Refurbished & Used 3D Printers: Best Deals

What Types of Refurbished and Used 3D Printers Are Available?

Refurbished and used 3D printers are available in various types. The main types include Fused Deposition Modeling (FDM) printers, Stereolithography (SLA) printers, Digital Light Processing (DLP) printers, and Selective Laser Sintering (SLS) printers. FDM printers dominate the market with a 68% share. SLA and DLP printers follow with a 15% share. SLS printers account for 13% of the market.

How Do FDM and Resin 3D Printers Compare in Quality and Capabilities?

FDM and resin (SLA/DLP) 3D printers differ significantly in print quality and capabilities. Consider these differences:

- Produce higher quality prints with finer details and smoother surfaces using resin printers.

- Print larger objects faster with FDM printers.

- Create small, detailed parts quickly with resin printers.

- Use a wider range of materials, including various thermoplastics, with FDM printers.

- Utilize specialized materials for specific applications with resin printers.

What Are the Advantages of Direct Drive vs. Bowden Extrusion Systems?

Direct Drive and Bowden extrusion systems offer distinct advantages. Compare these benefits:

Direct Drive Advantages:

- Control filament extrusion and retraction better.

- Handle flexible filaments more effectively.

- Reduce the likelihood of clogs due to a shorter filament path.

- Respond more quickly to print setting changes.

Bowden Extrusion Advantages:

- Allow for faster print speeds due to a lighter printhead.

- Improve print quality by reducing inertia on the X-axis.

- Print high-temperature materials more easily due to increased distance between the motor and hot end.

- Maintain and upgrade the system with greater ease.

How Do Different Bed Types (Glass, Metal, etc.) Affect Print Quality?

Different bed types significantly impact print quality and adhesion. Consider these effects:

- Achieve an extremely smooth first layer using glass beds, ideal for parts requiring a glossy bottom finish.

- Heat up quickly and provide even heat distribution with aluminum beds.

- Obtain superior adhesion for various materials using BuildTak and PEI surfaces.

- Remove prints easily and reduce warping with magnetic flexible beds.

Choose the bed type based on your specific materials and desired print quality. Use heated beds to improve print adhesion and reduce warping, especially for materials like ABS and PETG.

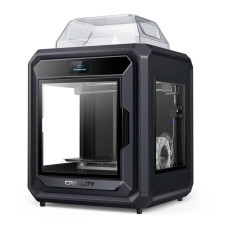

Which Brands Offer the Best Value in Used and Refurbished 3D Printers?

Creality, Elegoo, and Prusa offer excellent value in the used and refurbished 3D printer market. These brands provide quality machines at competitive prices.

What Makes Creality Ender 3 a Popular Choice for Beginners?

The Creality Ender 3 is popular among beginners for several reasons. Consider these factors that make the Creality Ender 3 a top choice:

- Purchase the Creality Ender 3 at a low entry price point.

- Benefit from a stable construction with reduced vibrations due to its metal structure.

- Achieve detailed prints with layer heights between 100 to 400 microns.

- Create a wide range of projects using the 220 x 220 x 250mm build volume.

- Modify and improve the printer easily due to its open-source nature.

Print at speeds up to 200mm/s with the Creality Ender 3. The Creality Ender 3 includes features like power recovery and a heated bed with a BuildTak-like surface for improved adhesion.

How Do Elegoo and Prusa Printers Compare in Terms of Features and Price?

Elegoo and Prusa printers offer different features and price points. Compare these aspects of Elegoo and Prusa printers:

- Elegoo Neptune 3:

- Print faster due to the lighter printhead of the Bowden extruder system.

- Access 3D printing at a more affordable price point.

- Maintain the printer more easily, making it suitable for beginners.

- Prusa i3 MK4:

- Use a wider range of materials with greater flexibility due to the Direct Drive extruder.

- Achieve higher precision and better control over filament extrusion.

- Access advanced features and reliability at a higher price point.

- Benefit from automatic bed leveling and a more robust build quality.

Purchase the Prusa i3 MK4 at a higher price than Elegoo models. The Prusa i3 MK4 offers higher print quality and more advanced features. Choose the Elegoo Neptune 3 for good value, speed, and efficiency with standard materials, especially if you're a beginner.

What Are the Benefits of Buying from Official Sources vs. Third-Party Sellers?

Purchasing from official sources provides several advantages over third-party sellers. Consider these benefits when buying from official sources:

- Receive full warranty coverage, ensuring protection against defects or malfunctions.

- Access direct manufacturer support for troubleshooting and technical assistance.

- Obtain guaranteed genuine products without the risk of counterfeit or modified units.

- Use printers with the most up-to-date firmware installed.

- Receive your printer through more secure packaging and shipping methods.

Third-party sellers may offer lower prices. Lower prices from third-party sellers often come with risks such as limited or no warranty, potential for counterfeit products, and lack of official support. Buy used or refurbished printers from official sources or certified resellers for greater assurance of product quality and support.

