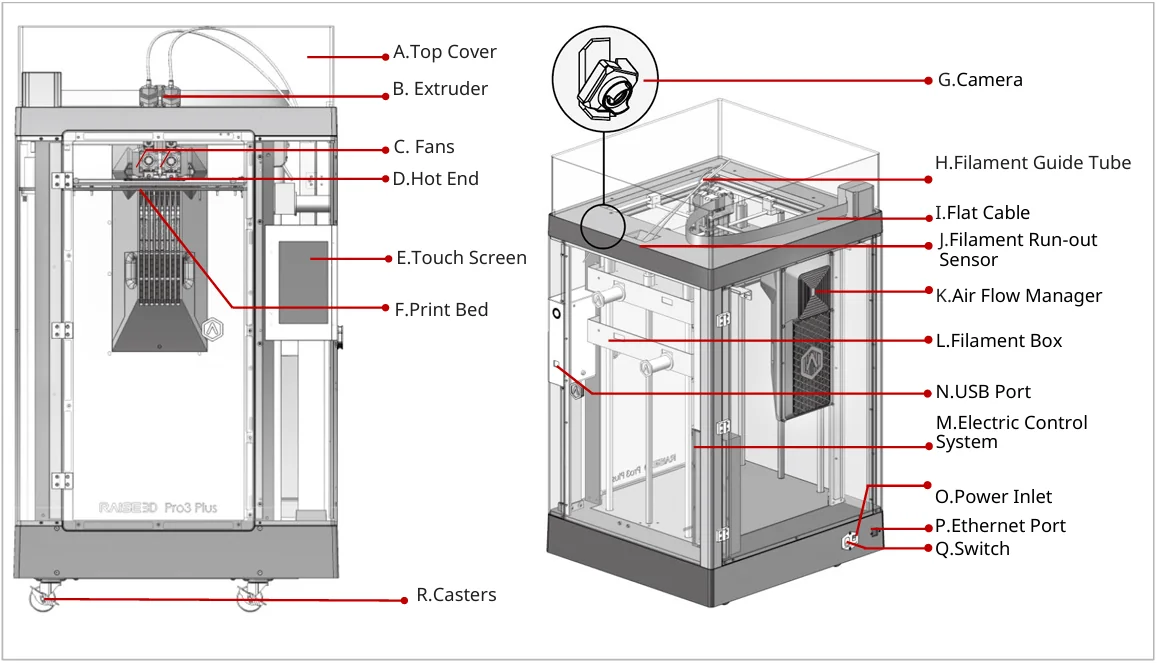

The Pro3 Plus is a professional dual-extruder 3D printer with a 300×300×605 mm build volume, designed for production and rapid prototyping across industries like engineering, aerospace, and education. It features a single-side nozzle lifting system with 5-micron repeatability, auto bed leveling, a flexible build plate, and a stiffer Z-axis for stability. Maintenance is simplified with tool-free, swappable hot ends, while the Air Flow Manager with HEPA filter ensures better cooling and print quality. Compatible with a wide range of filaments, it integrates seamlessly with Raise3D’s software ecosystem and operates quietly, making it ideal for reliable, continuous, high-quality printing.

The Raise3D Pro3 Plus offers high precision with 5-micron repeatability and 0.1 mm tolerance, printing at 10–150 mm/s (up to 350 mm/s with the Hyper Speed Upgrade Kit). The upgrade cuts print times by up to 66% — for example, reducing a calibration cube from 38 to 17 minutes and a Mandalorian helmet from 156 hours to 2 days — while maintaining sub-micron XYZ accuracy (0.78125, 0.78125, 0.078125 microns).

The Pro3 Plus delivers high dimensional accuracy, printing complex geometries and interlocking parts with 0.1 mm tolerance using Raise3D Premium PLA, demonstrating precision suitable for functional components.

The Pro3 Plus achieves excellent surface quality through consistent extrusion and mechanical stability. ABS parts printed at 0.2 mm layer height show flat, smooth surfaces suitable for production-grade assemblies where finish affects performance and fit.

The Pro3 Plus maintains consistent quality across complex geometries through precise linear motion control. PLA prints at 0.2 mm layer height show smooth transitions and accurate angular features. With XYZ step sizes of 0.78125, 0.78125, and 0.078125 microns, the system delivers the positional precision needed for intricate designs.

The Pro3 Plus excels in overhang performance, using optimized cooling airflow and speed to print smooth, support-free PC parts at 0.2 mm layer height. Its efficient thermal management enables steep overhangs while preserving structural integrity and surface quality.

