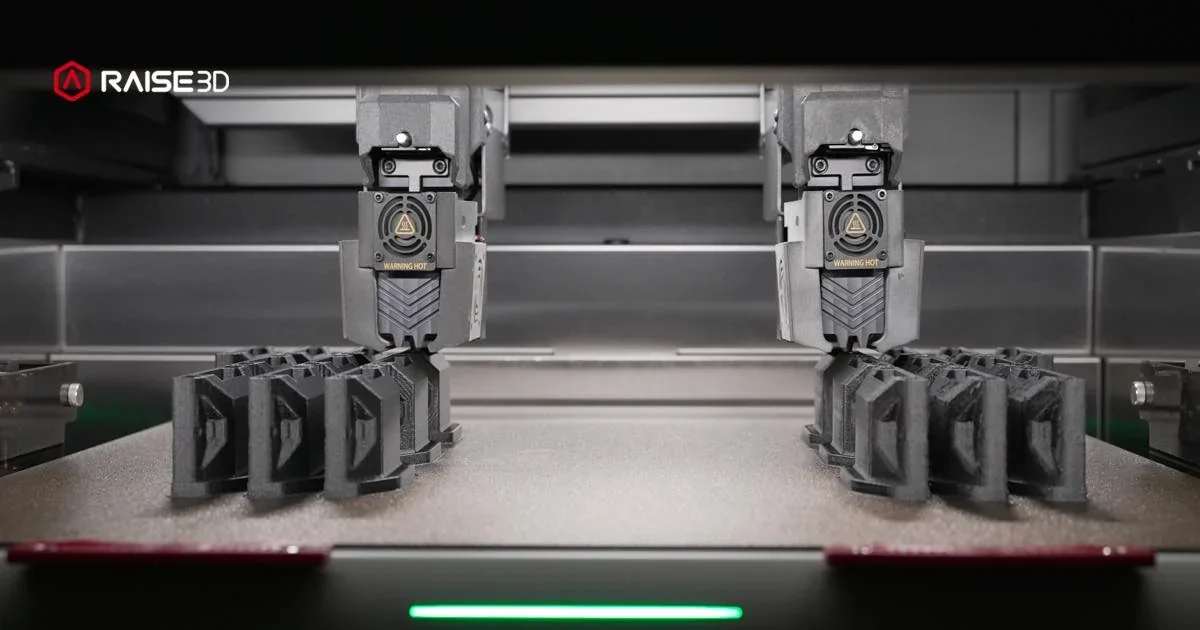

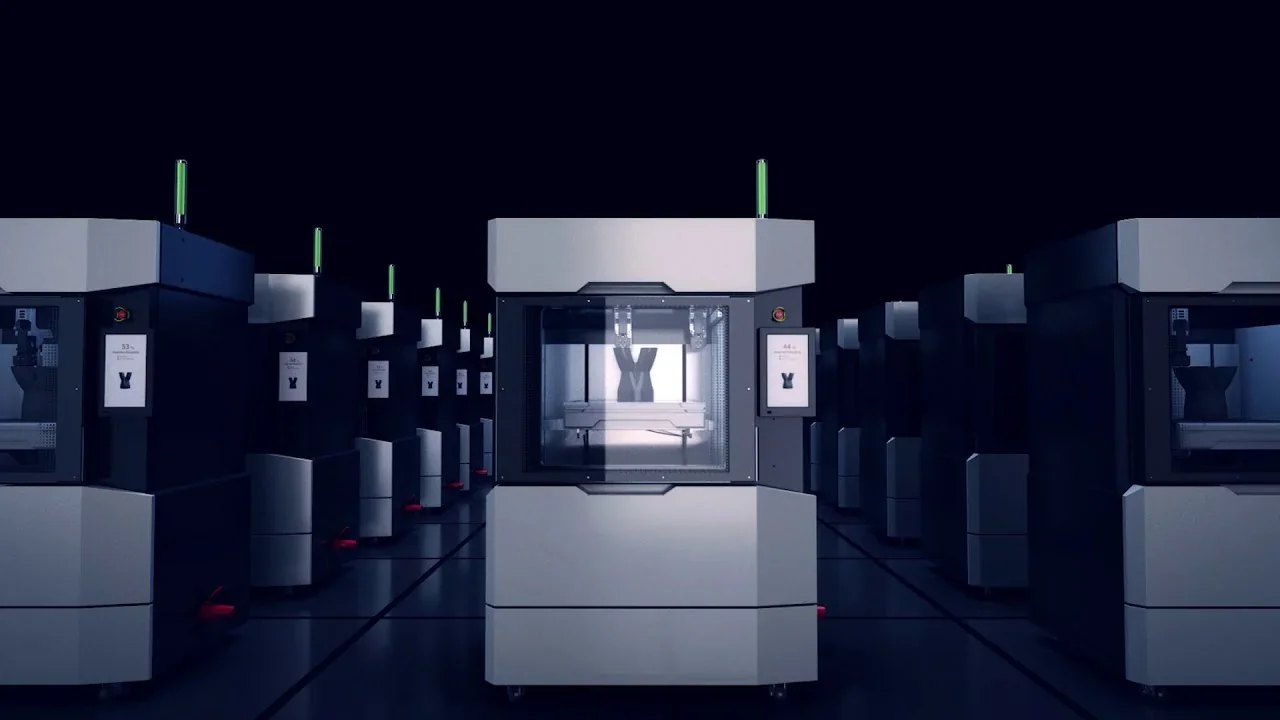

The Raise3D RMF500 is a large-format industrial Hyper FFF 3D printer with a 500 × 500 × 500 mm build volume and an IDEX system (independent dual extruders) for continuous, high-throughput production of end-use parts. It features a closed-loop synchronous control (±10 μm precision), high-load Z-axis, 330 °C SiC-hardened hotends, and a spring-steel magnetic bed with 110 °C auto-leveling — built for consistent accuracy at speeds up to 500 mm/s and 15,000 mm/s² acceleration.

