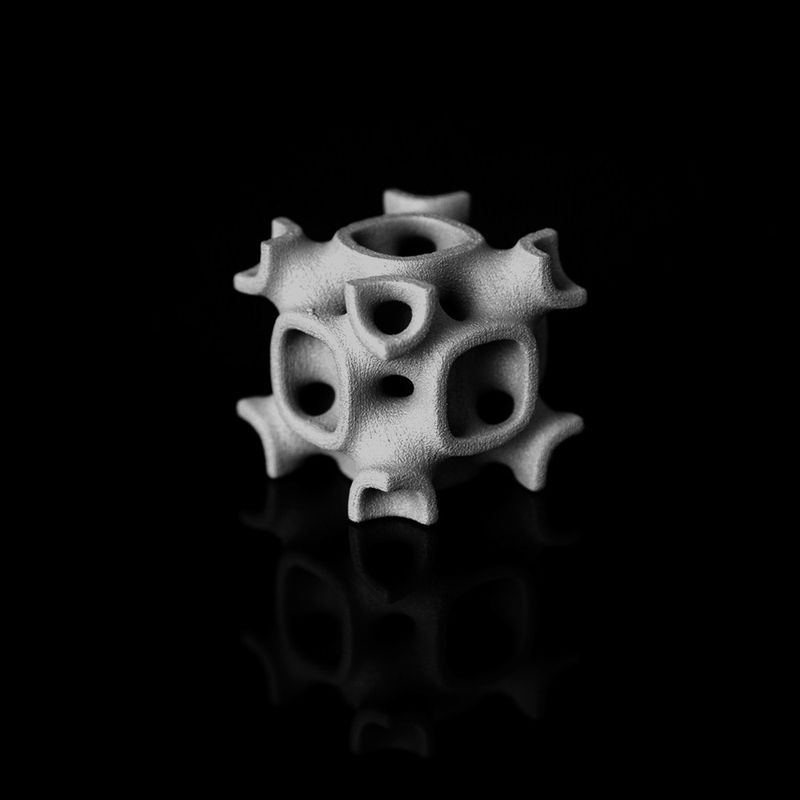

The Sinterjet M60 is a compact metal 3D printer based on binder jetting technology. The machine was designed by the Turkish-based Sintertek company as a more affordable and user-friendly solution for fully dense metal parts manufacturing, compared to large industrial SLM / DMLS systems. As opposed to LPBF (laser powder bed fusion), binder jetting technology uses a print head that selectively deposits an adhesive binder onto a powder bed in a layer-by-layer manner. As the model is encapsulated in powder during the building process, no support structures are needed, which allows creating complex parts with internal geometries and overhanging elements. The process takes place at room temperature which prevents any negative thermal effects on the part, like warpage or distortion.

Featuring modest build volume size, the M60 offers 1200 x 1200 dpi jet head resolution and is equipped with multiple jet heads to ensure finished part quality. Built-in IR heat sensors and humidity sensors help maintain optimal printing conditions. The machine can reach a print speed of 50 cc/h, which is fairly fast and allows for shorter time to market.

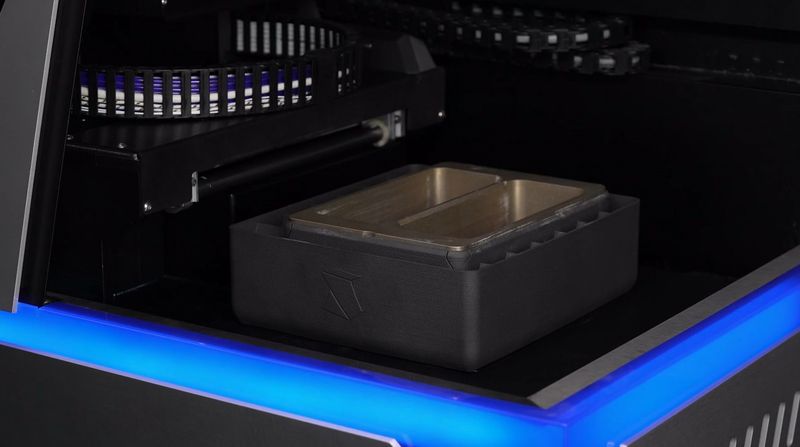

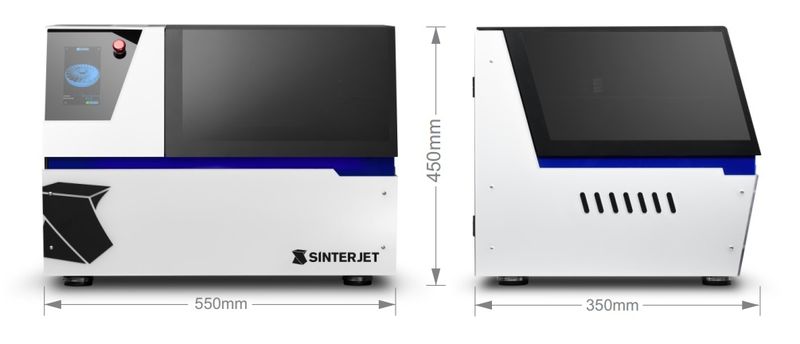

Having outer dimensions of 550 x 350 x 450 mm, the Sinterjet M60 is a true desktop machine that can fit in a limited space and requires no dedicated electrical connections or gas supply. The removable BuildBox was designed to allow for rapid material change between builds and to increase production throughput while minimizing downtime. With this excellent feature, loading a new print job or changing material at the end of a session can be done within seconds and with minimal effort. Once the print job is over, the BuildBox with the green part is removed from the printer and placed into a curing oven to activate the binding agent and fuse the metal powder together. After that the part can be removed from the BuildBox and placed inside a sintering furnace to achieve its full density.

The Sinterjet M60 can print layers at a minimum height of 20 microns, building high-quality metal parts with an impressive surface finish. Support-free printing and smooth surface reduce the need for post-processing steps other than sintering, thus speeding up the production cycle.

The Sinterjet M60 can print with a wide range of metal powders and binders. It is compatible with any powder with D50 of 10–60 µm size distribution. The manufacturer currently offers CoCrMo, CoNi, and SS 316L powders. Other materials, such as Copper, Ti Grade23, and Inconel 718 are soon to be added to the list.

The machine features a compact build volume of 160 x 60 x 60 mm suitable for manufacturing small-size high-quality metal parts for various industries. The removable BuildBox solution makes for fast and convenient operation.

The Sinterjet M60 is operated via a 5.5" capacitive touchscreen with an intuitive user interface. The user only needs to upload the digital model and select one of the print profiles, depending on the material being used and desired quality, and the M60 will start printing.

The Sinterjet M60 3D printer is available in a gray-and-black color scheme with blue trimmings. Its compact and stylish design makes it ideal for any workshop or R&D lab.

The machine dimensions are 21.7 x 13.8 x 17.7 in (550 x 350 x 450 mm). It weighs 154 lb (70 kg).

To learn the current price of the Sinterjet M60 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now