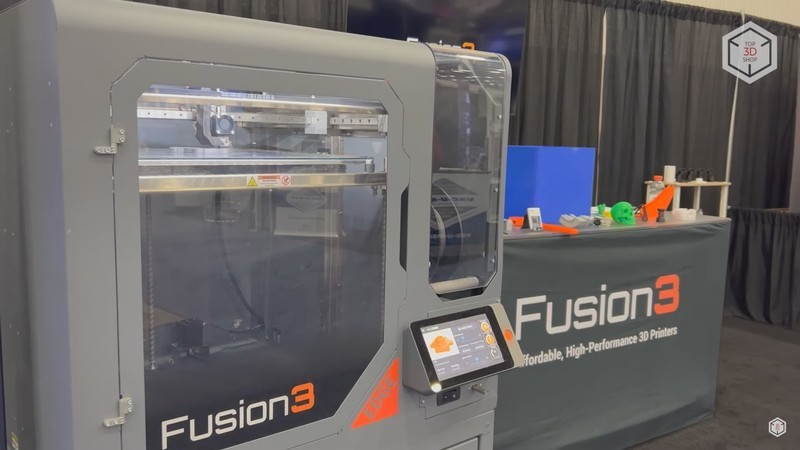

In early 2022, the American company Fusion3 introduced their new generation Edge 3D printer. The device is based on the F-Series kinematic scheme, which is an upgraded version of the classic Core XY motion control system. Let’s have a look at the printer’s technical specs and its most prominent features.

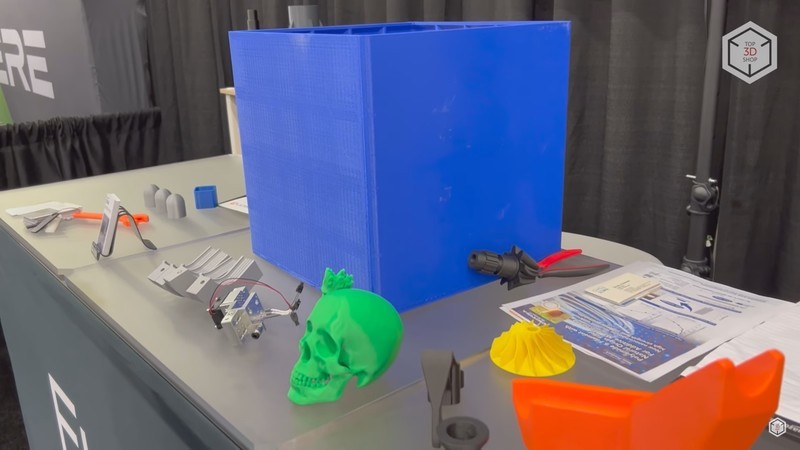

The Fusion3 Edge is an affordable industrial-grade 3D printer designed for small to medium-scale production as well as fast printing of large parts with refractory filaments. It is compatible with a wide range of consumables, including polycarbonate, polypropylene, nylon, thermoplastic polyurethane, and reinforced composites.

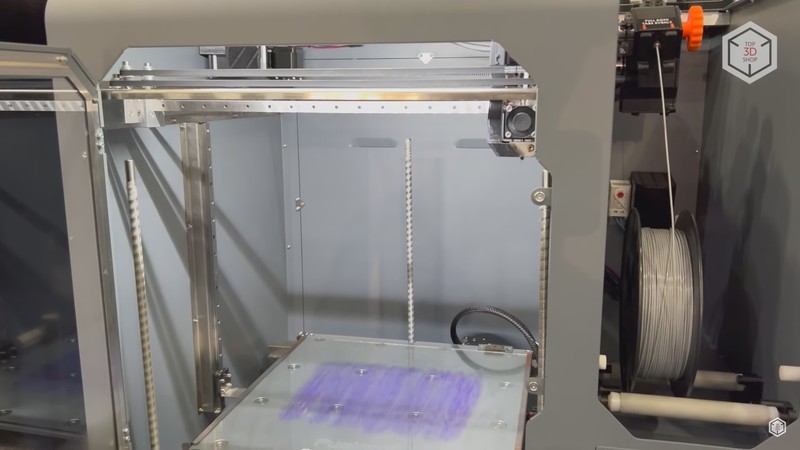

Some of the brand new features of the Fusion3 Edge include the patent-pending Anvil print head with the proprietary extruder, an improved bed leveling system, reinforced belts, precision linear rails and stepper motors, all of which allows increasing print speed and quality.