Operation and monitoring are managed through a 13.3-inch 1080p RaiseTouch interface with Wi-Fi, LAN, USB, and a built-in camera. The ideaMaker slicer, its built-in library, and the Open Filament Program offer validated profiles for Raise3D and third-party materials.

The RMF500 offers high precision with XYZ positioning resolution of 1, 1, and 0.09765 µm. Its XY closed-loop linear motor maintains ±10 µm accuracy under load or disturbance, enabling part tolerances within ±0.2 mm. It is a reliable and precise industrial 3D printer that produces small batch customized part with high repeatability.

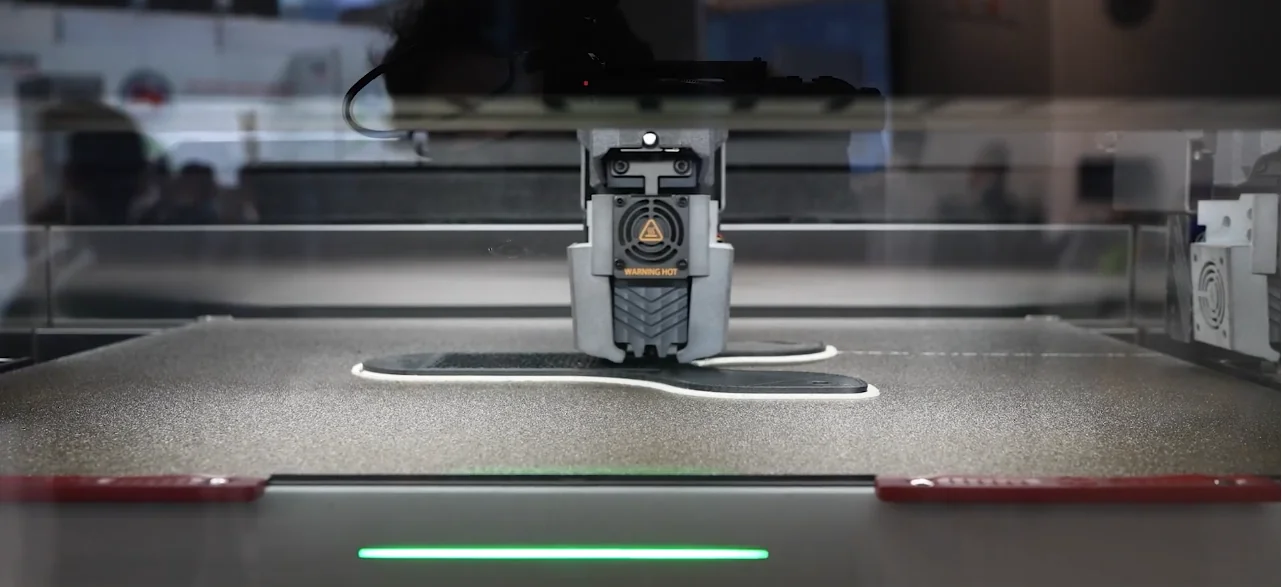

Auto bed leveling on a spring-steel magnetic build plate ensures consistent first-layer adhesion and surface finish.

SiC nozzles resist wear to maintain extrusion accuracy, while dual cooling fans improve overhangs and top-surface quality. For example, the following pipeline segments were successfully printed in PET-CF. Part size: 152.4 × 117.8 × 299 mm, weight: 416.2 g, layer height: 0.25 mm, print time: 16 hours 49 minutes.

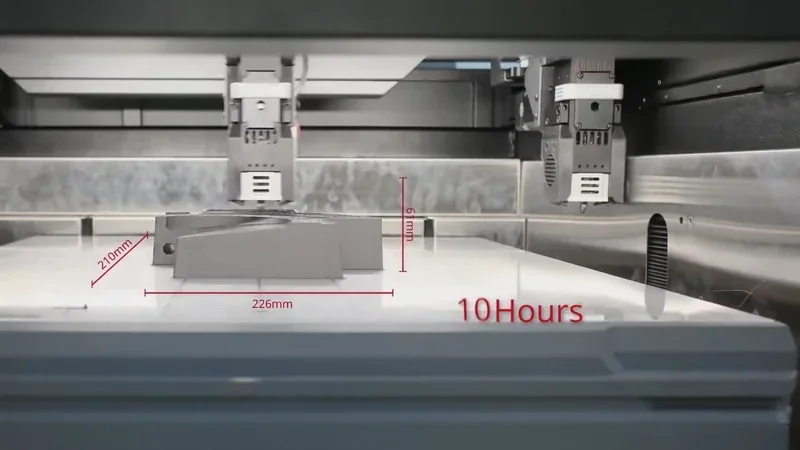

Rated for up to 500 mm/s print speed and 15,000 mm/s² acceleration, the RMF500 delivers high throughput without compromising precision. For example, it printed a 226 × 210 × 61 mm PA12 CF part with 20% infill in under 13 hours — over 3.5 times faster than the Pro2 Series, which took 48 hours for the same model — while maintaining dimensional accuracy and using more material for improved part strength.

The RMF500's IDEX system supports duplicate and mirror modes, with auto nozzle wiping, filament run-out detection, and auto filament switching for uninterrupted long prints.

A rigid all-steel construction frame and high-load Z-axis (supports up to 100 kg) minimize vibration and ensure uniform layers on large prints. The closed-loop linear-motor XY drive enhances path accuracy, while a high-torque extruder (4.65 gear ratio, 65 W, 120 N force) ensures consistent flow for rigid and flexible materials — improving adhesion and dimensional stability at speed.

PET-CF 3D print sample: A 416 x 416 x 138 mm wheel printed in 117 h 30 min. Part Weight: 1503 g, Layer Height: 0.25 mm.

PET-CF 3D Print Sample: Y-Shaped Duct

Case Study: Innovation Tech LLC used a Raise3D RMF500 to 3D print a carbon fiber-reinforced PA12 replacement bracket for an ABB robot in under 3 hours, restoring its full function – no post-processing required.

