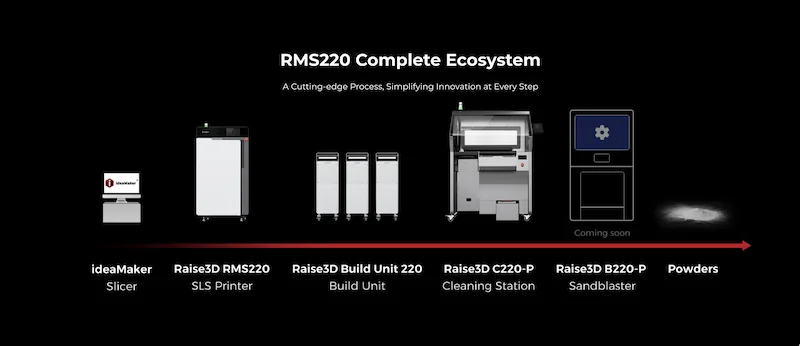

The Raise3D RMS220 is an industrial SLS (Selective Laser Sintering) 3D printer with a 220 x 220 x 350 mm build volume and a 75W laser (1064nm) using 30,000 mm/s galvo scanning. It offers up to 2.2 L/h print speed (at 20% packing) and 5 kg/day throughput. Designed for tight tolerances (±0.2 mm) and 0.5 mm thin walls (PA11), it features a 4-zone self-calibrating IR heater, Air/Nitrogen atmosphere with built-in nitrogen generator, RFID powder management system, and a modular design allowing 45-minute material changeovers for efficient batch production.

The RMS220 supports 0.05–0.40 mm layer heights, with 0.10–0.20 mm recommended for stability, allowing fine feature detail and controlled surface finish.

A 75 W, 1064 nm fiber laser with an F-theta lens and 30,000 mm/s galvo scanning ensures precise energy delivery for uniform sintering and strong layer adhesion. The 4-zone self-calibrating infrared heating system maintains chamber temperatures up to 220 °C with ±1.5 °C stability, ensuring uniform powder sintering and consistent part properties across batches. This thermal management system prevents dimensional deformation at different locations within the printing platform, delivering highly consistent and repeatable results.

The RMS220 prints up to 2.2 L/h at 20% packing density, with a throughput of up to 5 kg/day. A 123 x 211 x 151 mm skeleton foot model in PA12 Black V1 demonstrated high accuracy on complex geometry, printed in 4 h 38 min using 0.25 kg of powder.

High-Speed Printing: Preheating starts during slicing and reaches print temperature within 20 minutes. After printing, the Build Unit 220 cools below 100 °C in around 30 minutes, enabling quick job turnover.

The galvo system with F-theta optics ensures accurate spot placement at high scanning speed. Closed-loop thermal control maintains consistent part density across the Z-axis. An Air / Nitrogen atmosphere with a built-in nitrogen generator reduces oxygen exposure, while RFID, a powder-level sensor, and a 31.5 L hopper (expandable to 40 L) ensure reliable powder handling for long builds.

The RMS220 supports 7+ material types, including PA12 Black, PA11 Black, PA12 GB (glass bead), and multiple TPU variants (90A Black/White, 86A Black/White) from the 3D printer manufacturer Raise3D.

| Property | PA12 | PA11 | PA12 GB |

|---|---|---|---|

| Material Type | Polyamide 12 (Nylon 12) | Polyamide 11 (Bio-based Nylon) | Glass Bead Reinforced PA12 |

| Color | Natural/White | Natural/White | Natural/Grey |

| Tensile Strength | 45-50 MPa | 48-52 MPa | 31 MPa |

| Elongation at Break | 20-30% | 45-50% | 6% |

| Shore Hardness | 75-80 Shore D | ~78 Shore D | ~85 Shore D |

| Density | 1.01 g/cm³ | 0.99 g/cm³ | 1.45 g/cm³ |

| Melting Temperature | 184°C | 201°C | 186°C |

| Temperature Resistance | Up to 100°C continuous | Up to 180°C (0.45 MPa) | Similar to PA12 |

| Biocompatibility | FDA approved grades available | Skin contact approved | Not specified |

