The UFACTORY 850 is a high-performance industrial robotic arm that is primarily designed for high-precision tasks, easy deployment, and safe operation alongside human staff in dynamic environments. With all the necessary characteristics, it represents an easy-to-use machine with advanced compatibility, graphical programming interface, and ample development capabilities. Being a powerful robot for production spheres, it can handle various industrial challenges 24/7.

Apart from remarkable speed and repeatability, the machine provides intuitive and quick-to-learn control options, such as drag teaching, making it a perfect device both for beginners and experienced manufacturers looking for advanced automation opportunities. Due to reliable safety protocols, the UFACTORY 850 is perfect for harmonious work with people of multiple sectors and skills.

The UFACTORY 850 combines lightweight yet durable design, great working radius, and seamless integration with different accessories, which makes it an ideal device for precision work, machine tending, picking, visual automation, or research in modern industries where repetitive tasks take a lot of human time and effort.

Another appealing feature of the UFACTORY 850 is its plug-and-play architecture, thanks to which the device can be used right out of the box, with no technician needed.

The UFACTORY 850 possesses outstanding reliability coupled with high maneuverability and professional accuracy. It features 6 axes and is able to repeat the same movement within ±0.02 mm at a maximum speed of 1 m/s. In combination with 5 kg payload, this lets it perform even the most difficult precision tasks with ease.

According to the needs of modern industries, the machine is engineered with industrial-grade harmonic drive and servo motors with 17-bit encoder that guarantee consistent 24/7 operation. Crafted from carbon fiber and aluminum, the system weight is reduced by 50%, which ensures streamlined deployment.

The UFACTORY 850 robotic arm is fully operational from 0 °C to 50 °C.

With an impressive range, lightweight yet stable construction, and decent payload capacity, the UFACTORY 850 robotic arm is suitable for a wide variety of recurrent industrial operations. The recommended applications for the model include vision automation, machine tending, bin picking, robotic research, and more.

Apart from this, the UFACTORY 850 offers smooth integration with a number of official accessories, the list of which includes:

The reasonable implementation of UFACTORY robots allows you not only to automate manifold production processes, but also in many cases save time and costs while maintaining the workers’ safety and health.

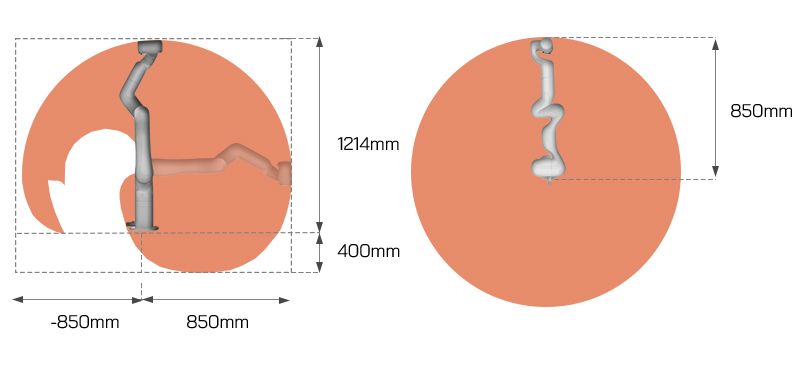

The UFACTORY 850 model possesses a maximum reach of up to 850 mm. This makes the robot perfect for a wide spectrum of precise repetitive tasks. Furthermore, due to its highly flexible structure, the machine can be effectively installed at any angle — horizontally, on a wall, mounted from above or on mobile platforms.

The advanced safety protocols and collision detection mechanisms ensure safe and comfortable work for human staff regardless of their position in relation to the robot.

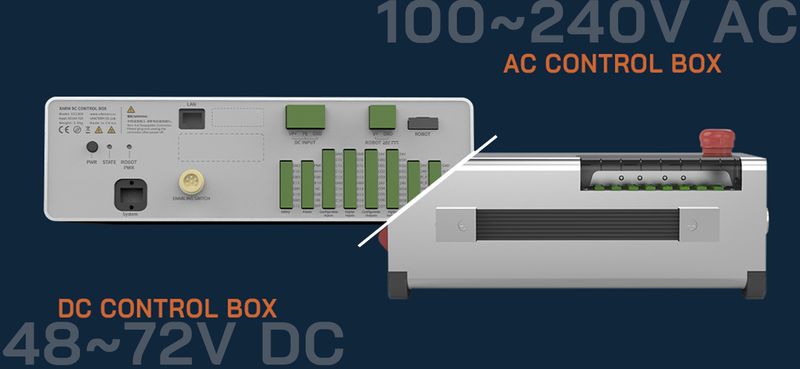

The UFACTORY 850 uses Modbus RTU (RS485) communication protocol. It can be manipulated via a dedicated control box included in the supply package. With AC and DC variations available, it is designed for both mobile platforms and stationary applications. The AC control box (100–240V) is equipped with an AC-DC adapter inside, and the DC option (48–72V) perfectly fits the battery system on mobile platforms.

Featuring Ethernet connectivity, the device has a standalone 100Mbps Ethernet cable that provides improved system stability. In addition, a standard CAT5 cable ensures compatibility with most 3rd party vision devices. When not needed, the Ethernet cable can be used as a physical signal cable.

The UFACTORY 850 can be easily programmed through the proprietary software or API to make necessary adjustments. It supports Python and C++ SDK as well as ROS and ROS2 packages. The included sample codes will facilitate the robot deployment for the operator of any level.

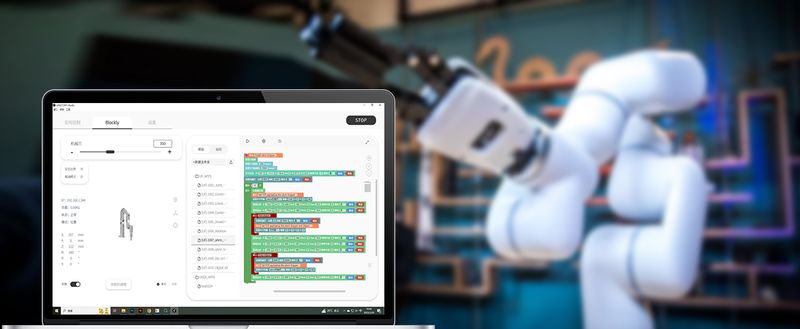

As for the software, the control box for the UFACTORY 850 comes with the web-based UFACTORY Studio software, which is compatible with computers powered by Windows 10, macOS, and Ubuntu. It has a control panel, recording mode, and other handy tools to simplify the set-up process.

Due to the intuitive block-based interface of the program, you can smoothly control the UFACTORY 850 through simple dragging and dropping commands that allow one to create complex tasks in short times.

The UFACTORY 850 robotic arm is available in white with metal trimmings. Its stylish look makes it ideal for industrial-grade applications and will decorate any factory, workshop, or lab.

The device offers a footprint of 190 mm in diameter, lightweight design, and reliable construction. It weighs approximately 37.5 lb (17 kg).

The price for the UFACTORY 850 robotic arm is $9,849.00, which is reasonable considering its flexibility, adaptability, and high performance.

Note: make sure to add the customs clearance add-on during checkout, so Top 3D Shop can successfully handle customs clearance of the uArm 850 on your behalf.

Update your browser to view this website correctly. Update my browser now