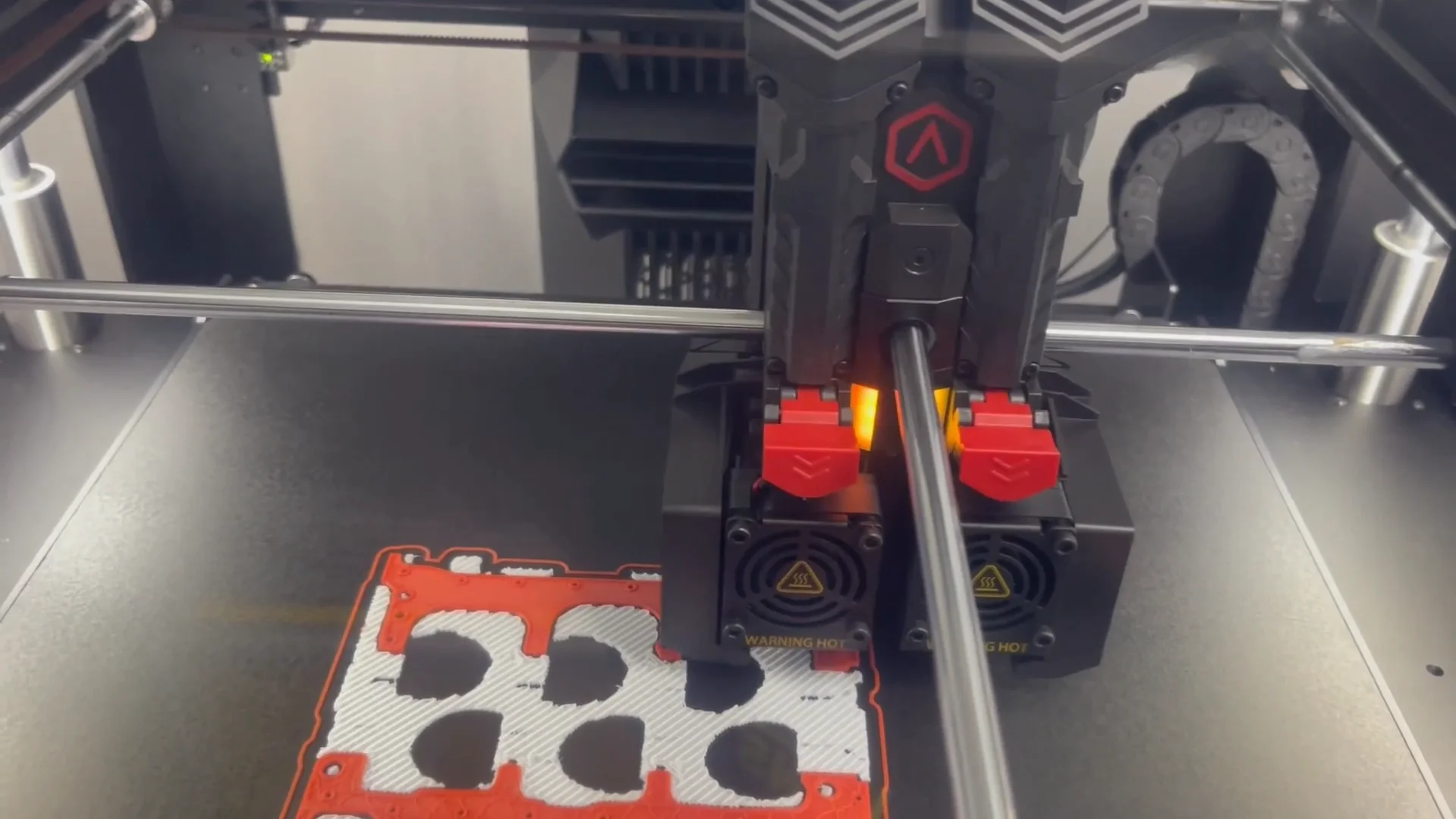

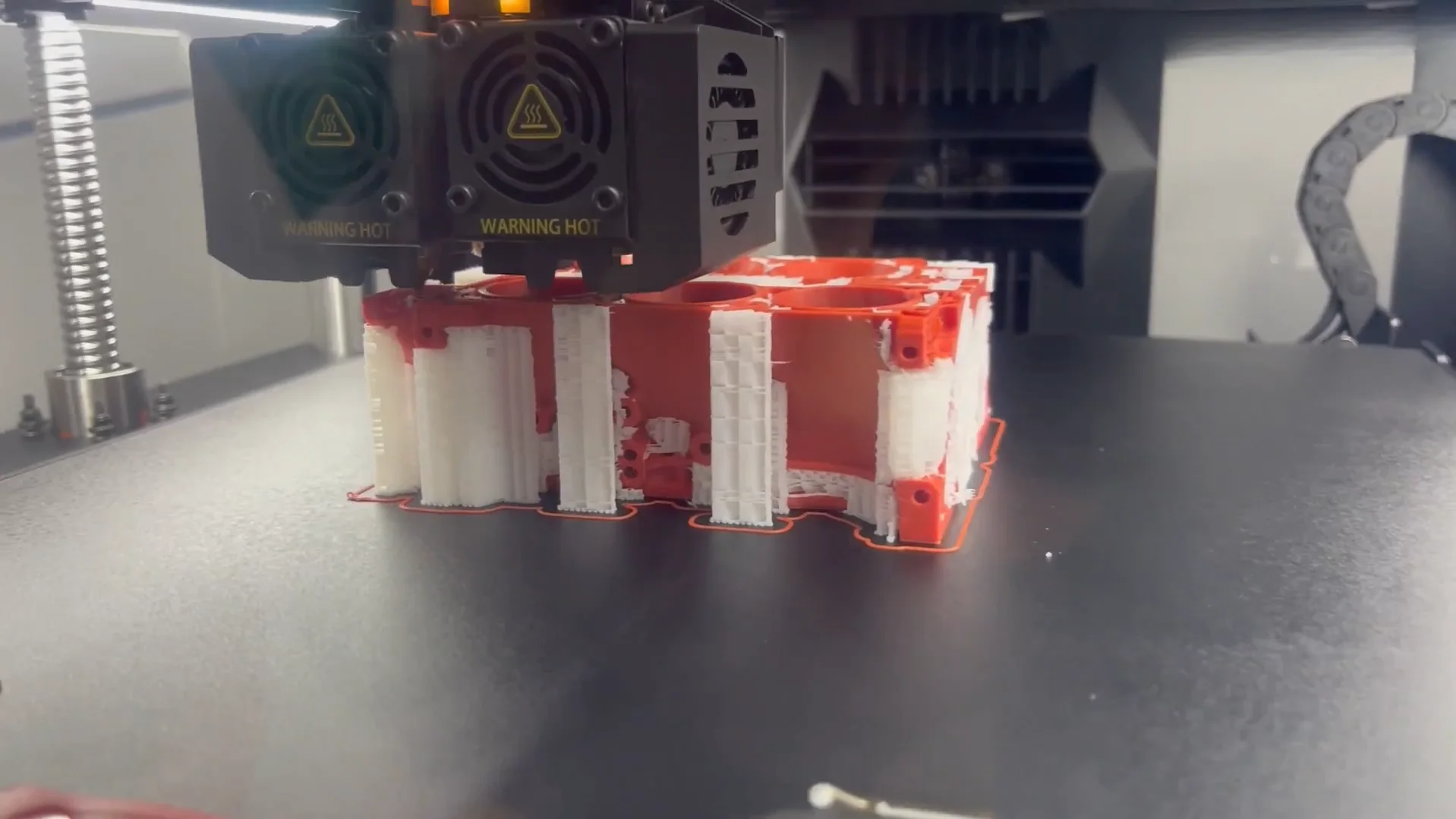

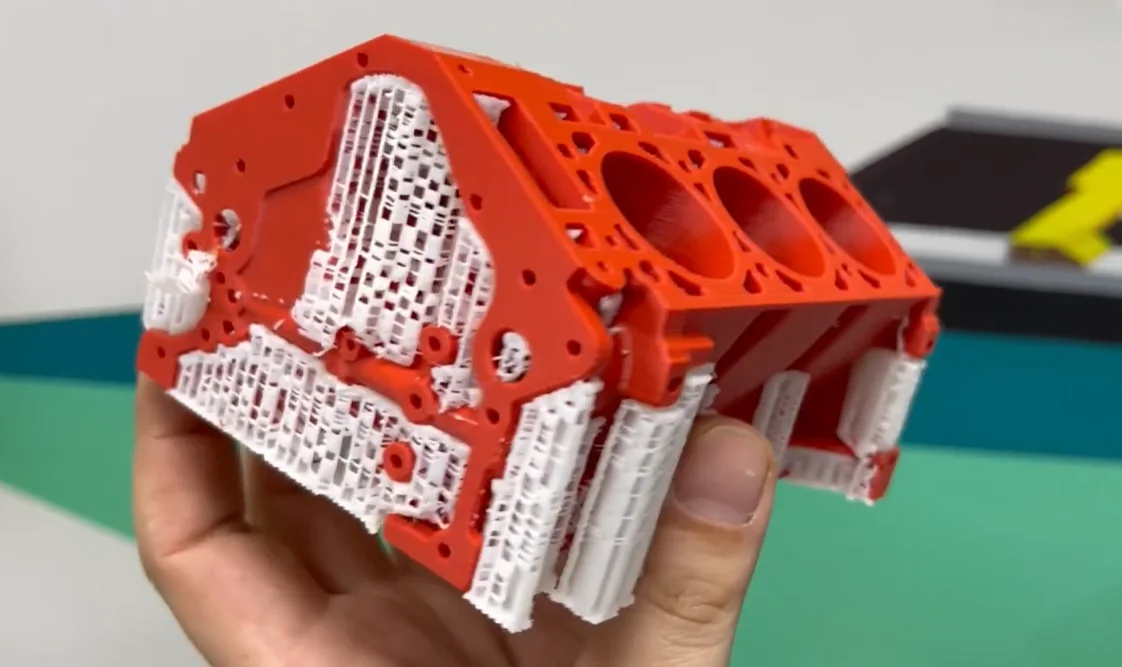

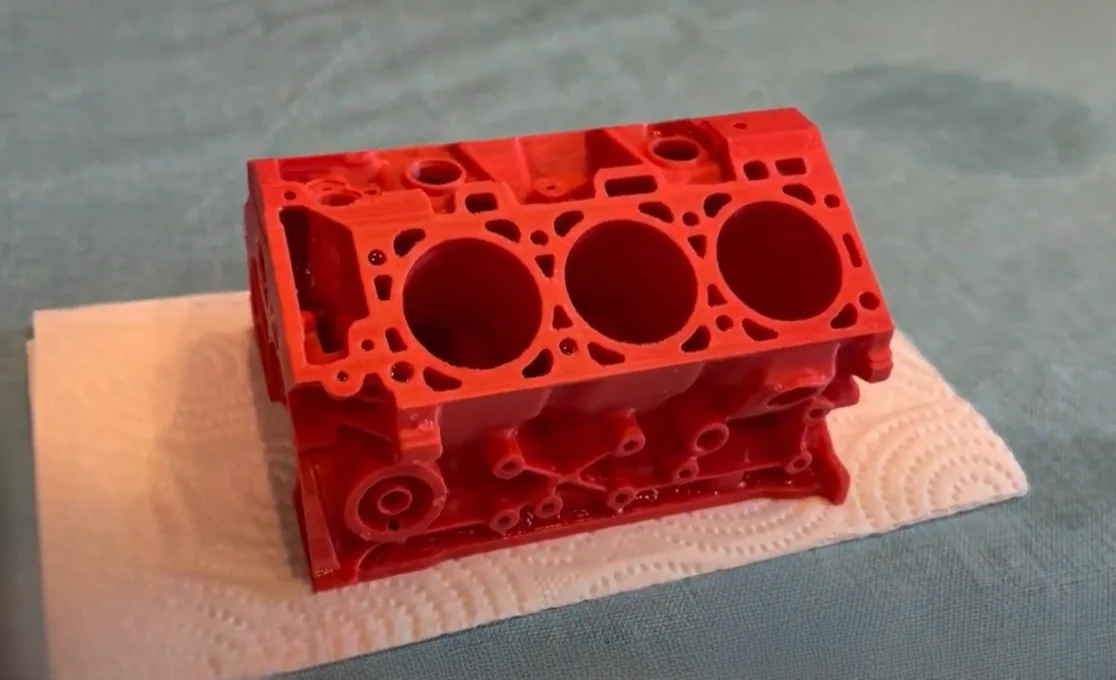

Real-world testing highlights the Pro3 Plus’s precision and reliability. A dual-material ABS and HIPS Ford V6 engine block replica printed at 60 mm/s, 0.25 mm layer height, and 10% infill demonstrates its ability to handle complex internal geometries, supports, and hollow sections while maintaining structural integrity.

Post-processing is efficient, with HIPS supports dissolving completely in D-Limonene within 3–4 hours, removing material from hard-to-reach areas while preserving the smooth finish of ABS surfaces.

The Pro3 Plus prints at 10–150 mm/s, typically 60 mm/s with 1000 mm/s² acceleration, delivering professional precision. The Hyper Speed Upgrade Kit boosts speeds to 200–350 mm/s and acceleration to 10,000 mm/s², cutting print times by 66% and increasing batch throughput up to 500%, achieving 600–1000g output per day. Tests show identical parts print in 4 hours at standard settings versus 3.5 hours with Hyper Speed, maintaining dimensional accuracy.

Calibration cube tests show the HS system reduces print time from 38 to 17 minutes at 0.2 mm layers while maintaining surface quality, detail, and precision, confirming professional results even at 10,000 mm/s² acceleration.

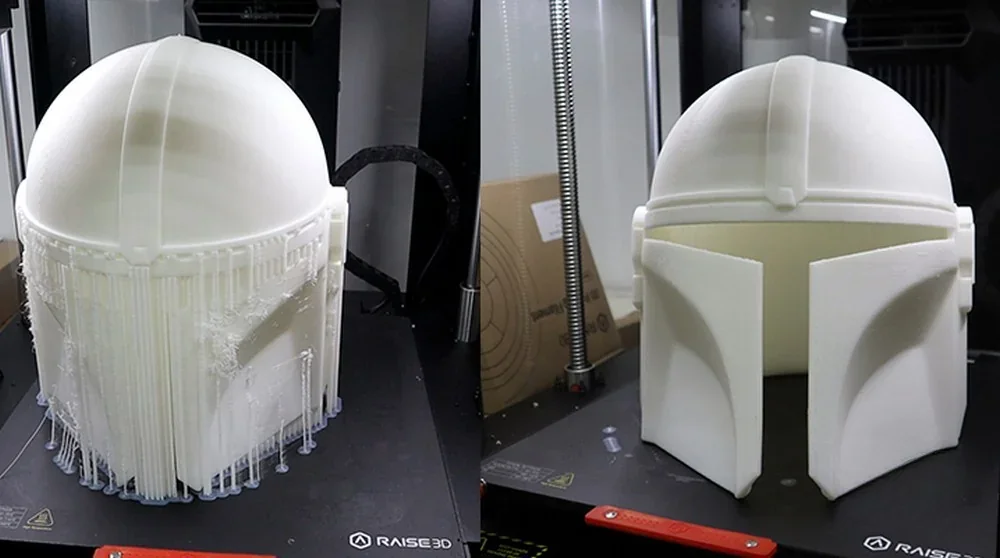

A full-scale Mandalorian helmet (30 cm x 26 cm) tested the HS-equipped Pro3 on complex geometry, overhangs, and heavy material use. It finished in 2 days versus 156 hours at standard settings, proving acceleration benefits scale to large builds. The print showed precise detail and clean support removal, confirming real-world production quality.

Beyond testing, the Pro3 Plus delivers measurable production benefits, reducing project time and costs through fast iteration and high material throughput. Automotive and biomedical applications confirm its ability to maintain accuracy at high speeds, shortening development cycles and accelerating research workflows.

Case Study: The Raise3D Pro3 Plus (with Hyper Speed Upgrade Kit) speeds up custom motorcycle part production using carbon fiber ABS at up to 300 mm/s. It delivers strong, smooth parts with precise magnetic insert placement. Prototyping times as short as one hour shorten development cycles, supporting faster launches and competitive advantage.

Case Study: KOKIDO, a global pool robot manufacturer with 75 million units sold in 58 countries, uses the Pro3 Plus with Hyper Speed Upgrade Kit to remove multi-day delays between Hong Kong design and mainland production. Running 50 hours weekly and producing 200+ validated parts, it enables same-day ergonomic and dimensional testing. “The speed and tolerance are within our standard,” says Alan Ma, Head of Product Development, noting gear assemblies now achieve precise performance through rapid test-and-modify cycles once requiring days.

Case Study: In biomedical research, the Raise3D Pro3 Plus (with Hyper Speed Upgrade Kit) enables fabrication of complex bioprinters and hydrogel structures. Precise fit and detail alignment ensure reliable assembly for live tissue printing, while fast prototyping boosts experimental efficiency and research quality in cellular engineering and organ modeling.