| Key Applications | General prototyping, functional parts | End-use parts, automotive, medical | Structural components, flat panels |

| Distinctive Features | Balanced properties, 70-80% reusability | Bio-based, superior impact resistance | 40% glass reinforcement, reduced warping |

| Property | TPU90A | TPU90A White | TPU86A Black | TPU86A White |

|---|---|---|---|---|

| Material Type | Thermoplastic Polyurethane | Thermoplastic Polyurethane | Thermoplastic Polyurethane | Thermoplastic Polyurethane |

| Color | Natural/Black | White | Black | White |

| Tensile Strength | 8.7 MPa (X/Y) | 8.7 MPa (X/Y) | 6-8 MPa (X/Y) | 6-8 MPa (X/Y) |

| Elongation at Break | 310% (X/Y) | 310% (X/Y) | 350-400% (X/Y) | 350-400% (X/Y) |

| Shore Hardness | 90A | 90A | 86A | 86A |

| Density | 1.10 g/cm³ | 1.10 g/cm³ | 1.08-1.12 g/cm³ | 1.08-1.12 g/cm³ |

| Melting Temperature | ~190°C | ~190°C | ~185°C | ~185°C |

| Temperature Resistance | Up to 94°C (Vicat) | Up to 94°C (Vicat) | Up to 90°C (Vicat) | Up to 90°C (Vicat) |

| Biocompatibility | ISO 10993 certified | ISO 10993 certified | ISO 10993 certified grades available | ISO 10993 certified grades available |

| Key Applications | Gaskets, seals, flexible parts | Medical devices, wearables | Flexible housings, protective covers, shock absorbers | Medical devices, consumer wearables, ergonomic parts |

| Distinctive Features | High elasticity, 66 kN/m tear resistance | Aesthetic white color variant | Softer elastomer, improved flexibility over 90A | Softer white variant for aesthetic applications |

Beyond the validated set, selected third-party powders are supported. An optional open material license allows broader experimentation, but unapproved materials require profile development before use.

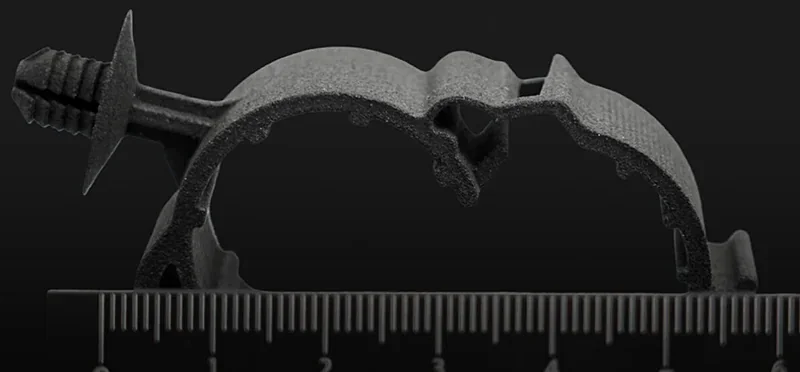

PA11 Print Samples

Cable clip: Material — Raise3D PA11 Powder; Printing time — 12min; Full capacity — 150 pcs

Compliant gasket: Material — Raise3D PA11 Powder; Printing time — 2min; Full capacity — 10527 pcs

PA12 Print Sample

Hairball trimmer: Material — Raise3D PA12 Powder; Printing time — 45min; Full capacity — 16 pcs

