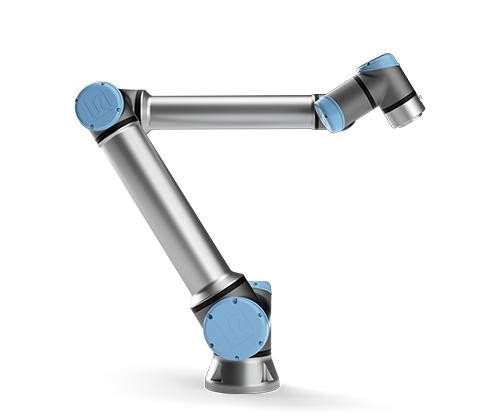

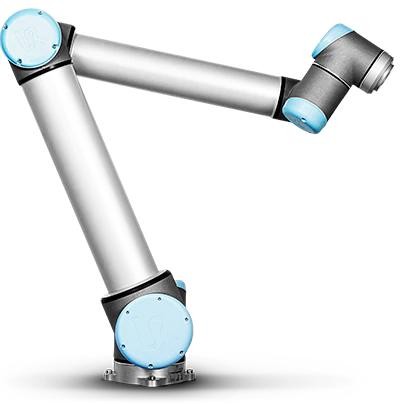

UR10 is a collaborative robot (cobot) of the Universal Robots’ e-series. The name clearly reflects its 10kg payload capability. It is composed of 6 different joints made of aluminum and steel with additional plastic covers. With 6 degrees of freedom and a long reach, this strong robot is more flexible and versatile than a human arm. No wonder that it can perform complex tasks with ease and precision. Simple to set up, it will be ready to work in just a few hours after unboxing.

It comes with a teach pendant for easy programming. Intuitive and user-friendly, it even supports manual teaching. This means you can record a path by manually moving the arm. The whole e-series is characterized by agility, versatility, and safety. Indeed, the UR10 can quickly learn how to perform new tasks for fast redeployment. Also, it can reuse programs in case of recurring activities. Equipped with a custom-made safety system, it stops dead when encountering someone in its path.

UR10 is used in a variety of applications allowing for production line automation. Read on to find out more.

For example, NASA has been using the UR10 for automatic inspection of fuselages.

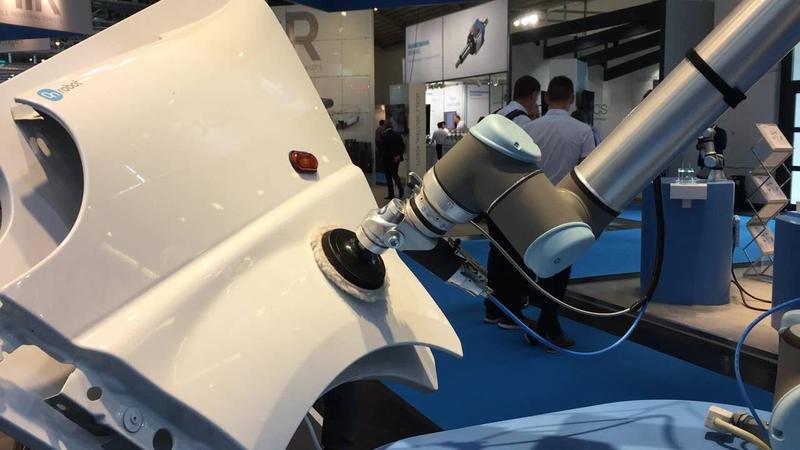

UR10 is capable of polishing flat and curved surfaces granting uniform finishing. It is ideal to speed up car parts production.

The UR10 collaborative robot can move within a maximum range of 1.300 mm lifting up to 10 kg. It provides movement repeatability of up to 0.1 mm. Considering its professional applications, precision and reliability are essential factors.

UR10 enables the automation of multiple processes, being capable of switching from one task to another in a snap.

The UR10 allows the automation of a variety of tasks. Ideal for heavy-weight collaborative activities, it has been adopted in different industries to streamline and speed up the production while reducing workplace injuries. Packaging, inspection, machine tending, and soldering are just some of the activities it can perform. Indeed, its extreme flexibility and quick learning make it a good fit for a lot of industrial, repetitive and dangerous processes.

A lot of companies and small businesses have been using the UR10 collaborative robot for:

Picking and placing products the whole day is a dull yet repetitive task. UR10 can do it for you. The integrated computer vision makes it capable of seeing, recognizing and sorting items, placing them where required. It can do it all day, even when your workers end their shift. No supervision is required.

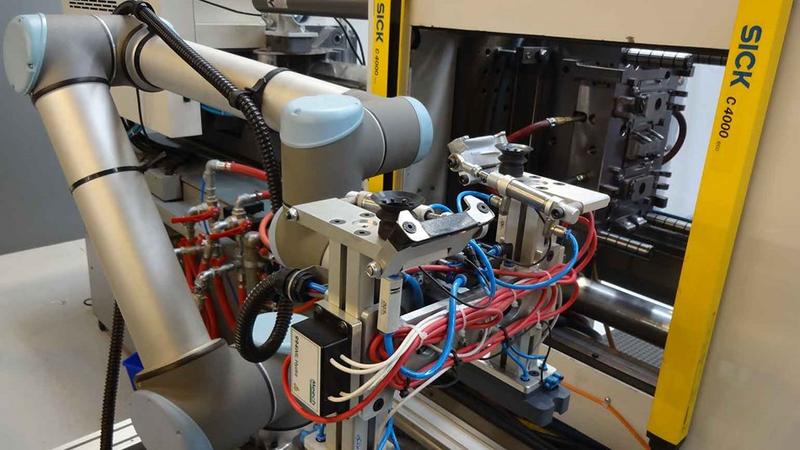

Handling injection molds is a dangerous activity. The UR10 can perform this task in total security granting high accuracy.

UR10 can take the place of human operators for machine tending operations, reducing the risk of injuries while speeding up the process.

A robotic arm is a good solution to automate heavy-weight tasks, including packaging and palletizing. In this way, you can optimize your production line maximizing your productivity.

The precision and repeatability of a movement allow testing and analyzing multiple items in a row. Computer vision allows detecting flaws and faulty parts, in order to reduce the risk of errors. It also enables 3D measurements.

Exploit the infinite rotation capability of the end arm to assembly and screw different items together, skyrocketing your production volume.

You can easily set the force of the arm in order to perform delicate processes such as surface polishing, gluing, and more. It also ensures uniform product quality over time.

The UR10 arm boasts a long reach of up to 1.300 mm. It allows performing tasks across wide spaces while ensuring optimal performances. Its wide radius lets you save time on production lines where distance matters.

The UR10 is controlled via a handheld, teach pendant. With an intuitive interface based on 3D visualization, you can simply program the arm through the large, on-screen arrows. For easier programming, just move the arm by hand to teach it the movements. It will then immediately repeat your path.

For some items, package content may change. In case of any questions, please get in touch.

UR10 is available in a gray and light blue color palette. Its stylish look makes it ideal for industrial use.

The robot dimensions are Ø 7.5 inches (Ø 190 mm). It weighs 73.9 lb (33.5 kg).

To learn the current price of the cobot, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now