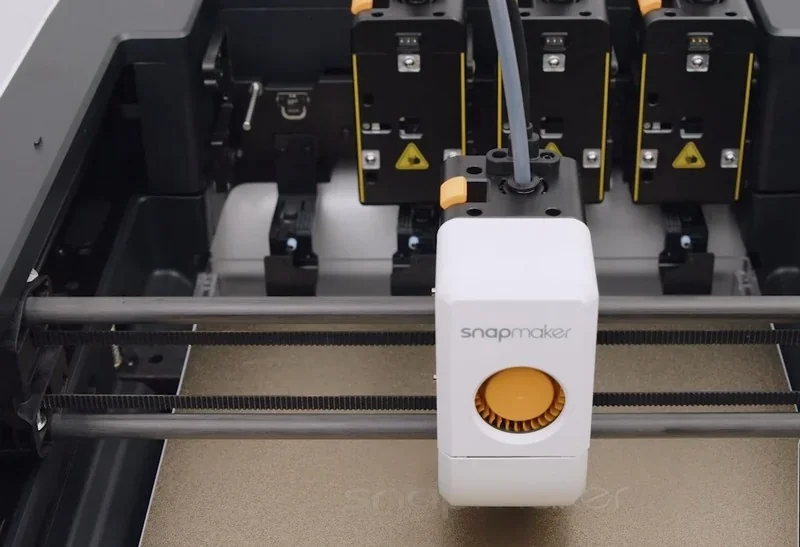

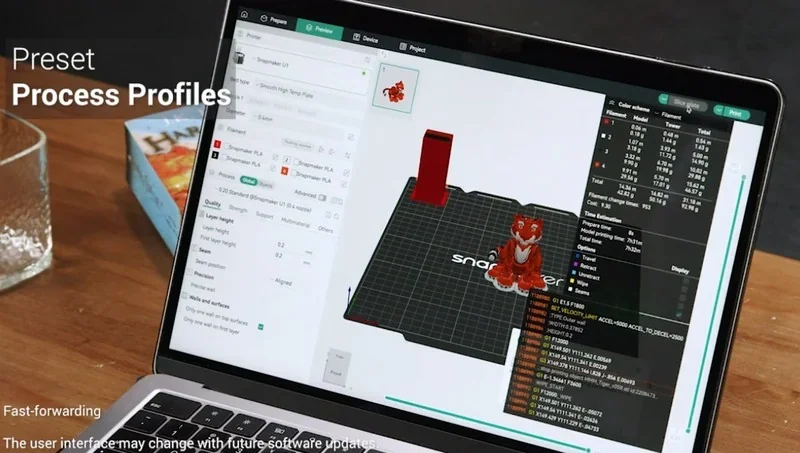

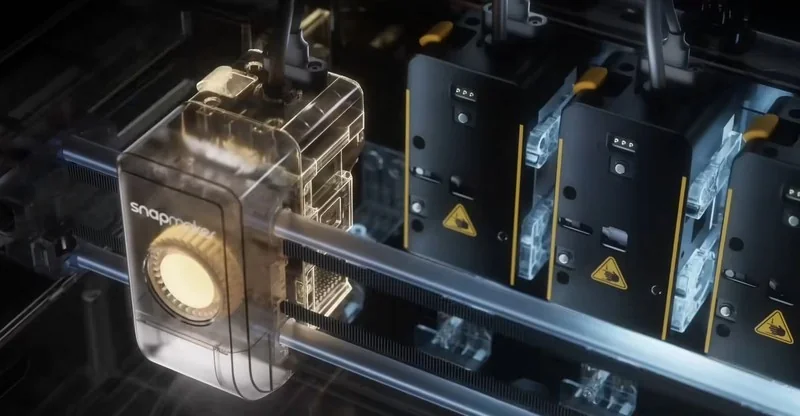

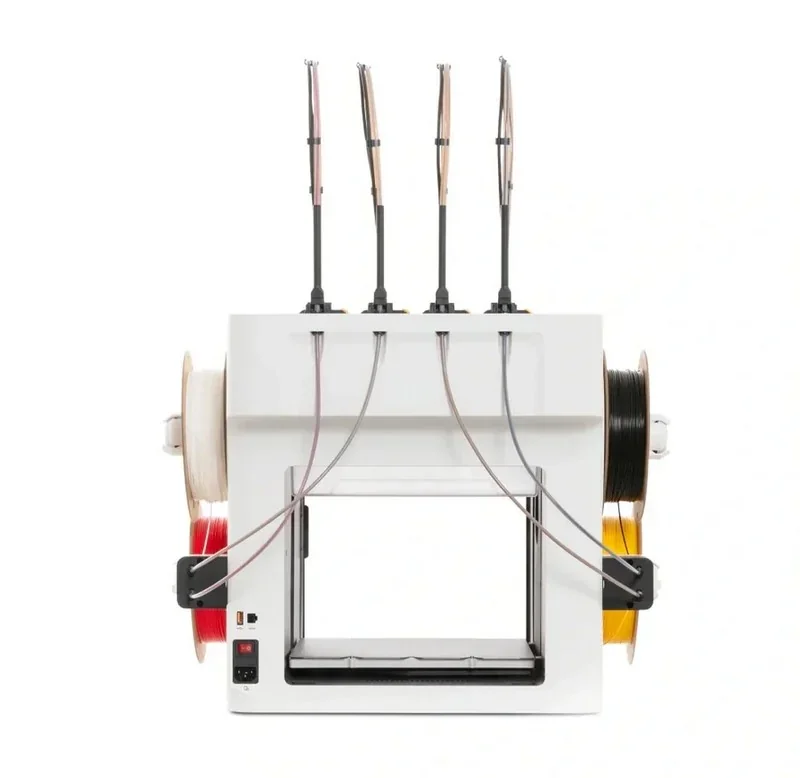

Snapmaker U1 is a CoreXY, four-toolhead toolchanger FDM 3D printer with a 270 × 270 × 270 mm build volume, engineered to deliver multi-material/4-color prints without purge waste by assigning each filament its own dedicated nozzle. It runs up to 500 mm/s (20,000 mm/s²) with 0.08–0.24 mm layer heights and achieves ±0.1 mm dimensional accuracy, backed by automatic bed leveling and a 300 °C hotend/100 °C heated bed for process stability. A built-in 2 MP (~1 Hz) camera supports remote monitoring, and the Klipper-based firmware (Moonraker/Fluidd) provides OTA updates for ongoing feature improvements.

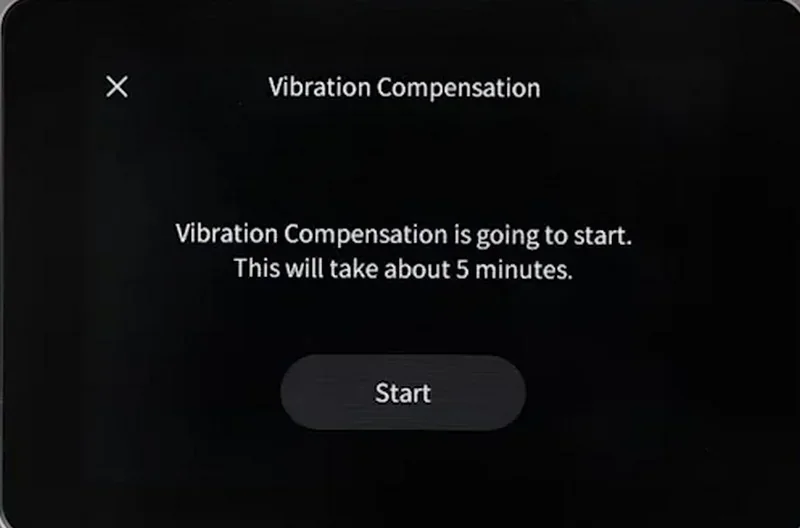

Print quality. The Snapmaker U1 supports 0.08–0.24 mm layer heights (0.20 mm recommended), enabling fine detail while keeping throughput high. It achieves dimensional accuracy up to ±0.1 mm on finished parts. Lab