Well-known in 3D printing industry for its FDM consumer 3D printers, the Flashforge company is extending the lineup with professional machines aimed at industrial customers’ needs. The company has updated its Guider series with the 3 and 3 Plus models. Like the Flashforge’s flagship Creator 4 with its IDEX technology and three available extruder types, the new Guider 3 series printers are designed to meet various demands of 3D printing professionals, be it prototyping, batch-production, or large-scale printing. Each model offers a unique set of smart features for the customer to choose the best option for their particular task.

This is Top 3D Shop, and in this article we are going to review the key features of the Flashforge Guider 3 FDM 3D printer and see how it is different from its 3 Plus sibling.

The Chinese-based Zhejiang Flashforge 3D technology company was founded in 2011 and became one of the first manufacturers of AM equipment in China. Today, the company is among the world’s leading brands in consumer 3D printing, its equipment being supplied to over 100 countries and regions. Meeting the needs of different business sectors, Flashforge has 10 product categories, including FDM, resin, and multi-jet 3D printers, printing materials, and software as well as comprehensive 3D printing services and after-sales customer support.

Flashforge at Formnext 2022

The aluminum frame of the Flashforge Guider 3 ensures stability while printing long hours at high speeds, and its outer shell is made of lightweight but durable ABS and acrylic sheets. Due to its surprisingly compact footprint and industrial modern look, the printer can be flexibly integrated into any production floor.

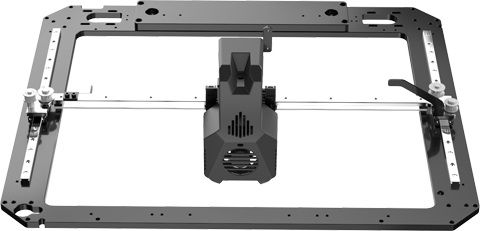

The machine adopts the CoreXY motion structure which ensures the most efficient use of the internal space and makes for the best build volume to footprint ratio. Compared to the previous Guider IIs, the build volume increased by 21% while the footprint became even smaller. Another advantage of using this structure is speed, which reaches an impressive value of 250 mm/s without sacrificing print quality. Speaking of print quality, we should mention that the CoreXY system allows the Guider 3 to print parts with high dimensional accuracy. In spite of ultra-fast operation, the machine is rather quiet, with the noise level not exceeding 50 dB.

The Guider 3 is an open material system, which means the user is not limited to proprietary filaments and has a wide choice of both Flashforge and third-party thermoplastics.

A couple of months before the launch of the Guider 3, Flashforge released another industrial-grade machine to the same series, the Guider 3 Plus. Both printers are extremely fast and targeted at the professional market, but while the Guider 3 is made primarily for time-efficient small-batch production, the Plus model, as the name suggests, is made for printing big, or tall, to be more exact. With a build volume of 350 x 350 x 600 mm, the Guider 3 Plus is ideal for large-scale 3D printing, such as architectural models, movie props, or art objects. It is also great for rapid prototyping and design verification tasks. The machines have a lot in common, sharing the same CoreXY motion structure with all its benefits, a smart management system, allowing for continuous 24/7 operation, and a powerful double-gear high-temp extruder. Unlike the Guider 3, the 3 Plus model does not have a dual build plate option, but it is equipped with two sealed filament chambers to store printing materials in the best condition. You can compare the main features of the Guider 3 series models in the table below.

