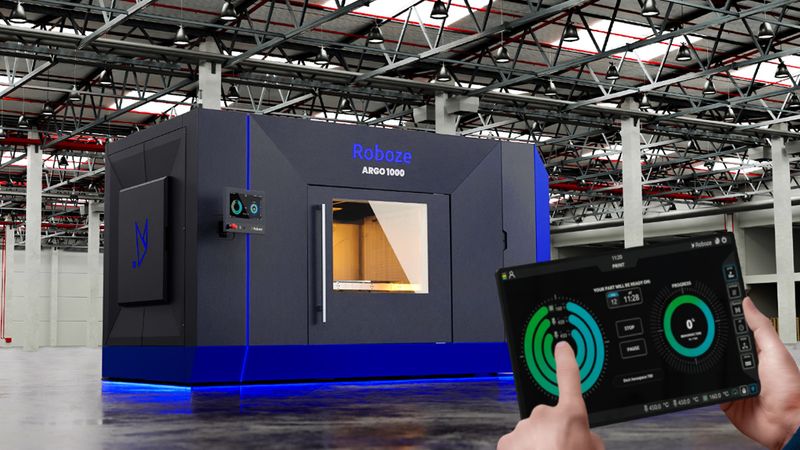

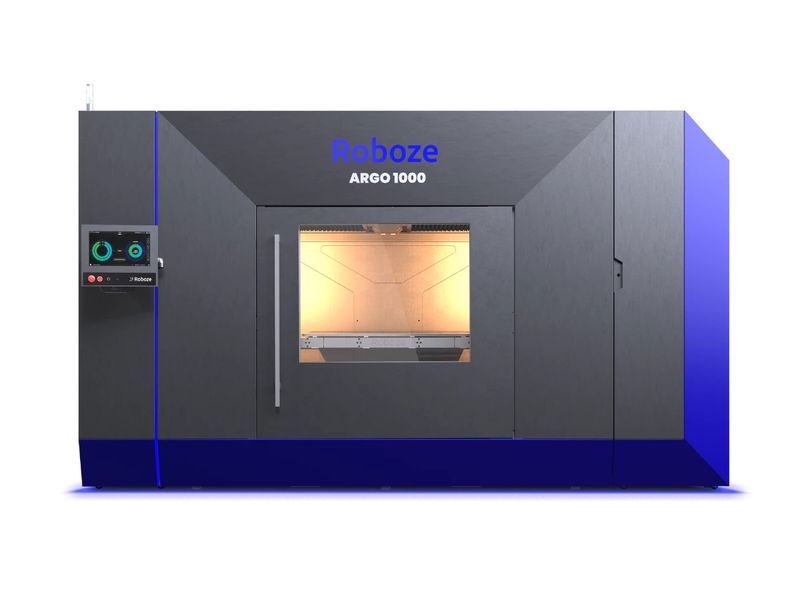

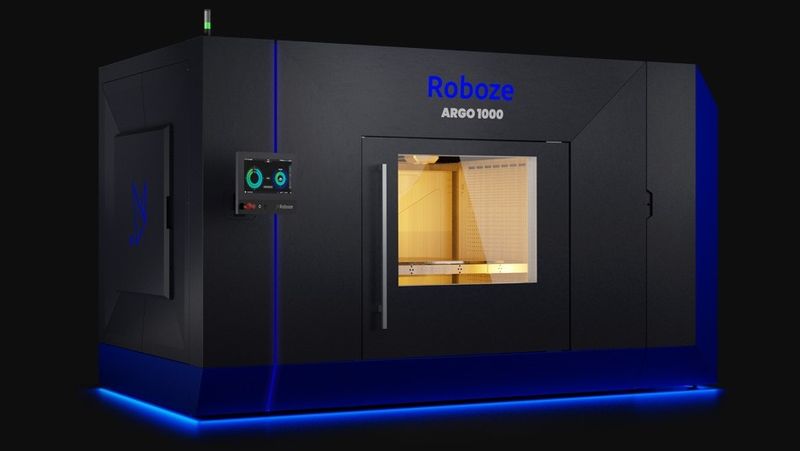

The Roboze ARGO 1000 is the latest addition to the Roboze Production series of industrial 3D printers. Being the Roboze flagship model, the machine features the largest of the series and one of the biggest in the market build volumes of 1 cubic meter.

