcoal for clean air, and an Air Flow Manager that stabilizes temperature during long prints.

A calibration cube was printed to test print speed and stability. Its rapid direction changes make it ideal for assessing precision. Using 0.2 mm layers and default speeds, two cubes were printed — one with Hyper Speed (HS) and one without. The HS cube finished in 17 minutes versus 28–38 minutes normally. Both had high-quality surfaces, though the HS cube was smoother with slight echoing on the letters, thanks to the active vibration reduction algorithm.

The Raise3D Pro3 Plus HS demonstrates high-speed reliability and versatility for industrial use. In one run, it printed eight 354.4 g red contact brackets in 19 hours and eight 93.9 g white jigs in 5 hours 20 minutes at 0.2 mm layers. With Hyper Speed technology, it achieved smooth surfaces, precise geometry, and strong bonding at up to 300 mm/s, proving its capability for consistent small-batch production.

The Raise3D Pro3 Plus HS reliably prints industrial-grade parts with complex geometries and tight tolerances. At a 0.2 mm layer height, each piece shows precise layer alignment, sharp outlines, and minimal surface flaws, making outputs suitable for technical integration and precision fit testing in engineering workflows.

A 30 cm Mandalorian helmet showcases the Raise3D Pro3 Plus HS’s strength in large, complex builds. Using Hyper Speed mode, it printed in 48 hours — about 65% faster than standard extrusion. Supports detached cleanly, revealing a smooth, warp-free shell with sharp edges. The result demonstrates consistent accuracy and a professional finish, confirming the printer’s reliability for rapid prototyping and full-scale production.

Two case studies demonstrate the Raise3D Pro3 Plus HS’s performance in industrial and scientific applications. Its high-speed extrusion, closed-loop motor control, and precise mechanics enable accurate, repeatable production of complex composite and bioengineered parts.

Case Study: The Raise3D Pro3 Plus HS speeds up custom motorcycle part production using carbon fiber ABS at up to 300 mm/s. It delivers strong, smooth parts with precise magnetic insert placement. Prototyping times as short as one hour shorten development cycles, supporting faster launches and competitive advantage.

Case Study: In biomedical research, the Raise3D Pro3 Plus HS enables fabrication of complex bioprinters and hydrogel structures. Precise fit and detail alignment ensure reliable assembly for live tissue printing, while fast prototyping boosts experimental efficiency and research quality in cellular engineering and organ modeling.

The Raise3D Pro3 Plus HS supports 14+ thermoplastics, including Hyper Core composites (PPA CF25, PPA GF, ABS CF15), standard materials (PLA, ABS, ASA), industrial options (PET CF, PET GF, PETG, Nylon), and engineering polymers (PC, TPU-95A). It prints carbon fiber composites at 200–300 mm/s and industrial materials at 100–150 mm/s, remaining compatible with third-party filaments via the Open Filament Program.

Hyper Core materials print up to four times faster with 20% stronger interlayer adhesion and Z-strength, maintaining surface quality through optimized molecular weight and rapid cooling.

These samples show the Raise3D Pro3 Plus HS can produce strong, precise Hyper Core composite parts for industrial and automotive use, emphasizing durability, accuracy, and customization.

Hyper Core PPA CF25 3D Print Sample: A 145×140×55 mm rim mounting fixture (233.3 g) printed at 0.2 mm layer height in 8 hours 44 minutes. Designed for automotive jigs and fixtures, it offers high strength, precision, durability, light weight, and customization.

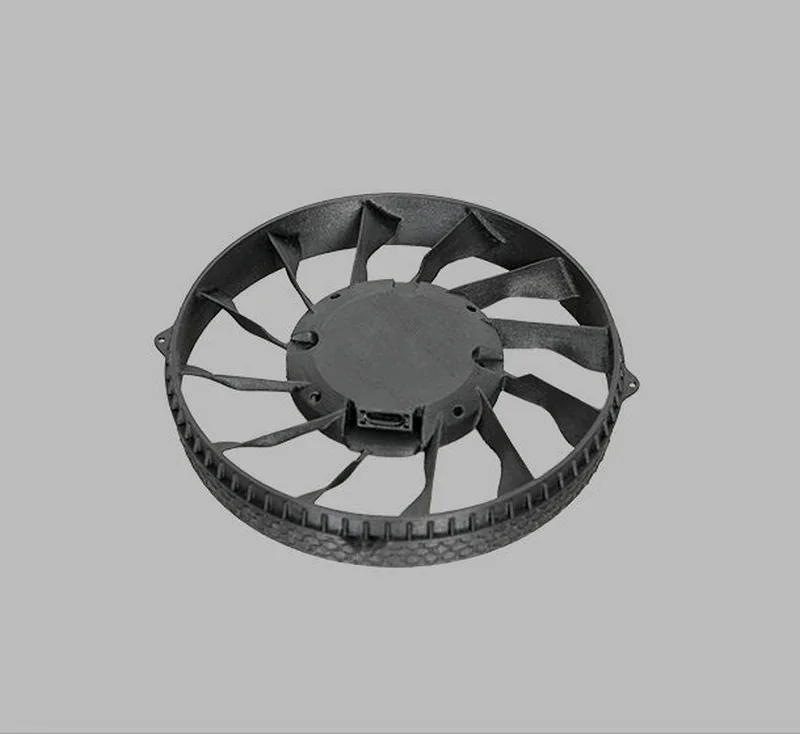

Hyper Core ABS CF15 3D Print Sample: A 160×160×24 mm cooling fan (77.2 g) printed at 0.2 mm layer height in 6 hours 9 minutes. Designed for industrial equipment, it delivers high strength, precision, durability, light weight, and customization for end-use parts.