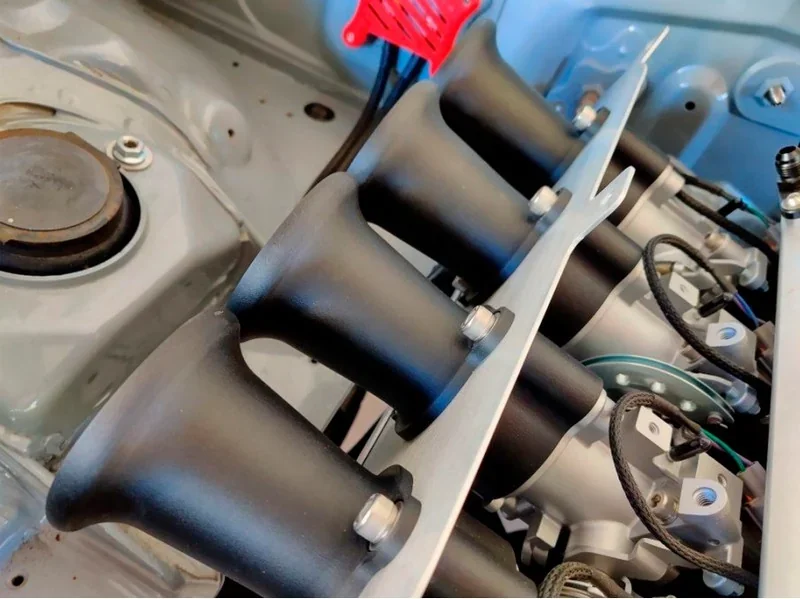

3D Printed Sample: Engine Components

3D Printed Sample: Elements of the Car Interior

3D Printed Sample: Wheel Hub

3D Printed Sample: Cooling Air Duct

The Raise3D RMF500 supports over 20 validated materials, including ASA, PETG, PPA CF, PPA GF, PET Support, PPA Support, and materials from the Industrial Family (PET CF, PET GF), Hyper Speed Family (ABS V2, PLA), and Hyper Core Family (ABS CF15, PPA GF25, PPA CF25). It also accepts 1.75 mm third-party filaments through the Open Filament Program (OFP).

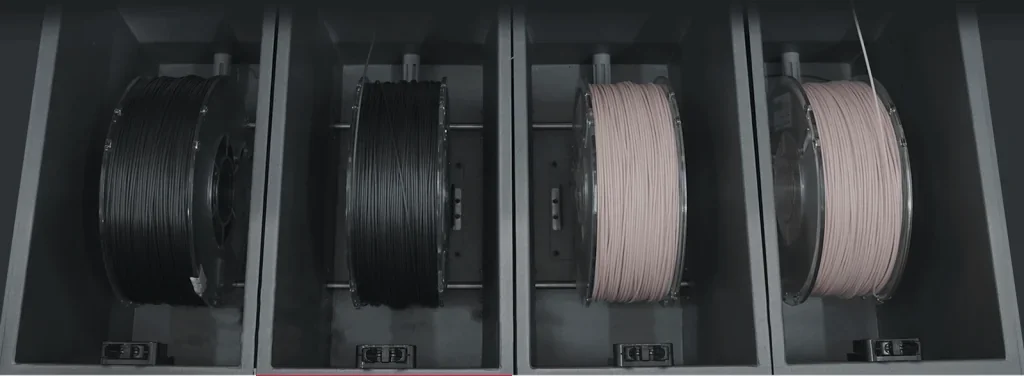

The filament drying chamber holds four 2.5 kg spools for extended composite printing, while four included dry storage bags help protect moisture-sensitive third-party materials. Positive pressure humidity control keeps chamber humidity under 5% relative humidity.

ABS 3D Print Sample: A 130 x 450 x 225 mm automotive Linkage arm printed in 30 hours. Part Weight: 369g, Layer Height: 0.25 mm.

PET-CF 3D print sample: A 326 x 273 x 400 mm handheld tool fixture printed in 46 h 46 min. Part Weight: 573g, Print Time: 46 hours 46 minutes.

ABS 3D Print Sample: A 360 x 306 x 84 mm Desktop Fixed Fixture printed in 33 h 6 min. Part weight: 1116 g, Layer Height: 0.25 mm.

ABS 3D Print Sample: A 450 × 450 × 480 mm pipe printed in 75 hours 41 minutes. Part weight: 728 g, Layer Height: 0.25 mm.

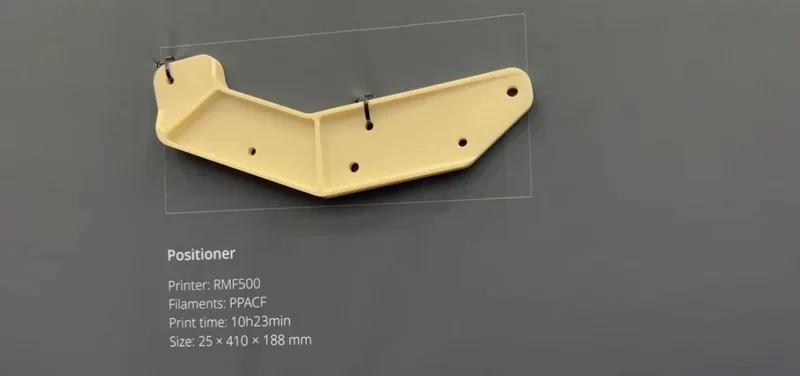

PPA-CF 3D print sample: A 25 x 410 x 188 mm positioner printed in 10 h 23 m.

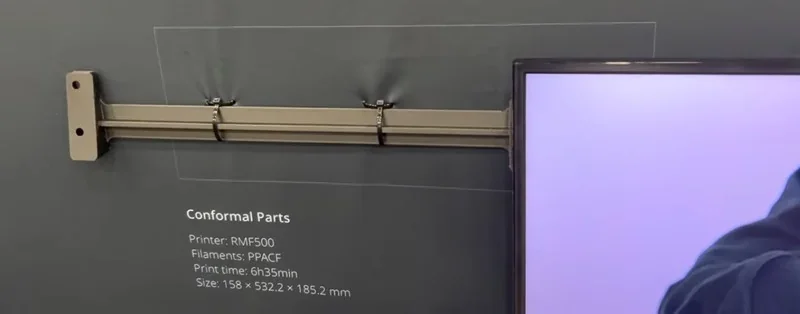

PPA-CF 3D print sample: 158 x 532.2 x 185.2 mm conformal part printed in 6 h 35 m.

