The Youibot L300 is an autonomous mobile robot designed to simplify and optimize internal transportation and logistics in workshops, factories and other indoor industrial facilities. Being the lightest and most compact model from the company’s AMR lifting series, the L300 nevertheless boasts rugged structural design, which makes it perfect for warehouses or manufacturing sites with narrow passageways.

With the integrated rotating lifting module and maximum payload of up to 300 kg, the L300 is highly flexible and capable of fulfilling a wide scope of routine, complex, and tedious tasks in various environments, including transfer, delivery, palletizing, and order processing at assembly stations, clean rooms, loading docks, stock rooms, etc.

The AMR comes with enhanced security protection to meet the requirements of modern industrial settings. Due to smart navigation algorithms and high positioning accuracy, the L300 ensures long-term consistent operation alongside other robots and human personnel. To achieve even more spectacular results, you can form a fleet consisting of several machines with different tasks, which are able to cooperate in an increasingly safe and harmonious way.

The reasonable implementation of the Youibot L300 AMR allows warehouses, distribution centers, and production facilities that apply manual procedures to improve the intralogistics management process, optimize material flow, reduce downtime and workforce scarcity as well as remove health and safety risks for their employees.

The L300 mobile robot is available with the auto charger station that is sold separately. Also, you can purchase YOUIFleet multi-machine scheduling collaboration system described below. For more information check out the “Add-ons and extras” section.

Due to on-board lasers and safety scanners, including 360° coverage with LiDAR technology, the Youibot L300 provides effective autonomous routing through precise environment mapping. At the same time, it does not require any facility modifications, such as floor magnets or navigational beacons, which makes for cost-effective digitalization.

To ensure the multi-level security protection as well as reliable 24/7 operation, the robot is engineered with a frontal 3D camera for low obstacle detection, emergency stop buttons on both sides, and safety bumpers all around the machine.

Another notable feature of the L300 AMR is its Battery Management System (BMS) that supports automatic charging and quick battery replacement. When deployed in a fleet, the BMS can schedule a charging timeline for each robot to ensure zero downtime in the production cycle. Furthermore, the Youibot L300 provides fast battery charging: it takes only 2 hours to fully recharge the device. Considering 8 hours of run-time with a full payload, the machine allows for almost non-stop workflow.

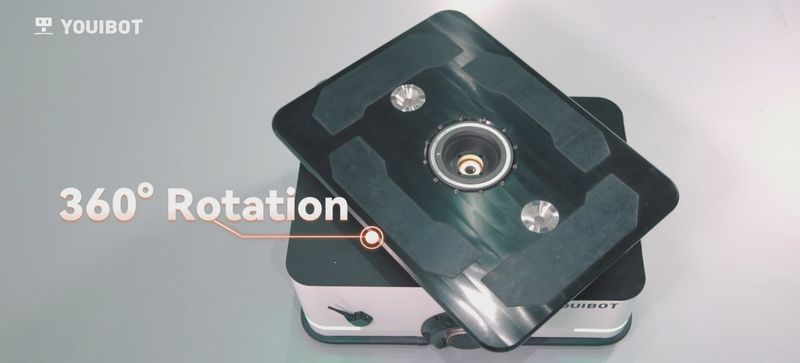

The L300 model is equipped with a rotating lifting module with a maximum height of 60 mm, which allows it to easily handle heavy loads and pallets of different types.

Thanks to the hybrid positioning and navigation technology, the L300 mobile robot is capable of repetitive indoor positioning accuracy of up to ±5 mm with ±1° angle accuracy. This allows it to effectively align for smooth docking with various equipment.

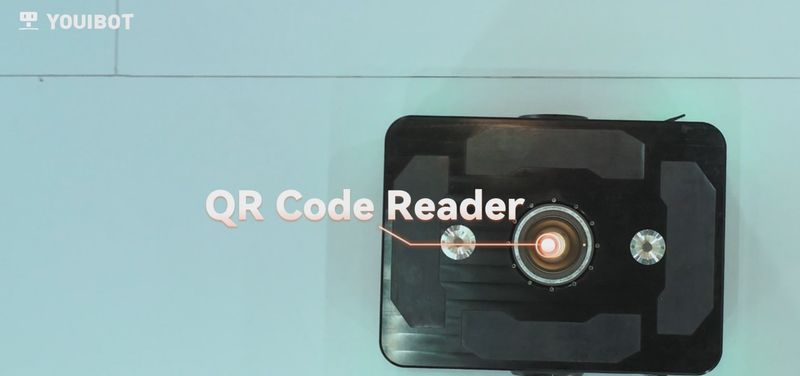

To further increase efficiency of the L300 AMR, it is possible to install a QR code reader on the top panel for enhanced picking and delivering capacity.

Thus, the L300 AMR not only offers quality service, but also ensures safe working conditions both for human staff and other machines.

With its impressive characteristics and flexibility, the Youibot L300 AMR can be deployed in a wide variety of applications across multiple industries.

Due to the high payload capacity, smart navigation, and advanced lifting module, the L300 allows the automatic transfer of heavy loads and pallets between line-side stations or from warehouses to workshops. The robot is able to transport pallet-size loads, functional parts, and other heavy equipment to achieve a streamlined production with the reduced risk of staff injuries.

Check out these use cases demonstrating the AMR’s capabilities in manufacturing industry:

The L300 mobile robot can be easily manipulated from the call-box, computer, tablet, or mobile device through the company’s self-developed YOUITMS robotic logistics system. It is specially designed to solve practical tasks and effectively manage all aspects of enterprise-level multi-workshop logistics. The program also allows for smart robot connection, configuration, real-time monitoring, and controls. With YOUITMS and integrated safety features, it is easy to deploy the robot and ensure its efficient collaboration with other machines.

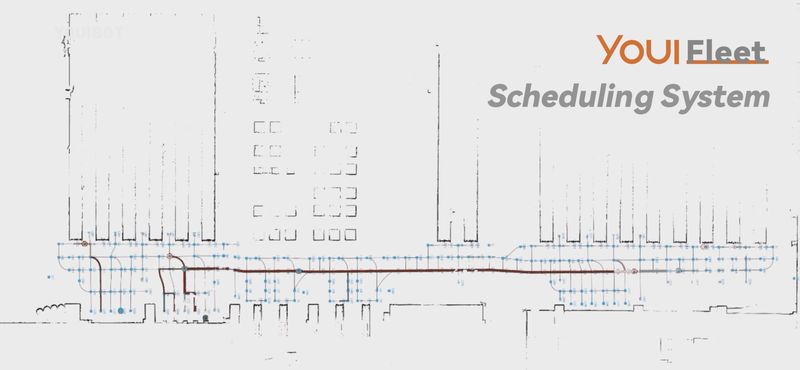

To facilitate the fleet managing procedures, the company provides the proprietary YOUIFleet scheduling application. It represents an intelligent multi-machine management system that delivers a coordinated fleet collaboration of up to 150 AMRs in the same scenario. The YOUIFleet offers a complete set of commands to distribute tasks across multiple robots with separate configurations, optimize path planning, manage traffic control and system parameters, supervise the status of each machine, collect analytical data, and more.

The Youibot L300 AMR is available in white with black trimmings. Its stylish look makes it ideal for advanced industry applications and will decorate any factory, workshop, or lab.

The device offers a compact yet robust design and reliable construction. The robot dimensions are 800 x 619 x 330 mm (31.5 x 24.4 x 13 in). It weighs approximately 180 kg (397 lb).

The price for the Youibot L300 AMR is $26,999.00, which is reasonable considering its functionality and high performance.

Update your browser to view this website correctly. Update my browser now