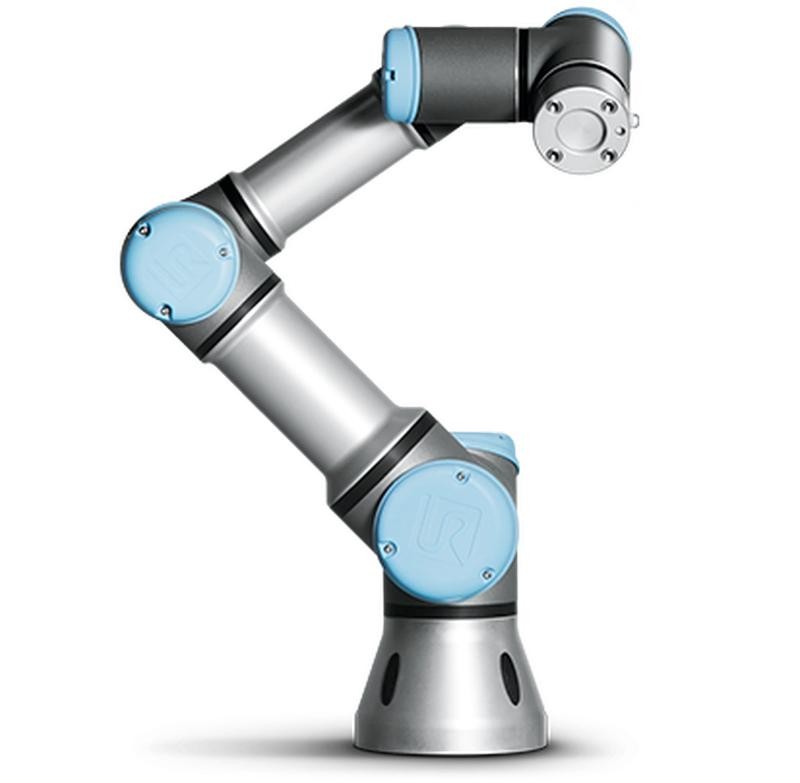

UR3, also known as UR3e, is a collaborative benchtop robot arm produced by Universal Robots. Part of the UR e-series, the UR3 is characterized by a compact design and 360° rotation on all arms, which makes it ideal for complex tasks in tight spaces. It gets where the UR5, UR10, and UR16 cannot. It is simple and fast to set up. You will be able to deploy it in half a day.

The UR3 is easy to program, even for unskilled employees. It features an intuitive interface and manual teaching to speed up the robot’s learning process. It is agile. It can be quickly redeployed to different applications in the same workflow allowing for fast change-overs. Also, it is capable of reusing a program in case of recurring tasks.

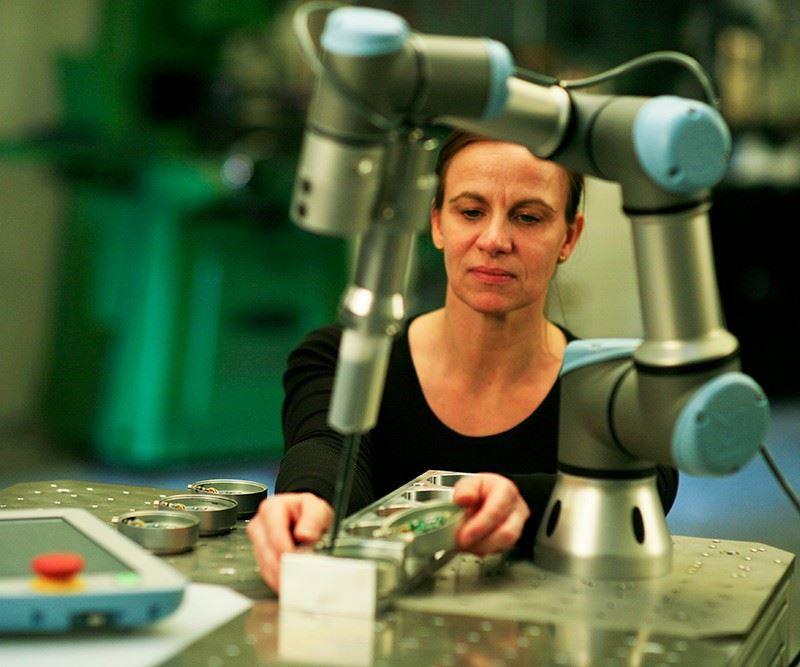

The UR3 is safe. It can work side-by-side with human operators doing dangerous, repetitive and dull activities. It features a safety system approved and certified by TÜV. It can stop when encountering a force of down to 50 Newton in its path (150 Newton default force sensing).

Sturdy and lightweight, it can lift up to 3 kg. It has been widely used by small businesses for light assembly automated activities and screw driving. Read the review for further specs.

Look at the picture. The UR3 is even capable of producing parts for itself.