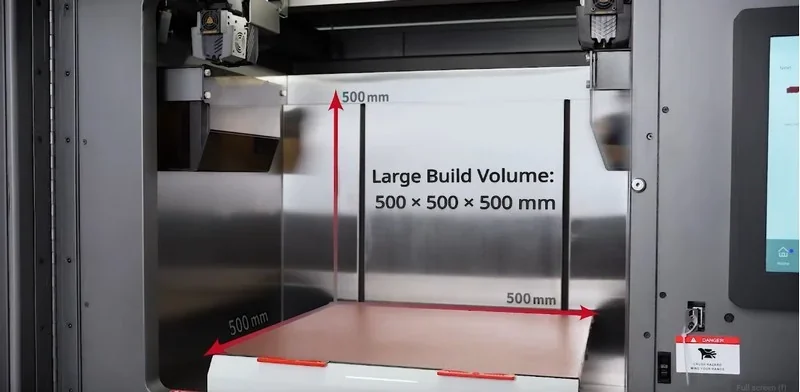

The RMF500 offers a 500 × 500 × 500 mm build volume (normal printing mode) with no reduction in dual-filament mode, though Raise3D advises keeping dual-filament jobs that use a raft under 480 mm to accommodate the raft margin.

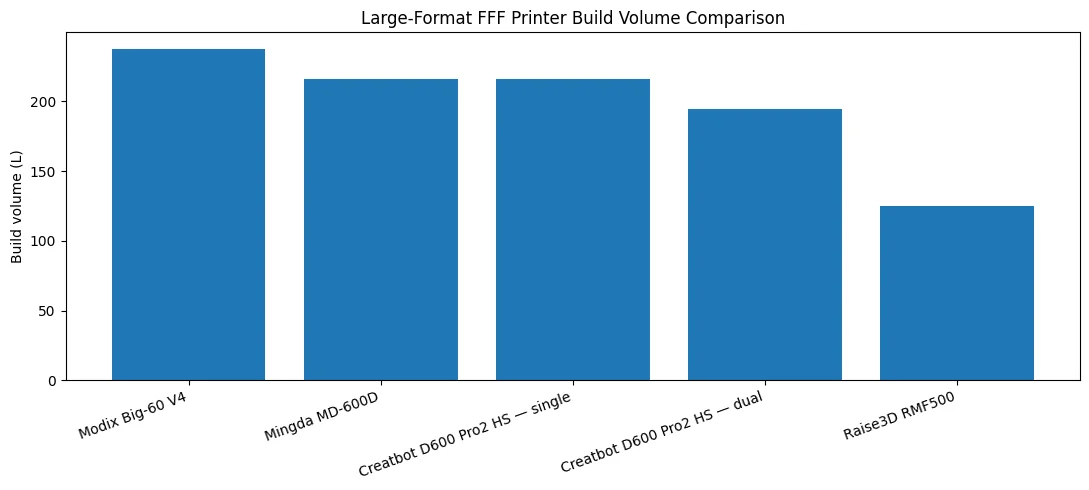

| Feature | Raise3D RMF500 | Mingda MD-600D | Modix Big-60 V4 | Creatbot D600 Pro2 HS |

|---|---|---|---|---|

| Build Volume (W×D×H) | 500 × 500 × 500 mm | 600 × 600 × 600 mm | 600 × 600 × 660 mm | 600 × 600 × 600 mm (single); 540 × 600 × 600 mm (dual) |

| Extrusion System | IDEX (standard) | Dual extruders (fixed) | IDEX (optional add-on) | Dual extruders with auto-rising |

| Max Nozzle Temp | 330 °C | ≤350 °C (≤320 °C rec.) | Up to 500 °C (tested to 340 °C) | 420 °C |

| Chamber Temp | Enclosed, no active heating | Enclosed, no active heating | Optional enclosure, no active heating | 70 °C (active heating) |

| Max Print Speed | 500 mm/s | 300 mm/s | 250 mm/s (Griffin Ultra) | 300 mm/s |

| Power Requirements | 3-phase 380 V, 25 A | 220 V, 50/60 Hz | 220–240 V (standard) | 240 V, 50–60 Hz |

| Weight | 790 kg | 200 kg | 120 kg | 200 kg |

| Official Price (USD) | $69,999+ | $24,779+ | $6,048+ | $16,999+ |

The Raise3D RMF500 justifies its premium with factory-grade features focused on precision and unattended reliability: a closed-loop XY linear motor (±10 µm, 1/1/0.09765 µm resolution), high-load Z-axis, IDEX with automation (nozzle wiping, run-out detection, filament switching), and a four-spool dry-storage system — all operating up to 500 mm/s and 15,000 mm/s² within a 500 × 500 × 500 mm build volume. These capabilities prioritize repeatable results over sheer size.

In contrast, the Modix BIG-60 V4 is a self-assembly kit, making accuracy dependent on user build quality. The CreatBot D600 Pro2 HS and MINGDA MD-600D are supported by China-based teams, which can lead to delayed technical support due to time zone differences and longer lead time for spare parts.

Bottom line: Choose the RMF500 when precision, uptime, and vendor-backed process control are critical; choose alternatives if lowest price or build volume outweighs the need for guaranteed performance.

