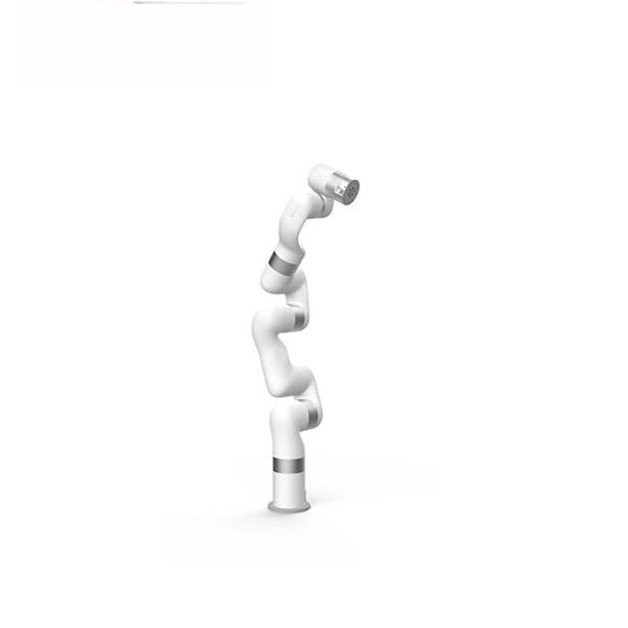

The UFACTORY xArm 5 is the most affordable industrial robotic arm in the UFACTORY xArm series. It is an entry-level robot that features five degrees of freedom and a payload of 3 kg. The device is created primarily for manufacturing industry and can perform a wide array of simple repetitive tasks, being a highly cost-effective solution. Due to its architecture that helps one to deploy the robotic arm smoothly, the xArm 5 desktop robot arm is ready to go almost right out of the box, no technician needed.

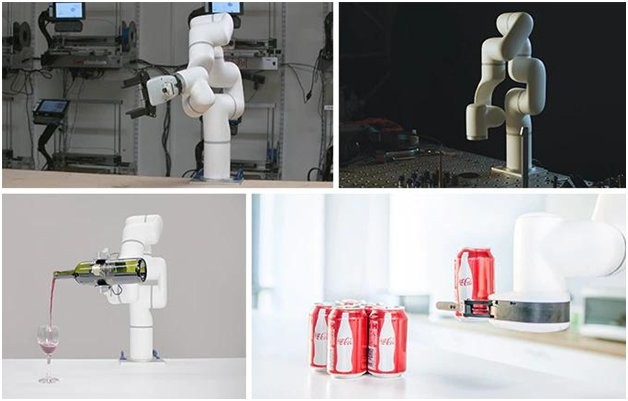

Unlike industrial robots, which are heavy and cumbersome to move, the xArm 5 is lightweight and convenient. It also has the lowest weight among the series models. The entire lineup is crafted from carbon fiber and aluminum, reducing at least 50% of weight. Intuitive and quick setup allows it to be applied to any process in a variety of conditions. While the xArm 6/xArm 7 robotic arms comes with connections that use a harmonic drive, the xArm 5 adopts a built-in harmonic reducer and a low backlash gearbox.The xArm industrial-grade devices are capable of performing multiple tasks, from holding a camera to accurately packing an object. Have a look at the examples below to get a better idea.

The UFACTORY xArm 5 robot arm provides high reliability and accuracy. It is capable of repeating a movement within 0.1 mm at 0.33 m/s.

The xArm 5 is engineered with a powerful X86 chip to easily handle the controlling algorithm, granting accurate movements. Also, it adopts a compact powertrain joint, a self-developed outer rotor brushless motor, and an integrated harmonic drive for higher repeatability and torque capability. All this makes the xArm joints durable and precise enough to work on long-term precise applications.

The xArm 5 features a programmable gripper for multiple applications. One can control its position, maximum speed, and force to effectively perform a variety of tasks. It also includes suction cups with a maximum vacuum degree of -90kpa. It can be used for pick-and-place operations, packing, sorting, and more. Using various add-ons, such as a force torque sensor and vacuum gripper, the device can be used for pick-and-place operations, packing, sorting, and more.

The multiple axes configuration makes the robot ideal for repetitive activities.

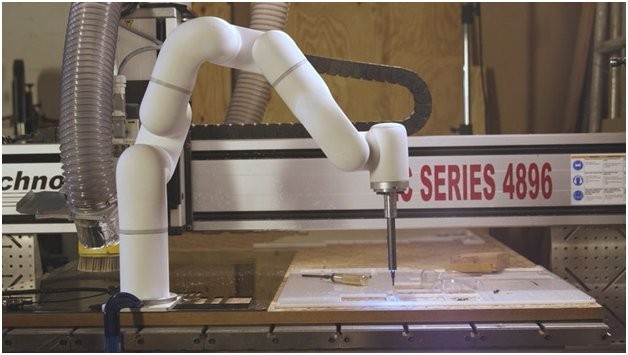

The extreme accuracy and precision of the robotic arm ensures error-free machine tending.