|

Model |

Flashforge Guider 3 |

Flashforge Guider 3 Plus |

|

Build volume |

300 x 250 x 340 mm |

350 x 350 x 600 mm |

|

Print speed |

10–250 mm/s |

10–250 mm/s |

|

Display |

4.3" touchscreen |

7" touchscreen |

|

Max. nozzle temperature |

320 °C |

320 °C |

|

Build plate |

dual: glass / flexible steel |

flexible steel |

|

Print bed leveling |

auto + auxiliary |

auto + auxiliary |

|

Layer thickness |

0.05–0.4 mm |

0.05–0.4 mm |

|

Filament runout sensor |

yes |

yes |

|

Print resume function |

yes |

yes |

|

Remote print monitoring |

yes |

yes |

|

Filament chamber |

no |

2 x 1 kg spool |

|

HEPA13 air filter |

yes |

yes |

|

Software |

FlashPrint 5 |

FlashPrint 5 |

|

Outer dimensions |

496 x 436 x 696 mm |

635 x 550 x 1070 mm |

|

Weight |

27 kg |

70 kg |

The Flashforge Guider 3 comes fully assembled with some extras you may need for printing. Apart from the printer itself, you will find the following items in the box:

For some items, package content may change. In case of any questions, please get in touch.

Apart from above mentioned advantages of the Guider 3, its high speed being one of the most notable, there are a number of smart features that make it a reliable machine for industrial applications.

The Guider 3 is equipped with a convenient swappable build plate. The glass build plate, great for smooth model surface, can be easily changed for a magnetic flexible steel sheet, which can be slightly bent for a hassle-free larger models removal.

Featuring automatic and auxiliary print bed leveling with a highly sensitive proximity sensor, the Guider 3 ensures precise distance between the nozzle and build plate during the entire printing process. This makes for perfect first layer adhesion and saves you pretty much time on manual printer setup.

Due to the upgraded double-gear design, the Guider 3 powerful extruder provides 150% higher feeding force than its predecessor, the Guider IIs, and ensures consistent filament feeding, efficiently preventing clogging issues. The extruder is equipped with a stainless steel 0.4 mm nozzle, featuring proprietary quick release mechanism, which can be easily replaced with an optional 0.6 or 0.8 mm diameter nozzle if needed.

The extruder can heat up to 320 °C and can work with a wide range of consumer and engineering filaments, including ABS, PLA, PC, PA, HIPS, ASA, PETG, PA-CF, PLA-CF, PETG-CF, PETG-GF, and others.

To affirm the printer’s true industrial nature, Flashforge engineers equipped it with a comprehensive management system for reliable continuous operation. The system includes real-time remote monitoring of the printing process and print resume function after a sudden power outage. Once the built-in camera is turned on, one can see live video of the printing process in the FlashPrint software. The user can manage multiple machines from a single computer to streamline the batch production process.

The Guider 3 comes pre-calibrated at the factory, but it is still recommended to level the print bed before the first use. After turning on the printer, click the Calibration icon on the touchscreen, and follow the instructions on the screen. The complete calibration process consists of three main steps.

First you need to calibrate the Z-axis, placing the leveling card between the nozzle and the build plate and adjusting the Z-offset on the screen until you feel slight resistance when trying to move the card. Click OK and move to the next step.

To perform the sensor calibration, select the corresponding icon in the Calibration menu and adjust the three leveling nuts underneath the build platform, following the screen prompts.

For the last step, select Assist Calibration in the calibration menu, choose Full Mode, and the machine will start automatic 25-point leveling.

Sensor calibration and Assist calibration can only be held with the equipped flexible platform. Each time you swap the glass and flexible build plates, you need to adjust the extruder height, performing Z-axis calibration.