testing demonstrates the printer’s performance via 1,000,000-cycle tool-swap endurance, accelerometer-based vibration/input-shaper characterization, multi-material print trials (PLA, PETG, TPU, PVA, ABS, ASA) with filament-usage benchmarking, dimensional-accuracy and toolhead-offset verification (≤0.04 mm), mesh bed-leveling/first-layer checks, and high-speed runs up to 500 mm/s.

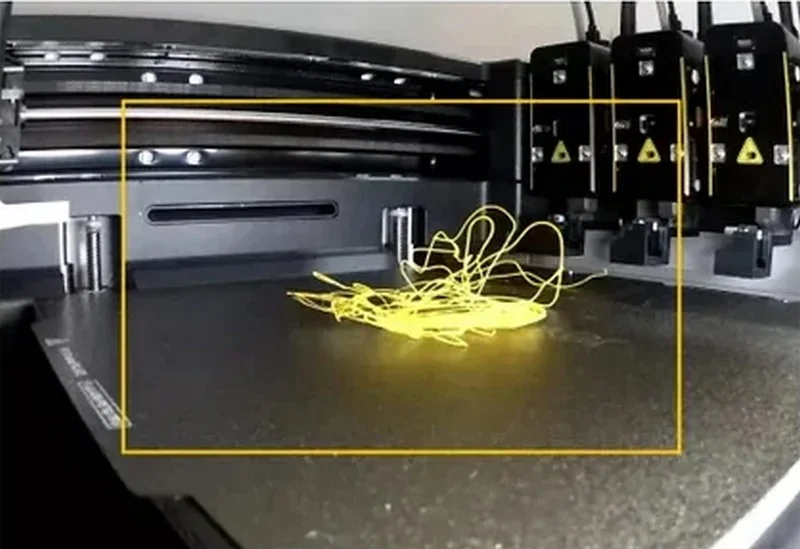

A prime-tower routine clears any heat-soaked residue during color changes to prevent oozing and poor layer bonding, helping maintain clean edges and consistent surfaces during multi-color 3D printing.

Performance. Maximum toolhead speed is 500 mm/s with up to 20,000 mm/s² acceleration. Compensation features keep results consistent at speed: the U1 auto-aligns XYZ offsets between toolheads within 0.04 mm for sharp color boundaries and seamless multi-head jobs, and uses Input Shaping and Pressure Advance to suppress ringing and flow-timing artifacts for smoother walls and crisper corners.