The ARGO 1000 is equipped with an industrial automation system allowing for remote operation and predictive maintenance to reduce downtime and increase efficiency. The remote management function allows for automatic software updates. For further analysis and model certification, the print log is saved after each print.

The automated printing process also includes auto bed leveling and extruder calibration, automatic material loading, and filament runout detection.

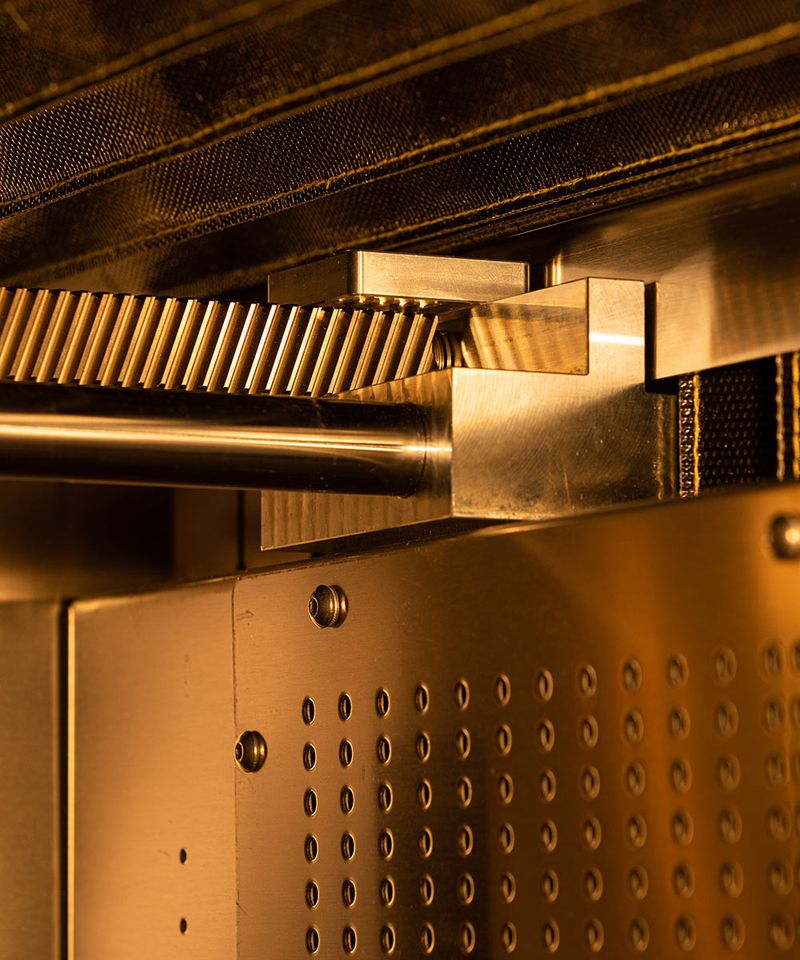

Based on the patented Beltless System which uses XY direct mechatronic movement with rack and pinion gears instead of conventional rubber belts, the ARGO 1000 provides high mechanical precision and repeatability of printing results. The high-temperature HVP extruder ensures continuous flow and allows printing with high-viscosity engineering polymers. To prevent model deformation and shrinkage, the build chamber of the ARGO 1000 provides homogeneous heating up to 180 °C. Polymer print sheets held on the print bed with a vacuum are used to improve first layer adhesion.

The integrated HT filament dryer reaching the temperature of 120 °C provides optimal material treatment and guarantees the consistent quality of the printed models.

The high-precision kinematics of the ARGO 1000, combined with a high-performance extruder and thermally controlled build chamber, as well as a heated print bed with auto leveling make for industrial-grade print quality of dimensionally accurate, highly detailed models with smooth surface finish, and ensure high level of repeatability. The XY printing accuracy is 10 microns and the Z accuracy is 25 microns.