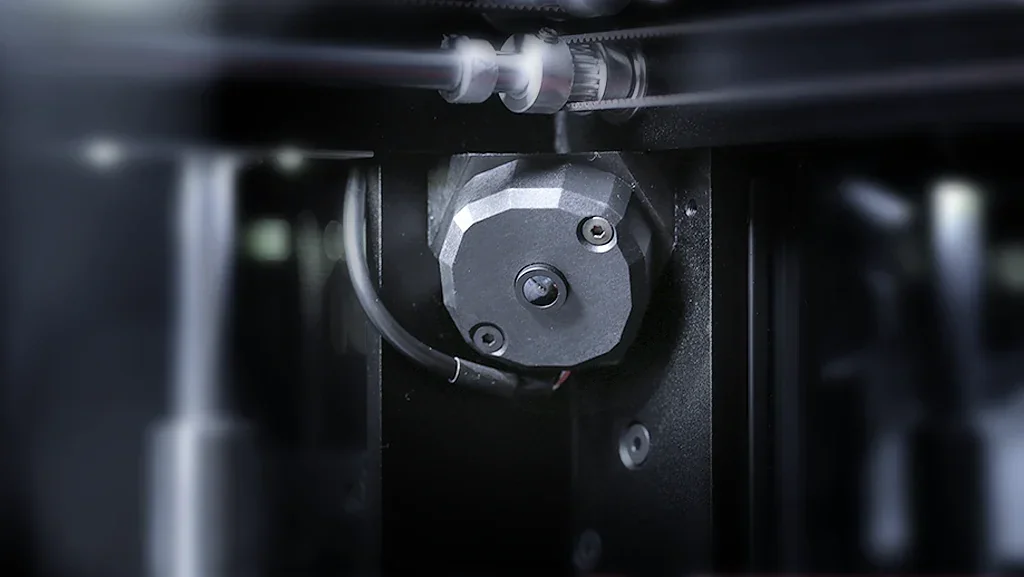

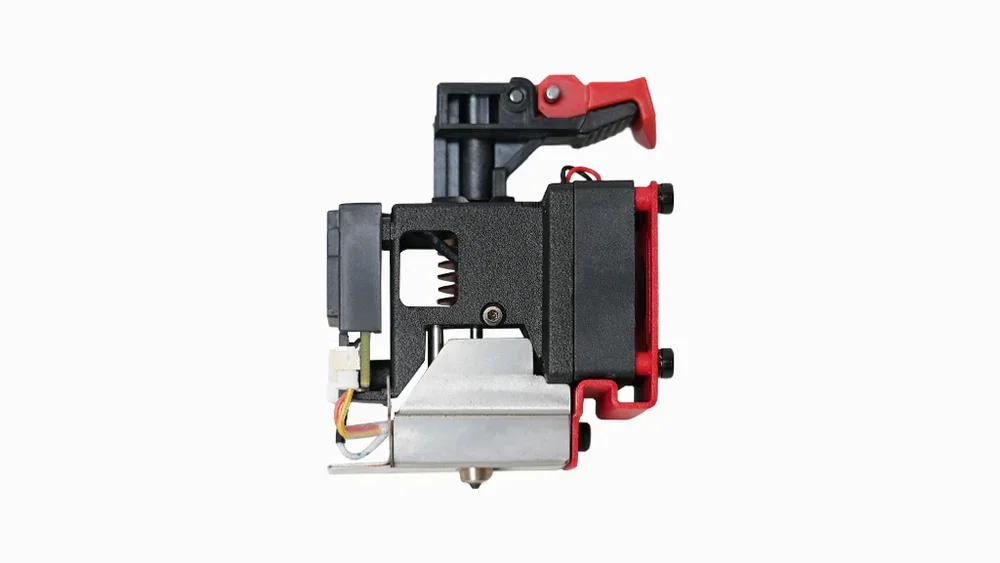

The series professional dual extruder 3D printer Pro3 Plus is lightweight dual direct-drive extruders improve filament control with less moving mass and detachable, quick-swap hot-ends. Integrated cooling focuses on improving heat dissipation to keep extrusion temperatures stable for precise material flow.

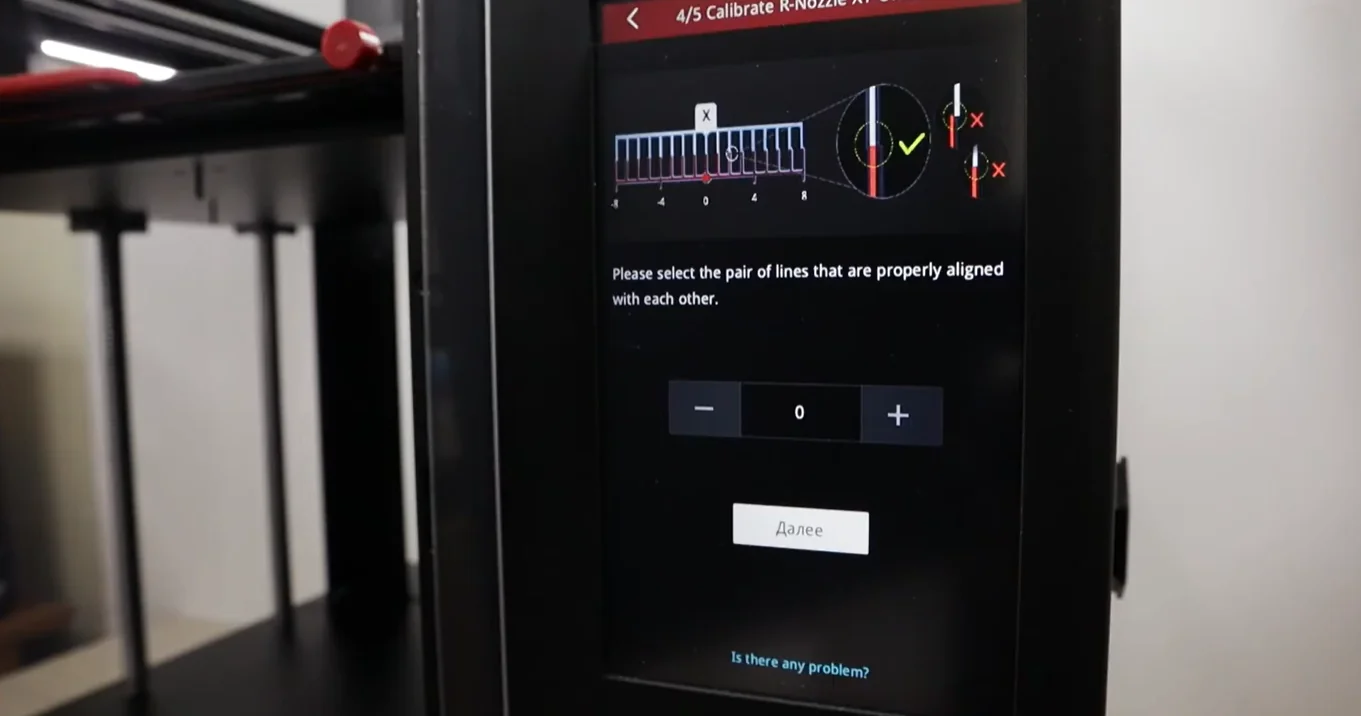

The Pro3 Plus uses BuildTouch sensors for automated 9-point bed leveling with 0.02 mm accuracy. It creates a 3D deviation map to keep consistent nozzle distance and adhesion across the 300×300 mm platform.

The Raise3D Pro3 Plus supports 20+ thermoplastic filaments categorized by performance:

For high-speed printing, Raise3D’s Hyper Speed PLA and ABS reach up to 300 mm/s — four times faster than standard filaments. Their optimized chemistry boosts interlayer adhesion and Z-axis strength by 20%, maintains surface quality, and prevents clogs or warping through better cooling and flow.

Impact Strength Testing Results: Tests show PLA (14 strikes) and ABS (30 strikes) offer basic durability, while PET GF (97) and carbon fiber composites (100+) provide superior resistance, showcasing the Pro3’s ability to process advanced materials for demanding uses.

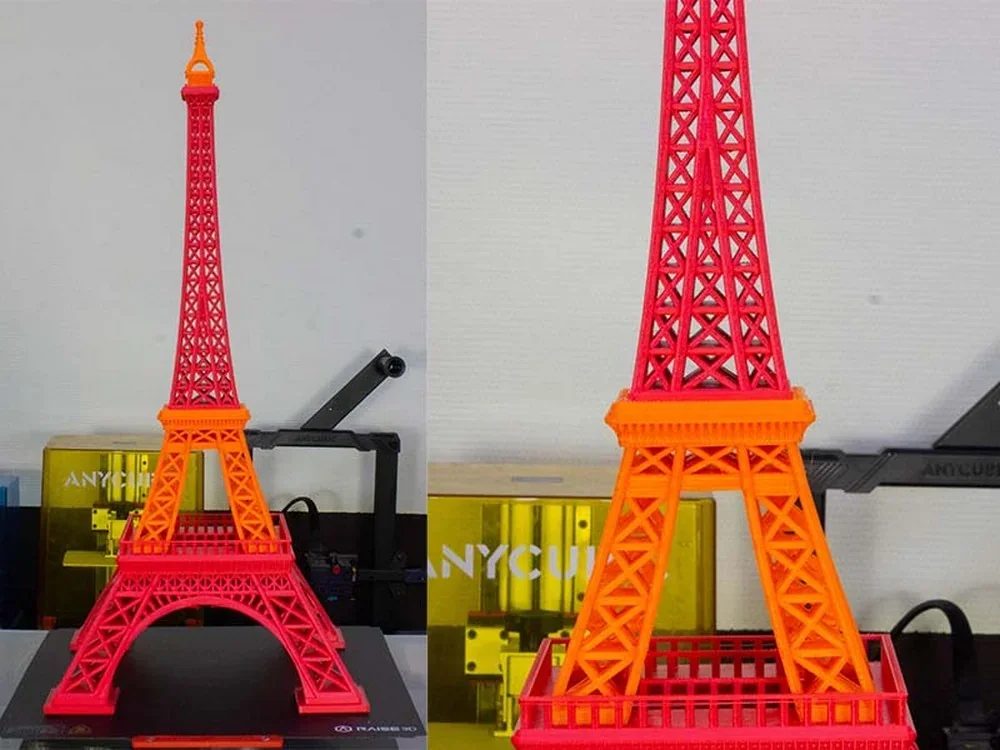

PLA 3D Print Sample: Eiffel Tower models with lattice structures, printed in red-to-orange and orange-to-red gradient filaments.

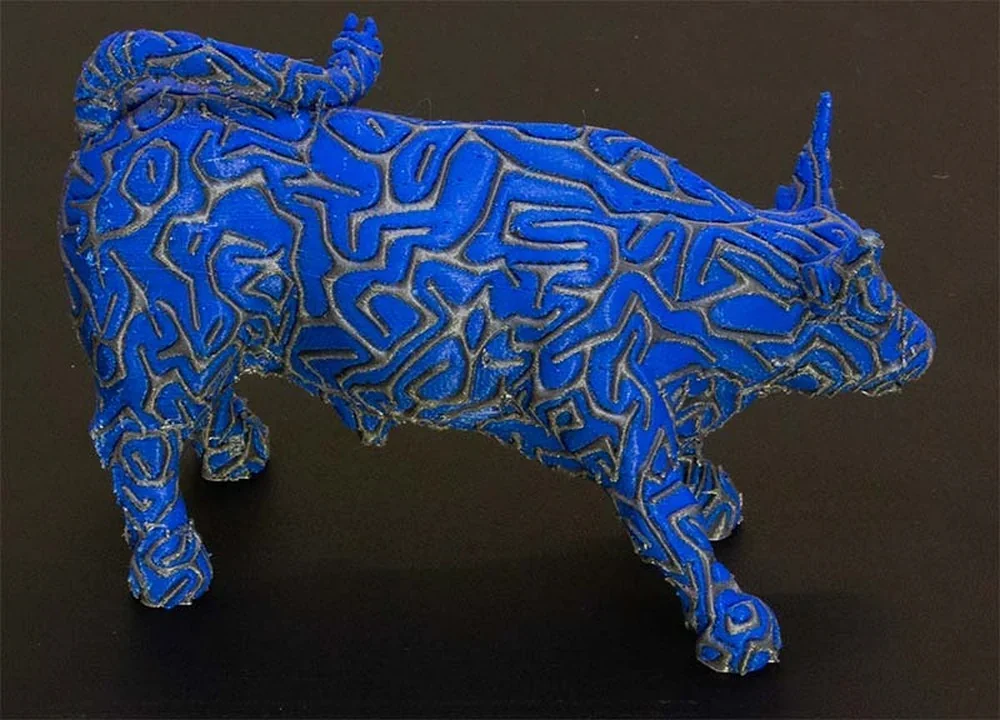

PLA 3D Print Sample: Bovine figurine with full-surface maze texture, printed in blue filament.