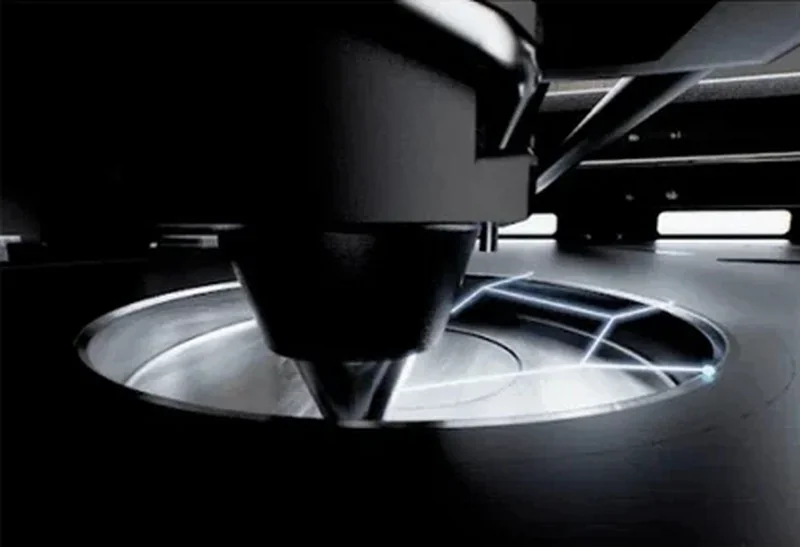

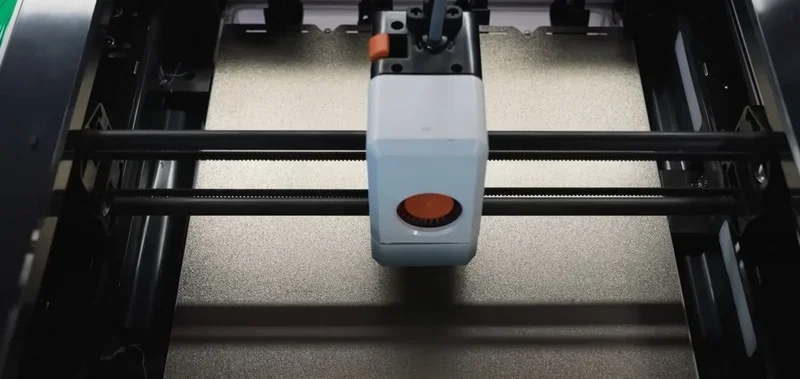

Mechanics that drive quality. A CoreXY motion system with a lightweight, rigid carbon-fiber X-axis rod reduces moving mass and vibration; all-metal Y/Z rails, linear bearings, and belt/lead-screw transmission provide stable motion. A fully automatic bed leveling routine (high-sensitivity probe) ensures a flat, reliable first layer.

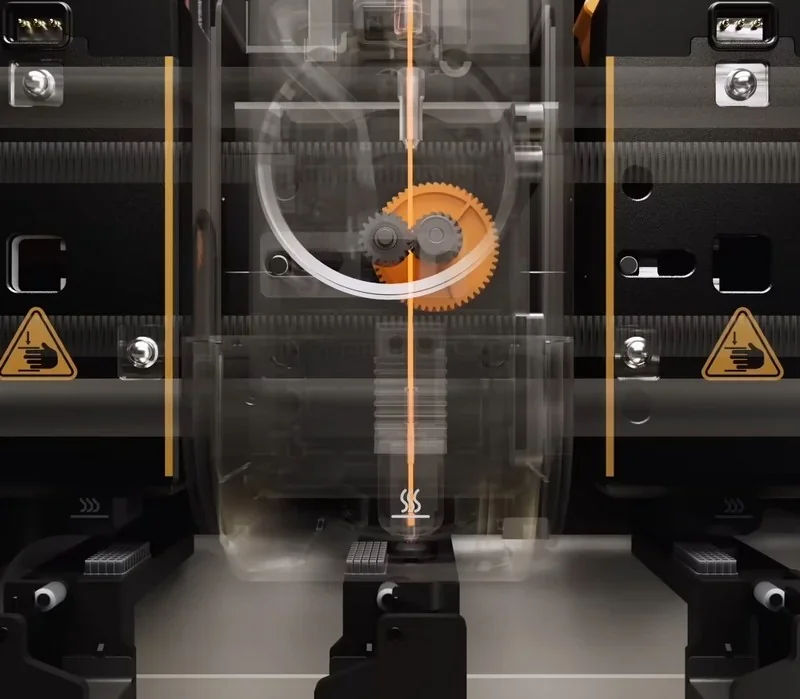

Extrusion stability is reinforced by a direct-drive system, 300 °C stainless-steel hotend with thermal isolation to prevent heat creep, and built-in nozzle cleaning/lift to reduce clogs. A 100 °C heated bed and 6.5 mm reinforced structure keep adhesion and mesh variation controlled for repeatable results.

Example: In the review by YGK3D, the four independent toolheads of the Snapmaker U1 delivered crisp multi-color PLA prints, clean PLA+TPU assemblies with minimal stringing, and carbon-fiber PETG parts with well-separated breakaway supports. Results showed accurate tool alignment, consistent surface quality, and low purge waste.