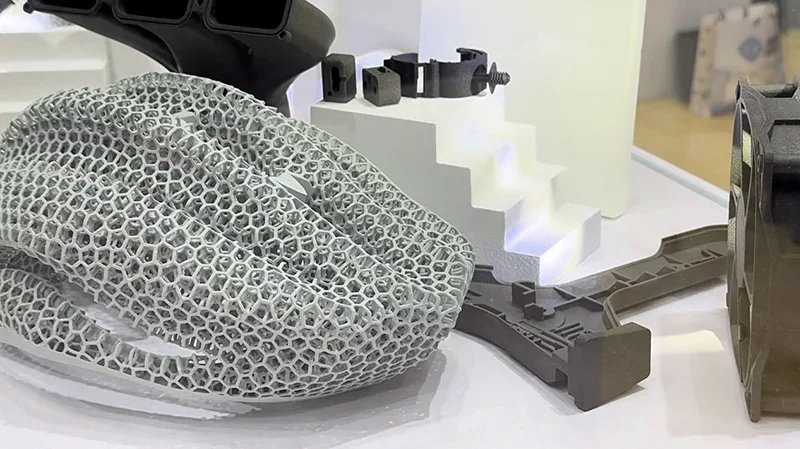

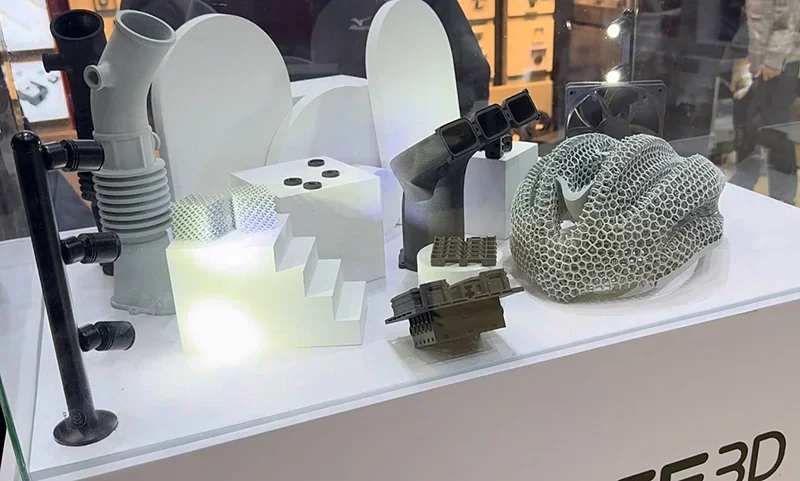

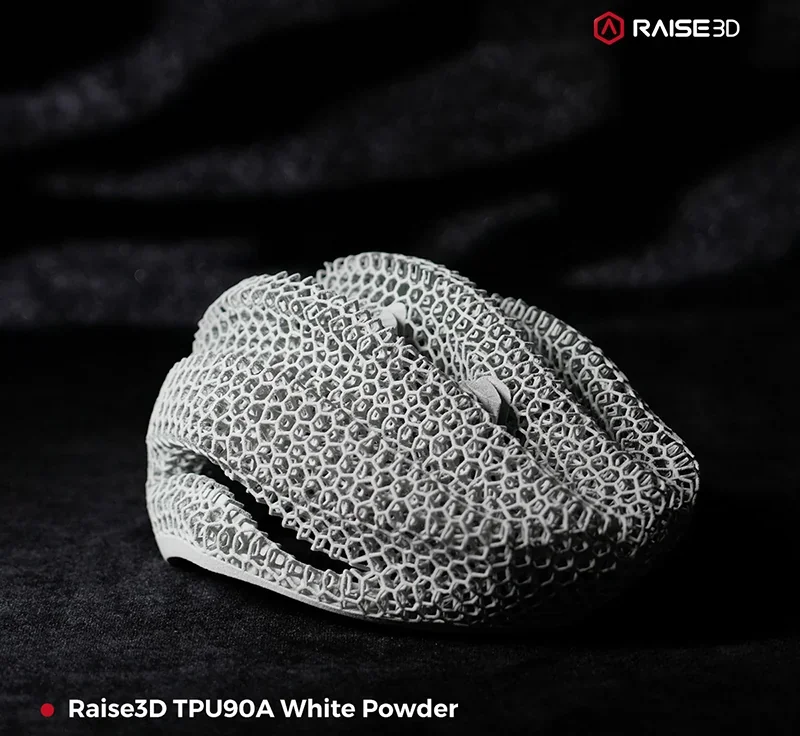

TPU90A White Powder Print Sample

Helmet lining: Material — Raise3D TPU90A White Powder; Printing time — 4h 25min; Full capacity — 3 pcs

PA12 GB Powder Print Sample

Shunt intake manifold: Material — Raise3D PA12 GB Powder; Printing time — 2h 23min; Full capacity — 4 pcs

The RMS220 uses RFID technology for automatic powder identification and parameter setup, eliminating manual input and reducing errors.