PLA and PVA 3D Print Sample: Water-soluble PVA supports dissolve completely.

TPU 3D Print Sample: Soft, rubber-like bellows connector prototype.

4

PETG 3D Print Sample: Medium-strength material between PLA and ABS, offering strong layer adhesion, chemical resistance, and durability for heavy post-processing.

Nylon 3D Print Sample: Strong, flexible, and impact-resistant, ideal for industrial prototypes and durable final parts.

ABS and PC 3D Printed Parts: Fire-retardant ABS and PC self-extinguish under UL94 standards, ideal for electrical housings and safety-critical applications.

The Raise3D Pro3 Plus supports both proprietary and third-party filaments through the Open Filament Program (OFP), a partnership with manufacturers to expand material compatibility. Its ideaMaker Library provides ready-to-use slicing profiles for Raise3D and OFP-certified materials, simplifying setup and ensuring consistent quality. This integration gives users flexibility in filament choice without sacrificing performance or reliability.

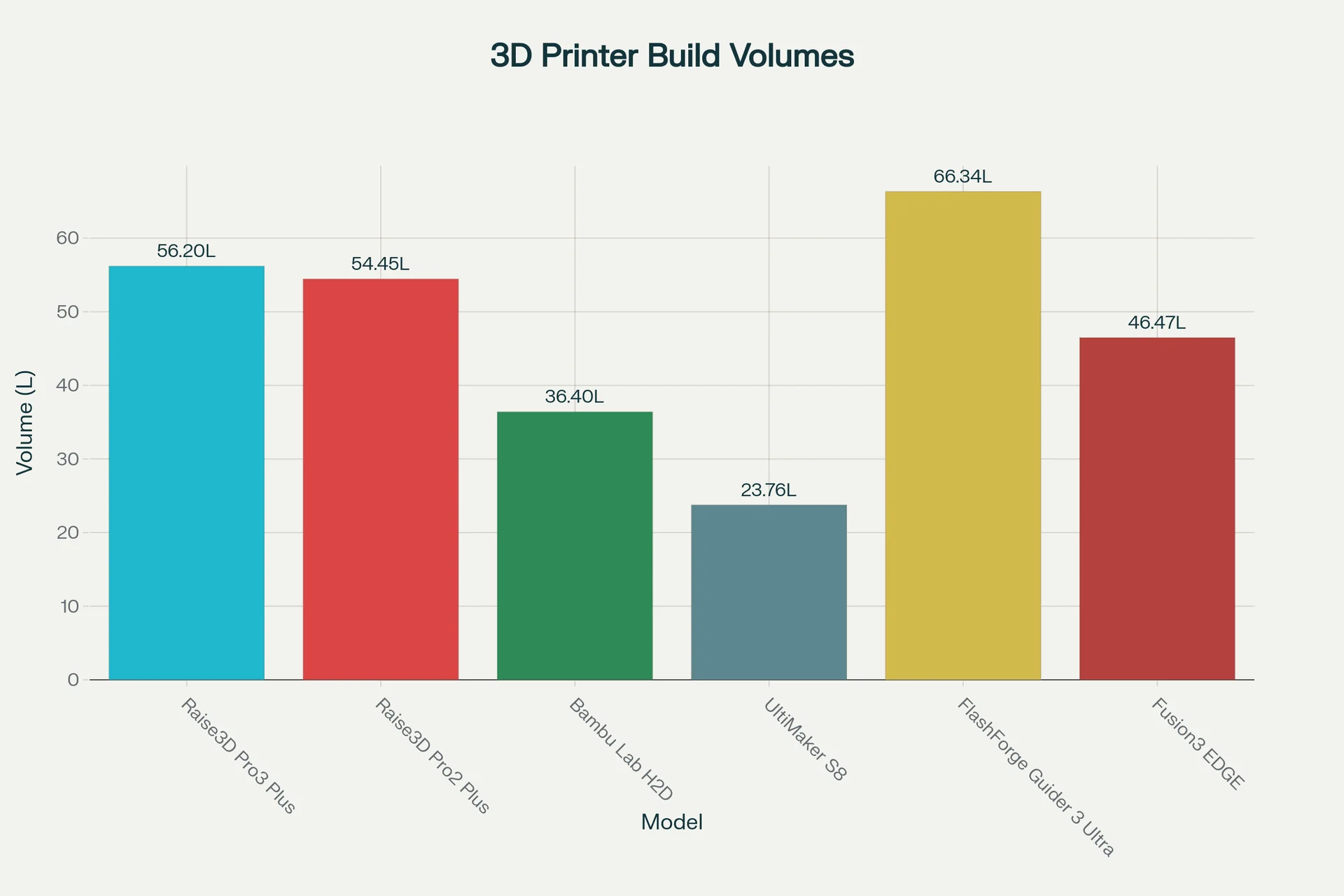

The Raise3D Pro3 Plus offers a build volume of 300×300×605 mm with one extruder, or 255×300×605 mm in dual-extruder mode. Its extended height doubles the Pro3’s vertical capacity, making it ideal for large-format, tall projects. Testing showcased the Pro3 Plus’s extended build volume with large prints like a scaled T-rex skull (158 hours, 1.4 kg PLA), a life-sized cosplay helmet, and a giant multi-color pylon. These examples demonstrate its strength in producing large prototypes beyond the capacity of smaller printers.

Raise3D Pro3 Plus — tall 605 mm Z, dual extruders with electronic nozzle lifting, mesh-leveling with flatness detection, 120 °C flexible steel build plate, HEPA + activated carbon filtration, up to 350 mm/s print-head travel, and the EVE assistant for guided maintenance.

In contrast:

| Specification | Raise3D Pro3 Plus | Raise3D Pro2 Plus | Bambu Lab H2D | Ultimaker S8 | Flashforge Guider 3 Ultra | Fusion3 Edge |

|---|---|---|---|---|---|---|

| Price (USD, from) | $5,600+ | $3,000+ | $2,000+ | $8,500+ | $3,000+ | $8,850+ |

| Build volume (mm) | 300×300×605 (single); 255×300×605 (dual) | 305×305×605 (single); 280×305×605 (dual) | 325×320×325 (single); 300×320×325 (dual) | 330×240×300 | 330×330×600 (single); 300×330×600 (dual) | 368×368×343 |

| Extruders / nozzles | Dual extruders, electronic nozzle lift | Dual extruders, electronic nozzle lift | Dual-nozzle system (single/dual printing) | Dual extrusion, auto nozzle lift | Dual extruders | Single extruder |

| Filament Ø | 1.75 mm | 1.75 mm | 1.75 mm | 2.85 mm | 1.75 mm | 1.75 mm |

| Max nozzle temp (°C) | 300 | 300 | 350 | 340 | 350 | 320 |

| Max bed temp (°C) | 120 | 110 | 120 | 120 | 120 | 140 |

| Chamber / enclosure | HEPA + activated carbon; no chamber °C spec | HEPA + activated carbon; no chamber °C spec | Active chamber heat up to 65 °C | Enclosed build volume < 50 °C (open-loop) | Fully enclosed; “Air Filter Net” (no HEPA grade/°C) | Enclosure to 70 °C |

| Speed / accel / flow | Travel up to 350 mm/s | Travel up to 150 mm/s | 1000 mm/s, 20,000 mm/s²; 40/65 mm³/s | 500 mm/s, 50,000 mm/s²; 35 mm³/s | 500 mm/s, 20,000 mm/s² | 250 mm/s print; 500 mm/s travel; 20/36/45 mm³/s |

Bottom-Line: Buy the Raise3D Pro3 Plus, if you need a tall, enclosed, dual-material workhorse with modern leveling, filtration, and a balanced speed/quality envelope. Step down to Pro2 Plus, if you're fine with manual leveling, or Guider 3 Ultra, if you're fine with single extrusion, to save money. Buy the Bambu Lab H2D, if you require maximum speed and accept a smaller Z-axis. Choose the Fusion3D Edge, if you need the 368 mm X-Y capacity. Avoid the Ultimaker S8, it offers the weakest specifications for the highest price.

The Raise3D Pro3 Plus features 7 controls accessible via its 7-inch touchscreen (1024 x 600 resolution), divided between the Home and Utilities menus.

Home Screen Controls:

Utilities Menu Controls:

The Print menu, also on the taskbar, lets users select print jobs from USB or network sources.

The Raise3D Pro3 Plus offers three connectivity options: two USB 2.0 ports, Ethernet, and Wi-Fi, all integrated with ideaMaker and RaiseCloud for smooth operation.

An onboard HD camera enables real-time print monitoring through RaiseCloud’s web or mobile app, updating every five seconds.

These features allow remote file transfer, print tracking, and progress alerts from any internet connection.

The Raise3D Pro3 Plus includes ideaMaker, a free slicer for Raise3D printers supporting STL, OBJ, 3MF, and OLTP files. It lets users import models, add automatic supports, and use material-based presets for different quality levels. For dual extrusion, models can be assigned to separate extruders and aligned to CAD coordinates. Sliced files can be exported via USB or uploaded over the network.

An EVE Smart Assistant offers troubleshooting guides, maintenance instructions, and scheduled reminders to maintain optimal performance.

The Raise3D Pro3 Plus has a professional enclosed design with a black metal frame, transparent panels, and a top cover for full print area protection. Measuring 620×626×1105 mm (24.4×24.6×43.5 inches) and weighing 66.6 kg (146.9 lbs), it features heavy-duty construction and four double-locking swivel casters for mobility. The build volume is 300×300×605 mm (11.8×11.8×23.8 inches) for single extruder use and 255×300×605 mm (10×11.8×23.8 inches) for dual extruders.

The Raise3D Pro3 series 3D printer uses a rigid all-metal cartesian XYZ system for precise, high-speed printing. The all-metal build improves rigidity and vibration control, making the Pro3 75% stronger than the Pro2 for greater durability and reduced deflection.

