The Chinese-based manufacturer Flashforge has expanded its reach into the professional FDM 3D printing market. Its new Guider 3 and Guider 3 Plus models are designed to meet the demands of industrial customers and have a plethora of smart features indispensable for efficient and convenient printing of high-quality parts.

This is Top 3D Shop, and today, we are going to take a closer look at the Flashforge Guider 3 Plus professional 3D printer made for large-scale printing.

Founded in 2011 in Zhejiang, China, today the Flashforge company is one of the leaders in the consumer FDM 3D printing market. The company offers its customers a wide array of consumer and professional 3D printing equipment, including FDM and resin-based printers, an industrial multi-jet machine for wax printing, and a large selection of printing materials and proprietary slicing software for different 3D printing technologies. Flashforge supplies its products to over 100 countries and regions and provides comprehensive customer support.

Flashforge at Formnext 2022

The Flashforge Guider 3 Plus looks different from the company’s other FDM printers, most of which have cube-shaped design. The Guider 3 Plus is noticeably taller, featuring an impressive 600 mm build volume height that allows printing tall models in one piece, without the need for future assembling.

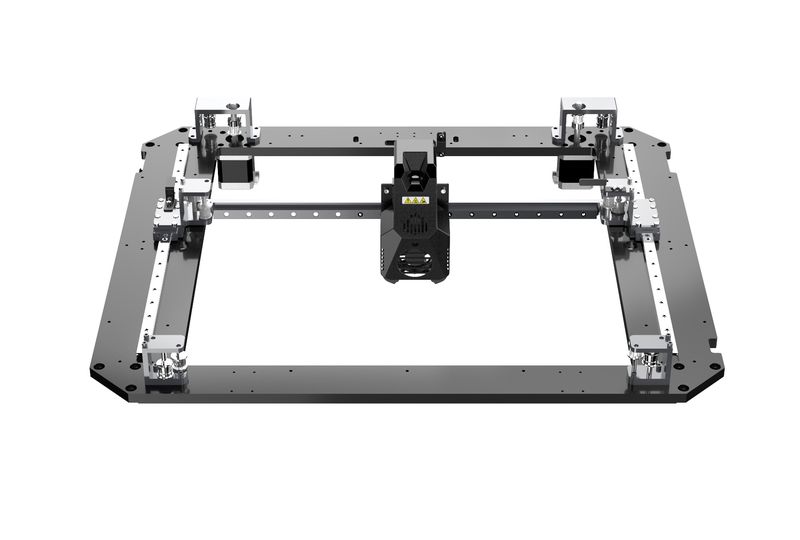

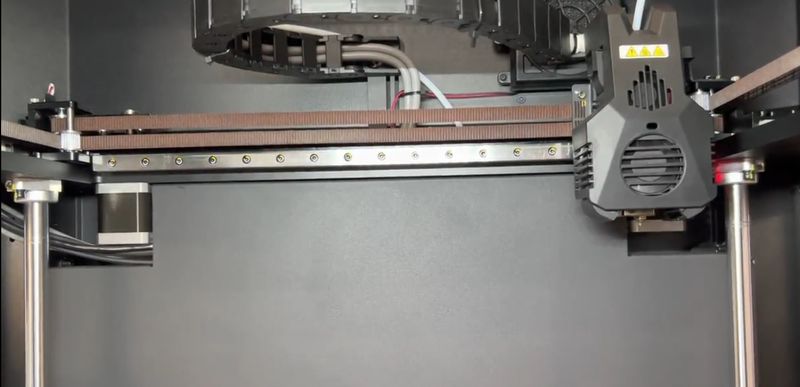

One of the most remarkable features of the Guider 3 Plus is its ability to print at lightning-fast speed of 250 mm/s. To achieve this, the printer is designed to eliminate any wobbling and vibrations that may occur while printing that fast. The rigid aluminum frame and durable ABS and acrylic sheets of the enclosure ensure high stability without adding extra weight. The Guider 3 Plus is equipped with a 16-mm Z-axis guide and 16-mm TBI ball screws on both sides, as well as high-precision XY-axes linear guide rails to ensure smooth motion and high speed even while printing large models.