Example: In the review by 247printing, the toolchanger automatically aligned its toolheads within the 270 × 270mm work area, producing a sharp 4-color PLA Deadpool (with rear oozing, no purge tower), a clean T-Rex wall piece, and a smooth large-scale Gordon Freeman. PETG and TPU results were mixed: minor stringing on a Voronoi deer, belt-pitch artifacts on coarse PETG, moderate TPU stringing, and a failed multi-material CT foot due to a TPU clog.

Example: In the review by WombleyWonders, a pre-production Snapmaker U1 was tested by printing a blue PLA ocarina with PLA breakaway supports. The overhangs were clean, and the supports were easy to remove, leaving only minimal surface texture from the support “bowl.” A separate collar, printed in brown PLA with an embedded yellow PLA Triforce (~3 mm features), finished in roughly 10 minutes with sharp edges and a seam neatly hidden on the reverse.

Example: In the review by 3D Prints By Vic, the Snapmaker U1 produced the Cinderwing 3D Mushroom Turtle in PLA (CookieCad “Blue Ombre Elixir”) in just over 5 hours, with uniform layer lines and well-defined surface details. The print showed noticeably more stringing compared to the K2+ reference print, which had been completed earlier in a drier, temperature-controlled room over approximately 12 hours. This highlights that the U1 supports printing with extra motors, providing consistent multi-axis control.

Snapmaker U1 supports 4 material types out of the box—PLA, PETG, TPU (≥90A), and PVA — and with the Top Cover it adds ABS and ASA; combining the Top Cover with hardened steel hotends further extends compatibility to PC, PA, PA-CF, and PA-GF. Temperature-sensitive filaments such as ABS/ASA benefit from the Top Cover’s passive chamber up to 50 °C for improved stability, while TPU below 90A is still being evaluated. The printer is open to third-party 1.75 mm filaments (when using these, material type settings can be manually selected). Hardware that broadens material support includes 300 °C hotends, a 100 °C heated bed, and optional hardened steel hotends for abrasive fiber-reinforced filaments; a SnapDryer add-on is available to dry hygroscopic materials.

PLA Print Sample:

PLA Print Sample:

PLA Print Sample:

PLA Print Sample:

PLA Print Sample:

PLA Print Sample (with PVA Supports):

PLA Print Sample (with PETG Supports):

Example: In the review by Aurora Tech, the Snapmaker U1’s 4-head toolchanger produced clean, multi-color PLA prints with sharp separation, minimal purge waste, and accurate first layers, including a functional Master Sword and detailed Benchy and Vegeta models, enabling 3D printing with a 4-head. It also handled PETG with PLA supports and TPU tires well, showing clean breakaways, flexible parts, and dimensional accuracy within 0.05 mm.

ABS, Nylon and ASA Print Samples:

Multi-color PLA Print Samples:

Example: In the review by The Next Layer, a 36-hour print on the Snapmaker U1 with 0.15 mm layers and around 10,000 tool changes delivered uniform walls and clean color/material transitions, with no missed swaps or under-extrusion. Only the support filament (old and moist) showed some stringing and caused a minor layer shift, while the main model material printed cleanly.

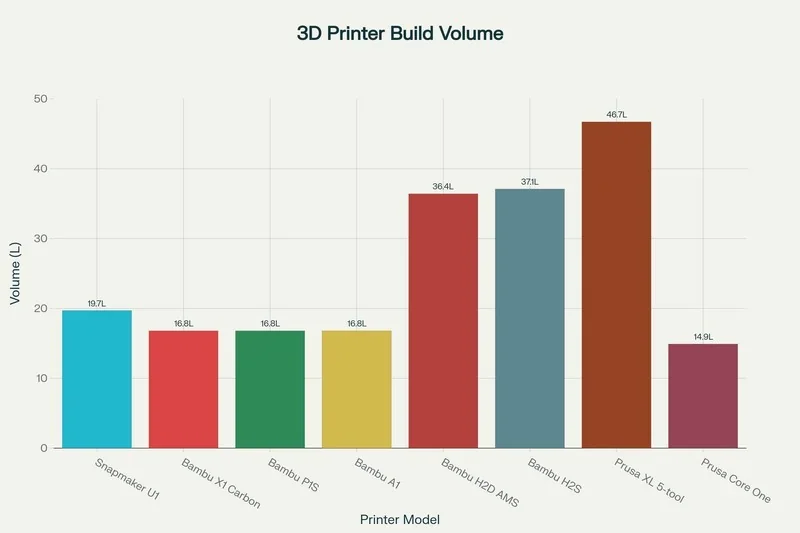

The printer offers a 270 × 270 × 270mm build volume, and because it uses a four-head toolchanger rather than a dual-nozzle carriage, there is no build-area reduction from a dual-extrusion mode.