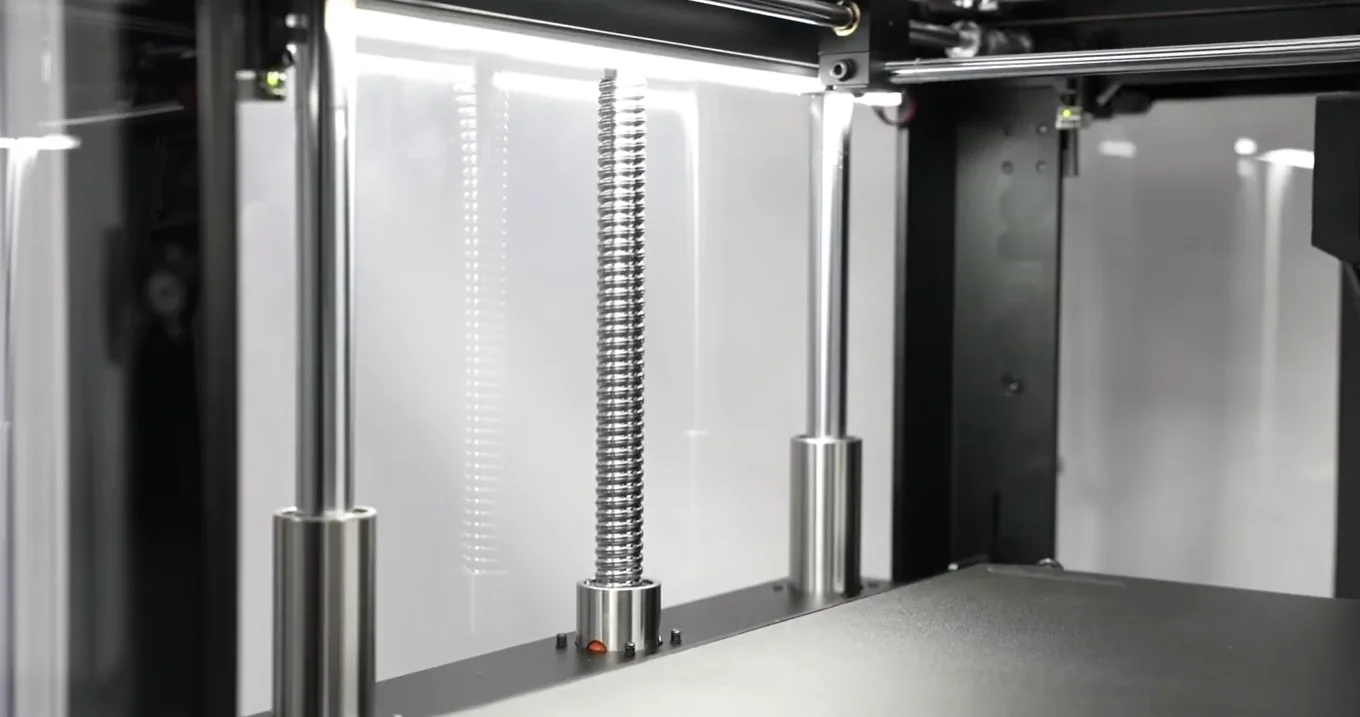

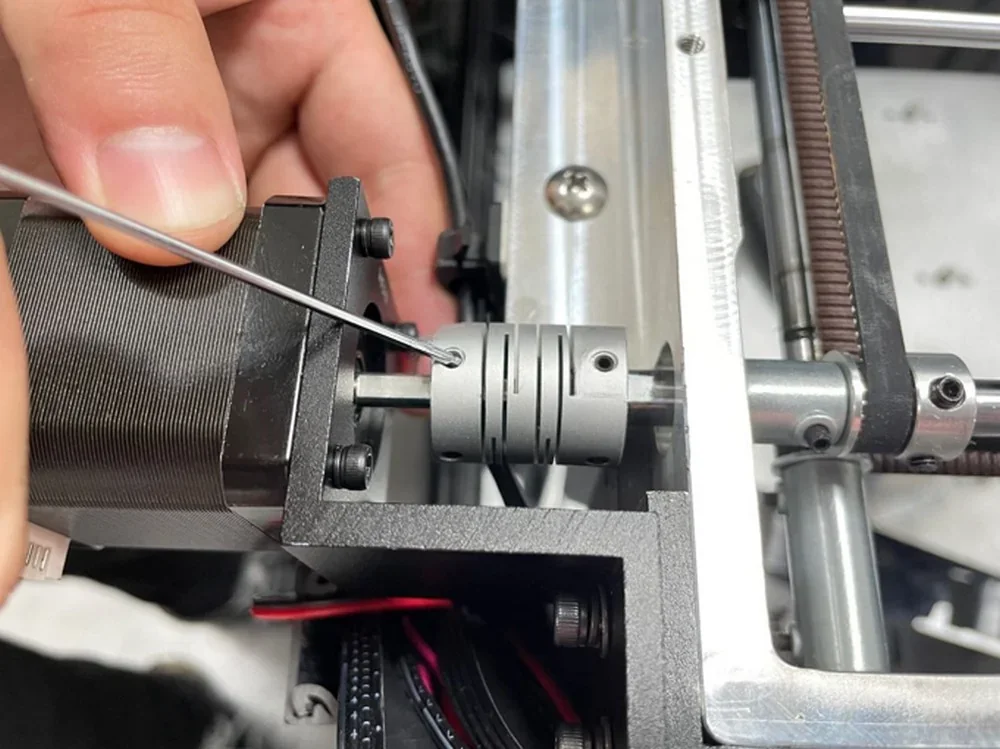

The cartesian XYZ system uses scissor kinematics for XY movement and dual lead screws for precise Z control, with 16 mm Z guides and 8 mm X/Y guides to boost stability and reduce play at high speeds.

The Raise3D Pro3 Plus uses an integrated flat cable to transmit signals from the motion controller to the extruder, replacing the Pro2 Plus is bulky drag chain. This lighter design reduces extruder weight and prevents cross-shaft sagging.

The Raise3D Pro3 Plus operates at 55 dB(A), offering quiet performance suitable for offices and classrooms.

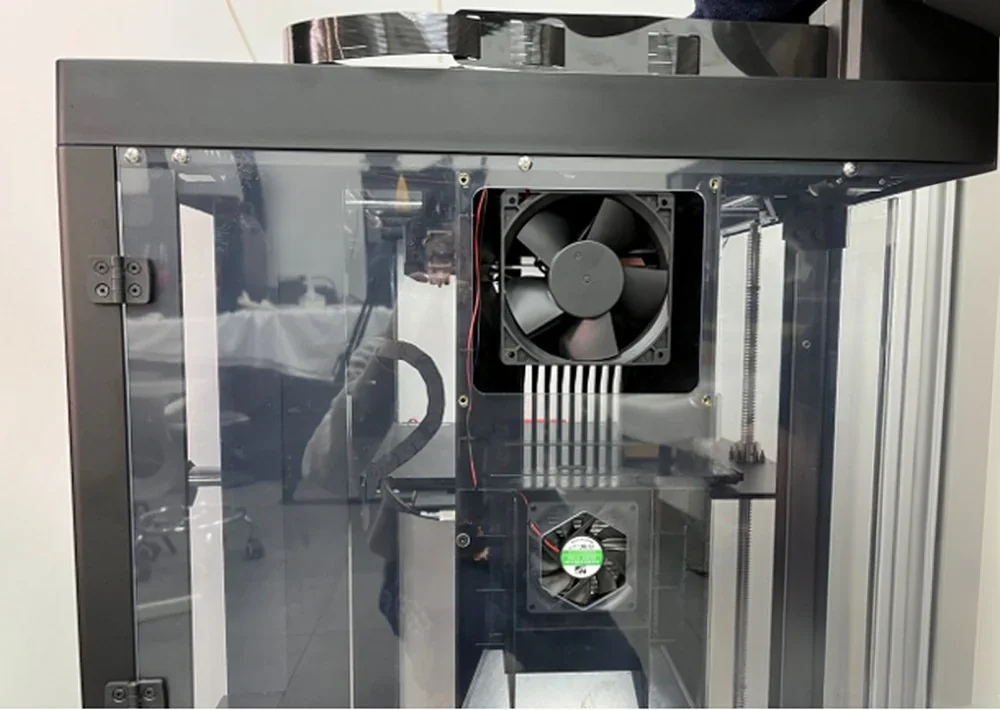

The printer’s noise mainly comes from its dual-fan Air Flow Manager on the rear panel, with a large cooling fan and a smaller filter fan. The rear cooling fan is the loudest part.

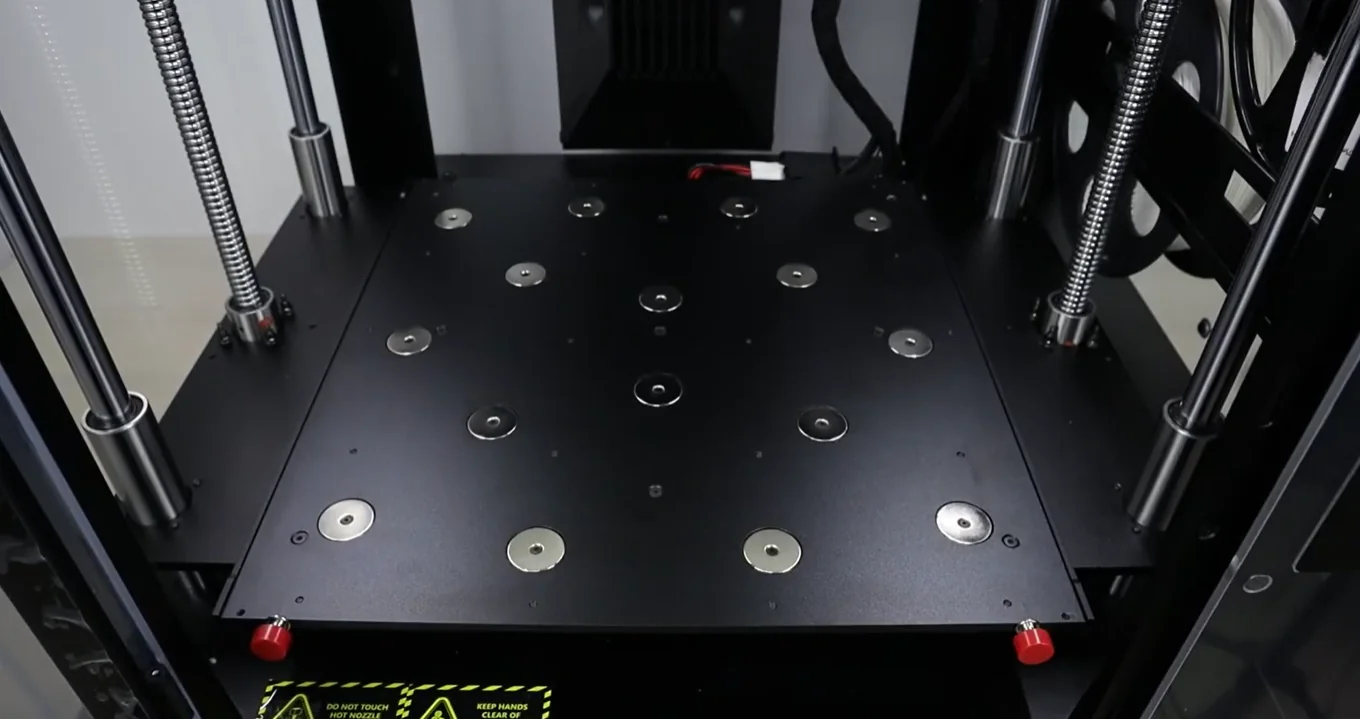

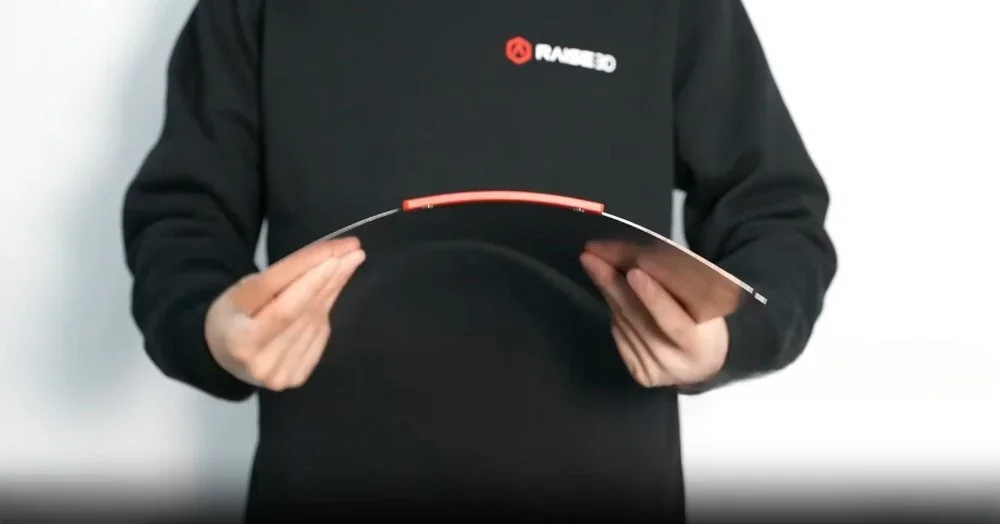

The Raise3D Pro3 Plus has a flexible steel build plate with a BuildTak surface, magnetically mounted to the silicone heated bed.