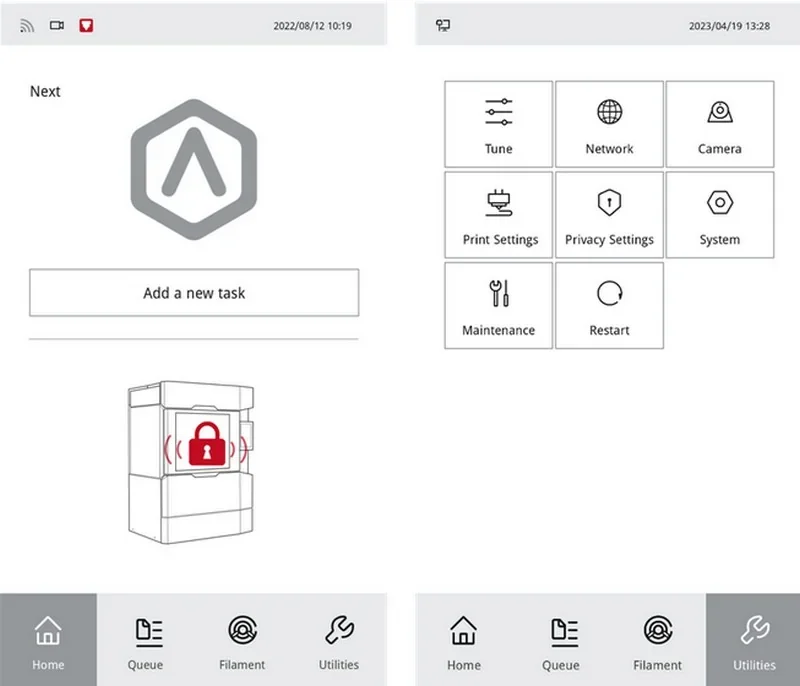

The RMF500 features a 13.3-inch (1920 × 1080) color touchscreen as its main control interface. The RaiseTouch UI includes tabs for Idle, Queue, Filament, Utilities, and Other. The Printing screen displays progress, time remaining, layer count, and temperatures, with Start/Pause and Stop buttons for direct control. The Queue tab allows job selection and review of print history, including time-lapses. Door lock status is shown on the Idle screen; the lock engages ~20 seconds after all doors close and can be manually unlocked, helping prevent handling errors.