| 3D Printer Model | Build volume (mm) | Chamber | Max nozzle (°C) | Max speed (mm/s) | Price (USD) |

|---|---|---|---|---|---|

| Snapmaker U1 | 270 × 270 × 270 | Enclosed | 300 | 500 | From $849 (pre-order). |

| Bambu Lab X1 Carbon Combo (X1C + AMS) | 256 × 256 × 256 | Enclosed | 300 | 500 | From $1,249. |

| Bambu Lab P1S Combo (P1S + AMS) | 256 × 256 × 256 | Enclosed | 300 | 500 | From $749. |

| Bambu Lab A1 Combo (A1 + AMS Lite) | 256 × 256 × 256 | Open frame | 300 | 500 | From $499. |

| Bambu Lab H2D AMS Combo (H2D + AMS 2 Pro) | 350 × 320 × 325 † | Active to 65 °C | 350 | 1000 | From $2,299. |

| Prusa CORE One (+ Multi-Material Unit 3) | 250 × 220 × 270 | Enclosed, active control; max chamber temp 55 °C | 290 | 300 | From $1348 Kit / $1,598 Assembled. |

| Original Prusa XL (5-toolhead) | 360 × 360 × 360 | Open (optional enclosure) | 290 | 400 | From $4,099. |

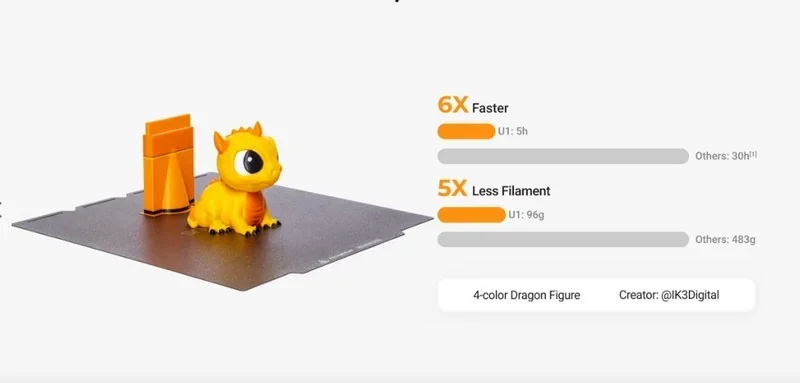

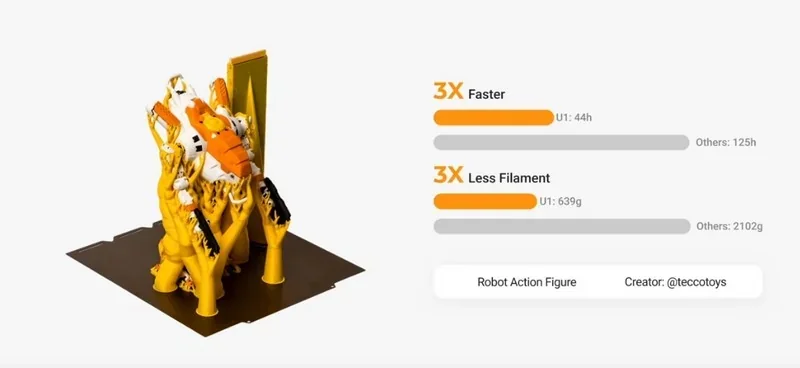

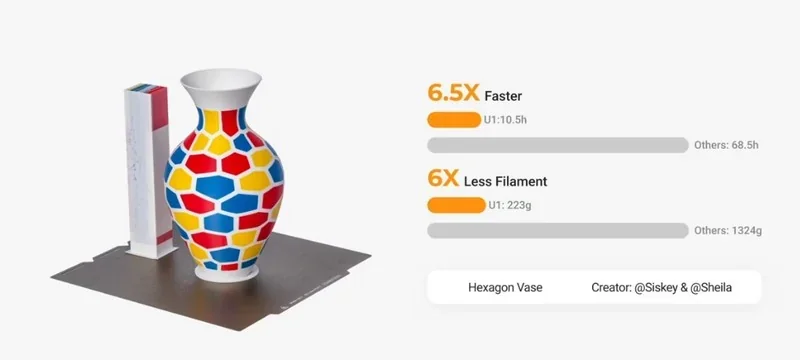

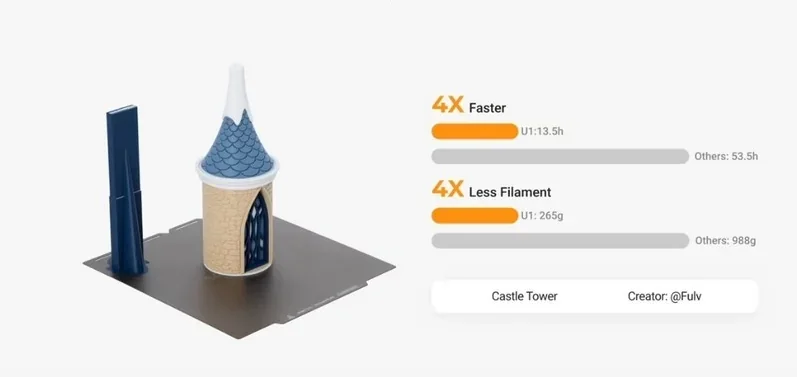

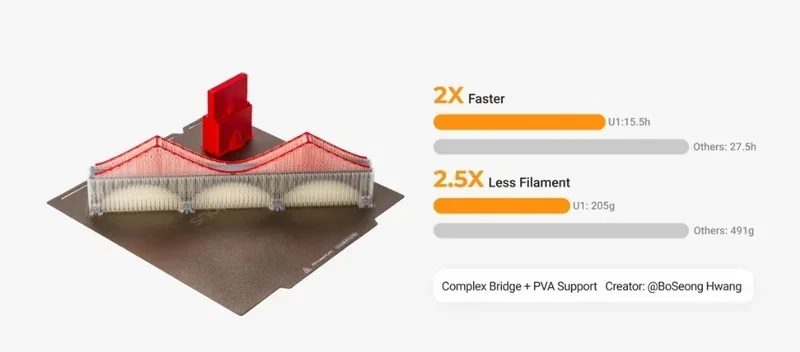

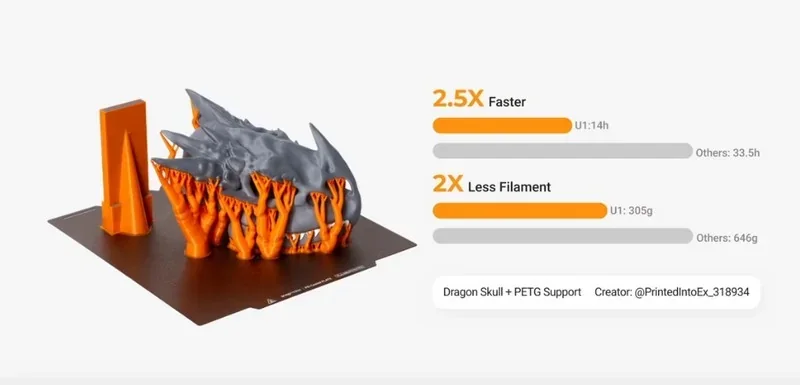

Snapmaker U1 — four-toolhead changer that keeps multicolor jobs fast and lean: color swaps take ~12 s vs ~90 s on AMS machines; a 3-color “spider” finished in 45:33 (≈+24 min over single-color) while a Bambu AMS printer added extra 2.5 hours; an X-Wing kit card took ~6.5 h on U1 vs 10:45 on Bambu H2S with ~60 g purge waste; against Prusa Core One the U1 printed a 473-swap miniature in 6:19 vs 13:14, and single-color in 1:04 vs 1:25.

In contrast:

– Bambu Lab H2D AMS Combo (H2D + AMS 2 Pro) — Wins: highest motion speed/dual-nozzle setup, active chamber and higher nozzle temp ceiling; Loses vs U1: still incurs purge/waste; higher cost; U1 remains more material-efficient on heavy color-swap jobs, for example, an X-Wing kit card took ~6.5 h on U1 vs 10:45 on the Bambu Lab H2 series with ~60 g purge waste.

– Bambu Lab P1S Combo (P1S + AMS) — Wins: lower upfront price and enclosure; Loses vs U1: AMS swap time overhead (~90 s vs 12 s) and purge waste make multi-color jobs much slower/heavier on filament (e.g., 2.5 h extra time added, when printing a 3-color spider; standard TPU can’t run through AMS.