Sixteen neodymium magnets in the heated bed ensure even magnetic adhesion and secure plate attachment.

Two red thumbscrews act as quick releases, allowing the steel plate to detach for part removal. The heated silicone bed reaches 120°C while keeping magnetic contact. Build volume is 300×300×300 mm with one extruder and 255×300×300 mm with two.

A BL Touch sensor enables automatic mesh-leveling and flatness detection. After plate removal, users flex it to release parts without tools.

This magnetic platform is more durable than adhesive-based surfaces.

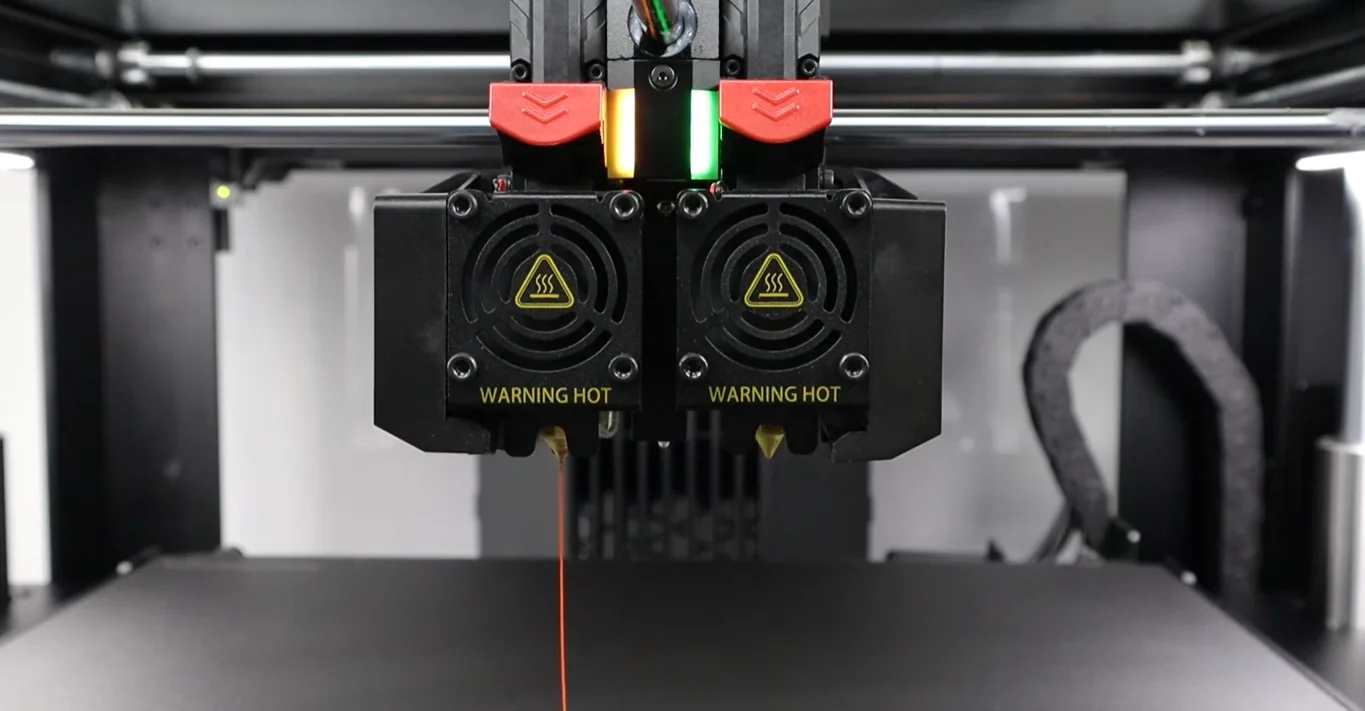

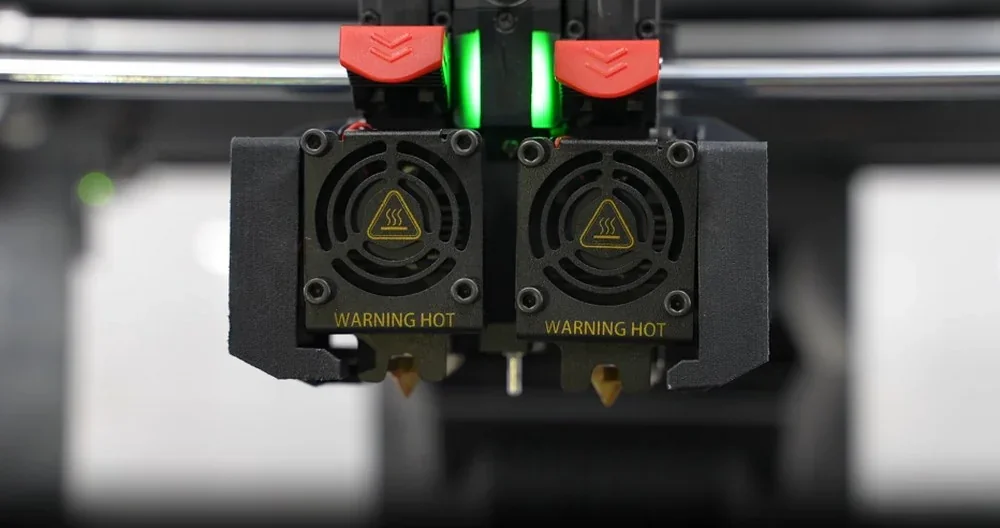

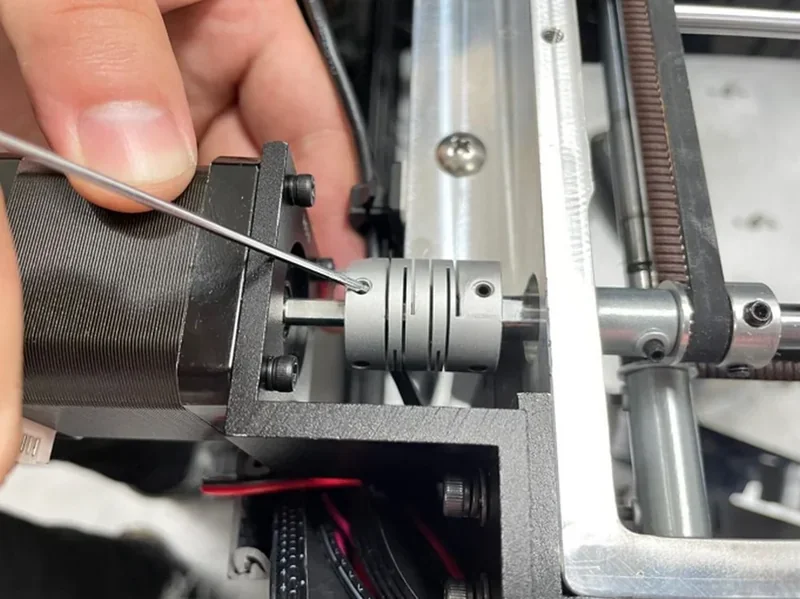

The Raise3D Pro3 Plus uses a dual-head system with an electronic lift that raises the inactive extruder 1.5 mm in under a second to avoid interference.

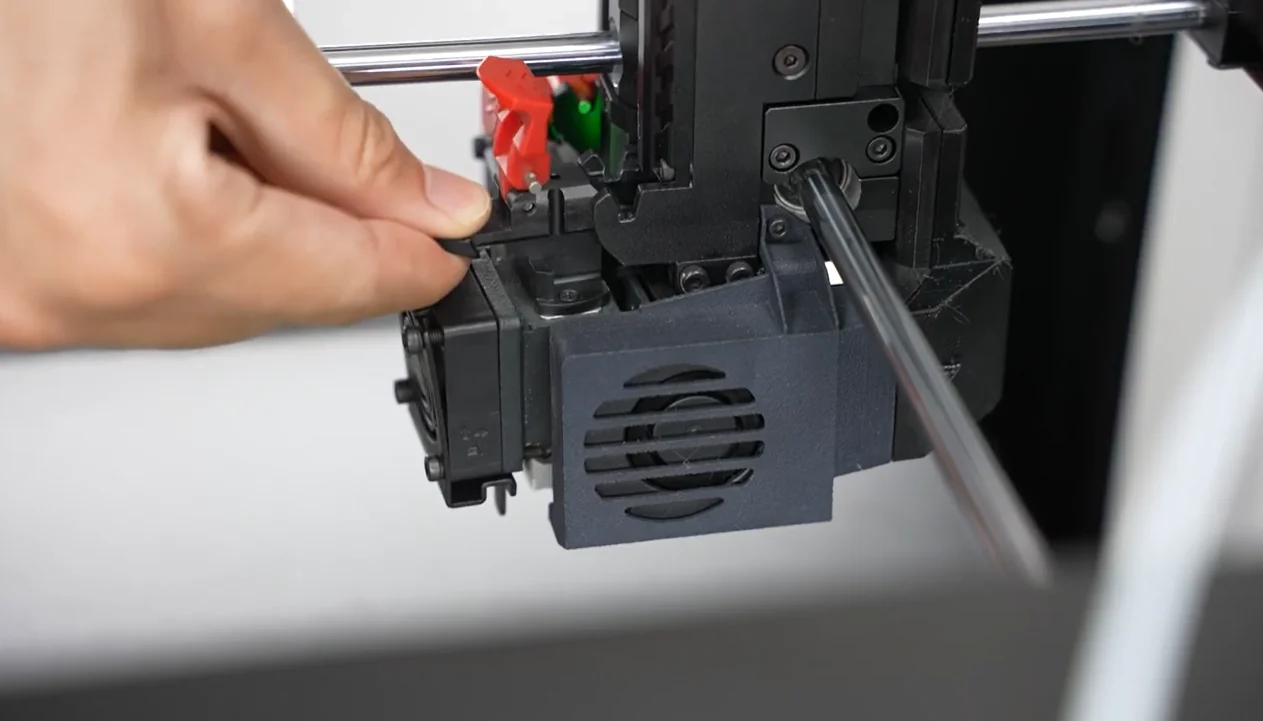

The hotend has a quick-release design with modular extruders that can be swapped in under a minute for maintenance.

The Raise3D Pro3 Plus supports up to 300°C nozzle temperatures for materials like PC, carbon fiber composites, and metal-filled filaments. It comes with a 0.4 mm nozzle, with options from 0.2 to 1.0 mm, and uses 1.75 mm filament. Improved cooling enhances heat dissipation, and redesigned extruders simplify assembly and maintenance compared to the Pro2 Plus.

The Raise3D Pro3 Plus features an integrated filament box that holds two 1 kg spools simultaneously.