Hyper Core ABS CF15 3D Print Sample: A-pillar cover, 131×96×487 mm, 314 g, printed at 0.2 mm layer height in 17 h 39 m. Designed for automotive interior prototypes needing high strength, precision, durability, and low weight.

Hyper Core PPA CF25 3D Print Sample: Contact bracket, 120×60×45 mm, 68.7 g, printed at 0.2 mm layer height in 3 h 43 m. Built for jigs and fixtures needing strength, precision, durability, light weight, and customization.

Impact Strength Testing Results: Tests show PLA (14 strikes) and ABS (30) offer basic durability, while PET GF (97) and carbon fiber composites (100+) deliver superior resistance, proving the Pro3’s capability with advanced materials.

The IDEX dual extruder system allows multi-material printing, producing multi-color models or parts with different support filaments at the same time.

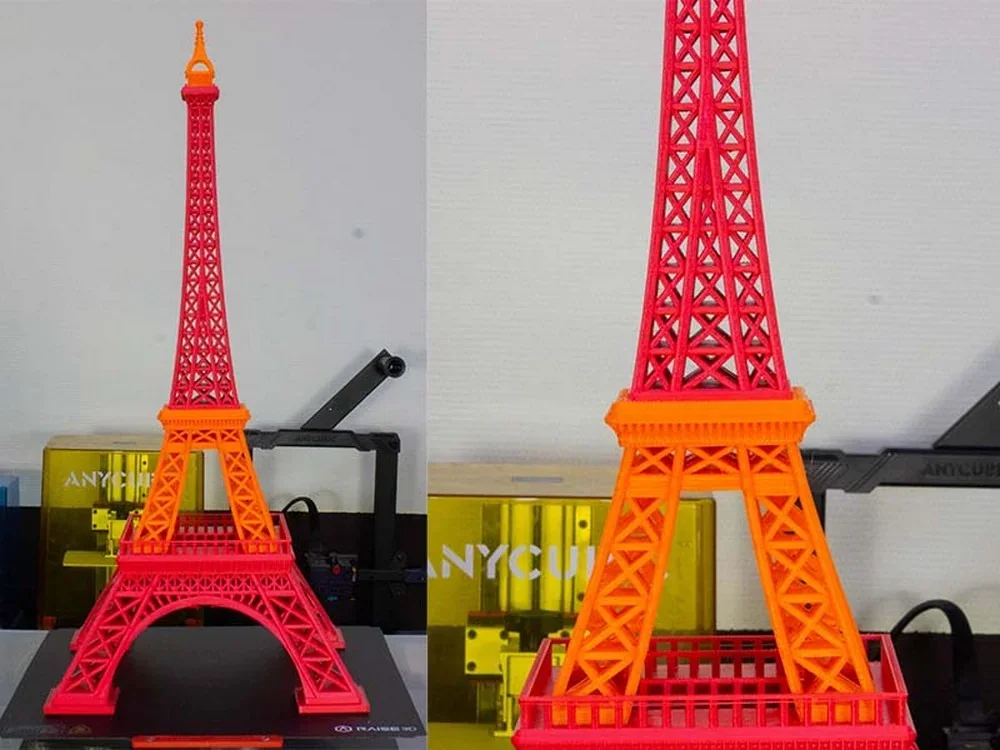

PLA 3D Print Sample: Eiffel Tower models with lattice structures, printed in red-to-orange and orange-to-red gradient filaments.

PLA and PVA 3D Print Sample: Water-soluble PVA supports dissolve completely.

The Raise3D Pro3 Plus HS expands material versatility with PETG, printing at 230°C between PLA and ABS. This glycol-modified polyester offers transparency, impact strength, and environmental stability, resisting UV and moisture for durable prototypes, optical housings, and outdoor parts requiring precision and mechanical reliability.

PETG 3D Print Sample: Medium-strength material between PLA and ABS, offering strong layer adhesion, chemical resistance, and durability for heavy post-processing.

The Raise3D Pro3 Plus HS supports advanced engineering materials beyond Hyper Core and PETG, using precise thermal control and dual extruders. Its heated chamber enables printing with elastomers, polyamides, and flame-retardant compounds for applications requiring certified performance, regulatory compliance, and durability under dynamic loads.

TPU 3D Print Sample: Soft, rubber-like bellows connector prototype.

Nylon 3D Print Sample: Strong, flexible, and impact-resistant, ideal for industrial prototypes and durable final parts.

ABS and PC 3D Printed Parts: Fire-retardant ABS and PC self-extinguish under UL94 standards, ideal for electrical housings and safety-critical applications.

