UFactory Collaborative Robots

Jump to Section:

- What is UFactory?

- What do experts think about UFactory robots?

- Why buy UFactory?

- Which UFactory Robot should I buy?

- What software can I use with UFactory robots?

- What parts and offocial accessories are available with the UFactory robots?

- What is the UFactory's warranty policy?

- How can I customize UFactory industrial robots?

What is UFactory?

Since 2014, UFactory has been at the forefront of robotics, launching the world's first table-top robot arm, uArm, and raising significant Kickstarter support. With a knack for innovation as their top priority, they introduced uArm Swift and xArm, redefining industry standards. In 2021, Lite 6 joined their lineup, catering to robotic researchers and engineers with its compact design.

Tearing down financial barriers for SMEs, UFactory's industrial robots are trusted by industry giants including Google, Intel, Orionstar, and Heer.

Strong support team: At UFactory, they provide steadfast assistance, ensuring smooth operations for users across the board.

UFactory authorized Top 3D Shop as its value-added reseller in 2019. Top 3D Shop has sold over 100+ robotic arms manufactured by UFactory and successfully completed 100% of the received client's support tickets. Customers who purchase directly through Top 3D Shop receive local customer support from our technical center in California, USA.

What do experts think about UFactory robots?

In the years we've been working with UFactory, we've always been impressed by their innovative approach. What sets UFactory apart in our portfolio is their blend of cost-efficiency with cutting-edge technology. They democratize robotics, making sophisticated tools accessible to small and mid-sized enterprises. We'd certainly recommend it to businesses looking to gain a competitive edge without breaking the bank. – Mohamed Eladawy, 3D Solutions Specialist at Top 3D Shop

Why buy UFactory?

Technological Innovation and Versatility: UFactory stands out for its trailblazing contributions to the robotics industry, starting with the world's first desktop robot arm, uArm. Each model from their product range serves distinct purposes, from light industrial tasks and educational uses to heavy-duty applications. The xArm, for example, is lauded for its balance of power and size, making it suitable for recurrent tasks like machine tending and lab automation. The Lite 6' robot arm, on the other hand, is celebrated for its affordability and compact design. It makes advanced robotics accessible to researchers and educators.

Affordability: By offering cost-effective solutions without compromising on quality, UFactory enables small and medium-sized enterprises to leverage robotic technology. The Lite 6 exemplifies this philosophy. It provides a cost-effective option for robotic research and engineering, thus democratizing access to robotic innovation.

Reliability and Ease of Use: UFactory's durable collaborative robots are designed for continuous operation, featuring industrial-grade harmonic drives and servomotors. Despite their robust construction, the UFactory industrial robots are user-friendly. They offer safe feature hand teaching, reduced system weight for easier deployment, and collision detection for safety. The graphical interface and open-source SDK make more flexible programming accessible for beginners and versatile for experienced users.

Broad Application Range: UFactory robots are designed to be multi-functional, from precision tasks like laser engraving and 3D printing with the uArm Swift Pro to industrial uses such as welding and screw driving with the UFactory 850. To easily achieve almost any purpose, they come with multiple hardware compatibility interfaces, interchangeable end-effectors, and extensive accessory options.

Responsive Support and Community: The provision of dedicated online support, real-time chat, and a plug-and-play setup reflects UFactory's commitment to user satisfaction. Additionally, the open-source nature of their products with API compatibility interfaces fosters a collaborative environment for users to share innovations, further enriching UFactory's ecosystem.

Which UFactory Robot should I buy?

Here is a list of the major UFactory robot models to choose from:

xArm

The UFactory xArm series, including xArm 5, xArm 6, and xArm 7 models, emerges as a formidable contender in the collaborative robot sector. Sporting up to 5 kg payload and 700 mm reach, the UFactory xArm 5 robotic arm is a beast built for precision. Ideal for machine tending, bin picking, lab and vision automation, its high-end harmonic drive and carbon fiber construction promise relentless performance of industrial-grade robots. Equipped with a user-friendly interface and open-source SDKs, xArm robot arm is a blend of power and simplicity.

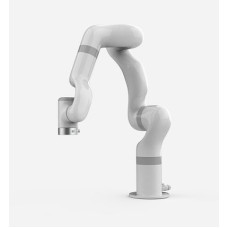

Lite 6

Targeting researchers and educationalists, the Lite 6 robot arm is the epitome of cost-effectiveness without compromise. With a 600 g payload and 440 mm reach, it's designed for 24/7 operation and effective space saving. Easy to re-deploy, this 6-axis robot perfectly fits multiple applications without changing your production layout. Despite its compact size, it doesn't skimp on features, offering hand teaching, collision detection, and a versatile programming suite.

UFactory 850

With a 5 kg payload, 850 mm reach, maximum speed of 1 m/s, and ±0.02 mm repeatability, the UFactory 850 6-axis robotic arm is tailored for tasks demanding high precision, such as welding and screw driving. Its standout features include an internal 100M ethernet cable for enhanced system stability and a lightweight design for flexible deployment, thanks to its carbon fiber and aluminum framework. This powerful robot arm is designed for both mobility and benchtop work. Due to its architecture that helps one to deploy the robotic arm smoothly, the UFactory 850 is ready to go almost right out of the box, no technician needed.

uArm Swift Pro

As a consumer-grade collaborative robot, the uArm Swift Pro robotic arm is a versatile companion for 3D printing, laser engraving, and more. Based on Arduino, it's a plug-n-play device that offers an offline learning mode for ease of use. With a stepper motor ensuring up to 0.2 mm position repeatability and a working range of 50-320 mm, it's as precise as it is user-friendly. The robot supports various end-actuators, transforming effortlessly from a printer to an engraver in seconds.

Case Studies

Frequently Asked Questions

What software can I use with UFactory robots?

UFactory robots are integrated with UFactory Studio software. This web-based technology is pre-installed in the robot's AC control box and accessible via all major browsers. The beginner-friendly programming compatible platform offers a graphical interface for intuitive configuration and control. Features include example codes, live control, blockly programming, custom libraries, recording, I/O setting, offline mode, collision detection, and hand teaching. All this is available for free, with monthly updates introducing new functionalities.

What parts and official accessories are available with the UFactory robots?

UFactory's range extenders and various end-effectors such as a vacuum gripper or force torque sensor boast seamless integration. These complement the robots' capabilities in pick-and-place tasks and laboratory automation. They offer code-free programming in Python and C++ through UFACTORY Studio's graphical interface.

What is the UFactory's warranty policy?

UFactory offers a 12-month warranty for their products, including robotic arms, vacuum grippers, BIO grippers, and control boxes. Warranty service may include repairs, replacements, or refunds, depending on the issue and timing of the service request. Read the full terms here: https://www.ufactory.cc/warranty-and-returns/.

How can I customize UFactory industrial robots?

UFactory's open-source robot API allows for custom adjustments and interfacing with other products, for example, mobile platforms. Integrations require custom code work, including the need to write custom libraries and install software packages not included with the robot.