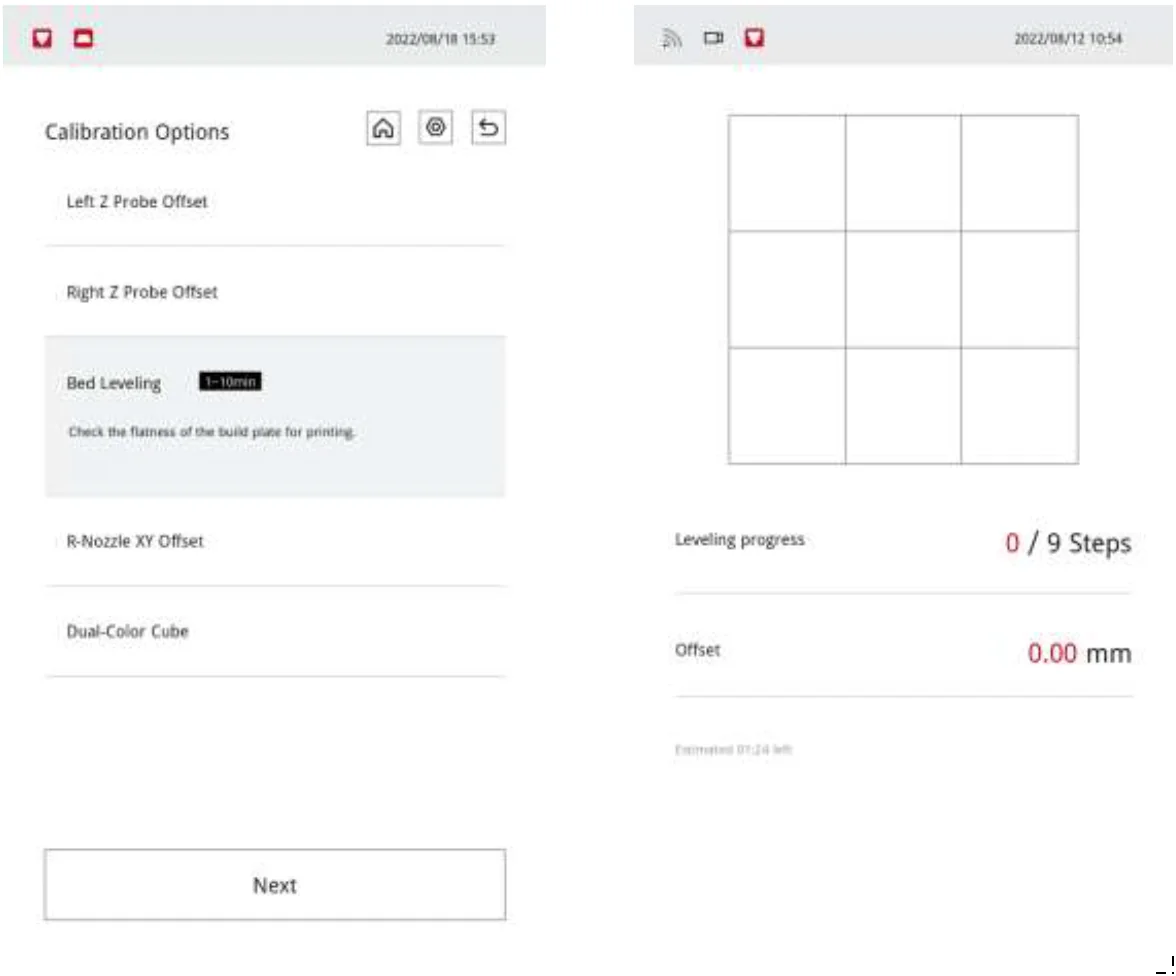

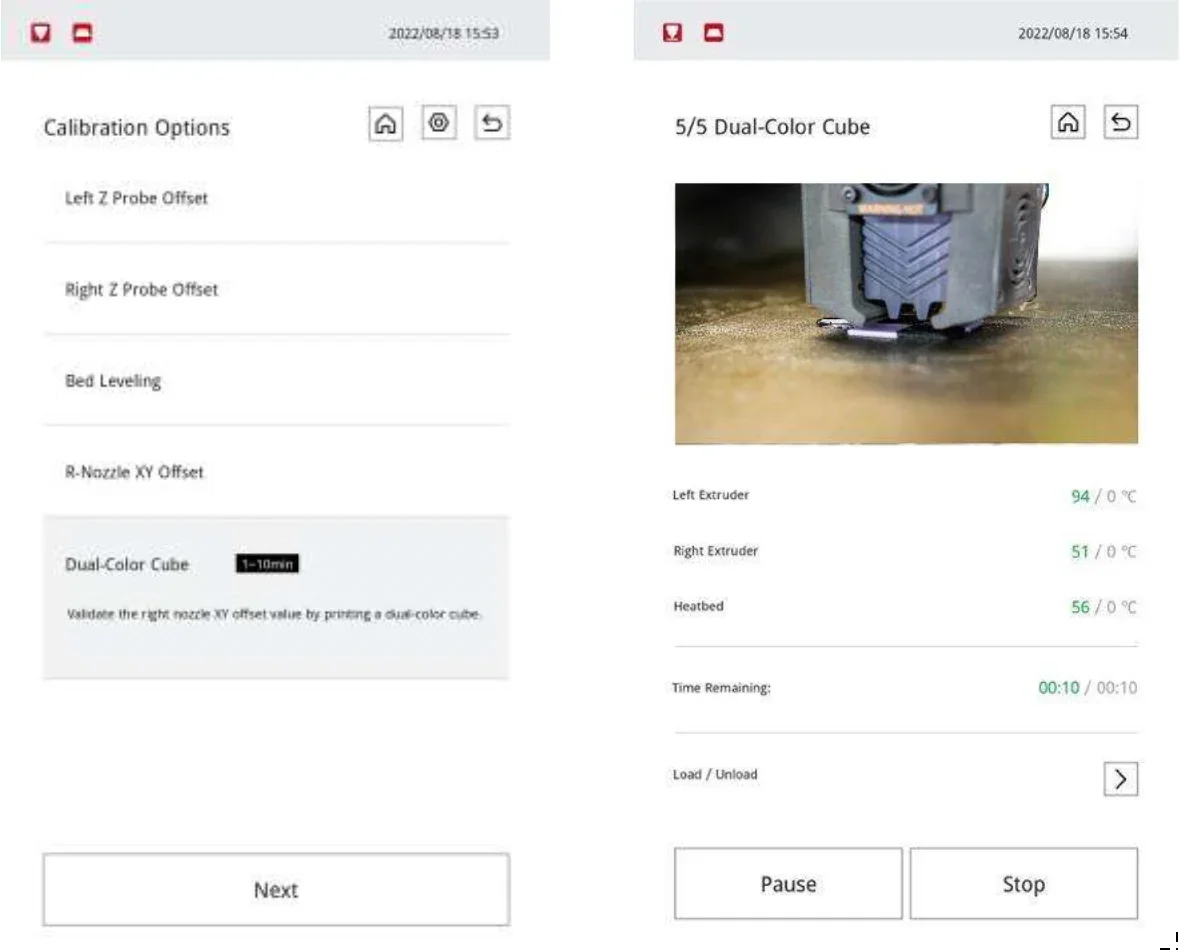

Calibration and adjustments are accessible under Utilities → Maintenance, including the guided Startup Wizard, Z-probe offsets for both nozzles, 3-minute bed leveling, XY-offset calibration for the right nozzle (verified with a dual-color cube), and real-time sensor checks. These built-in workflows ensure accurate nozzle and bed alignment, improving first-layer quality and dual-nozzle registration.

The Filament tab automates loading and unloading with preheating and 100 mm pre-feed. When paired spool boxes are loaded (M1/M2 for left, S1/S2 for right), the printer auto-switches spools when one runs out. The Tune panel allows real-time adjustments to nozzle and bed temperatures, fan speeds, flow rates, and overall feed rate—enabling on-the-fly corrections without stopping the print.

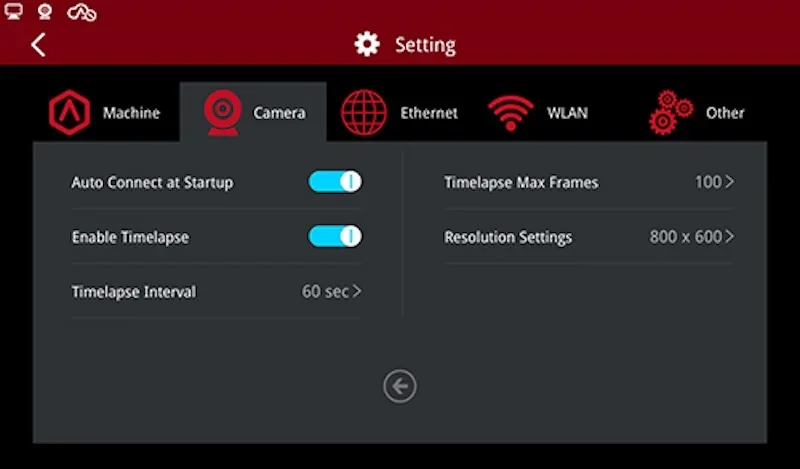

The Raise3D RMF500 offers Ethernet (LAN), Wi-Fi (802.11 b/g/n with 2×2 MU-MIMO), and a USB port for local file loading, along with a built-in live camera for remote monitoring and time-lapse capture. Users can manage network settings directly from the RaiseTouch interface, switching between wired and wireless as needed. Compatible with Windows, macOS, and Linux, the system supports file management via USB (Queue → USB) and stores jobs locally from ideaMaker. These connectivity options enable flexible, reliable workflows — whether operating offline, over a network, or directly at the machine.

The Raise3D RMF500 uses ideaMaker — a powerful slicing software, offering full control over print settings. Compatible with STL, OBJ, 3MF, and OLTP files, it runs on Windows, macOS, and Linux. Preloaded profiles for Raise3D and Open Filament Program materials simplify setup and optimize prints.