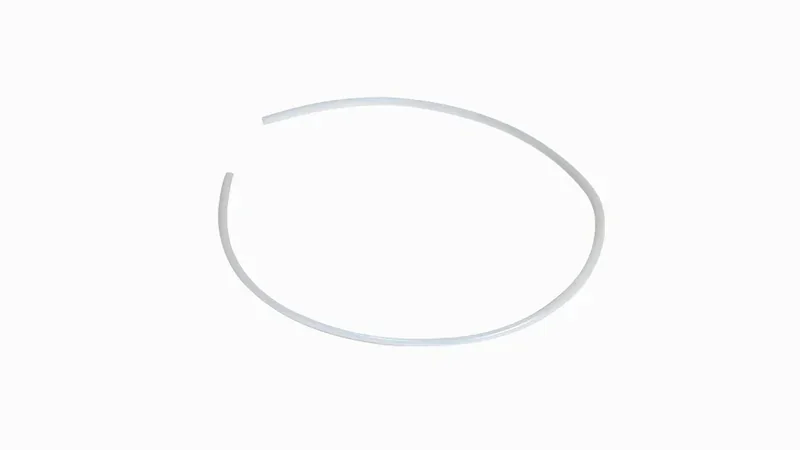

The filament system uses guide tubes to protect and direct filament from storage to the extruders.

The Raise3D Pro3 Plus uses optical run-out sensors to monitor filament and automatically pause printing when supplies run low. Quick-connect extruders enable fast guide tube changes, and filament holders support both clockwise and counterclockwise spool orientations.

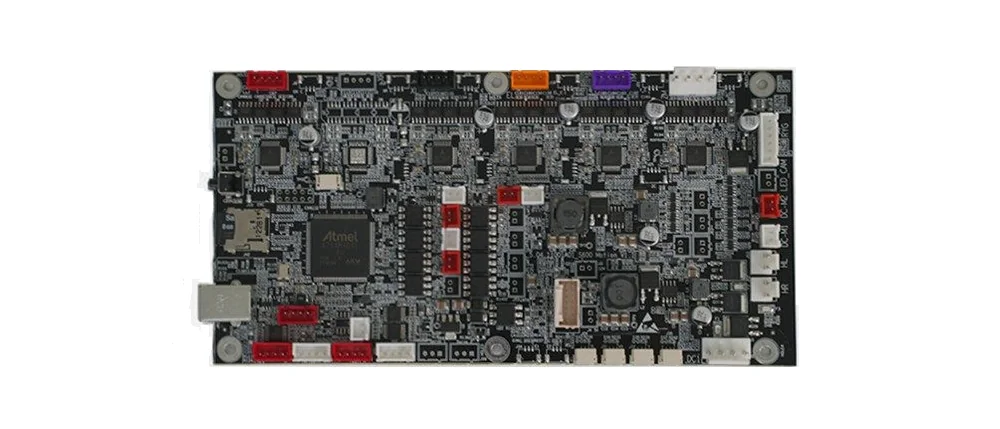

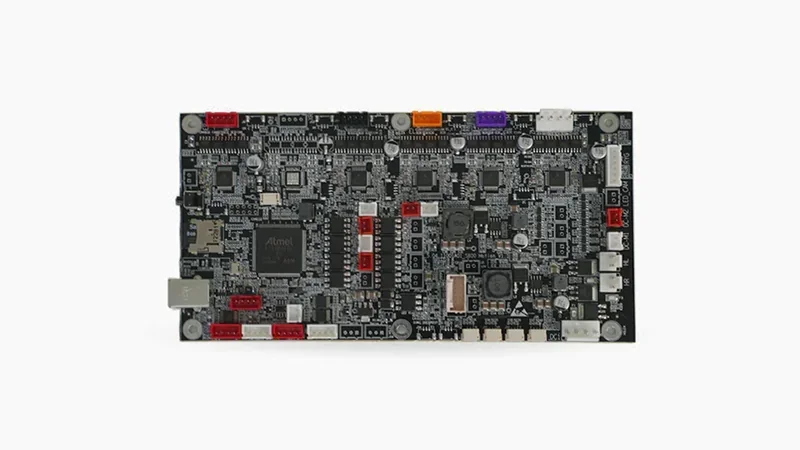

The Raise3D Pro3 Plus uses a dual-board control system. Its main board runs an ARM Cortex-A9 Quad 1 GHz processor with 1 GB RAM and 16 GB storage on embedded Linux, handling the interface, file management, networking, and external communication.

The Pro3 Plus is motion controller uses an ARM Cortex-M4 120 MHz processor for precise movement and real-time printing. Redesigned electronics integrate major components onto the board, connected to the main motherboard by a flexible cable instead of the old chain system. This dual-processor setup separates computing from motion control, improving stability and enabling features like power loss recovery. The modular design also simplifies board maintenance and replacement.

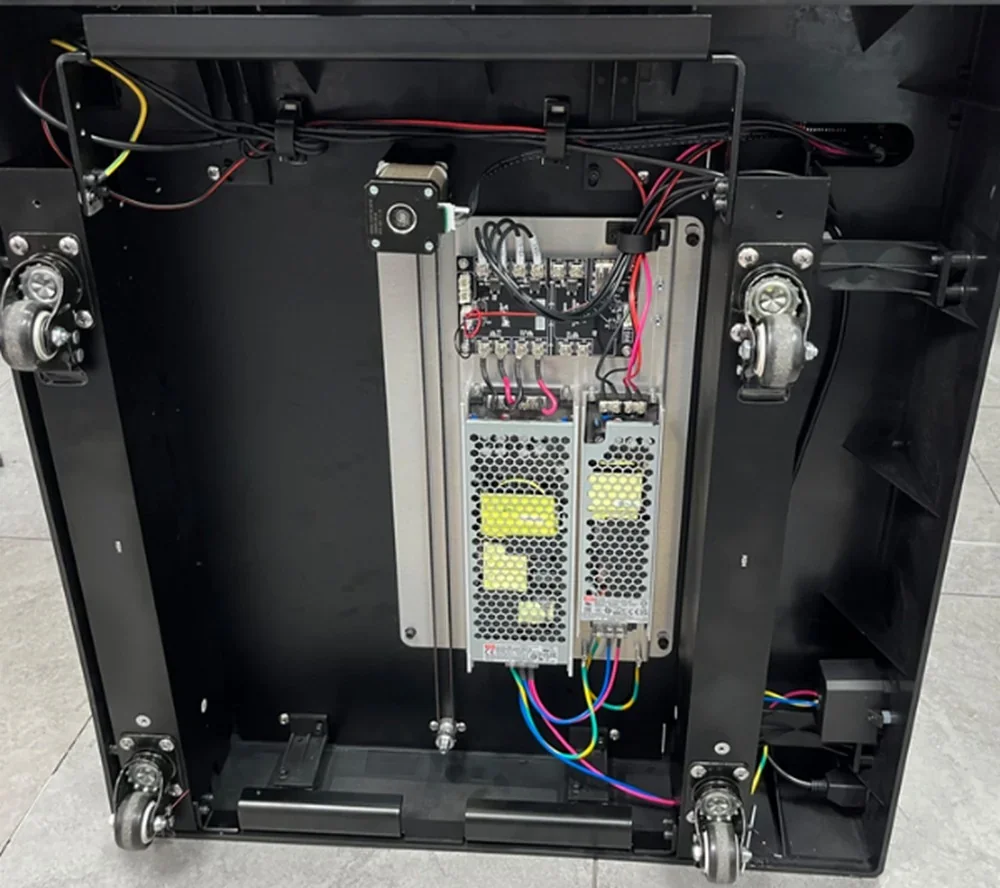

The Raise3D Pro3 supports 100–240 V AC input at 50/60 Hz, up to 3.3 A at 230 V, allowing global use without converters. It uses dual MEAN WELL power supplies — a UHP-500-24 and UHP-200-24 — providing 24 V DC at 600 W for stable, reliable power.

The electrical system features grounding, fuse protection, and an integrated power switch with a standard inlet compatible with regional power cords.

The printer complies with EN55032 Class A electromagnetic compatibility standards.

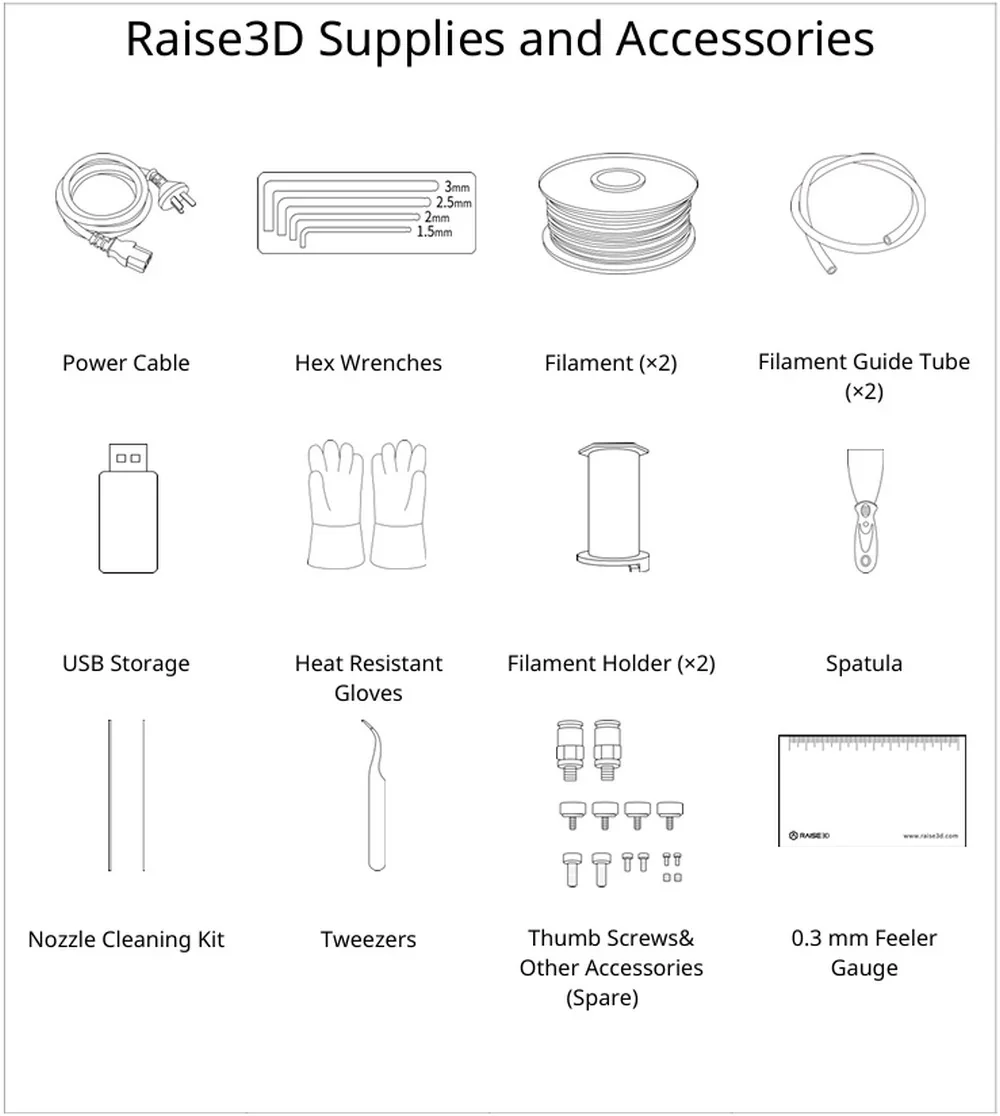

What's Included in the Box:

Power & Connectivity

3D Printing Materials & Feeding

Tools & Hardware

Maintenance & Safety

The Raise3D Pro3 and Pro3 Plus arrive fully assembled, needing only removal of shipping restraints (zip ties, spacers, screws) guided by the startup wizard. Accessories include two PLA spools, a calibration card, heat-resistant gloves, a spatula, and a USB drive with ideaMaker software (Windows, macOS, Linux) and test files.