The RMS220 delivers a large build volume of 220 x 220 x 350 mm. An optional material box expands hopper capacity from 31.5 L to 40 L.

Raise3D RMS-220 — largest build volume (220×220×350 mm), highest quoted throughput (≈2.2 L/h), broad layer range (50–400 µm), 75 W 1064 nm laser with fast galvos, built-in nitrogen generator for inert printing, and an integrated cleaning station (C220-P) geared for high-throughput production.

In contrast:

| Specification | Raise3D RMS220 | Formlabs Fuse 1+ 30W | Sinterit Lisa X |

|---|---|---|---|

| Technology / Laser | SLS; 75 W fiber laser, 1064 nm; galvo (max scan 30,000 mm/s). | SLS; Yb-fiber 30 W; ~200 µm spot; scan up to 12.5 m/s. | SLS; IR fiber-coupled diode 30 W, 976 ± 3 nm; galvo. |

| Build volume | 220 × 220 × 350 mm | 165 × 165 × 300 mm | PA/PP: 130 × 180 × 330 mm; TPU: 130 × 180 × 340 mm |

| Layer thickness | 0.05–0.40 mm (50–400 µm) | 110 µm fixed | 0.075–0.175 mm (75–175 µm) |

| Print speed (volumetric) | 2.2 L/h | 0.5 L/h | 0.5 L/h |

| Atmosphere / gas | Air / Nitrogen; built-in Nₒ generator (requires compressed air). | Air or Nitrogen (external supply required); sealed chamber, positive pressure; nitrogen specs: ≥99.5% purity, ≥0.5 SCFM (≈14 L/min), 36–125 psi, ≥18 °C inlet. Sources: cylinder, dewar, or generator. | Inert-gas control; typical Nₒ consumption ≈0.48 m³/h (8 L/min). |

| Powder handling & post-processing | RFID powder; level sensor; hopper 31.5 L (up to 40 L with material box). | Fuse Sift all-in-one recovery & auto-mix; modular build chamber; optional Fuse Blast cleaning. | Multi PHS workstation: multi-material presets (6), quick deep-clean ~10–30 min, 95–98% powder recovery to 20 L container, solo-sifting; compatible with compact & industrial SLS. Sandblaster SLS: sealed, HEPA-filtered; large 675 × 450 × 415 mm work area. Vapor smoothing: AMT PostPro SFX integration. |

| Compatible materials (OEM / validated) | PA12, PA11, PA12-GB, TPU 90A (black/white), TPU 86A (black/white). | Nylon 12, Nylon 12 GF, Nylon 11, Nylon 11 CF, TPU 90A. | PA11.5, PA12 Industrial, PA12 Smooth, PA11 Onyx, PA11 CF, PA11 ESD, PP (polypropylene), Flexa Performance (TPU), PBT Optimal (plus profile-only options). |

| Software / file types | ideaMaker; STL/OBJ/3MF/OLTP/STEP/STP/IGES/IGS; Win/macOS/Linux. | PreForm; STL/OBJ; Dashboard cloud monitoring. | Sinterit Studio; STL/3MF/OBJ/3DS/FBX/DAE; Windows. |

| Connectivity / UX | Wi-Fi, LAN, USB; real-time camera; 11.5″ touchscreen. | PreForm + cloud Dashboard (remote monitoring). | Wi-Fi / Ethernet / USB; built-in camera; 9″ touchscreen. |

| Machine size (W×D×H) | 861 × 685 × 1560 mm (w/o tower light) | 645 × 685 × 1070 mm (≈1655 mm with stand) | 650 × 610 × 1200 mm |

| Weight | 283 kg | 114 kg | 145 kg |

| Power | 190–240 VAC, 50/60 Hz, 230 V @ 16 A | EU 230 VAC @ 7.5 A; US 120 VAC @ 15 A | 230 VAC, 8 A or 100–120 VAC, 15 A |

| Basic Set Pricing (USD) | $39,999 — bundle includes RMS220 printer with built-in nitrogen generator, Build Unit 220, Cleaning Station C220-P, 1-year warranty. | $34,648 — $24,649 printer + $9,999 Fuse Sift. | $34,980 — $23,990 printer + $10,990 Multi PHS. |