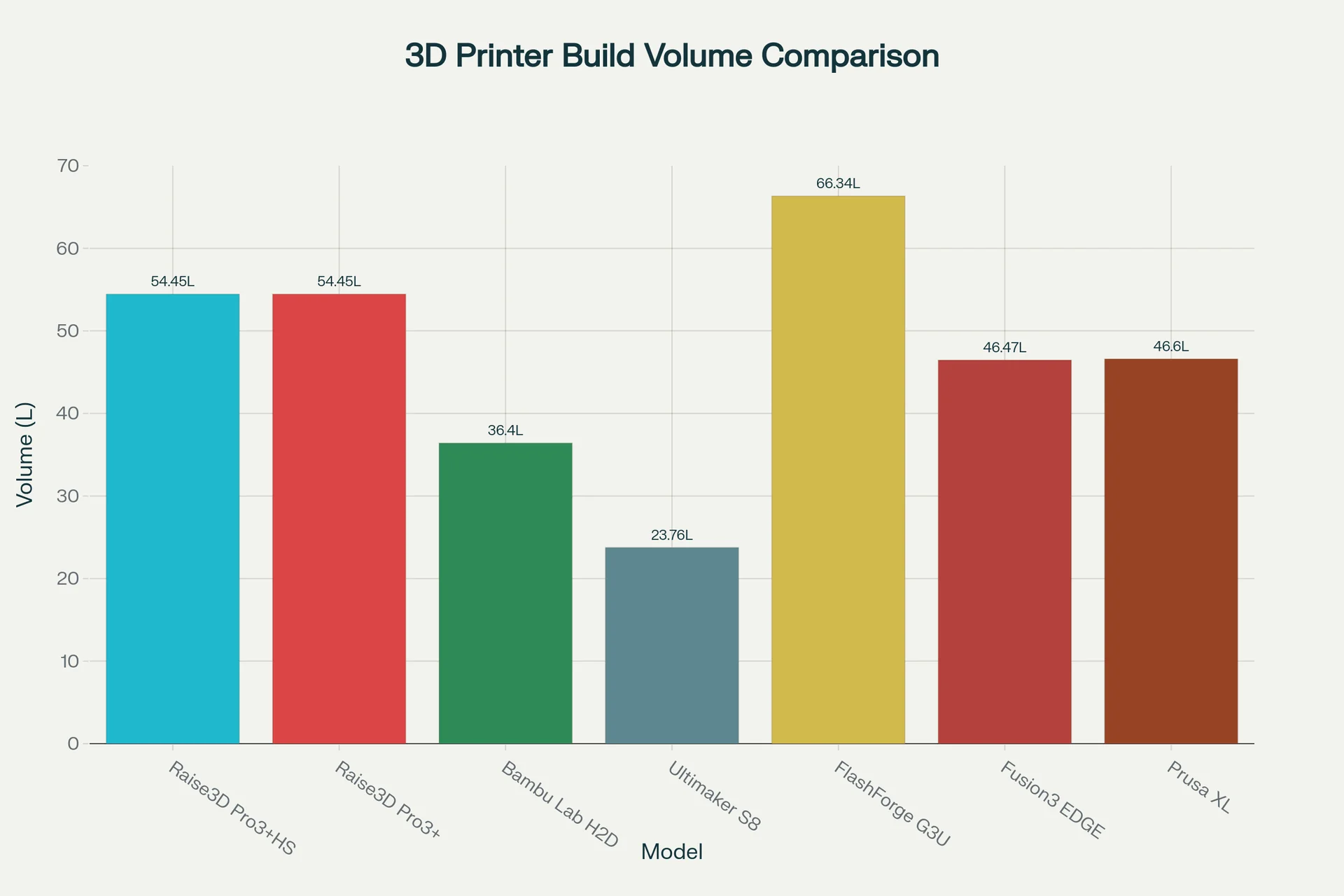

The Raise3D Pro3 Plus HS offers a 300×300×605 mm build volume with a single extruder, suited for tall and mid-sized parts. In dual-extruder mode, the X-axis shrinks to 255 mm, giving a 255 × 300 × 605 mm volume while retaining its strong vertical capacity.

Raise3D Pro3 Plus HS — tall 605 mm Z with dual extruders (electronic nozzle lift), max printing 500 mm/s, 320 °C nozzle, 120 °C bed, mesh-leveling with flatness detection, and HEPA + activated carbon filtration.

In contrast:

| Specification | Raise3D Pro3 Plus HS | Raise3D Pro3 Plus | Bambu Lab H2D | Ultimaker S8 | Flashforge Guider 3 Ultra | Fusion3 Edge |

|---|---|---|---|---|---|---|

| Price (USD, from) | $7,599+ | $5,600+ | $2,000+ | $8,500+ | $3,000+ | $8,850+ |

| Build volume (mm) | 300×300×605 (Single); 255×300×605 (Dual) | 300×300×605 (Single); 255×300×605 (Dual) | 325×320×325 (Single); 300×320×325 (Dual) | 330×240×300 | 330×330×600 (Single); 300×330×600 (Dual) | 368×368×343 |

| Extruders / nozzles | Dual extruders, electronic nozzle lift | Dual extruders, electronic nozzle lift | Dual-nozzle (single/dual print) | Dual extrusion, auto nozzle lift | Dual extruders | Single extruder (ANVIL) |

| Filament Ø | 1.75 mm | 1.75 mm | 1.75 mm | 2.85 mm | 1.75 mm | 1.75 mm |

| Max nozzle temp (°C) | 320 | 300 | 350 | 340 | 350 | 320 |

| Max bed temp (°C) | 120 | 120 | 120 | 120 | 120 | 140 |

| Chamber / enclosure | Enclosed; passive heating | Enclosed; passive heating | Active chamber to ~65 °C | Enclosed, passive heating | Enclosed; passive heating | Enclosed; passive heating |

| Speed / accel / flow | Max printing 500 mm/s (HS) | Max printing 100-150 mm/s (HS) | 1000 mm/s, 20,000 mm/s²; 40/65 mm³/s | 500 mm/s, 50,000 mm/s²; 35 mm³/s | 500 mm/s, 20,000 mm/s² | 250 mm/s print; 500 mm/s travel; 20/36/45 mm³/s |

Bottom-Line: Choose the Raise3D Pro3 Plus HS when you need enterprise-level technical support, application consulting, and an enclosed dual-material platform with a large build volume; buy the Raise3D Pro3 Plus, if you make tall parts, but the print speed is not a priority, or the Flashforge Guider 3 Ultra, if you don’t need dual material. Both will save you budget. Otherwise, the Bambu Lab H2D leads on speed/chamber heat per dollar (≈1000 mm/s, active chamber to ~65 °C), outcompeting the Raise3D Pro3 series on raw throughput. Buy the Fusion3 Edge if you specifically need the wider 368×368 mm XY with high-temperature capabilities (~70 °C enclosure, 140 °C bed), and pick the Prusa XL when 360×360 mm XY and multi-tool flexibility (up to 5 tools) matter more than enclosure and active chamber heat. The Ultimaker S8 targets the same enterprise segment as Raise3D but delivers a smaller 330×240×300 mm build volume at a much higher price, making it uncompetitive on capacity per dollar.