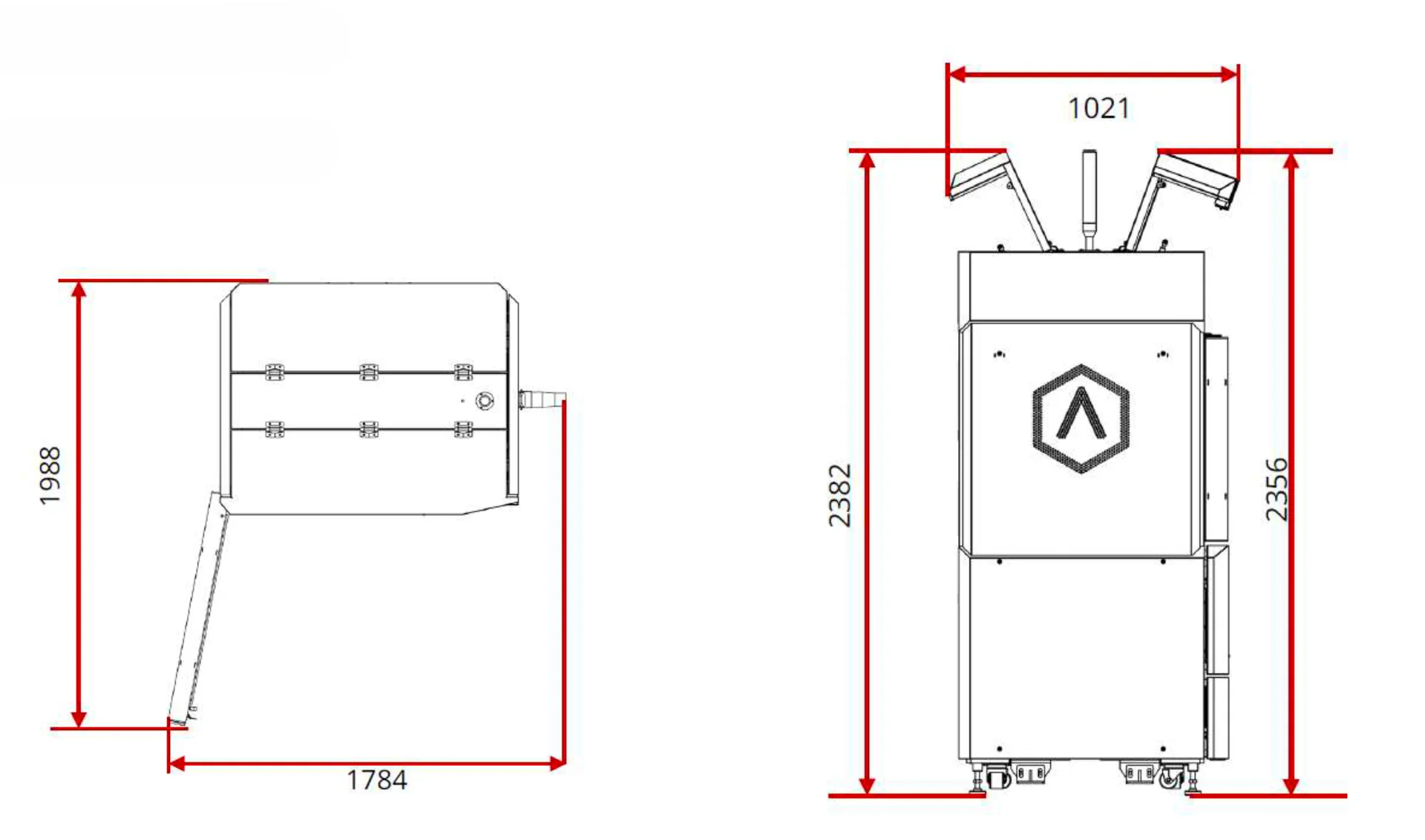

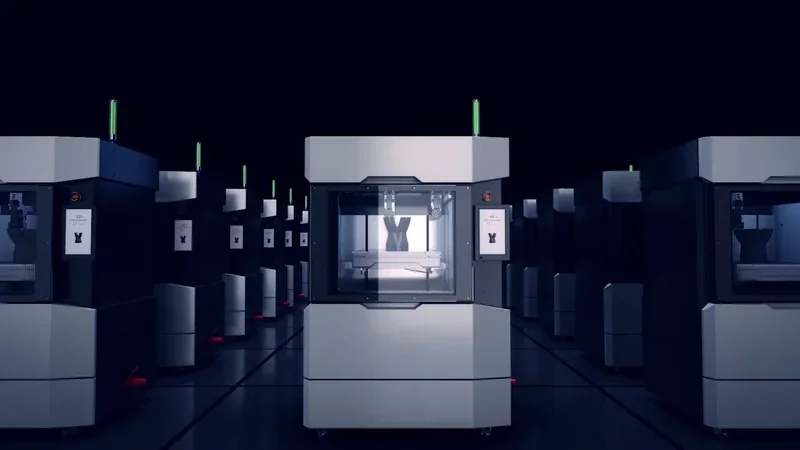

The RMF500 is a fully enclosed steel industrial printer with electronic door locks and a status indicator. It measures 1340 × 990 × 2370 mm and weighs 790 kg.