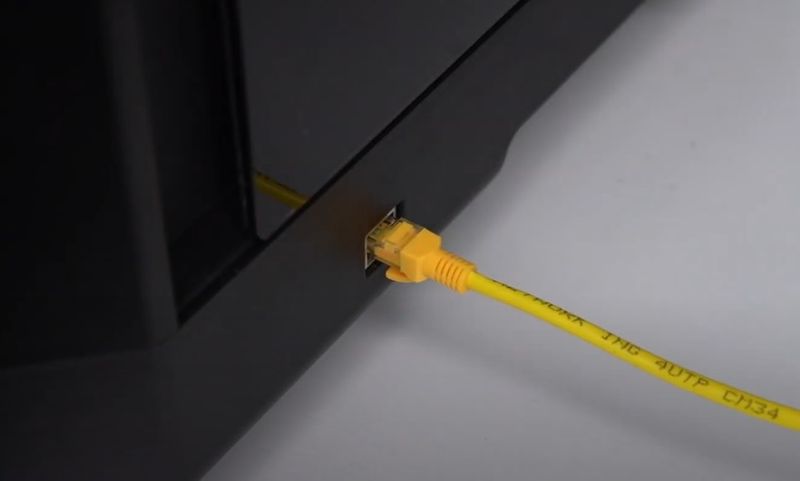

Before printing, you need to establish a network connection, either wirelessly or using an ethernet cable plugged in the corresponding port on the back of the printer.

From the Network menu choose wired or wireless option and connect your printer to the computer, following the screen prompts.

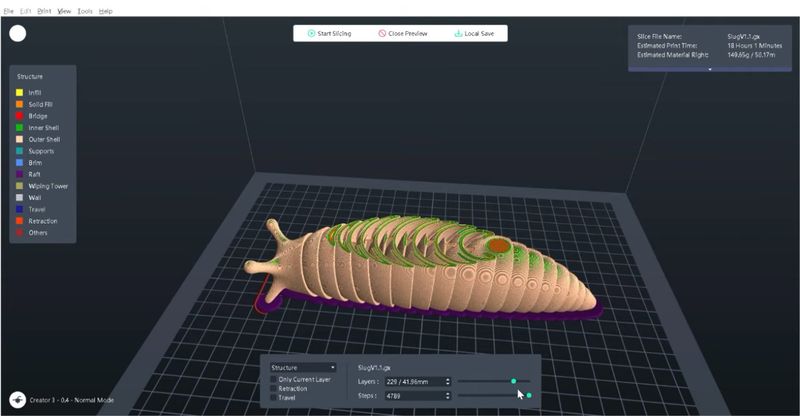

The Guider 3 is compatible with the dedicated FlashPrint software. The latest FlashPrint 5 version contains some major upgrades including both interface design and operation. FlashPrint 5 provides convenient remote monitoring of the printing process and supports multi-machine operation by creating grouping lists, allowing you to efficiently manage different groups of printers. The user can assign printing tasks and adjust printing parameters remotely, realizing the concept of continuous industrial-grade production.

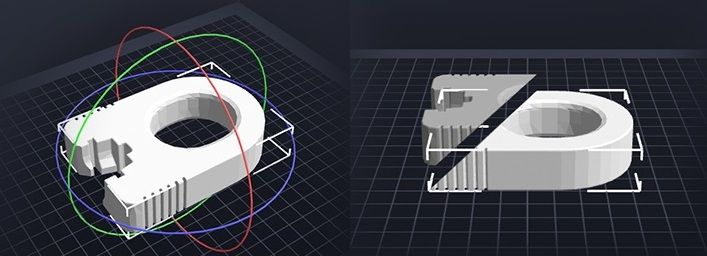

FlashPrint is compatible with STL, OBJ, FPP, and 3MF file formats and provides such useful editing functions as Model copy, Model cutting, allowing you to cut the model into several parts along the selected plane, or Rotation optimization, which automatically selects the optimal model position on the build plate.

Rotation optimization and Model cutting

The Flashforge Guider 3 is an ideal workhorse for small-batch production and can be employed for various applications where continuous, reliable, high-speed printing of quality parts is of crucial importance. The machine can be used in workshops or small-to-medium factories as well as in educational institutes.

The Flashforge Guider 3 FDM 3D printer is equipped with all the features necessary for an industrial machine, designed for time-efficient and low-cost manufacturing. With its fast and reliable performance, interchangeable build plates, and advanced management system, the Guider 3 is a highly versatile solution for any small enterprise.

Update your browser to view this website correctly. Update my browser now

Write a comment