Ultimaker S3 is an FDM desktop 3D printer equipped with a dual-extrusion system. It ships already assembled and factory calibrated reducing time-consuming manual operation. Its sturdy and stable frame allows producing consistent yet quality 3D printed models with a wide range of engineering materials, including Nylon and water-soluble PVA. It is considered one of the best 3D printers of 2019 by All3DP.

The machine features automatic bed leveling, NFC material recognition system, and hot-swappable print cores. It can be operated using both one or two nozzles simultaneously. According to the extrusion mode selected, you will benefit from two different printing sizes. The dual-extrusion system lets you print with different filament types and colors at a time.

Adopted by many professionals, it is successfully used in various industries, from manufacturing to architectural design. Keep reading our complete review.

The Royal Netherlands Air Force chose the Ultimaker 3 to print custom quality control tools. Its dimensional accuracy and extreme precision delivered top-notch results.

The printer has also been used to create a 3D printed headlight surround for the Honda Shadow 750.

Credit @maffeymoto / Instagram

The Ultimaker S3 has a minimum layer resolution of 20 microns. It allows producing quality prints with smooth surfaces and a high level of detail. Its industrial-grade construction ensures high stability, accuracy and optimum repeatability.

The model below is a valid example of the quality results achievable. It is a faithful reproduction of the 850-year-old Notre-Dame de Paris Cathedral destroyed by a fire in April 2019. Composed of 4 parts, it took 120 hours of printing. As you can see, Ultimaker S3 is a great ally for heritage preservation.

Credit @3dortgen / Instagram

Ultimaker S3 supports 4 different nozzle diameters (0.8, 0.4, 0.6 and 0.25 mm). Depending on your project requirements, it allows choosing the best solution in terms of detail and print speed.

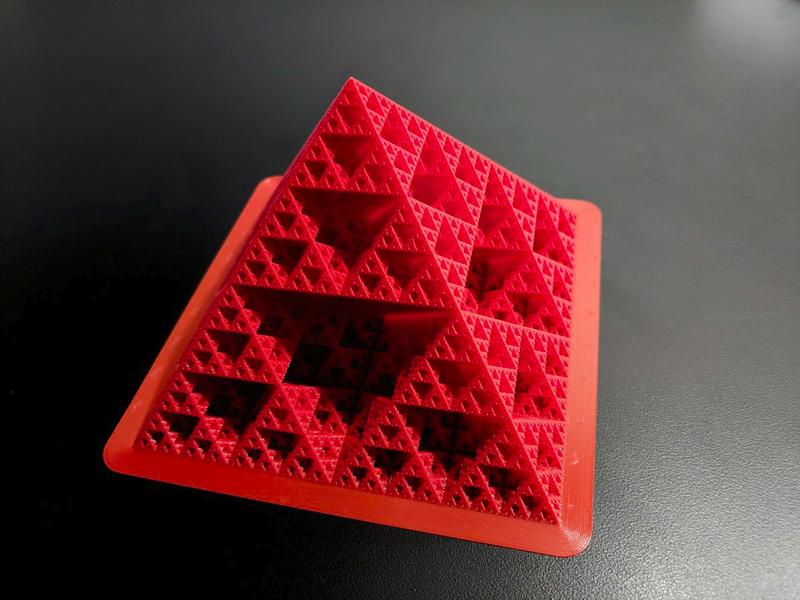

For example, look at this Sierpinski pyramid. It is made with 46,500 tiny pyramids and took about 20 hours to build.

The print head runs on rods with linear bearings, making the design more simple, lightweight and effective, all characteristics that are desirable in a 3D printer.

Ultimaker S3 prints with Nylon, PLA, ABS, CPE, CPE+, PVA, PC, TPU 95A, PP, and other materials.

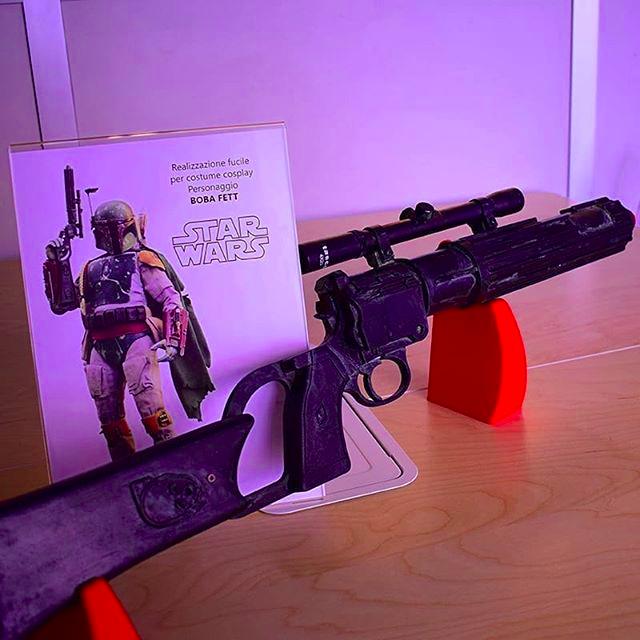

A Star Wars addicted realized a PLA-made Boba Fett’s gun for his cosplay costume. Thanks to the printer cooling fan, the model doesn’t show any warp.

Credit @prfilaments_official / Instagram

Unlike many FDM printers, the Ultimaker S3 has a heated print bed and closed print chamber, which means it can reliably print with ABS-type materials.

The Ultimaker S3 features an open material system. This means it can print with standard 2.85 mm filaments from any vendor, providing you with a wide choice of materials.

The maximum building area is 230 x 190 x 200 mm.

Both sizes let you print a large number of small-to-medium-sized objects, just like this dino head.

Credit @i_dream_in_gcode / Instagram

The printer is controlled via PC or the built-in LCD interface.

3D models can be printed from computer via Ethernet, USB cable or WIFI.

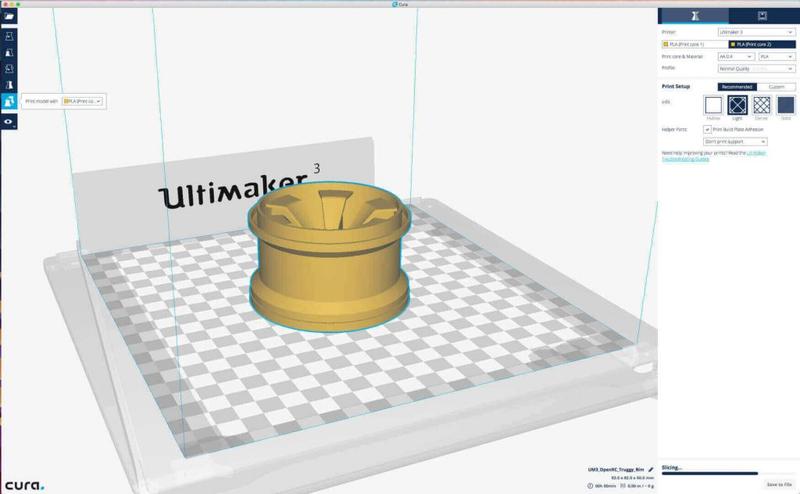

The printer is compatible with Cura software and works with 3D models in STL, OBJ, DAE and AMF formats. The software is available for Mac OS X, Windows, and Linux.

For some items, package content may change. In case of any questions, please get in touch.

Ultimaker S3 is available in white color.

The printer dimensions are 394 x 489 x 637 mm. It weighs 31.7 lb (14.4 kg). The spool holder is mounted on the back of the printer.

The price of the Ultimaker S3 is $4,450.00 which is reasonable considering its functionality.

Update your browser to view this website correctly. Update my browser now