– Bambu Lab X1 Carbon Combo (X1C + AMS) — Wins: polished, enclosed ecosystem with advanced convenience; Loses vs U1: same AMS time/waste penalties as above and the same AMS limitation, where it cannot directly feed TPU filaments.

– Bambu Lab A1 Combo (A1 + AMS Lite) — Wins: cheaper price; Loses vs U1: open frame and AMS multicolor overhead/waste remain, plus normal TPU through AMS is still a constraint.

– Prusa CORE One — Wins: reliability, community, and PrusaSlicer maturity (flawless runs in testing); Loses vs U1: much slower on heavy swap jobs (13:14 vs 6:19 with 473 swaps; 1:25 vs 1:04 single-color), more waste (~62 g purge tower vs U1’s small tower), smaller volume, and higher all-in price once MMU3 is included.

– Original Prusa XL (5-toolhead) — Wins: largest build volume (360 x 360 x 360 mm vs 270 × 270 × 270 mm) and five toolheads (versus four toolheads); Loses vs U1: far higher price ($4,099).

Bottom-Line: Among the multicolor 3D printers, the Snapamaker U1’s tool-changer architecture consistently outpaces AMS/MMU systems. Buy this unit as it offers this best price/performance ratio, if you're constantly working with multi-color/ multi-material prints, and you care about time-to-part and waste minimization. The Prusa XL outperforms the Snapmaker U1 in multi-material use but costs significantly more. Consider it only if you need five toolheads or a large build volume.

Built-in calibration/adjustment controls:

Multi-toolhead offset calibration wizard (run at first setup, after hotend changes, or if scraping/shift occurs; takes ~15–20 minutes). Once done, it’s not required before every print.

Direct operation & safeguards:

The Snapmaker U1 has a semi-enclosed metal frame with a clear rear panel, front door, and optional top cover. It measures 584 × 499 × 730 mm and weighs 18.2 kg.

The Snapmaker U1 uses CoreXY kinematics with a carbon-fiber X-axis rod and all-metal Y/Z structures. Motion is guided by linear bearings on precision rods, with timing belts for X/Y and lead screws for Z.

The Snapmaker U1 produces 55 dB of noise at 1 m during normal printing.

The Snapmaker U1 has a 270 × 270 × 270 mm build area on a heated bed up to 100 °C. The 6.5 mm thick bed (1.5 mm base + 5 mm ribs) has typical mesh variation ≤ 0.4 mm and includes a double-sided PEI steel sheet.

