Hi everyone! This is Top 3D Shop, and today, we will try to figure out the differences between two FDM 3D printers from the Flashforge’s Guider series known for its affordable and reliable models.

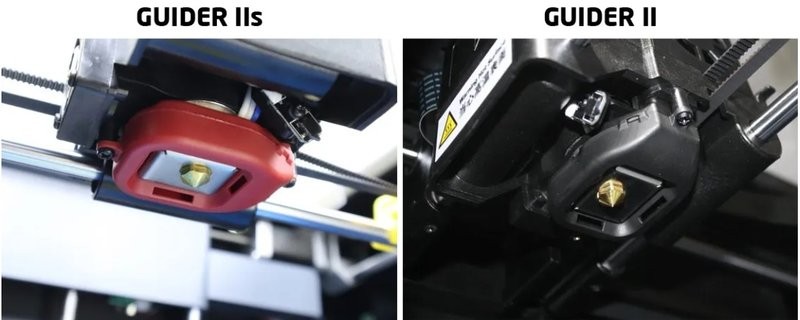

The Guider IIs is characterized as an upgraded version of the original Guider II. Visually, the devices are practically identical, except for the color: the first printer is black, while the other is closer to blue-gray. But what about their tech specs and functionality? Let’s find it out!

To start with, we suggest you have a look at the table below covering the main characteristics of the two models under consideration:

|

Guider II |

Guider IIs |

|

|

Technology |

FFF/FDM |

FFF/FDM |

|

Enclosure |

Closed |

Closed |

|

Build volume |

280 x 250 x 300 mm |

280 x 250 x 300 mm |

|

Min. layer height |

50 microns |

100 microns |

|

Extruder type |

Single |

Single |

|

Filament diameter |

1.75 mm |

1.75 mm |

|

Nozzle size |

0.4 mm |

0.4 mm |

|

Materials |

ABS, PLA, PVA, etc. |

PLA, ABS, PVA, PETG, HIPS, PA, PC, etc. |

|

Max. extruder temp |

240 °С |

300 °C |

|

Max. print bed temp |

120 °C |

120 °C |

|

Connectivity |

USB, Wi-Fi, Ethernet |

USB, Wi-Fi, Ethernet |

|

Operating system(s) |

macOS, Microsoft Windows |

macOS, Microsoft Windows |

|

Dimensions |

550 x 490 x 560 mm |

550 x 490 x 560 mm |

|

Weight |

11 kg |

30 kg |

|

Print bed |

Heated removable |

Heated removable |

|

Bed leveling |

Automatic assisted |

Automatic assisted |

|

Filament runout sensor |

+ |

+ |

|

Resume printing function |

+ |

+ |

|

HD camera |

- |

+ |

|

Air cleaning system |

- |

+ |

As you can see, the Guider IIs clearly fits the definition of an upgraded version. It sports major improvements on several points, which deserve a closer look.

Generally, the Guider IIs functionality has been refined and optimized in several important aspects. Let’s dwell on the most prominent of them.

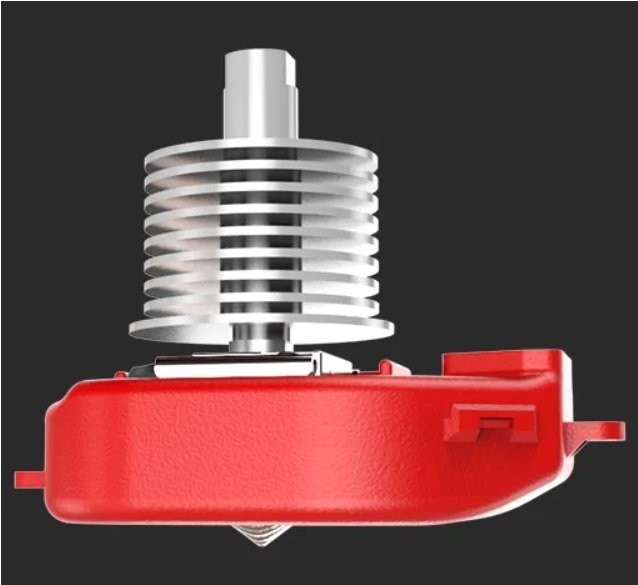

The first advantage over the previous version is the new extruder for the Guider IIs model. The bright red color is not the only difference from the predecessor — due to the advanced design features, the machine is capable of printing with flexible filaments.

The modification responsible for this innovation is the reduced distance between the feeder and the hotend. This solves the main problem with TPU and TPE plastics, where the softening filament frequently causes nozzle clogging.

The maximum operating temperature of the Guider IIs extruder reaches 300 °C, while the Guider II has a limit of 240 °C.

This refinement expands the range of applications and, in addition to low-temperature materials like PLA, allows you to make better use of such plastics as ABS and PETG, as well as print in nylon and polycarbonate.

The temperature of the heated print bed remains the same — up to 120 °C.

The Guider IIs boasts a built-in HD camera for remote online monitoring of the printing process, which is accessible through the FlashCloud web service.

This certainly makes for convenient printing. If something goes wrong in the process, you can pause or stop it via the cloud. Also, you can connect and control several devices simultaneously.

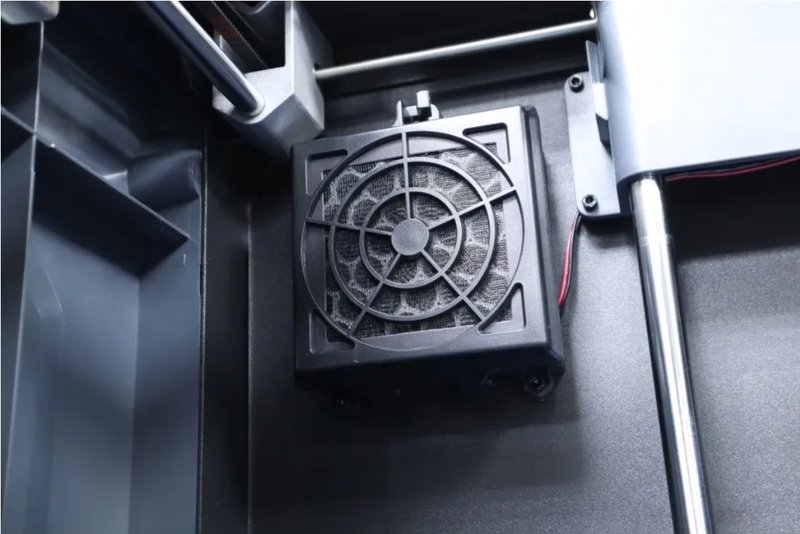

The Guider IIs also received a valuable improvement in the form of an air filter and fan, which constitute a proper air cleaning system that minimizes harmful emissions. Although this feature is not the highest priority, it makes the printer much more comfortable to work with.

So, both the Flashforge Guider II and Guider IIs are professional printers with excellent functionality and ample opportunity. Both printers feature sturdy frames that provide stable, vibration-free operation. Besides, the machines have a common resume printing function and filament runout sensor.

One of the Guider IIs’ most important differences is the ability to print with a wider range of materials. The improved design of the extruder provides good results when printing with flexible filaments, and the increased extruder temperature makes it possible to obtain quality outputs from more options of consumables. Some users will surely appreciate the camera allowing them to control the process remotely and thus streamline the workflow. Finally, the air filter is a nice bonus for safe and comfortable manufacture.

If you, however, print with standard filaments and don’t have a need to monitor the printing remotely, the original version of the Guider II is likely to suffice.

Update your browser to view this website correctly. Update my browser now

Write a comment