The Raise3D Pro3 Plus HS features a 7-inch touchscreen (1024×600 resolution) with 7 printer controls:

The Raise3D Pro3 Plus HS offers three connectivity options: dual USB 2.0 ports for direct file access, an Ethernet (RJ45) port for wired connections up to 3 meters, and built-in Wi-Fi.

The Raise3D Pro3 Plus HS supports remote operation via RaiseCloud, enabling wireless print management and monitoring from any device. Its built-in HD camera provides live video through RaiseCloud for real-time print verification without being physically at the printer.

The Raise3D Pro3 Plus HS includes ideaMaker, Raise3D’s slicing software for Windows, macOS, and Linux. It converts STL, OBJ, 3MF, OLTP, STEP, STP, IGES, and IGS files into GCODE. ideaMaker offers L1/L2 templates optimized for standard or high-speed printing based on velocity, acceleration, and flow rate. For the Pro3 Plus HS, it adds threshold alerts for these parameters to ensure print quality. The software also connects to Raise3D’s cloud to access material profiles for consistent results across filaments.

The printer uses the EVE Smart Assistant for intelligent monitoring and automated alerts.

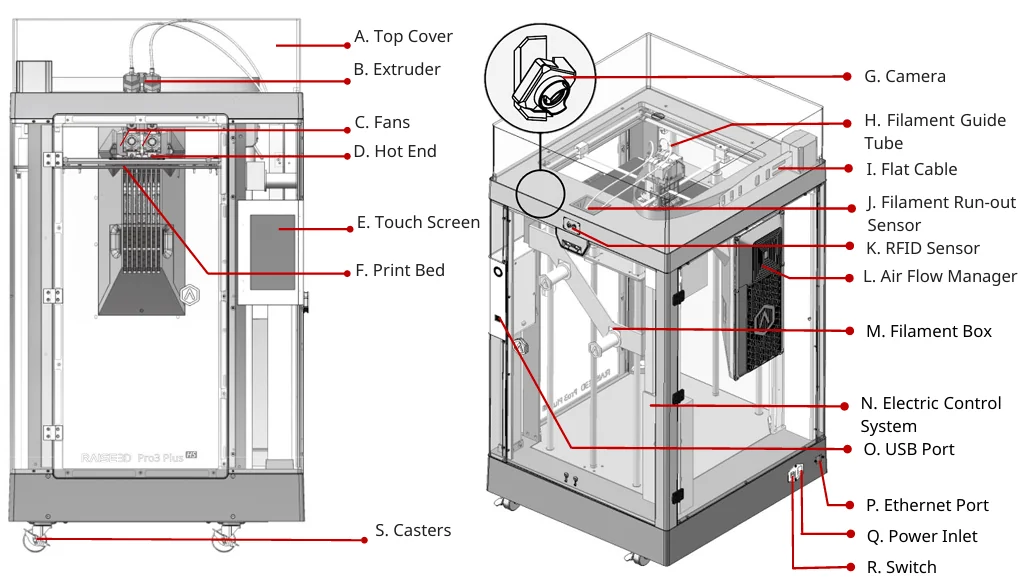

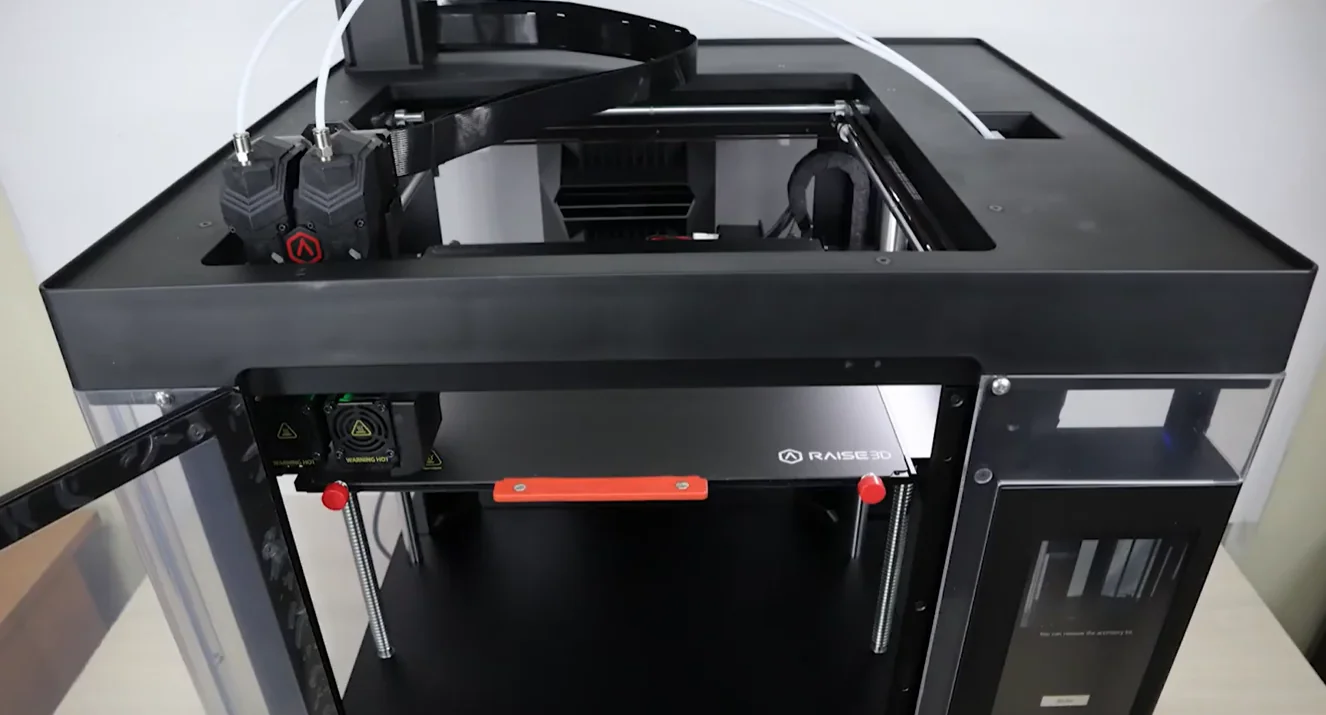

The Raise3D Pro3 Plus HS has a professional enclosed design measuring 620×626×1105 mm (24.4×24.7×43.5 in), featuring a black frame with a transparent full enclosure.

The design includes a front door for easy chamber access, four double-locking casters for mobility and stability, and a removable top cover for maintenance. Its construction balances functionality with a professional look.

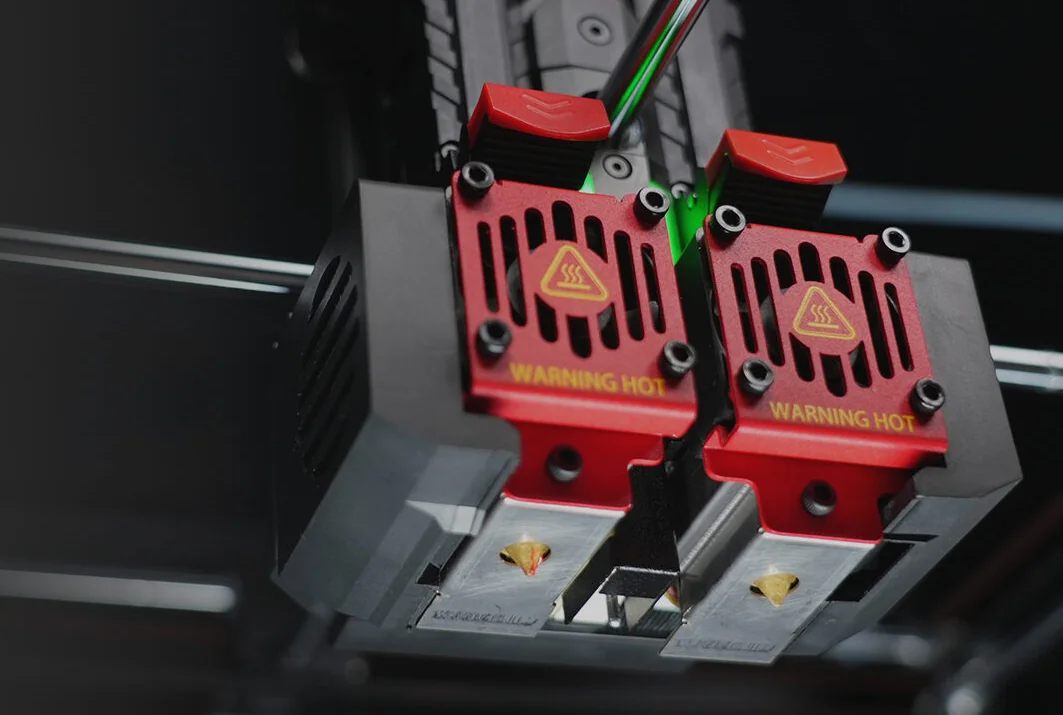

The Raise3D Pro3 Plus HS uses a dual-head motion system with electronic lift functionality.

