In this article, we will introduce you to the Polish brand Sinterit, one of the major participants in the European market of 3D printer manufacturers. Here you can learn more about the history of the company and its products.

Source: facebook.com/pg/Sinterit

Sinterit is a major SLS 3D printer manufacturer from Poland. The company was founded in 2014. After years of reliable service, the main purpose of Sinterit remains to create advanced, yet practical 3D printers based on SLS (Selective Laser Sintering) technology. They claim that it could drastically change the world of manufacturing.

SLS technology is a new step in the development of 3D printing. It allows you to produce parts that cannot be created using FDM (Fused Deposition Modeling), the most popular method on the 3D printing market at the moment. The Sinterit Lisa series, including Lisa, Lisa Pro, the company’s signature 3D printers, are well-known and loved all over the world. In the six years of the company’s existence, Sinterit has collected a large number of various Polish and European awards such as CD3D: The Best Polish 3D Printer of 2015 and Best desktop SLS 3D Printer - winter, spring, summer and fall 2018 according to All3DP.

Source: all3dp.com

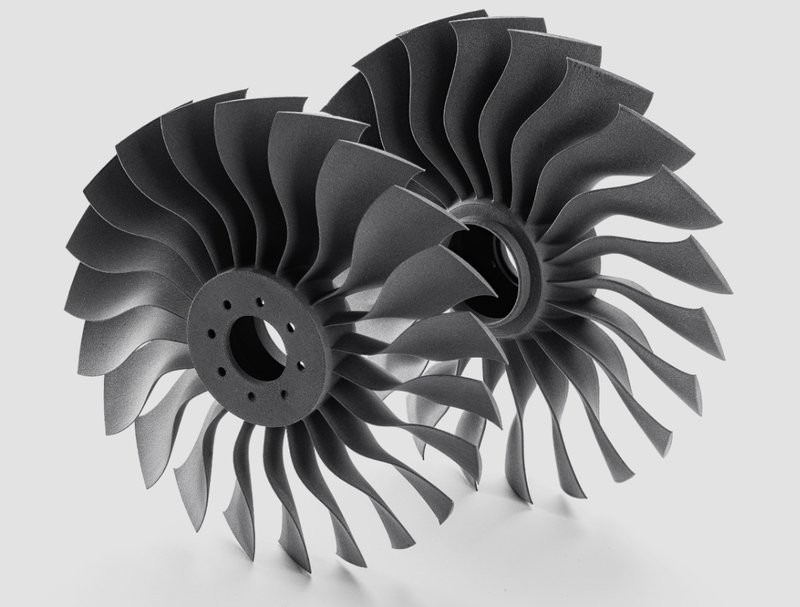

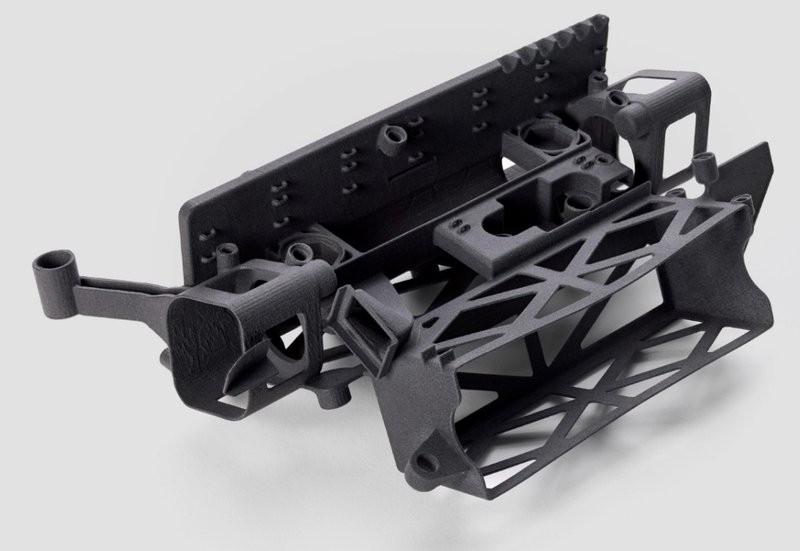

As we’ve already said, Sinterit specializes in the production of 3D printers based on SLS or selective laser sintering. This technology is implemented by sequentially sintering layers of powder material using high-power lasers. Since the powder material, which surrounds the model during the process of printing, serves as a kind of support for the model, there is no need to create any special supporting structures or jumpers between the elements of the printed part.