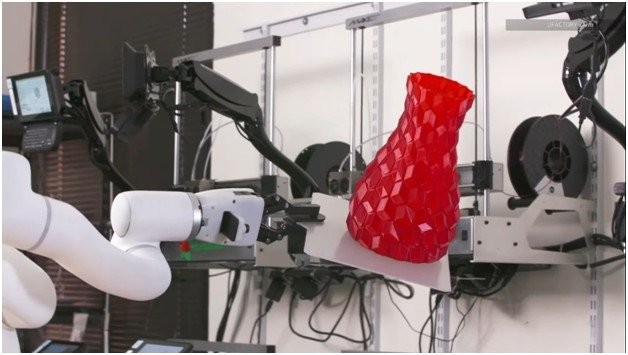

The xArm 5 robotic arm comes integrated with a computer vision system, which allows detecting when a print job is done. In this way, it can automatically unload the printed model from the print bed.

The device has a reach of up to 700 mm, being capable of performing a variety of tasks.

Despite their robust construction, the UFACTORY collaborative robots are extremely user-friendly. They offer intuitive and safe feature hand teaching as well as reduced system weight for flexible deployment, and collision detection for safety.

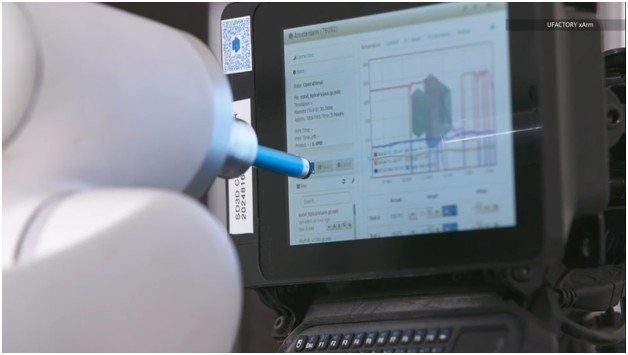

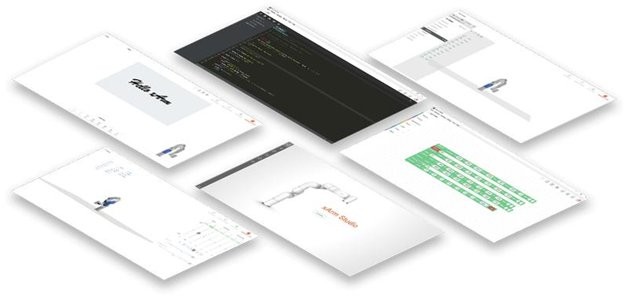

The built-in software works perfectly with xArm Studio, a web-based technology with graphical interface that features one-system solution decreasing engineering and manufacturing time significantly and providing access to raw data. With its block-based interface, it allows dragging and dropping commands to create complex paths in short times. For easy tasks, it also supports manual teaching. Just move the xArm 5 arm, and it will repeat your path. Additional features include example codes, live control, custom libraries, recording, I/O setting, offline mode, collision detection, and more.

xArm Studio is compatible with multiple operating systems on both computers and tablets and accessible via all major browsers. It is perfectly suitable for macOS, iOS, Windows, and Android. Apart from this, xArm SDK includes Python, ROS, and C++. Fully open-source software platforms make more flexible programming accessible for beginners and versatile for experienced users.

The company also provides a set of optional add-ons (purchased separately):

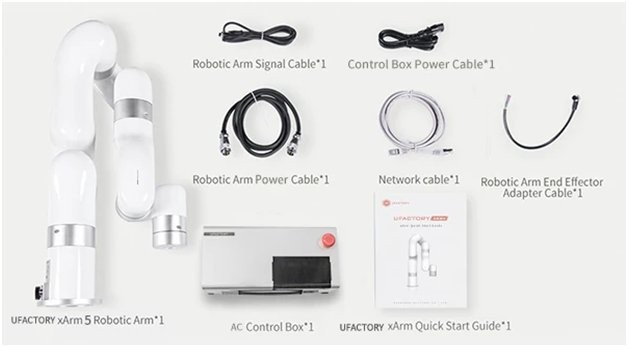

For some items, package content may change. In case of any questions, please get in touch.

The UFACTORY xArm 5 robot arm is available in white with light gray trims. Its stylish look makes it ideal for service automation, AI research, filming, and more.

The robot footprint is Ø 126 mm (Ø 5 inches); it weighs 11.2 kg (24.7 lb).

The price of the UFACTORY xArm 5 robot arm is $5,749.00, which is reasonable considering its functionality and expandability.

Note: make sure to add the customs clearance add-on during checkout, so Top 3D Shop can successfully handle customs clearance of the xArm on your behalf.

Update your browser to view this website correctly. Update my browser now