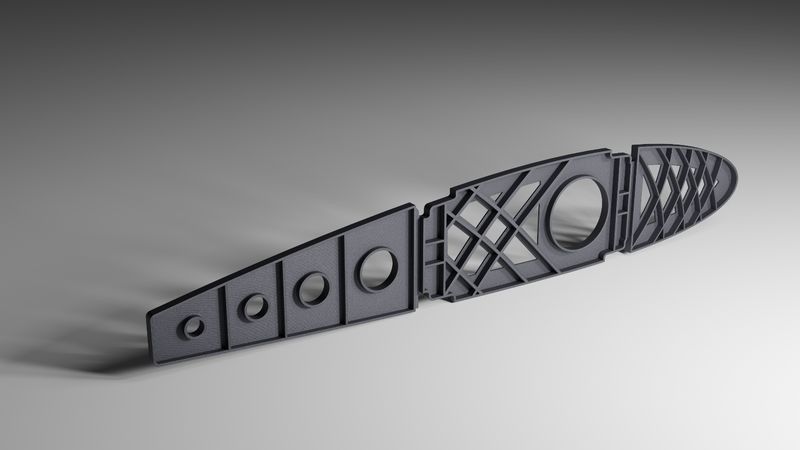

This door-holding fixture was printed with Roboze PEEK.

And below are Carbon PEEK models.

The high-performance extruder with a 0.4 mm diameter nozzle heats up to 450 °C, allowing printing with engineering thermoplastics and composites such as PEEK, Carbon Peek, Carbon PA, Ultem AM9085F, PC, Functional-nylon, ABS-ESD, PP, Flex-TPU, Strong-ABS, and Ultra-PLA. Roboze produces a wide range of high-performance filaments perfectly compatible with the company’s industrial 3D printers.

The ARGO 1000 build volume is 1000 x 1000 x 1000 mm. Such an impressive size combined with outstanding print quality offers a plethora of new opportunities for aerospace, defense, energy, and other industries, allowing for production of very large models or high-volume manufacturing of smaller parts.

The printer features USB, Wi-Fi, and Ethernet connectivity options. Automated operation and remote control functions allow for a highly efficient end-to-end manufacturing cycle.

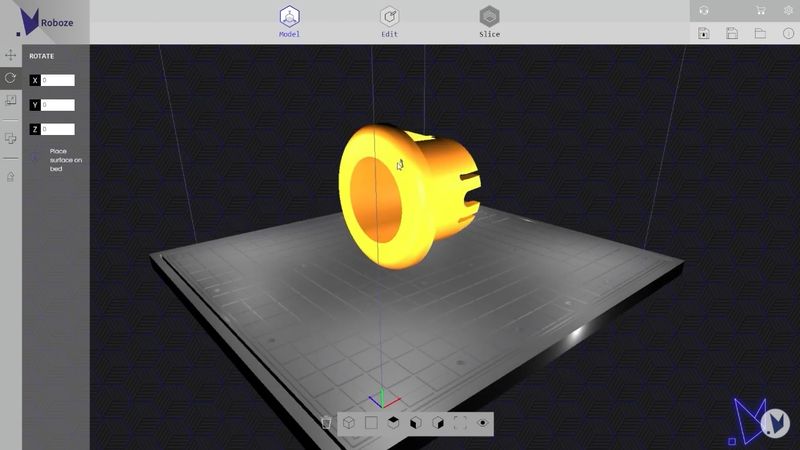

The dedicated Prometheus slicing software features versatile tools to ensure seamless workflow and speed up print preparation. The slicer features optimized profiles for Roboze 3D printers and filaments.

For some items, package content may change. In case of any questions, please get in touch.

The Roboze ARGO 1000 3D printer is available in a black color scheme with blue trimmings. Its solid look makes it ideal for a large industrial enterprise.

The machine dimensions are 153.5 x 88.6 x 84.5 in (3900 x 2250 x 2150 mm). It weighs approximately 8818.5 lb (4000 kg).

To learn the current price of the Roboze ARGO 1000 3D printer, click the "request a quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now