Featuring the CoreXY motion system, the Guider 3 Plus is capable of not only fast but quiet printing with a noise level less than 50 dB. Excellent stability allows building high-quality models with great dimensional accuracy.

The Flashforge Guider 3 and 3 Plus models are designed for industrial customers to get all the benefits of additive manufacturing technologies, such as reduced production cycle and costs and convenient, flexible printing process. Both machines boast the same CoreXY structure and solid design that make for outstanding print speed, silent operation, and high dimensional accuracy of the printed parts. On the outside, the printers look very much alike, the Guider 3 Plus being pretty bigger and having a larger touchscreen. Another difference is the built-in filament chamber on the back side of the Guider 3 Plus.

The difference in the build volume determines different applications the printers are best suited for. The Guider 3 users will benefit from rapid prototyping and small-batch production, while the 3 Plus, also perfect for printing prototypes, will show its true potential in large-scale printing in automotive, art, architectural, and other industries. Both machines will also be a good choice for educational institutes.

A set of smart features, including an advanced management system, a powerful extruder with a quick release nozzle design, auto shut off function, and others is basically the same for both models. The advantage of the Guider 3 is a swappable build plate, with glass and magnetic steel plates included in the standard set.

You can compare the main features of the Guider 3 series models in the table below.

|

Model |

Flashforge Guider 3 |

Flashforge Guider 3 Plus |

|

Build volume |

300 x 250 x 340 mm |

350 x 350 x 600 mm |

|

Print speed |

10–250 mm/s |

10–250 mm/s |

|

Display |

4.3" touchscreen |

7" touchscreen |

|

Max. nozzle temperature |

320 °C |

320 °C |

|

Build plate |

dual: glass / flexible steel |

flexible steel |

|

Print bed leveling |

auto + auxiliary |

auto + auxiliary |

|

Layer thickness |

0.05–0.4 mm |

0.05–0.4 mm |

|

Filament runout sensor |

yes |

yes |

|

Print resume function |

yes |

yes |

|

Remote print monitoring |

yes |

yes |

|

Filament chamber |

no |

2 x 1 kg spool |

|

HEPA13 air filter |

yes |

yes |

|

Software |

FlashPrint 5 |

FlashPrint 5 |

|

Outer dimensions |

496 x 436 x 696 mm |

635 x 550 x 1070 mm |

|

Weight |

27 kg |

70 kg |

The Flashforge Guider 3 Plus comes fully assembled. Below is the full list of parts and accessories you will find in the box:

For some items, package content may change. In case of any questions, please get in touch.

The Flashforge Guider 3 Plus is packed with a whole number of smart features for convenient operation and flawless printing results.

For many filaments, proper storage conditions play a crucial role in the final result. Printing with damp material may lead to poor surface quality and worse mechanical properties of the printed models. To keep the filament dry and ready for printing, the Guider 3 Plus is equipped with two chambers, each of them housing a 1 kg spool. The chambers are sealed and contain packs of silica gel desiccant, which allows maintaining the humidity level below 20% within 5 days, with only 3 packs of desiccant used inside each chamber. There is a hygrometer in the filament chamber for the user to know when to change the desiccant.