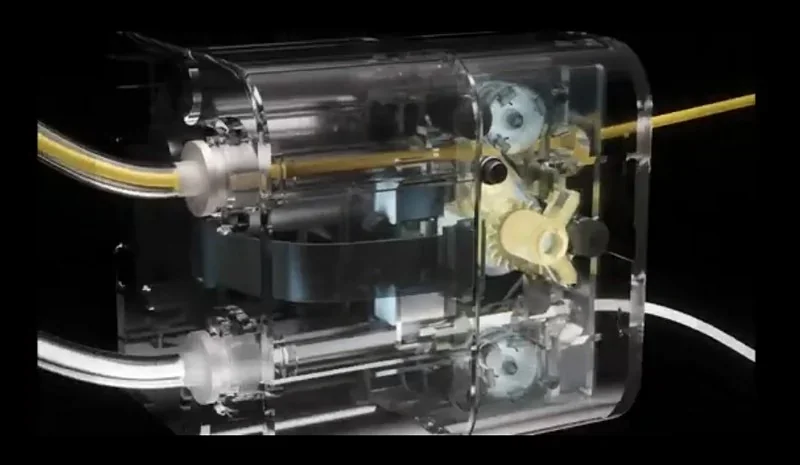

The Snapmaker U1 uses proprietary four independent extruders (four included, one spare) that reach 300 °C. The hotend integrates the heatsink, heat break, block, and nozzle as a single, non-replaceable unit. It features direct-drive extrusion with hardened-steel gears, plus automatic nozzle cleaning and lift routines.

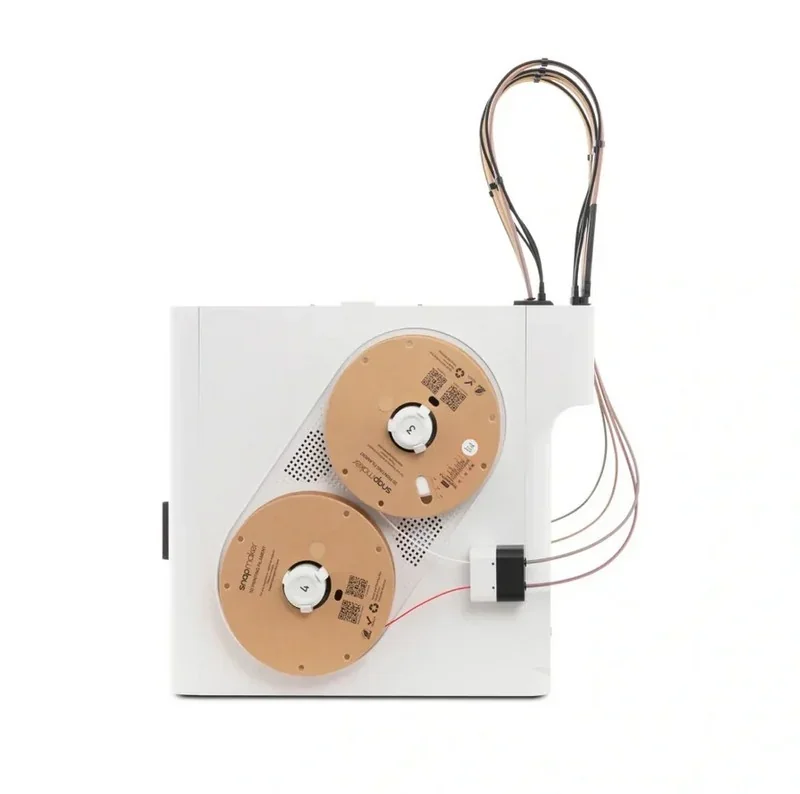

The Snapmaker U1 uses side-mounted spool holders for spools with 52–60 mm inner diameters, up to 70 mm wide and 1 kg in weight. Its automatic filament system includes detection, loading, and runout sensing. Snapmaker filaments with RFID are auto-identified; third-party spools are compatible but lack RFID support.

The Snapmaker U1 uses a proprietary controller running Klipper with Moonraker, supports OTA firmware updates, and has service-accessible internal electronics, including the Toolhead Hub PCB and mainboard.

The Snapmaker U1 supports 100–240 V input with a regional power cord. Max power is 400 W at 100–120 V and 1150 W at 220–240 V. Max current is 4 A or 6 A, respectively.

Printer: Snapmaker U1 (PEI steel sheet included) (1×)

Assembly state: Pre-assembled, but requires user assembly of the toolheads, following the printed manual (1×)

Safety & Documentation: Safety Guidelines (printed) (1×), Quick Start Guide (printed) (1×)

Tool/Accessory Box (1× set):

Consumables & lines: included as supplied (filament tubes/connectors, etc.) (1× set)

The printer supports over 33 upgrades and accessories.