Through the following table provides the information on the main characteristics of the company’s 3D printers:

|

Parameter |

Lisa |

Lisa PRO |

Lisa X |

NILS 480 |

|

Build volume |

110 x 160 x 155 mm

4.3 x 6.3 x 6.1 in |

110 x 160 x 245 mm

4.3 x 6.3 x 9.6 in |

130 x 180 x 330 mm

5.1 x 7.1 x 13.0 in |

200 x 200 x 330 mm

7.9 x 7.9 x 13.0 in |

|

Max. print diagonal |

248 mm

9.8 in |

313 mm

12.3 in |

398 mm

15.7 in |

435 mm

17.1 in |

|

Print speed |

3 mm/h |

3 mm/h |

10-14 mm/h |

10-14 mm/h |

|

Laser type |

IR 5 W |

IR 5 W |

IR 30 W |

IR 30 W |

|

Wavelength |

808 nm |

808 nm |

976 nm |

976 nm |

|

Layer height |

0.075–0.175 mm

0.003–0.006 in |

0.075–0.175 mm

0.003–0.006 in |

0.075–0.175 mm

0.003–0.006 in |

0.075–0.175 mm

0.003–0.006 in |

|

Scanning type |

XY |

XY |

Galvo |

Galvo |

|

Laser spot size |

400 μm

0.0157 in |

400 μm

0.0157 in |

650 μm

0.0256 in |

560 μm

0.0220 in |

|

Feed bed capacity |

3.4 L |

5.2 L |

14 L |

30 L |

|

Inert gas control system |

- |

✔ |

✔ |

✔ |

|

Automatic Powder Distribution System (APDS) |

- |

- |

- |

✔ |

|

Continuous Printing System (CPS) |

- |

- |

- |

✔ |

|

Outer dimensions |

620 x 400 x 660 mm

24.4 x 15.8 x 26.0 in |

690 x 500 x 880 mm

27 x 20 x 35 in |

650 x 610 x 1200 mm

25.6 x 24.0 x 47.2 in |

1200 x 1200 x 1750 mm

31.5 x 47 x 69 in |

|

Weight |

44.0 kg

96.8 lbs |

90 kg

198 lbs |

145 kg

330 lbs |

300 kg

660 lbs |

|

Display |

4" interactive touchscreen |

7" interactive touchscreen |

9" interactive touchscreen |

15.6" interactive touchscreen |

|

Software |

Sinterit Studio |

Sinterit Studio |

Sinterit Studio |

Sinterit Studio 2 |

|

Connectivity |

Wi-Fi, USB |

Wi-Fi, USB |

Ethernet, Wi-Fi, USB |

Ethernet, Wi-Fi, USB |

Source: sinterit.com

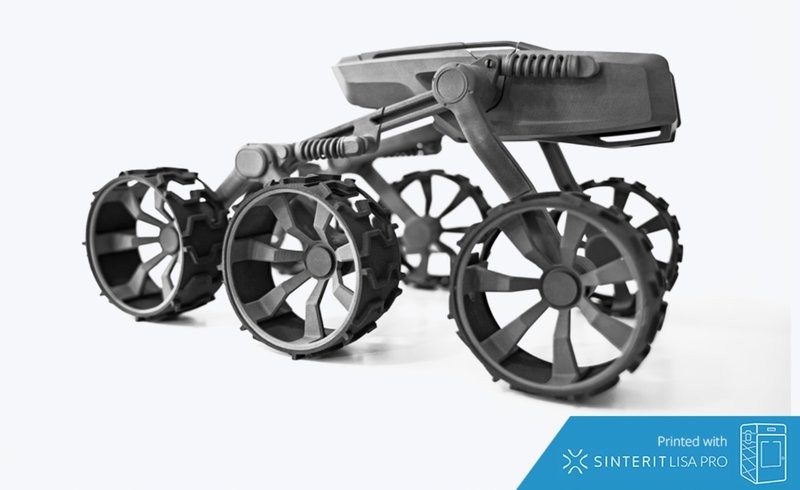