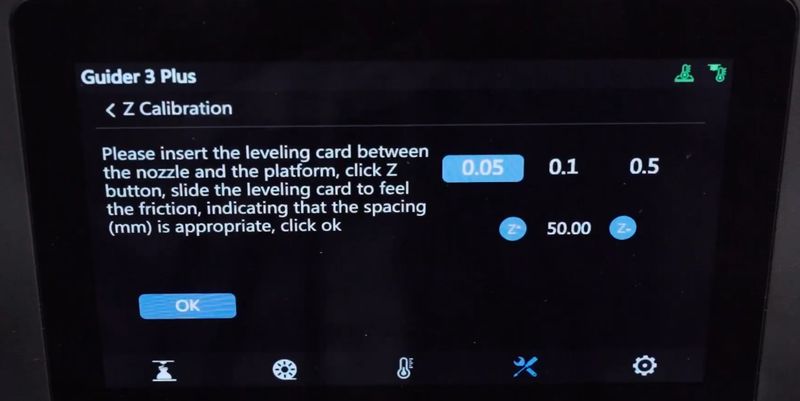

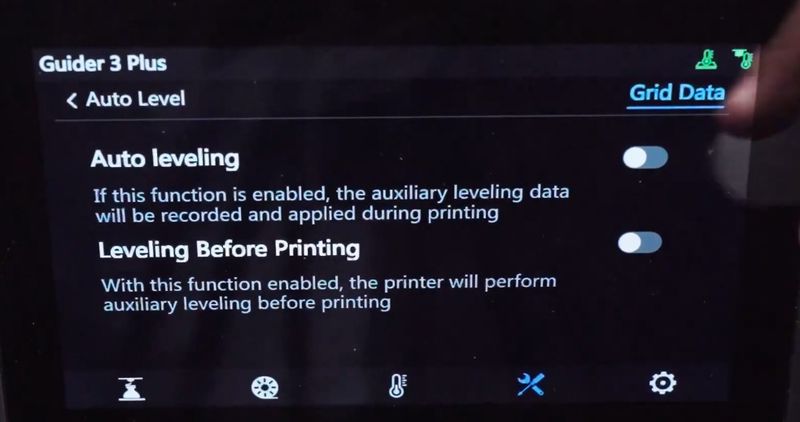

All makers know that an unleveled print bed can completely ruin the model, which becomes even more obvious for larger parts. To ensure perfect layer adhesion and reduce the risk of model deformation, the Flashforge Guider 3 Plus is equipped with a fully automatic bed leveling system that saves a lot of time and ensures precise calibration. The printer comes factory calibrated, but it is recommended to perform the calibration before the first use. The Level and Calibration menu contains two options, namely Z Calibration and Auto Level. Z-axis calibration is performed with the leveling card placed between the nozzle and the build plate. The user adjusts the Z-offset until slight resistance of the card is felt.

The Auto Level function initializes 12-point auto bed leveling and can be used in two modes.

Like the Guider 3 model, the Guider 3 Plus uses a powerful high-temp extruder with a quick release nozzle system. The standard 0.4 mm stainless steel nozzle can be changed for an optional 0.6 or 0.8 mm nozzle according to the user’s printing needs. For fiber-reinforced filaments, the manufacturer recommends using a hardened nozzle.

Due to the maximum extruder temperature of 320 °C, the printer is compatible with a wide range of consumer and engineering filaments, including ABS, PLA, PC, PA, HIPS, ASA, PETG, PA-CF, PLA-CF, PETG-CF, PETG-GF, and others. The Guider 3 Plus is an open material system and can work with third-party filaments.