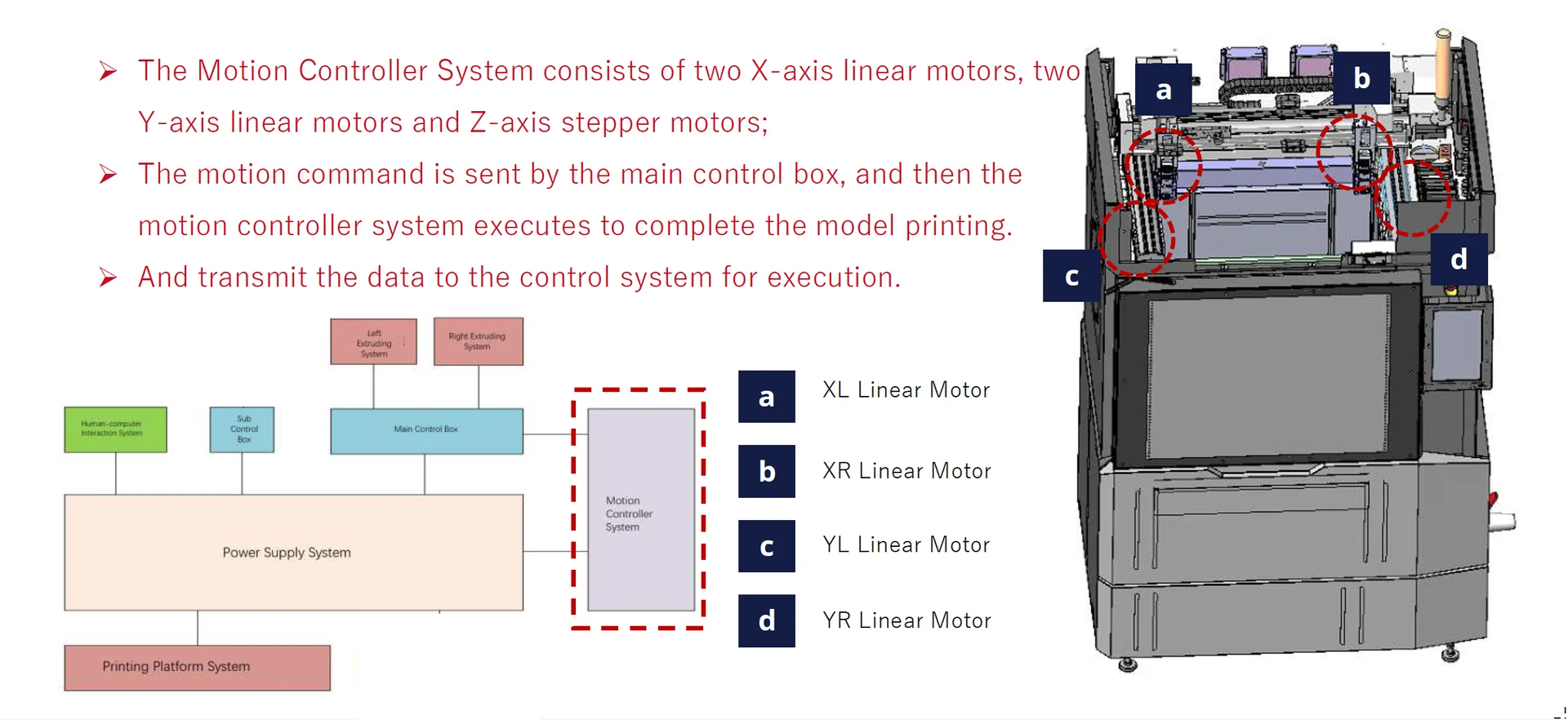

The Raise3D RMF500 uses a closed-loop linear-motor drive system on XY (two X and two Y motors) and lead-screw stepper motors on Z. A rigid steel frame and reinforced Z platform reduce vibration.

The Raise3D RMF500 operates at < 65 dBA when idle and < 66 dBA when printing.

The Raise3D RMF500 has a large build volume of 500 × 500 × 500 mm with a heated aluminum bed up to 120°C. It includes a PEI-coated flexible steel sheet for strong adhesion and easy part removal.

The Raise3D RMF500 features a dual-gear direct-drive extruder and a high-flow hotend that reaches 300°C with a 25 mm³/s flow rate. It includes a wear-resistant ruby nozzle and a toolhead with automatic nozzle cleaning and filament purging.

The Raise3D RMF500 has an internal filament compartment for four 1 kg or 2.5 kg spools. A dual-input system handles feeding with automatic switching and runout detection on each input.

The RMF500's control system includes a main control box (for motion, heating, and extrusion), a sub-control box (for signal feedback), and a touchscreen HMI board. A USB port is accessible at the platform assembly for HMI use.

The RMF500 requires 3-phase 380 V AC at 25 A and operates in environments of 15–30 °C with 30–70% relative humidity (non-condensing).

Assembly state: Fully assembled industrial printer; site work involves uncrating, positioning, and connecting the supplied power cable before running the built-in startup calibrations.

Package contents may change without notice. Contact a Top3DShop sales representative to confirm current items before ordering.

Raise3D supplies 5 replacement parts and accessories for the Raise3D RMF500 3D printer.

| Accessory | Function | Price (USD) | Image |

|---|---|---|---|

| Hot End and Nozzle Parts | |||

| High Power Hot End | Replacement hot end assembly for Raise3D RMF500; heats filament and supports extrusion during printing. | $799.00 |  |

| Alloy Steel Nozzle 0.4 | Replacement 0.4 mm nozzle for Raise3D RMF500; defines extrusion diameter for printing. | $109.00 |  |

| Build Plate Parts | |||

| Flexible Build Plate | Replacement flexible build plate for Raise3D RMF500; allows easier part removal by flexing the plate. | $169.00 |  |

| Category: Air Filtration Parts | |||

| Air Filter | Replacement air filter for Raise3D RMF500; supports air filtration inside the printer. | $19.00 |  |

| Filament Storage and Moisture Protection | |||

| Filament Dry Bags 1kg | 8 Filament dry-storage bags for 1 kg spools; helps protect filament from moisture during storage. | $109.00 |  |

The Raise3D RMF500 requires over 20 maintenance procedures to sustain dimensional accuracy, reliable filament feeding, and clean operation across initial setup, operational upkeep, and a documented 3-year maintenance plan. These include:

Before first use (Starting-up Wizard, on-printer):

Pre-print checks (on-printer):

Filament system upkeep (at spool change or if feeding issues are observed):

Build platform handling:

Periodic mechanical service (lubrication & inspection):

Environmental maintenance:

Raise3D offers a 12-month limited warranty covering defects in materials and workmanship under normal use. The warranty excludes damage from improper use, failure to follow the official manual, lack of maintenance, unauthorized repairs, external causes, and non-approved filaments. Warranty extensions are available to the original purchaser under Raise3D’s terms.

During the warranty period, Raise3D provides:

Support Channels

The price of the Raise3D RMF500 is $69,999.00. The Raise3D RMF500 is a precise industrial 3D printer with a 500 x 500 x 500 mm build volume, 500 mm/s speed, and support for carbon-fiber-reinforced thermoplastics. Designed for professional use, its price varies by service and support — contact Top 3D Shop for a quote.

Update your browser to view this website correctly. Update my browser now