Sinterit’s Lisa is one of the most affordable desktop SLS 3D printers available on the market. Despite the compact volume, it boasts high productivity. The main feature of the model is the ability to simultaneously make several different parts on the print bed, regardless of their connection to each other.

The printer is equipped with a 5-Watt laser print head. In addition to that, it has a microcomputer that enables autonomous wireless printing. The device also has an built-in camera and a touch screen which make it possible to monitor the printing process.

Source: sinterit.com

Source: sinterit.com

The Sinterit Lisa Pro is a desktop 3D printer for small-scale production of industry-grade quality parts. Thanks to its built-in nitrogen chamber, it is possible to use a wide range of materials for printing: PA11, PA12 Smooth, Flexa Soft, TPE, and more.

Compared to the previous model, the Lisa Pro boasts an enlarged print chamber and gas supply system. The machine can produce large-scale parts up to 32 cm with high accuracy and complex structure.

Credit: sinterit.com

Aimed at increasing your business efficiency, the printer can be successfully used in prototyping and small-scale manufacturing.

Credit: sinterit.com

The Sinterit Lisa X is a brand new professional compact SLS 3D printer, the fastest in the series. Due to the increased print speed and extra build volume, the machine allows you to multiply your production by taking advantage of numerous smart features that improve the performance of the device.

The Lisa X provides revolutionary speed and outstanding powder refresh ratio, fast cooldown, simple material change, responsive display with user-friendly interface, and many advanced functions. It allows you to get detailed, high-quality outprints in a short time.

Credit: sinterit.com

The Sinterit Lisa X is designed mainly for (functional) prototyping and small to medium manufacturing in a variety of industries. The device is a perfect tool for designers, engineers, small and medium-sized businesses, and everyone who is ready to work with professional 3D equipment. Also, it is great for education and advanced R&D.