What Should You Consider When Buying a Used or Refurbished 3D Printer?

Consider several factors when buying a used or refurbished 3D printer. These factors include the power supply, potential upgrades, and warranty policy.

How Important Is the Power Supply in a Refurbished 3D Printer?

The power supply is crucial in a refurbished 3D printer. Consider these aspects of the power supply:

- Ensure stable voltage to prevent print failures and hardware damage.

- Check the wattage requirements for optimal performance.

- Verify proper cooling to prevent overheating during long print jobs.

- Look for built-in safety features such as short circuit and overload protection.

- Consider upgrading to a higher quality power supply if the original shows wear or instability.

What Upgrades Should You Look for in a Pre-Owned 3D Printer?

Look for these upgrades in a pre-owned 3D printer:

- Check for upgraded extruders that improve filament feed and print quality.

- Look for enhanced cooling systems for better bridging and overhang performance.

- Verify if the printer has an upgraded build plate for improved bed adhesion.

- Check for firmware updates that may have added new features or improved performance.

- Look for aftermarket modifications that enhance print quality or ease of use.

How Does the Warranty Policy Differ for Refurbished vs. New 3D Printers?

Warranty policies differ significantly between refurbished and new 3D printers. Consider these differences:

- Expect shorter warranty periods for refurbished printers.

- Understand that refurbished printer warranties often cover only core components.

- Be aware that some manufacturers offer similar warranty coverage for both new and refurbished printers.

- Note that warranty service for refurbished printers may be provided by authorized resellers.

- Check if the warranty covers both parts and labor for refurbished printers.

Verify the specific warranty terms before purchasing a refurbished 3D printer. Some manufacturers offer extended warranty options for an additional cost.

How Can You Find the Best Deals on Used 3D Printers?

Find the best deals on used 3D printers through online marketplaces, manufacturer refurbished programs, and local listings. Compare prices, conditions, and warranties across multiple platforms to ensure you're getting the best value.

What Are the Advantages of Buying Refurbished vs. Used 3D Printers?

Refurbished and used 3D printers offer different advantages. Consider these benefits:

- Undergo thorough inspection and restoration by the manufacturer or authorized dealer for refurbished printers.

- Receive a warranty on refurbished printers, typically ranging from 90 days to 12 months.

- Get updated firmware and replacement of worn parts in refurbished models.

- Find lower prices on used printers compared to refurbished models.

- Access a wider variety of models and brands in the used market.

How Can You Quickly Search and Compare Deals Across Different Platforms?

Search and compare deals efficiently using these methods:

- Use aggregator websites to compile listings from multiple marketplaces.

- Set up alerts on platforms like eBay or Facebook Marketplace for specific 3D printer models.

- Join 3D printing forums and communities to find member-posted deals and sales.

- Check manufacturer websites for official refurbished programs and clearance sales.

- Utilize price comparison tools to track historical prices and identify good deals.

What Are the Potential Pitfalls to Watch Out for When Buying Second-Hand 3D Printers?

Be aware of these potential issues when buying second-hand 3D printers:

- Encounter hidden damage or wear that may not be immediately apparent.

- Face outdated firmware that may limit functionality or compatibility with newer slicing software.

- Find missing or damaged components that could be expensive to replace.

- Lack warranty or support from the manufacturer for used models.

- Risk purchasing counterfeit parts or unauthorized modifications in used printers.

Mitigate these risks by requesting detailed photos, asking for print samples, and inspecting the printer in person before purchase if possible. Use secure payment methods and platforms that offer buyer protection for online purchases.

How to Choose the Right 3D Printer for Your Needs?

Choose the right 3D printer by considering several factors. These factors include your experience level, intended use, and specific requirements for print quality and materials.

What Features Should Beginners Look for in Their First 3D Printer?

Beginners should prioritize the following features in their first 3D printer:

- Look for printers with user-friendly interfaces and plug-and-play functionality.

- Choose printers with auto-leveling beds for simplified calibration.

- Select printers with enclosed build areas for better temperature control and safety.

- Opt for brands known for responsive customer service and extensive online resources.

- Consider affordable entry-level printers like the Creality Ender 3 or Prusa Mini+.

The Flashforge Adventurer 5M (FA5M) is designed for beginners. The FA5M features a fully enclosed build area, auto-leveling, and a quick-release nozzle for easy maintenance.

How Do Print Volume and Speed Limits Affect Your Buying Decision?

Print volume and speed limits significantly impact a 3D printer's capabilities. Consider these factors when making your buying decision:

- Choose print volumes based on your project needs:

- Select small volumes (150-300mm) for figurines, jewelry, and educational purposes.

- Opt for medium volumes (300-500mm) for most hobbyist and small business needs.

- Consider large volumes (500mm+) for industrial applications or large-scale prototyping.