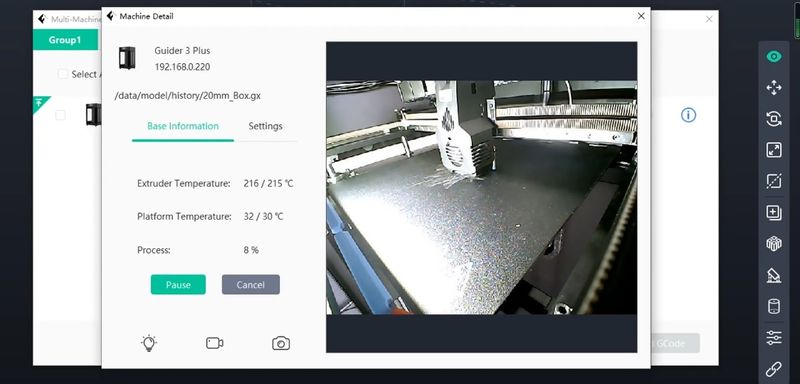

A powerful management system allows the user to control multiple machines remotely and assign tasks for each printer using the FlashPrint 5 software. The built-in 720p camera provides a live view of the printing process. To increase efficiency and minimize downtime, the printer automatically saves progress in case of a sudden power outage and resumes printing when the power is on. It is also equipped with a filament run-out sensor and Auto-Shutdown function which turns off the machine once printing is over.

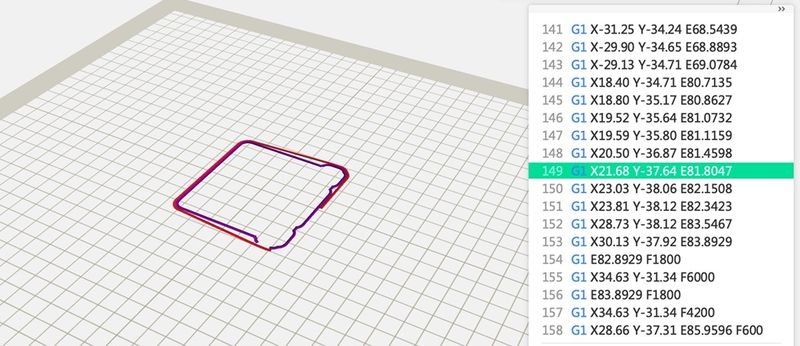

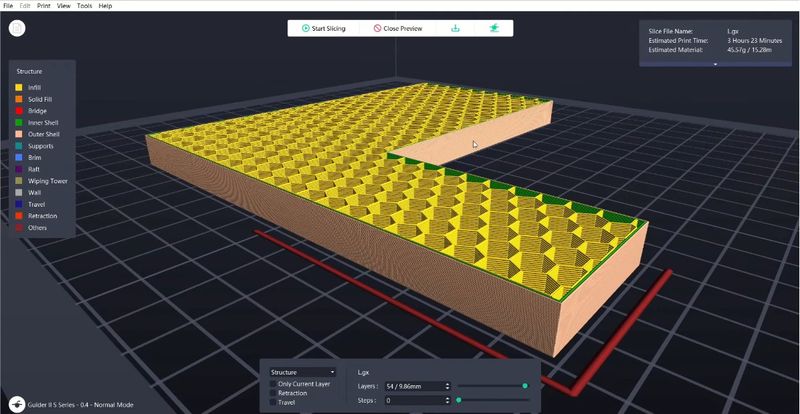

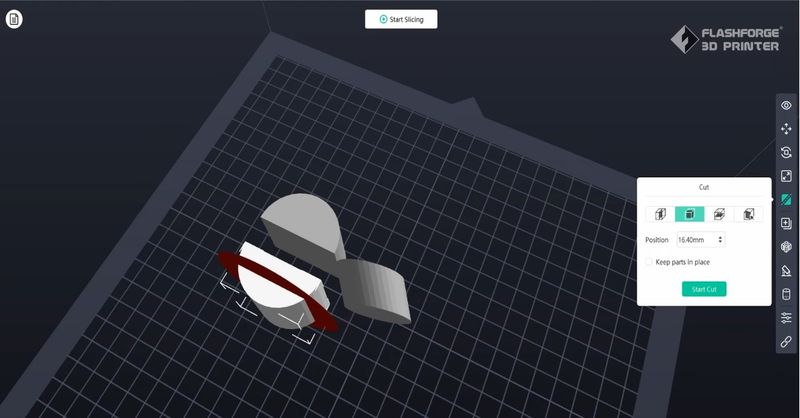

The proprietary FlashPrint software in its fifth iteration provides the user with the instruments for remote management of multiple printers combined in groups for convenience. FlashPrint 5 also features a renewed interface design and some new features for faster and more efficient work. The slice preview function allows the user to see the printing paths or 3D structure of the sliced model.