Credit: sinterit.com

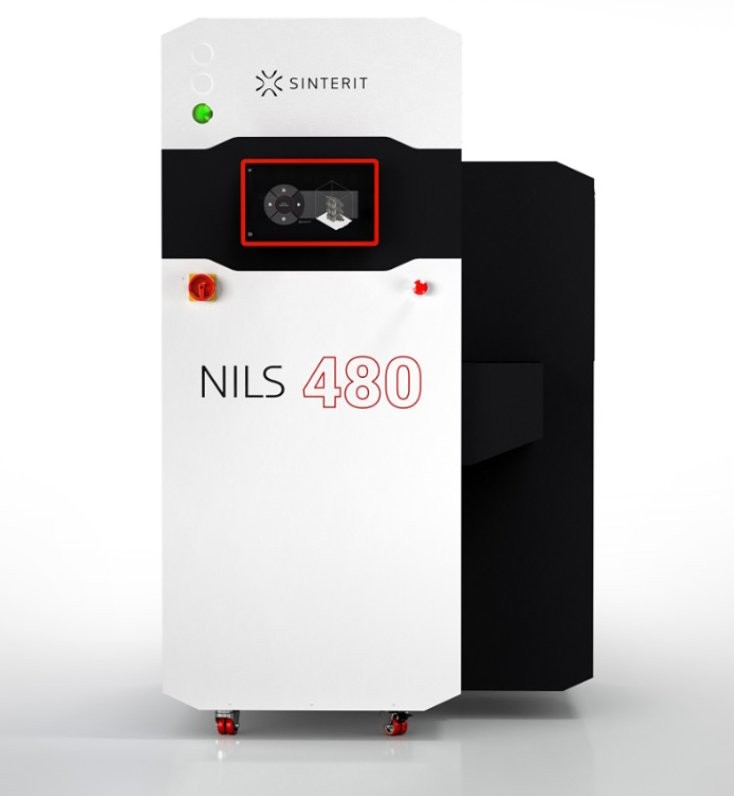

The Sinterit NILS 480 is a professional industrial-grade SLS 3D printer for time- and ost-saving manufacture. Due to its enlarged build size, the application range is virtually unlimited.

NILS stands for New Industrial Laser Sintering, and provides excellent automation, performance, maintenance, machine speed, and other features that have been upgraded to accelerate the workflow and deliver quality results. The model is also known for its automated systems for powder distribution and continuous printing.

Credit: sinterit.com

The Sinterit NILS 480 can be used in a great many industries, the applications for this printer being virtually unlimited. For example, it can print large medical models, orthoses, automotive prototypes, housing for electronic devices, single-piece shoes, and a wide range of parts for different purposes.

Source: sinterit.com

PA materials are polyamide-based, one of the most well-known PA materials is nylon. Flexa materials are based on thermoplastic polyurethane.

Powder particle size, nanometers:

The table below shows the compatibility of the powders with the Sinterit printers.

|

|

NILS 480 |

LISA X |

LISA PRO |

LISA |

|

Standard |

|

|

|

|

|

PA12 Smooth 2/6 kg |

✔ |

✔ |

✔ |

✔ |

|

PA11 Onyx 2/6 kg |

✔ |

✔ |

✔ |

|

|

Performance |

|

|

|

|

|

PA11 CF 2/6 kg |

✔ |

✔ |

✔ |

|

|

PA11 ESD 2/6 kg |

On demand |

✔ |

✔ |

|

|

PP 6 kg |

On demand |

✔ |

✔ |

|

|

Flexible |

|

|

|

|

|

TPE 2 kg |

On demand |

✔ |

✔ |

|

|

Flexa Bright 2 kg |

On demand |

✔ |

✔ |

|

|

Flexa Soft 2 kg |

On demand |

✔ |

✔ |

|

|

Flexa Grey 2/6 kg |

✔ |

✔ |

✔ |

✔ |

Source: facebook.com/Sinterit

Sinterit offers its own 3D modeling software, which helps create models for 3D printing. The program is called Sinterit Studio and it is an ideal tool for building 3D models of any kind. On top of that, it allows the user to monitor the state of the printer from the beginning to the end of the printing process and select the necessary amount of material. With this program, you can not only create your own projects, but also upload existing files in a wide range of formats: STL, OBJ, 3DS, FBX, DAE, 3MF. The software features:

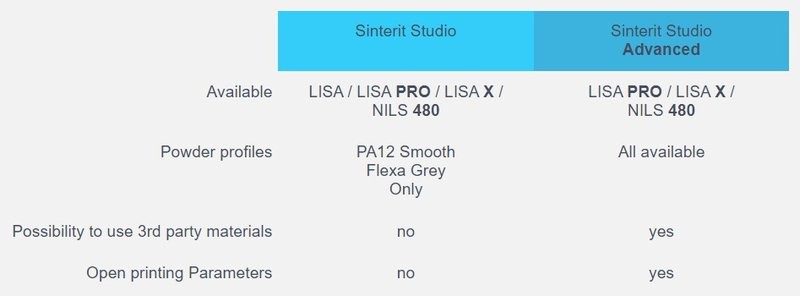

The company offers two different versions of the program with varying feature sets:

Sinterit Studio: provides you with all the functionalities to print with basic Sinterit powders (PA12 Smooth, Flexa Grey) in a standard manner, without additional printing parameters or 3rd party materials.

Sinterit Studio Advanced: gives access to flexible printing parameters including experimental printing settings and allows you to use 3rd party materials making for an open system.