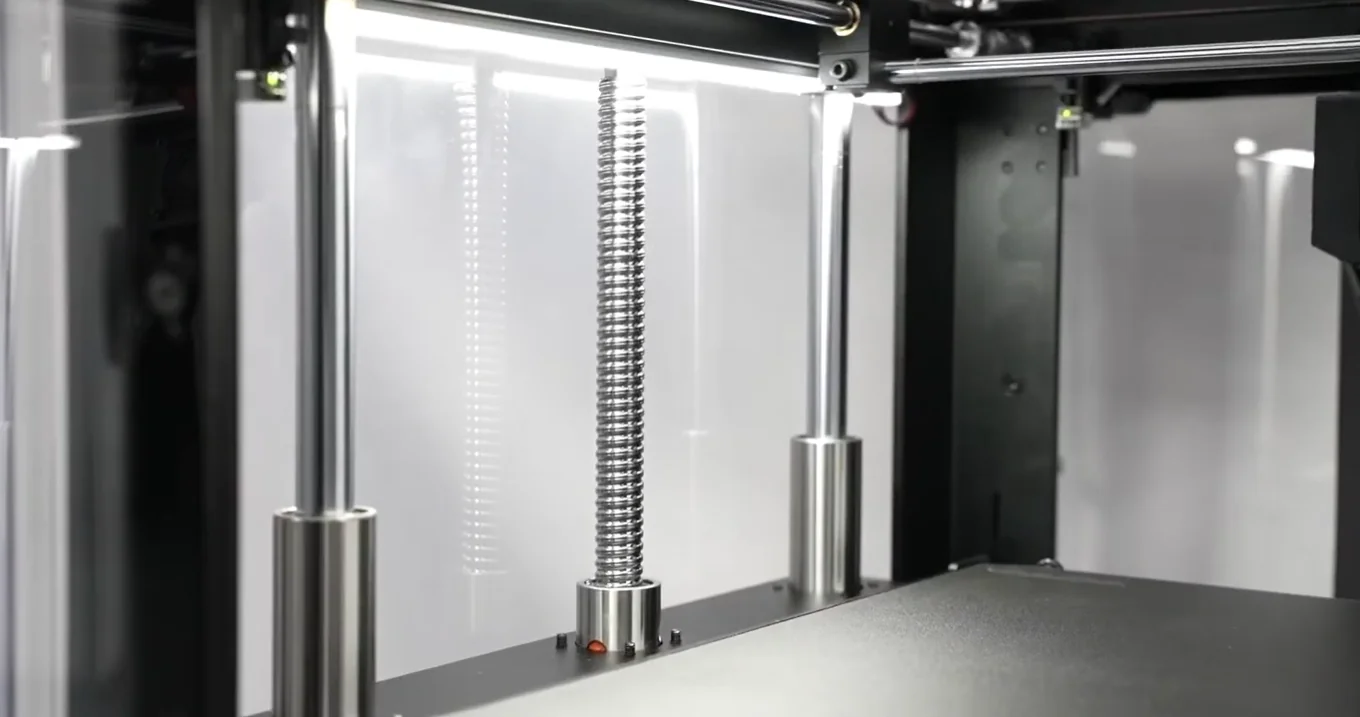

The mechanical framework uses precision linear guides with 16 mm Z-axis rods and 8 mm X- and Y-axis rods.

The system supports print head speeds of 30–300 mm/s. Reinforced CVP screws boost rigidity by 75% over previous models. A new flat cable system replaces drag chains, reducing extruder weight, preventing shaft sag, and transmitting signals from the controller to the extruders.

The Raise3D Pro3 Plus HS prints at under 55 dB(A), making it relatively quiet for a professional 3D printer.

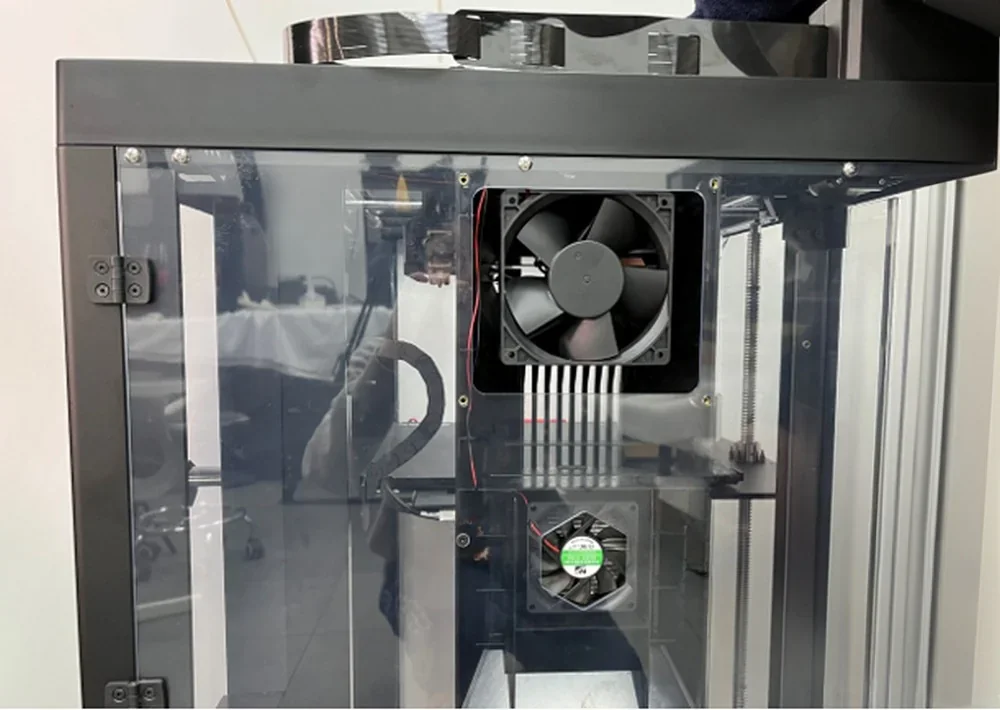

The printer’s noise mainly comes from its dual-fan Air Flow Manager on the rear panel, with a large cooling fan and a smaller filter fan. The rear cooling fan is the loudest part.

Users often report lower noise levels around 40 dB during printing. The difference from official specs likely comes from testing conditions, room acoustics, and print settings affecting perceived noise.

The build platform uses a flexible steel plate with a BuildTak surface for easy print removal. Silicone heaters raise the bed temperature to 120°C, while a magnetic mounting system with multiple magnets secures the flexible surface.

The mesh-leveling system detects 64 points across the build plate to create a virtual height map for compensation. BL-Touch sensors provide precise Z-axis positioning and automatic calibration before each print. Build volumes are 300×300×605 mm for single extruders and 255×300×605 mm for dual setups.