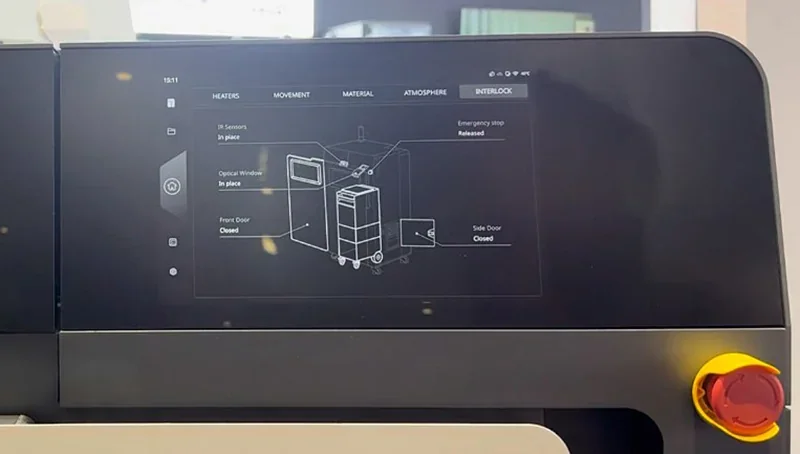

The Raise3D RMS220 production system provides 7 printer controls for operation and monitoring:

Touchscreen Interface Controls (4):

Visual Status Monitoring (1):

Automated Systems (2):

The 11.5″ touchscreen (2560 x 1600) with a Linux-based HMI serves as the main control interface, supported by a status light for real-time machine feedback. Automated heating and RFID systems require no user input, maintaining part temperature and enabling ~45-minute material changeovers.

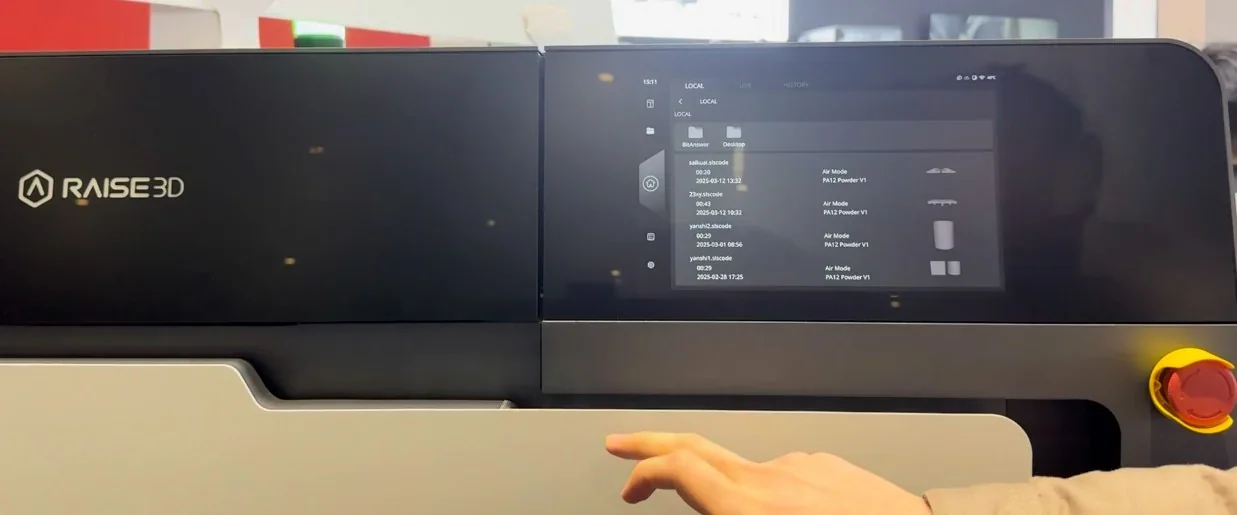

The RMS220 offers 4 connectivity options: Wi-Fi, Ethernet, and USB 3.0 for job loading and networked operation, plus a built-in camera for remote monitoring. It supports Windows, macOS, and Linux workstations. USB allows quick offline transfers, while Wi-Fi and Ethernet enable centralized LAN access.