Note: Package contents may change; confirm with a Top3DShop sales representative before ordering.

Raise3D supplies 46 upgrades, accessories and replacement spare parts.

| PEI Build Plate (Pro3 HS Series and Pro3 Series Only) | Replacement PEI build plate; provides a PEI print surface for first-layer adhesion and part release. | $49.99 |  |

| Flexible Plate with BuildTak | Replacement flexible build plate with BuildTak surface; supports adhesion and easier part removal by flexing. | $89.99 |  |

| BuildTak Build Surface | Replacement BuildTak print surface sheet; restores the BuildTak adhesion surface when worn. | $59.99 |  |

| Flexible Steel Build Plate | Replacement flexible steel build plate; enables easier part removal by flexing the plate. | $45.99 |  |

| Hardened Nozzle V3 | Replacement hardened nozzle (V3); wear-resistant nozzle option for printing. | $24.99 |  |

| Brass Nozzle V3 0.4mm | Replacement 0.4 mm brass nozzle (V3); Made of brass, it supports up to 300 °C, offering strong thermal conductivity, precise flow, and smooth extrusion with <0.02 mm diameter variation. Compatible with non-abrasive filaments (PLA, ABS, PETG, ASA, PC, TPU, TPE, NYLON, PVA, HIPS, and some filled types). Not recommended for abrasive composites like carbon fiber or metal-infused filaments. | $19.99 |  |

| Steel Nozzle with WS2 Coating | Replacement steel nozzle with WS2 coating; With Mohs hardness 7.8, max temp 450 °C, thermal conductivity 26 W/m·K, and CTE 12 μm/m·°C, it ensures durable, smooth extrusion of abrasive composites (carbon fiber, ceramic, metal). | $49.99 |  |

| Interchangeable Hot End | Replacement interchangeable hot end unit; restores hot end hardware for a toolhead. | $119.99 |  |

| Interchangeable Hot End Assembly with V3H Nozzle | Replacement hot end assembly with V3H nozzle; restores a complete hot end setup. | $129.99 |  |

| Standard Pro3 Series Hot End | Replacement standard hot end; restores a standard Pro3 hot end configuration. | $79.99 |  |

| P Thermocouple | Replacement thermocouple temperature sensor; measures hot end temperature for temperature control. | $19.99 |  |

| Hot End Controller Board | Replacement hot end controller board; controls hot end heater and sensor signals. | $119.99 |  |

| Hot End Adapter Board | Replacement adapter/interface board for hot end wiring; connects hot end signals to the printer system. | $29.99 |  |

| Hot End Connecting Cable | Replacement cable for hot end electrical connection; restores hot end wiring between modules. | $19.99 |  |

| Raise3D Hyper Speed Upgrade Kit | It boosts print speeds from 50–80 mm/s to 200–350 mm/s and acceleration from 1,000 to 10,000 mm/s² while maintaining accuracy. It includes software upgrades, two 0.4mm Hyper Speed Hot Ends, an Auto Calibrator for automatic frequency tuning, and one spool each of Hyper Speed PLA and ABS filament. With full setup, a Pro3 can output 600–1,000 g of filament in 24 hours or complete parts under 400 g in 12 hours. | $399.00 |  |

| Raise3D Hyper Speed Hot End Assembly 0.4mm | Replacement Hyper Speed hot end assembly (0.4 mm); restores a Hyper Speed hot end setup. | $139.00 |  |

| Raise3D Hyper Speed Hot End Assembly with Brass Nozzle 0.4mm | Replacement Hyper Speed hot end assembly with 0.4 mm brass nozzle; restores a Hyper Speed hot end setup. | $139.00 |  |

| Raise3D Hyper Speed Hot End Assembly with Silicon Carbide Nozzle 0.4mm V3 | Replacement Hyper Speed hot end assembly with 0.4 mm silicon carbide nozzle (V3); restores a Hyper Speed hot end setup. | $229.00 |  |

| Raise3D Hyper Speed Hot End Assembly with Silicon Carbide Nozzle 0.6mm V3 | Replacement Hyper Speed hot end assembly with 0.6 mm silicon carbide nozzle (V3); restores a Hyper Speed hot end setup. | $229.00 |  |

| Raise3D Hyper Speed Hot End Assembly with V3H Nozzle 0.6mm | Replacement Hyper Speed hot end assembly with 0.6 mm V3H nozzle; restores a Hyper Speed hot end setup. | $129.00 |  |

| Raise3D Hyper Speed Auto Calibrator | Automatic calibration accessory for Hyper Speed setup; supports calibration for compatible printers. | $199.00 |  |

| Left Extruder without Hot End Assembly | Replacement left extruder module (without hot end); restores the left extruder drive unit. | $199.99 |  |

| Right Extruder without Hot End Assembly | Replacement right extruder module (without hot end); restores the right extruder drive unit. | $229.99 |  |

| Extruder Bearing | Replacement extruder bearing; supports smooth movement inside the extruder mechanism. | $25.99 |  |

| Flexible Filament Tube (2 in a pack) | Replacement flexible filament tube (2-pack); guides filament through the filament path. | $25.00 |  |

| Guide Tube | Replacement filament guide tube; guides filament from spool area to the extruder. | $19.99 |  |

| Coupler | Replacement filament tube coupler; connects filament tubing to the printer’s filament path components. | $19.99 |  |

| Left Model Cooling Fan | Replacement left model cooling fan; cools the printed part during printing. | $29.99 |  |

| Right Model Cooling Fan | Replacement right model cooling fan; cools the printed part during printing. | $29.99 |  |

| Extruder Front Model Cooling Fan | Replacement extruder front model cooling fan; provides part cooling airflow during printing. | $19.99 |  |

| Left Side Model Cooling Fan Cover | Replacement left fan cover; protects the fan and helps direct cooling airflow. | $19.99 |  |

| Right Side Model Cooling Fan Cover | Replacement right fan cover; protects the fan and helps direct cooling airflow. | $19.99 |  |

| Left Filament Run-out Sensor | Replacement left filament run-out sensor; detects filament absence on the left side. | $39.99 |  |

| Right Filament Run-out Sensor | Replacement right filament run-out sensor; detects filament absence on the right side. | $39.99 |  |

| Endstop Limit Switch Board | Replacement endstop limit switch board; provides axis endstop (home/limit) detection. | $29.00 |  |

| Auto-Leveling Assembly | Replacement auto-leveling assembly; supports automatic build plate leveling operation. | $86.99 |  |

| Motion Controller Board | Replacement motion controller board; controls motors and motion functions. | $319.99 |  |

| Flat Cable | Replacement flat cable; restores internal electrical connections between modules. | $49.99 |  |

| PC Cable Support | Cable support bracket for a connected PC cable; helps manage the cable and reduce strain. | $19.99 |  |

| Touchscreen Assembly | Replacement touchscreen assembly; restores the printer’s user interface display and touch control. | $684.99 |  |

| Filter | Replacement filter for the printer filtration system; supports air filtration during printing. | $24.99 |  |

| Top Acrylic Lid | Replacement top acrylic lid; covers the top opening of the printer. | $159.99 |  |

| Raise3D Cabinet for Plus Size Printer | The cabinet includes two support frames for filament/dry boxes, a tool drawer, shelving with dividers, and locking wheels. Made of PC, PE, and metal, it measures 620 × 590 × 530 mm, offering organized storage and mobility for offices, workshops, or homes. | $799.00 |  |

| CF Accessory Kit | Carbon-fiber (CF) accessory kit; supports CF filament printing workflows on compatible printers. It includes a 2.5 kg filament box, a Hyper Speed Hot End with 0.6mm silicon carbide nozzle, and two 1kg spools (Hyper Speed PET CF and Hyper Core PPA CF25). All components are required for reliable composite material printing in industrial applications. | $469.00 |  |

| Raise3D 2.5 kg Filament Box |

The Raise3D 2.5 kg Filament Box stores one 2.5 kg or two 1 kg spools in a sealed environment with real-time humidity and temperature monitoring via digital display. Measuring 466 × 190 × 455 mm and weighing 2.8 kg, it helps preserve filament quality. |

$79.00 |  |

The Raise3D Pro3 Series requires 20+ maintenance tasks to ensure print quality and longevity.

Daily (per print):

Every 400 hours:

Every 800 hours:

Safety:

Only perform maintenance after prints are finished, filament is unloaded, printer is cool, and while wearing protective gear.

The Raise3D 3D printers come with a 1-year limited warranty covering non-electronic and non-consumable parts. RaiseShield warranty extensions (1, or 2 years) offer full coverage for electronic and mechanical components, excluding consumables and cosmetic defects.

| Warranty Plan | What’s Included | Price |

|---|---|---|

| Standard Limited Warranty (12 months) | Coverage for the printer and its parts against defects in materials/workmanship under normal use; excludes consumables such as Hotend(s), Hotend(s) Assembly(ies), Nozzle(s), Fan Cover(s), Build Surface, Build Plate(s), Top Acrylic Lid, Filter, Extruder Front Model Cooling Fan, P Thermocouple, Screw Buckle, Raise3D 2.5KG Filament Box, PC Cable Support, Short Tube, Filament Detection Assembly (Filament Run-out Sensor Assembly), 2.5kg Filament Support Shaft Sleeve, Top Cover(s), USB flash drive, SD card, E3 Desiccant Storage Box(es), or other items that are expended in the normal operation of the product, nor does it cover external devices, accessories or parts added to the PRODUCTS after the system is shipped from RAISE3D. | Included (with printer purchase) |

| 1-Year RaiseShield Warranty Plan | Full warranty coverage of electrical and mechanical components of Raise3D Pro3 Series printers for 1 year, consumables and cosmetic imperfection not included. | $800 |

| 2-Year RaiseShield Warranty Plan |

Full warranty coverage of electrical and mechanical components of Raise3D Pro3 Series printers for 2 years, consumables and cosmetic imperfection not included. |

$1200 |

Technical Support

Support Center: Access user guides, maintenance tips, and troubleshooting resources at https://support.raise3d.com/.

Submit Tickets: For access to the Raise3D team, submit tickets via http://help.raise3d.com/.

Phone Support:

Educational Resources

Certifications

Access CE, CB, FCC, and RoHS certifications on the Raise3D website.

Full warranty terms: https://www.raise3d.com/download/raise3d-limited-warranty-all-versions/

The Raise3D Pro3 Plus is available at $5,599.00, representing a professional large-format dual extrusion printer with a 300×300×605 mm build volume, interchangeable hot ends, and Raise3D software integration. The Hyper Speed Upgrade Kit adds about 8% to the cost, boosting speeds to 300 mm/s and output to 600–1,000 g per day. The RaiseShield warranty adds 15–18%, extending coverage from one to three years. Contact sales for configuration options, volume discounts, or custom implementation quotes.

Update your browser to view this website correctly. Update my browser now