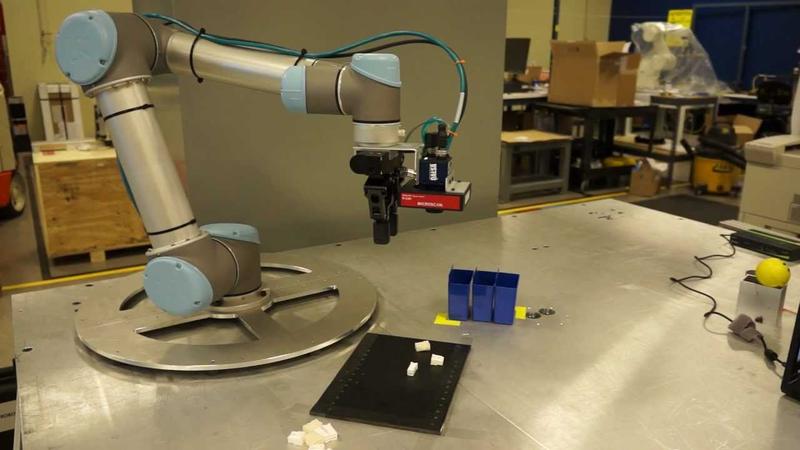

This machine vision-enabled cobot can recognize, pick and sort a variety of objects automating repetitive, pick-and-place activities.

UR3 is a flexible, 6-axis collaborative robotic arm. It features 0.1 mm repeatability. Weighing only 11kg, it withstands up to 3 kg. It features 360° rotation on all arm and infinite rotation on the end joint. Safe and reliable, it can perform even the most intricate tasks thanks to its flexibility and 6-degree freedom.

The UR3 is a universal robot. This means it can perform multiple tasks. Quick to program and extremely flexible, it provides fast change-overs, switching from one task to another in short times. It is capable of assembling and screwing parts, picking, placing, polishing and gluing. It delivers uniform product quality and finishing.

The robot can be used for:

UR3 lets you automate repetitive tasks boosting your production. Ideal for short-run production, it lets you employ workers in more important tasks. Computer vision allows quick and accurate recognition of parts for effective pick and place operations.

The arm can be used in plastic and polymer production. It can accurately handle any injection mold, a dangerous operation for human operators. Also, it can work autonomously, doing its job even when workers have gone home.

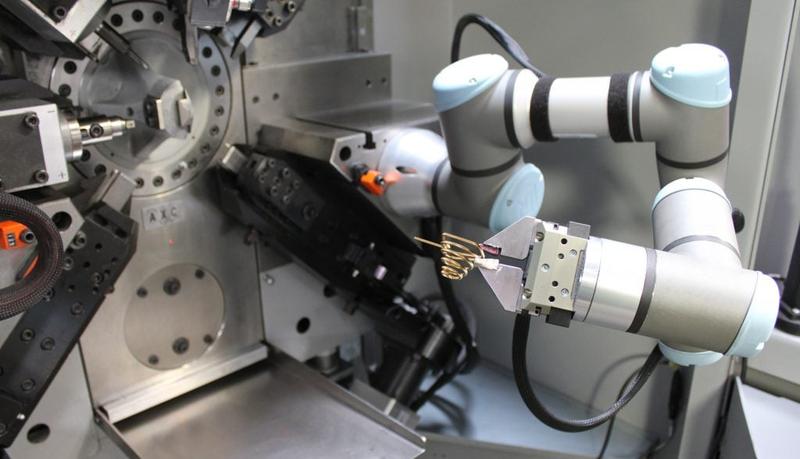

UR3 can take the place of human operators for machine tending operations, reducing the risk of injuries while speeding up the process.

Adopting a robotic arm for packaging and palletizing might be the right way to simplify and speed up the workflow improving your productivity. UR3 is capable of loading and packing products with extreme efficiency and accuracy. No more manual, heavy lifting.

The robot precision and movement repeatability grant consistency and uniform quality. Indeed, they allow repeating the same job for hours with the same accuracy. Also, the integrated vision camera enables non-destructive testing and 3D measurements, immediately detecting faulty parts and other issues. These are fundamental features for quality inspection, lab analysis, and testing.

The robotic arm can assembly parts of various materials, namely metals, woods, plastics, and etc. The infinite turn of the end joint and the force control are ideal for screw driving.

Force control, flexibility, repeatability and accuracy enable consistent operation while delivering uniform product quality. They allow performing various tasks, including polishing buffing, sanding, gluing, dispensing and welding.

The arm has a working radius of up to 500 mm.

The UR3 is controlled via a handheld, touch screen tablet. 3D visualization enables easy programming. This means you can quickly reprogram and redeploy the cobot across multiple operations.

For some items, package content may change. In case of any questions, please get in touch.

UR3 is available in gray with light blue covers. Its stylish look makes it ideal for industrial use. It is widely used to assembly medical devices, circuit boards, and other electronics.

The robot footprint is Ø 5 inches (Ø 128 mm). It weighs 24.7 lb (11.2 kg).

To learn the current price of the cobot, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now