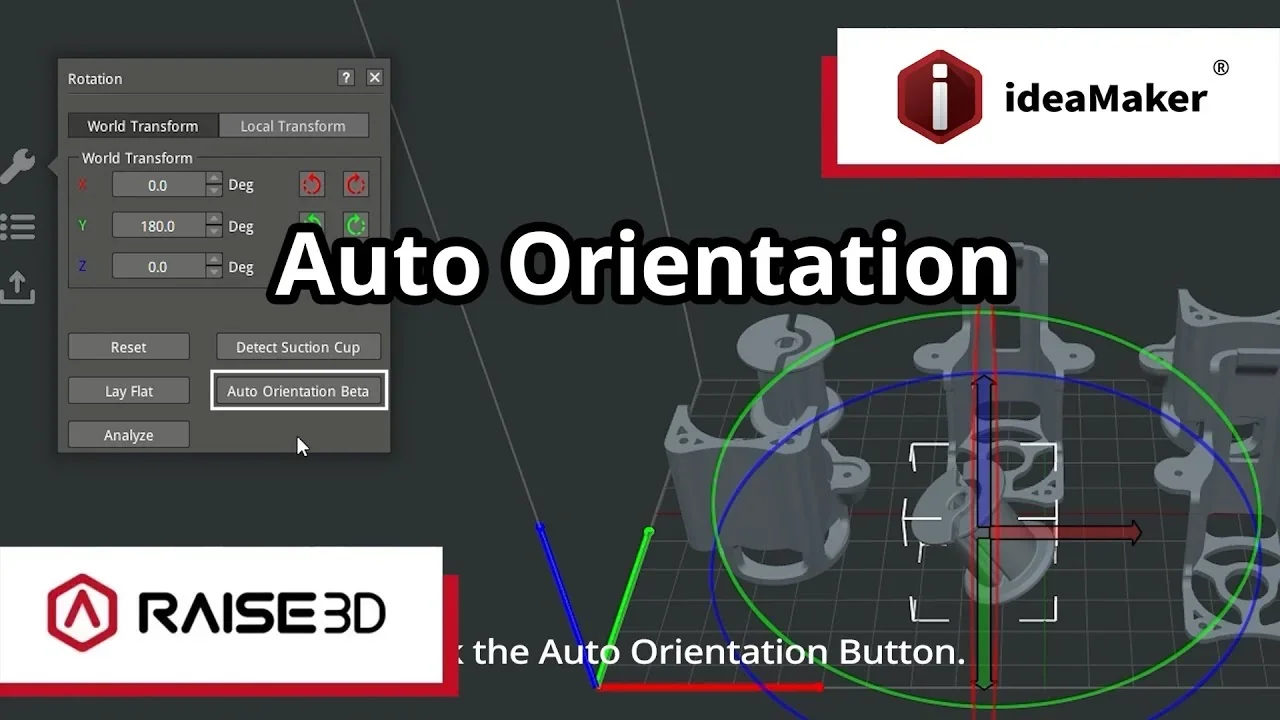

The RMS220 uses Raise3D’s free ideaMaker software, compatible with STL, OBJ, 3MF, OLTP, STEP, and IGES imports, and exports .slscode. It runs on Windows, macOS, and Linux.

IdeaMaker organizes SLS job prep into steps: choose printer/material presets and layer height, optionally adjust parameters like energy scaling, laser settings, temperature offsets, and shrink compensation. Use precise tools for part arrangement (move, rotate, scale), collision checks, visibility locks, and auto-nesting. Slice to generate time and powder estimates, preview layers in 2D/3D, and send jobs to connected printers.

Features include per-model overrides, open-parameter controls for material development, and settings for warmup/cooldown and powder refresh ratios. Raise3D integrates this with RaiseCloud for browser/mobile-based remote monitoring and workflow management.

The RMS220 3D printer as a single-machine unit includes:

The RMS220 Series Standard Package (bundle) includes:

The RMS220 is delivered fully assembled; professional installation is sold separately. Powder, the Material Box, and the Build Unit 220 are shipped without material.