| Name (official) | Functionality / what it solves | Price |

|---|---|---|

| Top Cover | Passive enclosure for better thermal stability and fume containment | $149.00 USD |

| SnapDryer by Polymaker | Filament drying to reduce moisture-related print defects | From $63.99 USD |

| Graphic Effect Steel Plate | Alternate textured build surface for different first-layer finishes | $19.99 USD |

| PEI Steel Sheet | Spare build sheet for rapid swaps or replacement | From $24.99 USD |

| Hot End | Replacement 0.4 mm integrated hotend assembly | From $15.99 USD |

| Tool head 1 Left Slot | Replacement docking bay (left position) | $64.99 USD |

| Toolhead 2/3/4 Right Slot | Replacement docking bay (right positions) | $64.99 USD |

| Auxiliary Cooling Fan | Additional/replaceable part-cooling fan | $19.99 USD |

| Camera Kit with FPC Cable | Built-in camera add/replace for remote monitoring | $19.99 USD |

| Hub Adapter Board | Replacement interface board for hub connections | $19.99 USD |

| Main Control Board | Replacement mainboard | $109.99 USD |

| 3.5-inch Touchscreen | Replacement on-printer display | $19.99 USD |

| Heated Bed | Replacement heater/bed assembly | $94.99 USD |

| Automatic Filament Feeder Module | Additional/replacement feeder with detection/loading | $19.99 USD |

| Filament Runout Sensor Kit | Replacement runout sensor components | $9.99 USD |

| XY-Axis Timing Belts 3.5 m | Replacement X/Y belts | $14.99 USD |

| Z-Axis Timing Belt | Replacement Z belt | $9.99 USD |

| Extruder Unit | Replacement direct-drive extruder | $34.99 USD |

| Extruder Motor | Replacement extruder motor | $19.99 USD |

| Toolhead PCB | Replacement toolhead control board | $24.99 USD |

| Toolhead USB Cable 2-Pack | Spare data cables for toolheads | $24.99 USD |

| Hot End Silicone Sock 4-Pack | Nozzle block insulation; reduces ooze/heat loss | $4.99 USD |

| Part Cooling Fan | Replacement part-cooling fan | $9.99 USD |

| Hot End Cooling Fan | Replacement hotend heatsink fan | $9.99 USD |

| Part Cooling Fan Adapter Board 2-Pack | Replacement fan interface boards | $14.99 USD |

| Part Cooling Duct Kit | Replacement airflow ducting | $4.99 USD |

| Nozzle Cleaning Brushes & Parking Pads Kit | Replacement cleaning station consumables | $4.99 USD |

| Right Nozzle Wiper | Replacement wiper (right) | $4.99 USD |

| Left Nozzle Wiper | Replacement wiper (left) | $4.99 USD |

| Filament Holder | Spare spool mount (side-mounted) | $4.99 USD |

| Toolhead Thick Filament Tube 6 mm 4-Pack | Replacement PTFE tubes (toolhead) | $14.99 USD |

| Toolhead Rear Cover | Replacement rear cover panel | $4.99 USD |

| Screw Set | Replacement fasteners | $4.99 USD |

The Top Cover for Snapmaker U1 is an enclosure add-on with HEPA and activated carbon filtration, passive chamber heating up to 50 °C, dust-proof protection, tool-free installation, and U1 compatibility, with final design details pending release.

The SnapDryer by Polymaker is a modular filament drying and storage system with a single 24 V/68 W dock servicing sealed SnapDryer Boxes for 1.75 mm and 2.85 mm filaments (up to Ø205 × 78 mm), offering multi-material support (PLA, PETG, ABS, ASA, TPU, PA, PC, PVA, PLA breakaway), three heat settings, continuous drying, and safe operation within 20–35 °C and <90% RH.

To ensure reliable printing and multi-material performance, the U1 requires several maintenance routines:

Standard Limited Warranty:

The standard limited warranty covers major U1 printer modules from the date of delivery for the original purchaser, with claims requiring a valid invoice. Limited-warranty parts (e.g., extruders, filament holders) are covered for 3 months, while consumables are not covered. Damage resulting from third-party parts, misuse, modification, accidents, or normal wear is excluded, and shipping/taxes for returns or inspection are not included.

Warranty Period

Start date: The clock starts on the date of delivery to the first end customer (per the purchase invoice).

Consumables (no warranty): Nozzles, ceramic heater, thermistors, fans, hot-end socks, extruder gears, PEI sheet, filament tubes/connectors, filaments, waste collector, nozzle parking pad/cleaning brush, included tools; Snapmaker may replace a failed consumable only for manufacturing defects while the printer is in warranty, at Snapmaker’s discretion.

Exclusions (not covered): Expired warranty; purchases from unauthorized/second-hand sources; wear and tear/consumables; misuse/improper maintenance; unauthorized repair/modification/disassembly; damage from extreme temperatures/water/chemicals/pests/foreign objects; issues from illegal software/third-party compatibility; return-shipping damage; force majeure; claims like uninterrupted or error-free operation.

Other: Replacement parts inherit the remaining warranty (no reset/extension).

Extended Coverage (Snapmaker Care 1-Year Plan)

Adds +12 months to the standard warranty and +3 months to limited-warranty parts. Exclusions apply for improper operation, external factors, unauthorized modification, or force majeure.

Full warranty terms: https://support.snapmaker.com/hc/en-us/articles/34227294357783-Snapmaker-U1-Warranty-Policy

The price of the Snapmaker U1 is $999.00. The Snapmaker U1 is a four-toolhead, purge-free toolchanger platform supporting multi-material printing in up to 4 colors. It offers 500 mm/s high-speed performance, automated calibration, on-device camera, and app-based control — all engineered to minimize waste and time compared to filament-switching systems.

Update your browser to view this website correctly. Update my browser now