- Consider print speed requirements:

- Expect standard speeds of 40-100 mm/s for most consumer printers.

- Look for high-speed printers reaching 150-300 mm/s for reduced print times.

- Explore industrial printers like the Raise3D RMF500 for speeds up to 500 mm/s.

Evaluate your project requirements when choosing print volume and speed. Remember that larger volumes and higher speeds generally increase cost and complexity.

What Role Does Filament Compatibility Play in Choosing a 3D Printer?

Filament compatibility is crucial in selecting a 3D printer. Consider these factors related to filament compatibility:

- Check the printer's temperature range for compatibility with desired materials.

- Choose all-metal hotends for printing with a wider range of materials, including abrasive filaments.

- Select appropriate bed surfaces for different materials, such as PEI sheets or glass beds.

- Ensure the printer matches available filament diameters (1.75mm or 2.85mm).

- Consider dual extruders for printing with multiple materials or colors.

The Prusa i3 MK3S+ (Pi3MK3S+) offers compatibility with a wide range of filaments. The Pi3MK3S+ supports PLA, PETG, ABS, ASA, and flexible materials due to its all-metal hotend and heated bed with a PEI surface.

What Are the Latest Innovations in 3D Printing Technology?

Recent innovations in 3D printing technology focus on improving print speed, quality, and material capabilities. These advancements drive the adoption of 3D printing in various industries.

How Is AI Being Integrated into 3D Printing Systems?

AI integration in 3D printing systems enhances various aspects of the printing process. Consider these AI applications in 3D printing:

- Analyze 3D models and compare them to the ongoing print process using AI algorithms for quality control.

- Optimize print parameters for specific designs using AI to improve print quality and reduce material waste.

- Generate optimized designs based on specific requirements using AI for creating stronger and more efficient structures.

- Predict potential printer failures using AI systems to reduce downtime and maintenance costs.

- Optimize print settings without extensive manual tuning using AI-powered slicing software.

The "Spaghetti Detector" feature in some desktop FFF printers uses computer vision and machine learning to detect print failures. Bambu Lab printers incorporate AI-powered first layer LIDAR scanning for improved print success rates.

What Are the Benefits of Remote Monitoring and Control in 3D Printers?

Remote monitoring and control systems offer several advantages for 3D printing operations. Consider these benefits:

- Track print progress, temperature, and other parameters from anywhere using real-time monitoring.

- Start, pause, or cancel prints without being physically present at the printer using remote control.

- Share print data and collaborate on projects remotely to improve workflow efficiency.

- Gather valuable data on print performance for analysis and process improvement.

- Manage multiple printers or print farms to support larger-scale operations.

3DPrinterOS offers cloud-based software that enables real-time monitoring of multiple printers. The software tracks print time, temperature, files, and color information from a single interface.

How Are Advancements in Materials Science Improving 3D Printed Products?

Materials science advancements significantly enhance the properties and applications of 3D printed products. Consider these material improvements:

- Use advanced polymers like PEEK, PEKK, and ULTEM for improved strength, heat resistance, and chemical resistance in industrial applications.

- Incorporate ceramic fibers, graphene, or carbon fibers into metal powders to enhance strength, stiffness, and wear resistance of printed parts.

- Create 3D printed electronics and smart objects using conductive inks, electrostrictive polymers, and self-healing materials.

- Improve strength, conductivity, and thermal stability of printed materials by integrating nanoparticles, nanotubes, and nanofibers.

- Create patient-specific implants and tissue-engineered constructs using bioinks and biomaterials.

Research is ongoing to optimize existing metal powders for specific applications. The research aims to reduce costs and handling difficulties. Innovations in ceramic and composite materials expand the range of high-temperature resistant, durable, and biocompatible 3D printed products.

These advancements in 3D printing technology, AI integration, remote monitoring, and materials science drive the adoption of additive manufacturing across industries. The industries benefiting from these advancements include aerospace, healthcare, consumer products, and beyond.

![Phrozen Sonic XL 4K 2022 Resin 3D Printer [CLEARANCE], photo Phrozen Sonic XL 4K 2022 Resin 3D Printer [CLEARANCE]](https://top3dshop.com/image/cache/catalog/products/3d_printers/phrozen/sonic_xl_4k/phrozen_sonic_xl_4k_image_3-228x228.jpg)

![Flashforge Creator 3 3D Printer [Clearance], photo Flashforge Creator 3 3D Printer [Clearance]](https://top3dshop.com/image/cache/catalog/products/3d_printers/flashforge/creator_3/flashforge_creator_3_3d_printer_3-228x228.jpg)

![Creality CR-5 Pro High-temp Version 3D Printer [Clearance], photo Creality CR-5 Pro High-temp Version 3D Printer [Clearance]](https://top3dshop.com/image/cache/catalog/products/3d_printers/creality/cr_5_pro_ht/creality_cr_5_pro_ht_image10-228x228.jpg)