Please Note: Package contents are determined by the manufacturer and may change without notice. To confirm the current items included with this product, please contact a Top3DShop sales representative before placing your order.

| Name | Function | Price (USD) |

|---|---|---|

| Raise3D Build Unit 220 | Extra modular build unit for hot-swapping builds to minimize downtime and accelerate turnover | $4,999 |

| Raise3D C220-P Cleaning Station | Post-processing hub for powder recovery, part extraction, and powder mixing | $9,999 |

| Material Box | Expands hopper capacity 31.5 L → 40 L for longer unattended runs | Request a quote |

| Open Material License | Enables fully open materials beyond validated powders for R&D / third-party use | Request a quote |

Raise3D Build Unit 220 — a second build unit that lets you prepare the next job and swap immediately after print completion to keep the RMS220 producing continuously.

Raise3D C220-P Cleaning Station — integrates part extraction, powder recovery, and powder mixing to speed post-processing and recycle material efficiently.

Material Box — increases effective hopper capacity from 31.5 L to 40 L to extend build duration without refills.

The Raise3D RMS220 requires 12+ maintenance procedures to maintain optimal printing performance, dimensional accuracy, and system reliability.

Pre-Print Maintenance (3 procedures)

Every 30 Hours (2 procedures)

Every 100 Hours (4 procedures)

Every 500 Hours (2 procedures)

Every 1000+ Hours (1+ procedure)

Material Change Procedures (Variable)

The RMS220’s modular design allows material changeovers in 45 minutes with RFID-based parameter matching, avoiding the multi-day cleaning typical of traditional SLS systems. Its 4-zone IR heater self-calibrates, reducing manual thermal adjustments.

Exclusions

Installation

Raise3D offers extended warranty packages for the RMS220 Series: RaiseShield adds priority support, annual 2-hour product training, and a preventive maintenance kit with self-service + remote guidance, while RaiseShield Pro adds everything in RaiseShield plus an annual on-site maintenance visit.

| Feature | Raise3D Standard Warranty | RaiseShield | RaiseShield Pro |

|---|---|---|---|

| Service Years Options | 1 year | 2,3,4,5 years | 1,2,3,4,5 years |

| Warranty Coverage (Parts & Shipping) | ✓ | ✓ | ✓ |

| Priority Phone & Email Support | Email Only | ✓ | ✓ |

| Remote Product Training of RMS220 Series (2 hours/Year) | ✕ | ✓ | ✓ |

| Preventive Maintenance Kit | ✕ | ✓ Self Service, Remote | ✓ Self Service, or combined with onsite support |

| Onsite Tech. Support | ✕ | ✕ | ✓ Max. 1 Visit/Year |

| Service package | Total coverage term | Price (USD) | Image |

|---|---|---|---|

| RaiseShield — 2 Year | 2 years | $3,760.00 |  |

| RaiseShield — 3 Year | 3 years | $5,640.00 |  |

| RaiseShield — 4 Year | 4 years | $7,520.00 |  |

| RaiseShield — 5 Year | 5 years | $9,400.00 |  |

| RaiseShield — 1 Year Renewal | +1 year | $1,880.00 |  |

| Service package | Total coverage term | Price (USD) | Image |

|---|---|---|---|

| RaiseShield Pro — 1 Year | 1 year | $4,500.00 |  |

| RaiseShield Pro — 2 Year | 2 years | $9,000.00 |  |

| RaiseShield Pro — 3 Year | 3 years | $13,500.00 |  |

| RaiseShield Pro — 4 Year | 4 years | $18,000.00 |  |

| RaiseShield Pro — 5 Year | 5 years | $22,500.00 |  |

| RaiseShield Pro — 1 Year Renewal | +1 year | $4,500.00 |  |

The RMS220 is priced at $34,999.00. The Raise 3D RMS220 Series Standard Package, which includes the Build Unit 220 and C220-P Cleaning Station, costs $44,998.00. For a customized quote with on-site installation and training, contact Top 3D Shop.

Update your browser to view this website correctly. Update my browser now