Credit: sinterit.com

Source: facebook.com/Sinterit

Source: sinterit.com

Sinterit Sandblaster cleaning stations is an excellent solution for cleaning and polishing 3D printed parts. With the help of a stream of compressed air and an abrasive material (small glass balls), it is possible to penetrate the curves and corners of the model and polish every detail.

Credit: sinterit.com

The Sandblaster SLS is an advanced machine used to clean the SLS prints of powder residues, highlight every detail, polish the print surface, and enable better operation of moving parts. Compressed air and small glass beads provide exemplary quality in post-processing.

The Sandblaster SLS is compatible with the ATEX Vacuum Cleaner which makes for a dustless working environment.

Credit: sinterit.com

The ATEX Vacuum Cleaner is a perfect solution for efficient collecting and cleaning unsintered powder. Its handy functions will substantially streamline your workflow at a low cost. The proper certification guarantees a safe working environment.

Source: sinterit.com

Sinterit’s Powder Sieve sifting station is designed to help the user preserve the remaining material after printing for later use. All you have to do is to pour the used powder into the chamber and press the button. The sifted material can be mixed and used together with the fresh material to print other objects.

Source: sinterit.com

As part of her final project at the Royal College of Art in London, fashion designer Mingjing Lin tried to combine traditional fabrics and 3D technologies. She created a series of unique costumes for the Beijing Opera House.

Source: sinterit.com

Though the costumes are very flexible, they are capable of retaining their shape perfectly, which is practically impossible to achieve when using classic cotton and silk. 3D printing technologies turned out to be a perfect fit for the task. Using the Sinterit Lisa printer and the Sinterit Flexa Black powder, the design team managed to create costumes that follow the actors' free movements.

Source: sinterit.com

The texture of 3D fabrics is significantly different from traditional. These unusual materials gave a completely new quality to the costumes. This was sure to attract new listeners to the show, who were amazed by this innovative solution for Chinese Opera.

Source: sinterit.com

When the design for this military eyeglass case was in the process of development, the main challenge was to create an individual design with a strong structure. One of the main priorities was to design a one-piece product, since the absence of connecting elements could significantly increase the durability. Using the new Sinterit Lisa Pro and PA11 Onyx powder, it was possible to create a prototype that meets these requirements.

Source: www.sinterit.com

Source: sinterit.com

The radio station Radio Krakow from Poland as been using the same NAGRA Ares M voice recorders for more than ten years. It’s safe to say, that with such a long-term operation, the issue of lack of spare parts is almost inevitable. In this case, the battery slot covers were the weak spot. It’s a well-known fact that mechanical fasteners are fragile. But considering that the devices still worked perfectly well, the station staff decided to find an alternative to buying new voice recorders and contacted Sinterit.

The challenge was to create a perfectly sized cover, that wouldn’t affect the recording and playback of audio.

Source: sinterit.com

The size of the cover and its elements had to be as accurate as possible. The best solution to this task was to use SLS technology and PA12 Smooth powder. The second aspect was the printing time and the number of iterations. Since SLS technology allows to fill the print bed with a great number of such small models, it is possible to print quite a large amount of different prototypes in a single session. This way, you can test out several different concepts and options at once.

Source: sinterit.com

This is a great example of another interesting application of SLS technology — manufacturing of spare parts. The ability to not only create prototypes of new products, but also to change existing concepts, can have a significant impact on the production of fasteners and enclosures for various devices in the future.

Credit: sinterit.com

The Sinterit Lisa series and NILS 480 are advanced SLS 3D printers, which serve as a perfect tool for prototyping and producing detailed elements and moving parts. Due to their advanced features and fair price, they make it possible for small and medium-sized enterprises to take advantage of the incredible possibilities of selective laser sintering.

With the service from Top 3D Shop, you can now choose the best option for your purposes.

You can get help installing and integrating Sinterit 3D printers at Top 3D Shop.

Update your browser to view this website correctly. Update my browser now

Write a comment