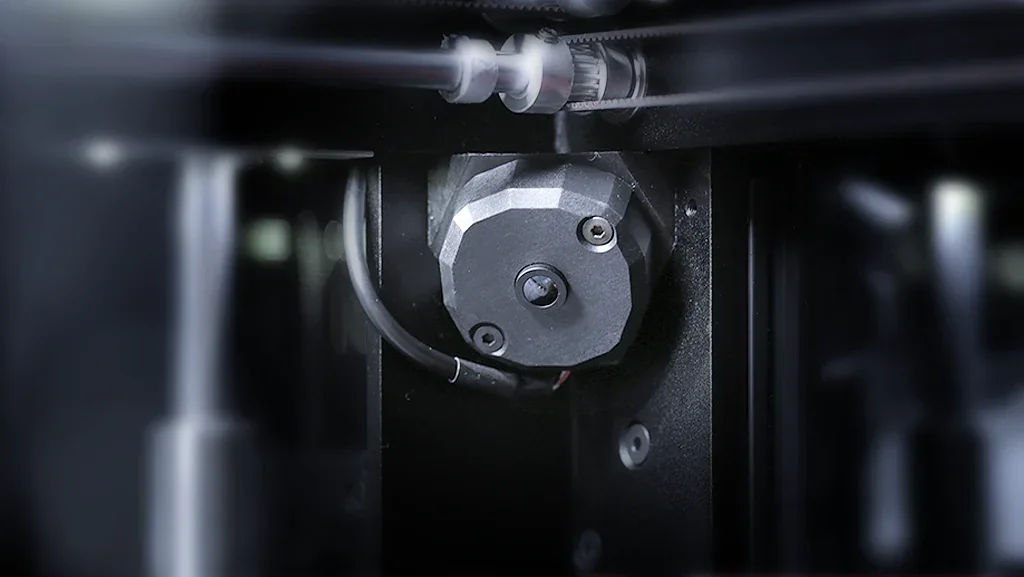

The Pro3 Plus HS uses redesigned unitized extruders with quick-release functionality, allowing disassembly in under a minute for maintenance or nozzle changes. It supports 1.75 mm filament and comes with 0.4 mm V3 brass nozzles, with optional sizes of 0.2, 0.6, 0.8, and 1.0 mm.

The hotend reaches up to 300°C for printing engineering-grade materials. Each extruder has dedicated cooling fans and a Hyper Speed Hot End optimized for high-speed printing. The interchangeable hotend assembly supports SiC nozzles for greater durability.

The Pro3 Plus HS includes an internal filament compartment that holds two 1 kg spools simultaneously.

The filament feeding system uses guide tubes to protect and direct material from the storage compartment to the extruders.

Automated optical sensors detect filament run-out and pause printing to prevent failures. RFID sensors communicate with compatible spools for automatic material identification and parameter optimization.

External filament feeding is supported via left and right inlets on the printer’s right side for external sources. Quick-connect mechanisms on the extruders allow easy filament loading and guide tube attachment.

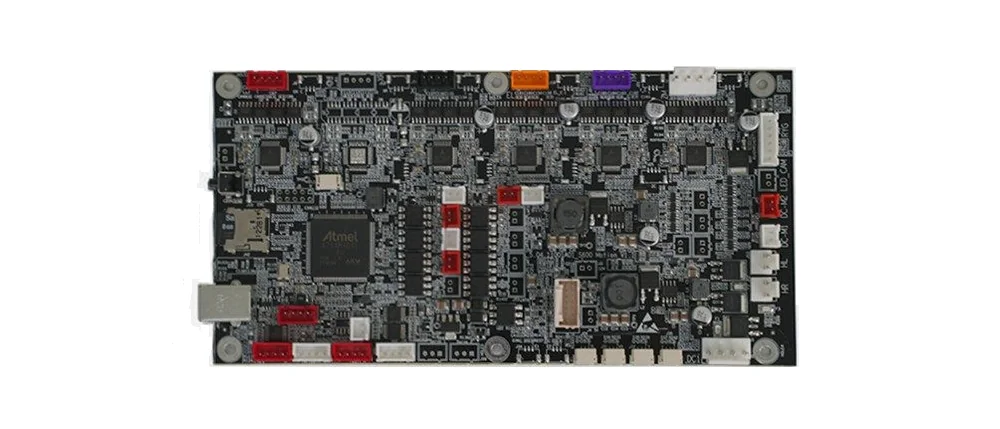

The Pro3 Plus HS features a dual-controller system: an Atmel ARM Cortex-M4 handles motion control, while an NXP ARM Cortex-A9 Quad-Core manages logic and user interface tasks.

The mainboard includes 1 GB RAM, 16 GB flash storage, and runs embedded Linux.

The Pro3 Plus HS operates on 100–240 VAC, 50/60 Hz (230 V @ 3.3 A) for global compatibility. Its 600 W power supply delivers 24 V DC output with grounding, fuse protection, and a main power switch for full isolation. The design ensures stable, safe operation compliant with international standards.

What's Included in the Box:

Power & Connectivity

3D Printing Materials & Feeding

Tools & Hardware

Maintenance & Safety

Hot End Components

The Raise3D Pro3 Plus HS comes fully assembled and ready for use after minimal setup. It includes essential maintenance tools and two spools of Hyper Speed PLA filament for immediate printing after calibration. A built-in Start-up Wizard guides users from unboxing to printing.

Note: Package contents may vary; confirm current items with a Top3DShop sales representative before ordering.

