The WAZER waterjet is a unique cutting machine offering industrial-grade performance and powerful capabilities in a benchtop design at an extremely competitive price. The device is available in a desktop and stand-alone versions, the latter being supplied with a special rack. The waterjet comes with a pump box unit which is also rather compact in size.

Unlike large industrial machines, the WAZER is easy to set up and operate. The pump unit is connected to a household water supply and creates a high-pressure stream of water which is mixed with sand-like abrasive particles and does the cutting work. The WAZER uses 80 mesh garnet as abrasive. Below the cut bed there is a tank, and the collection system separates water from the used abrasive that can be disposed of in a usual manner.

The transparent plastic lid covers the working space of the machine to ensure safe operation. When the lid is open the WAZER automatically shuts down, and besides, there is an emergency stop button on the control panel.

One of the numerous advantages of the WAZER waterjet is its ability to cut nearly any material, be it titanium, silicone, or such difficult-to-cut fragile materials as glass or ceramics. Such versatility and ease of use allow for endless applications of the WAZER and make it an invaluable tool for a great number of industries.

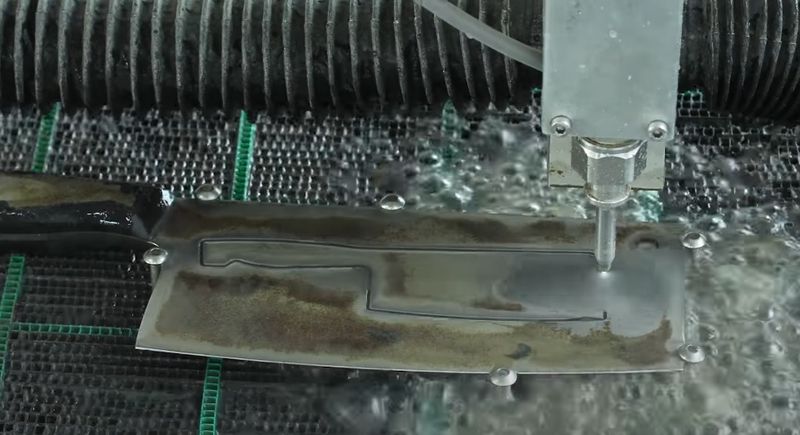

In the photo below, you can see the WAZER cut a knife out of a knife.

The WAZER is capable of cutting virtually any material, being a highly versatile tool for any production process that requires precise and quick cutting. The list of compatible materials includes metals, such as aluminum, titanium, or steel, glass, plastic, composites, like carbon or glass fiber, tile and stone materials, rubber, and foam.

Aluminum bicycle sprocket: 0.188", 1 h 36 min

Silicone pipe gasket: 0.125", 23 sec

Polyurethane foam packaging: 0.5", 3 min

Maximum thickness of the material to be cut and the cutting speed depend on the material type. In the table below you will find some examples of the most common materials the WAZER can handle.