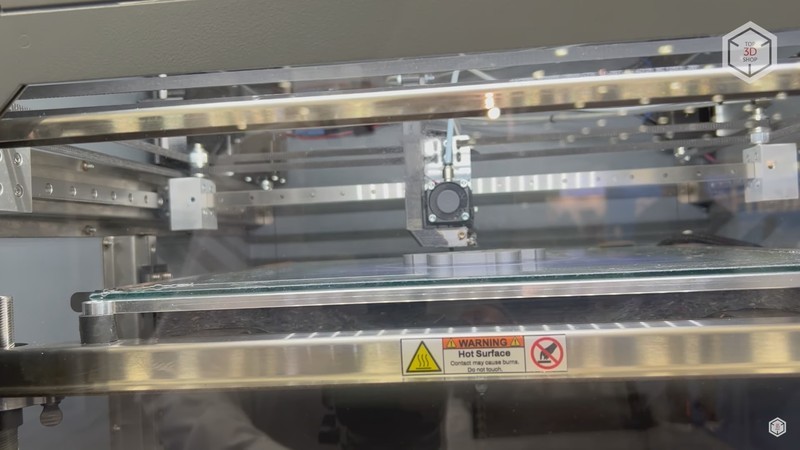

The Anvil printhead combines the proprietary extruder and the company’s know-how of using surgical steel tubes instead of traditional interchangeable nozzles. This solution enables faster printing and wear-resistance for the use with abrasive composite filaments. The maximum operating temperature here is 320 °C.

The passively heated build chamber temperature can reach 70 °C, while the general print volume is 368 x 368 x 343 mm. Featuring the automatic leveling system, the multi-zone heated print bed is a 0.25 inch aluminum plate with glass surface, capable of heating up to 140 °C. These parameters ensure smooth processing of high-temperature materials.

In addition to this, the Fusion3 Edge is engineered with a rigid aluminum enclosure that reduces vibration to ensure fast, high-quality printing.

Due to the upgraded motion control components, the machine boasts increased printing stability, tight tolerances, and impressive print speed, which for some materials can be as high as 250 mm per second.

The Fusion3 Edge 3D printer can be managed through a 7" color touchscreen with enhanced sensitivity. It features a clear intuitive interface providing all necessary data and convenient remote management tools, including maintenance reminders.

It is also possible to control the machine remotely. Overall, the connectivity options encompass USB and Ethernet as well as optional Wi-Fi and Bluetooth modules.

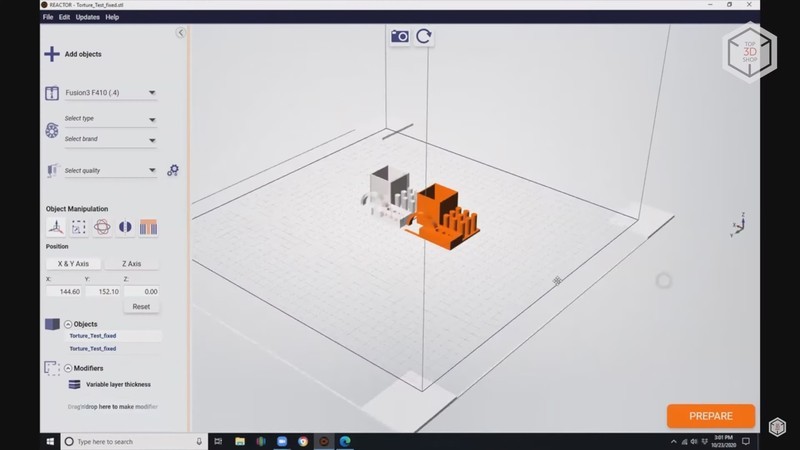

To prepare files for printing, the Fusion3 engineers have developed the proprietary Reactor software that is based on the RealVision slicer from the Danish “Create It Real” company. Apart from manifold standard tools for build preparation, it offers streamlined interface, adaptive printing algorithms, flexible settings for different parameters, real-time updates, and optimized profiles for each material.

The program works with the STL and OBJ file formats and runs exclusively on Windows.

Considering its technical parameters and advanced functions, the Fusion3 Edge 3D printer is ideal for educational and professional use in various spheres, including aerospace, automotive, metal fabrication, and other major industries. Undoubtedly, the machine is able to rapidly produce top-quality parts in fine detail.

All the reviewed peculiarities, such as improved technology, reliable construction, efficient manufacture, safe operation, and powerful control system, make the Fusion3 Edge 3D printer an extremely valuable tool for industrial production considering its price and performance.

Update your browser to view this website correctly. Update my browser now

Write a comment