The Raise3D Pro3 Plus HS supports 10+ accessories to enhance performance, extend lifespan, and adapt to specific printing requirements.

| Accessory | Function | Target User | Price (USD) |

|---|---|---|---|

| CF Accessory Kit | Complete kit for carbon fiber printing | Industrial composite users | $470+ |

| 2.5 kg Filament Box | Vacuum-sealed filament container | Users managing large filament volumes | $80+ |

| Cabinet for Plus Size Printer | Enclosure with temperature control and safety | Commercial large-format printer users | $800+ |

| Brass Nozzle V3 0.4mm | Standard nozzle | All users (basic consumable) | $20+ |

| Steel Nozzle with WS2 Coating | Coated nozzle for abrasion and heat resistance | Advanced technical material users | $50+ |

| Hardened Nozzle V3 | Durable nozzle for abrasive filaments | Users handling tough materials | $25+ |

| Silicon Carbide Nozzle 0.4mm | Ultra-durable nozzle for industrial abrasive filaments | Specialized industrial users | $100+ |

| Hyper Speed Hot End Assembly with Brass Nozzle 0.4mm V2 | Upgraded hot end for faster printing without quality loss | Production and advanced users | $140+ |

| Build Plate with Handle & Buildtak Surface | Build surface with strong adhesion and easy removal | All users (reliable printing) | $90+ |

| Filament Detection Assembly | Automatic filament monitoring | Production users needing uninterrupted prints | $70+ |

The CF Accessory Kit, designed for Raise3D Pro3 HS Series and Pro3 Series printers with the Hyper Speed Upgrade, enables composite filament printing. It includes a 2.5 kg Filament Box, a Hyper Speed Hot End with a 0.6 mm silicon carbide nozzle (V3), and one spool each of Hyper Speed PET CF and Hyper Core PPA CF25 (black, 1 kg). The kit provides composite material options and ensures high-performance fiber-reinforced printing compatibility.

The Raise3D 2.5 kg Filament Box holds one 2.5 kg or two 1 kg spools, maintaining controlled humidity and temperature with a digital display. Weighing 2.8 kg and measuring 466 × 190 × 455 mm, its sealed design protects filaments from environmental exposure during storage.

The Raise3D Cabinet for Plus Size Printers supports the Pro3 Plus HS, Pro3 Plus, Pro2 Plus, and Forge1 models. It includes filament and dry box frames, a drawer with tool slots, and a large compartment with shelves for materials and tools. Made of PC, PE, and metal, it measures 620 × 590 × 530 mm, weighs 48.1 kg (with packaging), and features lockable wheels for printer stability.

The Raise3D Brass Nozzle V3 0.4 mm, compatible with Pro3 HS Series, Pro3 Series, Pro2 Series, E2, and E3 printers, offers efficient heat transfer up to 300°C for non-abrasive filaments. Its 0.4 mm opening with <0.02 mm variation ensures smooth, consistent extrusion. Made of corrosion-resistant brass, it features a chamfered, grooved design to reduce resistance and leakage. Suitable for PLA, ABS, PETG, TPU, and reinforced filaments, though abrasive materials cause faster wear. Users should recalibrate after replacement and handle the hot nozzle with care.

The Steel Nozzle with WS2 Coating, compatible with Raise3D Pro3 HS Series, Pro3 Series, Pro2 Series, E2, and E3 printers, is available in 0.4, 0.6, and 0.8 mm sizes for 1.75 mm filament. Its tungsten disulfide coating reduces friction and buildup, providing lubrication and abrasion resistance up to 450°C. With a Mohs hardness of 7.8, it delivers durable, consistent extrusion for abrasive composite filaments, while unfilled materials are best printed with brass nozzles.

The Hardened Nozzle V3, compatible with Raise3D Pro3 HS Series, Pro3 Series, Pro2 Series, E2, and E3 printers, comes in 0.2–1.0 mm sizes. It offers superior durability and wear resistance for precise extrusion with abrasive materials. Measuring 130 × 110 × 5 mm and weighing 9 g packaged, it’s built for long-lasting use across various filaments.

The 0.4 mm Silicon Carbide Nozzle, made for Raise3D Pro3 HS Series, E2CF, and E3 printers, delivers durable, precise extrusion for abrasive filaments. Its silicon carbide build ensures high wear resistance. Packaging measures 110 × 130 × 10 mm and weighs 7.8 g.

The Raise3D Hyper Speed Hot End Assembly with 0.4 mm brass nozzle (V2) is a replacement for Pro3 Series and Pro3 HS Series printers. Measuring 144 × 116 × 66 mm, it supports high-speed printing through efficient filament melting and extrusion.

The Build Plate with Handle and Buildtak Surface, made for Raise3D Pro3 HS Series and Pro3 Series printers, enhances adhesion and simplifies model removal. Measuring 400 × 350 × 10 mm and weighing 469.2 g packaged, it provides a stable, user-friendly printing platform.

The Filament Detection Assembly for Raise3D Pro3 HS Series printers monitors filament levels and alerts users when low, preventing print interruptions. Weighing 154.9 g, it integrates seamlessly to improve reliability and workflow continuity.

The Raise3D Pro3 HS Series requires over 17+ maintenance tasks to ensure print quality and printer longevity.

Per Print Maintenance:

400-Hour Maintenance:

600-Hour Maintenance:

The Raise3D 3D printers come with a 1-year limited warranty covering non-electronic and non-consumable parts. RaiseShield warranty extensions (1, 2, or 3 years) offer full coverage for electronic and mechanical components, excluding consumables and cosmetic defects.

Technical Support

Support Center: Access user guides, maintenance tips, and troubleshooting resources at https://support.raise3d.com/.

Submit Tickets: For access to the Raise3D team, submit tickets via http://help.raise3d.com/.

Phone Support:

Educational Resources

Certifications

Access CE, CB, FCC, and RoHS certifications on the Raise3D website.

Full warranty terms: https://www.raise3d.com/download/raise3d-limited-warranty-all-versions/

The Raise3D Pro3 Plus HS is priced at $6,649.05. It offers dual extrusion, large build volume, automated bed calibration, advanced motion system, and compatibility with materials from the Open Filament Program. The printer includes a manufacturer warranty. For custom installations, service packages, or specialized setups, contact Top3DShop for a personalized quote.

Update your browser to view this website correctly. Update my browser now