|

Material |

Max thickness (in) |

Cut rate (in / min) |

Pierce time |

|

Aluminum |

0.5 |

0.5 |

4 m 44 sec |

|

Brass |

0.25 |

0.5 |

1 m 59 sec |

|

Copper |

0.188 |

0.5 |

1 m 49 sec |

|

Mild steel |

0.25 |

0.4 |

2 m 44 sec |

|

Stainless steel |

0.188 |

0.5 |

2 m 02 sec |

|

Titanium |

0.188 |

0.5 |

1 m 37 sec |

|

Tool steel |

0.156 |

0.5 |

1 m 34 sec |

|

Borosilicate glass |

0.5 |

0.7 |

50 sec |

|

Soda lime glass |

0.75 |

0.5 |

1 m 35 sec |

|

Acrylic |

0.5 |

0.7 |

1 m 21 sec |

|

HDPE |

0.625 |

0.6 |

2 m 23 sec |

|

Polycarbonate |

0.5 |

0.5 |

2 m 56 sec |

|

Carbon fiber |

0.25 |

0.6 |

1 m 55 sec |

|

Ceramic tile |

0.31 |

8.5 |

6 sec |

|

Porcelain tile |

0.31 |

1.7 |

16 sec |

|

50A neoprene |

0.625 |

0.6 |

2 m 11 sec |

|

50A silicone |

0.75 |

0.7 |

5 m 33 sec |

|

60A polyurethane |

0.438 |

0.5 |

1 m 02 sec |

|

Polyurethane foam |

1.0 |

36.8 |

1 sec |

The WAZER honeycomb-structured cut bed is made of polypropylene and has dimensions of 13 x 19 in (330 x 485 mm) with an effective working area of 12 x 18 in (305 x 460 mm). The cut bed is considered a consumable and might need to be replaced every 20–60 hours of operation.

On the right top side of the machine you will find the control buttons as well as the LCD screen, start / stop button, SD card slot, and the emergency stop button.

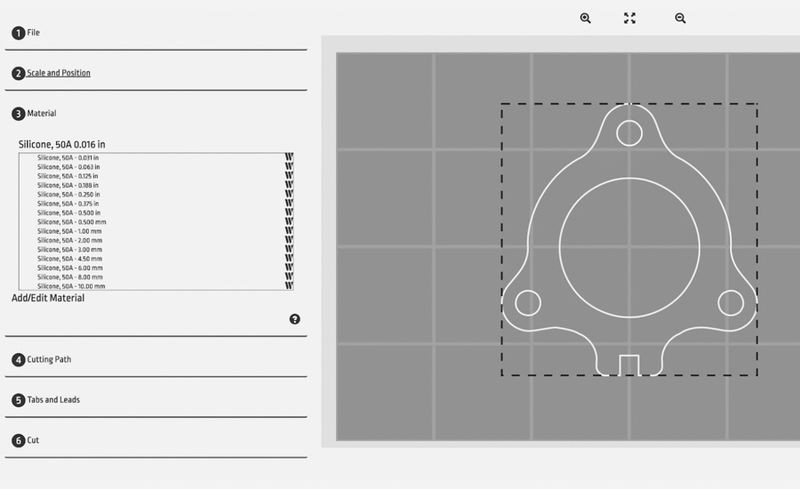

The proprietary cloud-based WAM software is free and does not require installation, so you can run it on any computer. It converts a DXF or SVG file with your design to WAZER-compatible g-code format cutting instructions. The software allows you to scale and position your model, select the appropriate material type and thickness from a vast library, and set the cut quality, choosing between coarse, medium, or fine options. In case the desired material is not on the list, you can easily add it on your own. It can also show the estimated time and abrasive quantity needed for the project. Once your g-code file is ready, it can be saved and transferred to the WAZER waterjet on an SD card, with no need for additional cables or the internet connection.

With its compatibility and smart features, the WAZER waterjet is a highly versatile machine that can find its use in a lot of fields.

In engineering WAZER allows creating functional prototypes using the same material as the final part is going to be made of. The opportunity to create multiple design variations, tooling, or complex assemblies in-house, instead of outsourcing, reduces the manufacturing cycle and cuts the production costs.

The WAZER is a flexible manufacturing tool, allowing for the fabrication of jigs, fixtures, and components on-demand. It also provides great customization opportunities which is extremely important for customer-oriented businesses.

Art and craft studios will greatly benefit with the use of WAZER as it allows saving time and creating unique designs that could hardly be cut manually, even when fragile materials are used.

The WAZER is also a great educational tool as it helps students to explore the modern CNC waterjet technology while giving a boost to their creativity and imagination.

Credit: @AxLab_UChicago / Twitter

For some items, package content may change. In case of any questions, please get in touch.

The WAZER desktop waterjet is available in dark gray with a metal frame and a transparent lid. Its stylish design and compact footprint make it ideal for any workshop.

The machine dimensions are 34 x 25.5 x 22 in (856 x 648 x 551 mm). It weighs approximately 110 lb (50 kg) when empty and 400 lb (180 kg) loaded.

To learn the current price of the WAZER waterjet, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now