You can easily customize your models by adding a convex pattern to the part surface, simply dragging the image to the software.

There are such useful functions as Auto repair, Rotation optimization, Model copy, Model cutting, and more. You can also change the font size and choose the theme color.

The FlashPrint 5 slicer is compatible with STL, OBJ, FPP, and 3MF file formats.

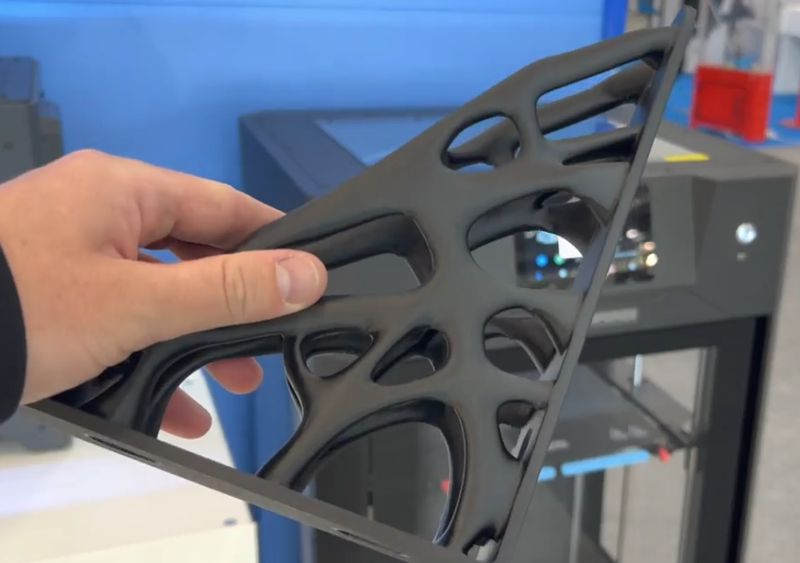

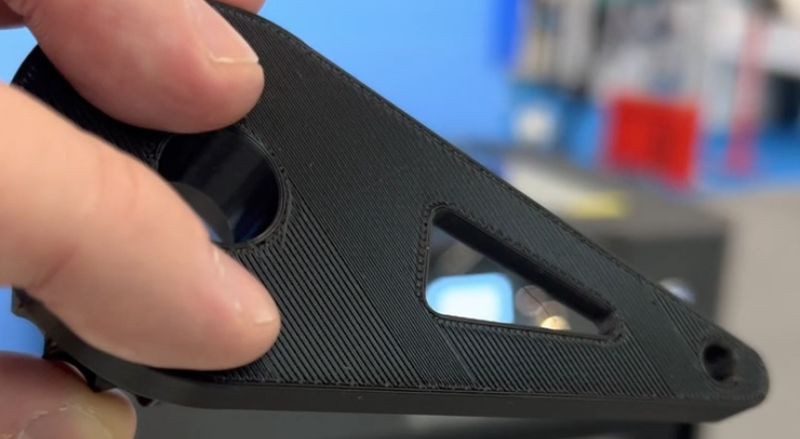

Thanks to its huge build volume, the Flashforge Guider 3 Plus is ideal for industrial large-scale printing in various fields as well as for rapid prototyping.

Below you can see the high quality of the models printed on the Guider 3 Plus.

Credit: @3d_aura / Instagram

Designed for high-speed continuous printing of large models, the Flashforge Guider 3 Plus is packed with a lot of smart features and can greatly add to the production cycle of design, movie, and architecture studios, workshops, and small-to-medium factories. Its smart management system will allow the customers to speed up production and shorten delivery times in the most cost-efficient manner.

Update your browser to view this website correctly. Update my browser now

Write a comment